Patents

Literature

169results about How to "Material selection science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porcelain granules containing carbon and preparation method thereof

InactiveCN101580349AReduce manufacturing costLight weightSolid waste disposalThermal insulationExpanded clay aggregate

The invention discloses a preparation method for porcelain granules containing carbon. According to the weight percentage, 5%-40% of carbon powder, 5%-25% of gold mine tailing powder and 35%-70% of fly ash make up main raw materials. The preparation method comprises the steps of: (1) the gold mine tailing powder is dipped in a HCl solution; (2) the carbon powder, the fly ash and the modified mine tailing powder are uniformly blended; and then water is added for wet mixing; (3) the wet material is prepared into spheric granules with the grain diameter of 5-20mm; (4) the spheric granules are dried and sintered to obtain the porcelain granules containing carbon. The porcelain granules containing carbon are multifunctional porcelain granules with the functions of adsorption, light weight, high strength, heat preservation, thermal insulation, etc.

Owner:ZHEJIANG UNIV

Corn chip and making method thereof

The invention discloses a corn chip which is characterized by being made from the following components in parts by weight: 100 parts of mashed potatoes, 20 parts of corn starch, 10 parts of glutinous rice flour, 0.2 part of green tea powder, 0.5 part of balsam pear, 2 parts of pumpkin, 2 parts of green pepper, 1 part of hericium erinaceus, 1 part of apple butter, 1 part of spinach juice, 1 part of rhizoma galangae, 0.3 part of cortex moutan, 0.3 part of herba cepbalanoplosis segeti, 1.0 part of bicarbonate soda, 2 parts of salt, 10 parts of white sugar, 0.5 part of monosodium glutamate and a proper amount of water. The corn starch, the red tea powder, the balsam pear, the pumpkin, the green pepper, the hericium erinaceus, the apple butter and the spinach juice of the chip are rich in vitamins, are capable of improving the immunity function of a human body and are favorable for the health; and the rhizoma galangae, the cortex moutan and the herba cepbalanoplosis segeti are capable of invigorating the stomach and have the function of heath care. The corn chip accords with the demand of a human body, ensures that the health is maintained while people enjoy the food, and belongs to the delicious food.

Owner:WUHU XIANGRONG FOOD

Ceramic particles with iron tailing powder and manufacturing method thereof

ActiveCN102503370AOvercoming obvious technical shortcomings in recyclingMaterial selection scienceCeramic materials productionClaywaresExpanded clay aggregatePerformance index

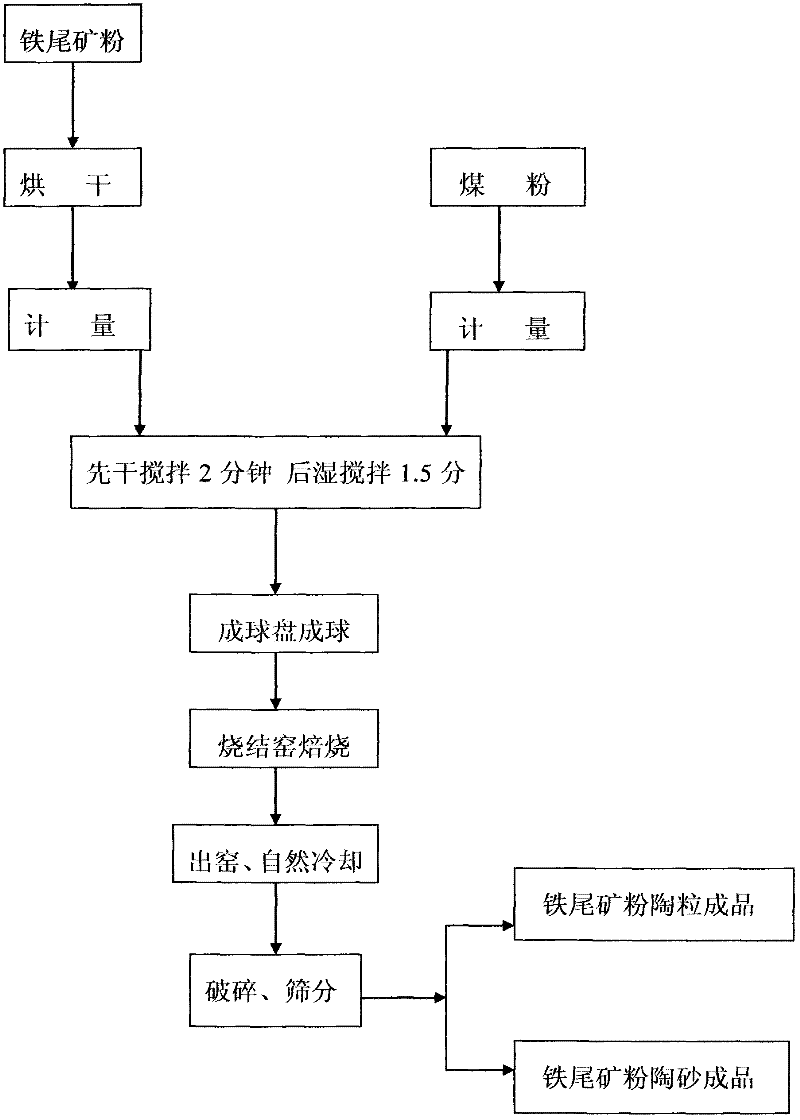

The invention relates to ceramic particles with iron tailing powder and a manufacturing method thereof, which contain materials and the technological processes of proportioning and manufacturing. The mixture ratio of the materials is as follows: 90 to 93 percent of iron tailing powder and 7 to 10 percent of coal powder; the technological processes are as follows: drying the iron tailing powder firstly, then sieving, metering, adding 1 / 2 of water after conveying the iron tailing powder and the coal powder to a stirring machine and stirring for about 2 minutes in a dry way, then stirring for about 1.5 minutes in a wet way, conveying a wet powder material after being stirred into a balling disk, then adding the water for balling, placing the raw balls of the ceramic particles of the iron tailing powder into a double-layer continuous type ceramic particle sintering kiln for calcining, taking out of the kiln, cooling, crushing and sorting; and the ceramic particles with the iron tailing powder and the manufacturing method thereof are characterized in that the operation of proportioning is simple, the waste utilization rate of the iron tailing powder is very high, the water absorption rate of the ceramic particles is low, the cost is low, the strength is high, and each performance index of the ceramic particles of the iron tailing powder conforms to the requirements of national standards.

Owner:范峪铭

Mustard-flavored potato chip and preparation method thereof

The invention discloses a mustard-flavored potato chip which is prepared from following raw materials in part by weight: 100 parts of mashed potato, 2 parts of mustard, 10 parts of green bean powder, 10 parts of glutinous rice flour, 2 parts of leaf mustard, 2 parts of cauliflower, 2 parts of Chinese cabbage, 1 part of champignon lyophiled powder, 1 part of black fungus lyophiled powder, 2 parts of purple perilla seed oil, 2 parts of pear juice, 2 parts of ginger, 0.2 part of lotus leaf, 0.2 part of rhodiola rosea, 1.0 part of baking soda, 2 parts of salt, 10 parts of white sugar, 0.5 part ofmonosodium glutamate, and appropriate amounts of water. The green bean powder, the leaf mustard, the cauliflower, the Chinese cabbage, the champignon lyophiled powder, the black fungus lyophiled powder, the purple perilla seed oil and the pear juice are rich in vitamins, meanwhile can improve the immune function of the human body, and are good for health, and the ginger, the lotus leaf and the rhodiola rosea can promote digestion, improve the immune function, depress blood-fat, and have health-care functions; and the mustard-flavored potato chip belongs to a delicious food.

Owner:WUHU XIANGRONG FOOD

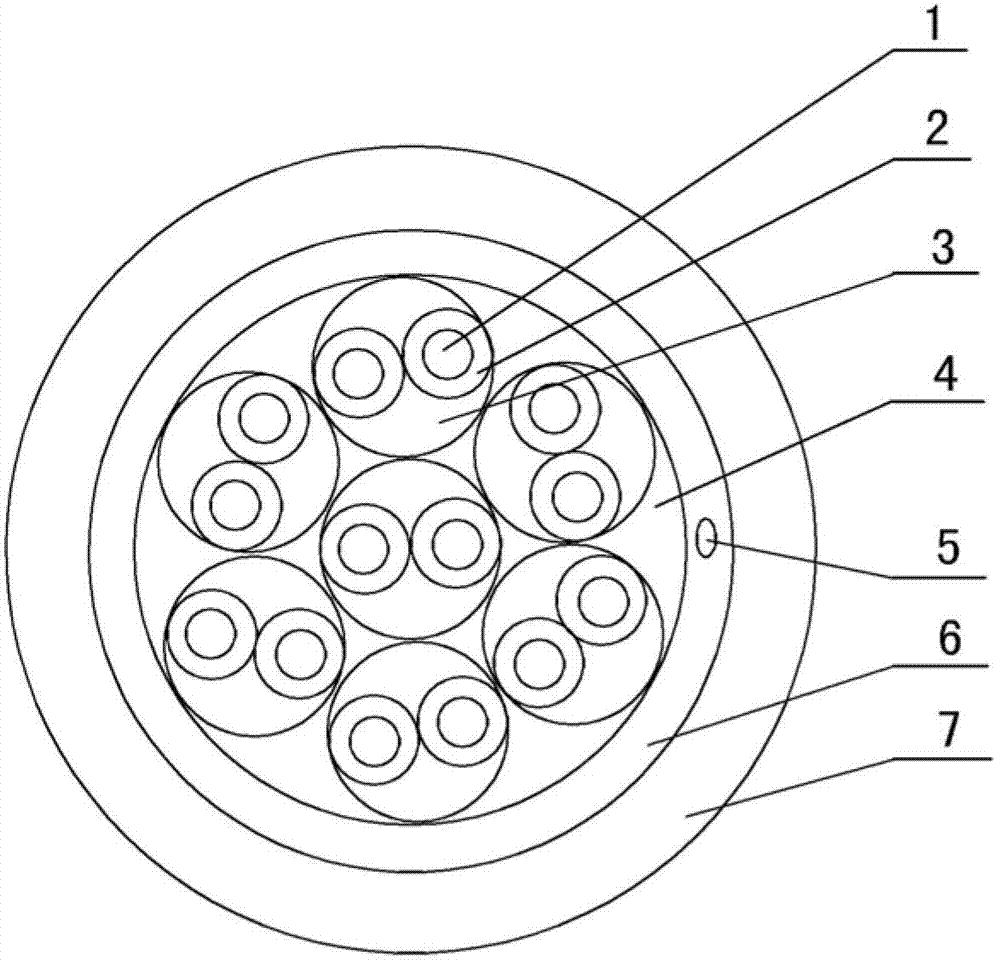

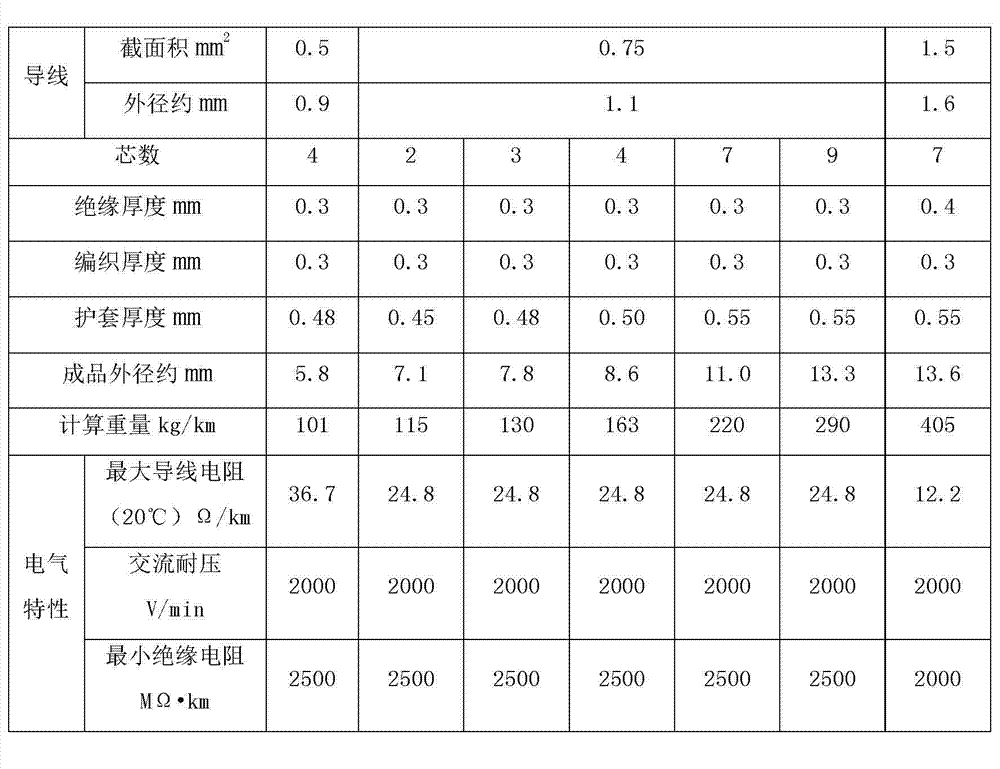

Heat-resistant instrument cable for ships and manufacturing process of heat-resistant instrument cable

ActiveCN102760517ASmall structure sizeImprove electrical performanceNon-insulated conductorsInsulated cablesElectrical conductorCopper wire

The invention discloses a heat-resistant instrument cable for ships and a manufacturing process of the heat-resistant instrument cable, and is characterized in that a cable conductor is formed by twisting a plurality of tin-plated copper wires which are drawn by a copper rod and are treated by annealing and tin plating; the conductor is extruded with an insulating layer to form an insulating cable core; a twisted-pair unit is formed by two insulating cable cores; a cable core is formed by twisting a plurality of twisted-pair units; the outer surface of the cable core is provided with a longitudinally-added drainage wire, a shielding layer weaved by the tin-plated copper wires and an extrusion sheath layer in sequence; and the insulating layer and the outer sheath layer are respectively made of fluororesin extruding materials. The heat-resistant instrument cable is suitable to be used as an electric instrument connecting line under the severe high-temperature environments such as near diesel engines and in control chambers, and has the advantages of small structural size, high temperature resistance, water vapor resistance, flame retardance, acid-alkaline chemical agent resistance, fire resistance and excellent electric performance and mechanical performance.

Owner:ANHUI GUODIAN CABLE GRP

Brown rice roll and preparation method thereof

The invention relates to a brown rice roll and a preparation method thereof, and belongs to the technical field of subsidiary foodstuff processing. According to the brown rice roll, a main raw material formula comprises brown rice powder, full corn powder, konjac flour, soya bean lecithin and the like; an auxiliary raw material formula comprises yellow powder, ground seaweed, cream powder, whole milk powder and the like; and the brown rice roll with yellow flavor, seaweed flavor and milk flavor can be manufactured according to different auxiliary raw material formulas. By the preparation process, the brown rice is easy to process, and the nutrition essence, the unique flavor and the various taste of the brown rice are retained; and the brown rice roll tastes crisp and delicious and is rich in nutrition. The problems that the brown rice is difficult to process in the prior art, the rice bran tastes bad and cannot be directly eaten, fat of the rice bran is easy to rot, the rice bran is always used for making feeds, only refined rice can be used for making the rice roll and is lack of nutrition, and the refined rice is bad for the body health of a customer are completely solved. Selected materials and the proportions are scientific; the brown rice roll is beneficial for the health; and the prepared brown rice roll is suitable for all the customers.

Owner:FUWA GROUP

Stale refuse residue powder and fly ash ceramsite and manufacturing method thereof

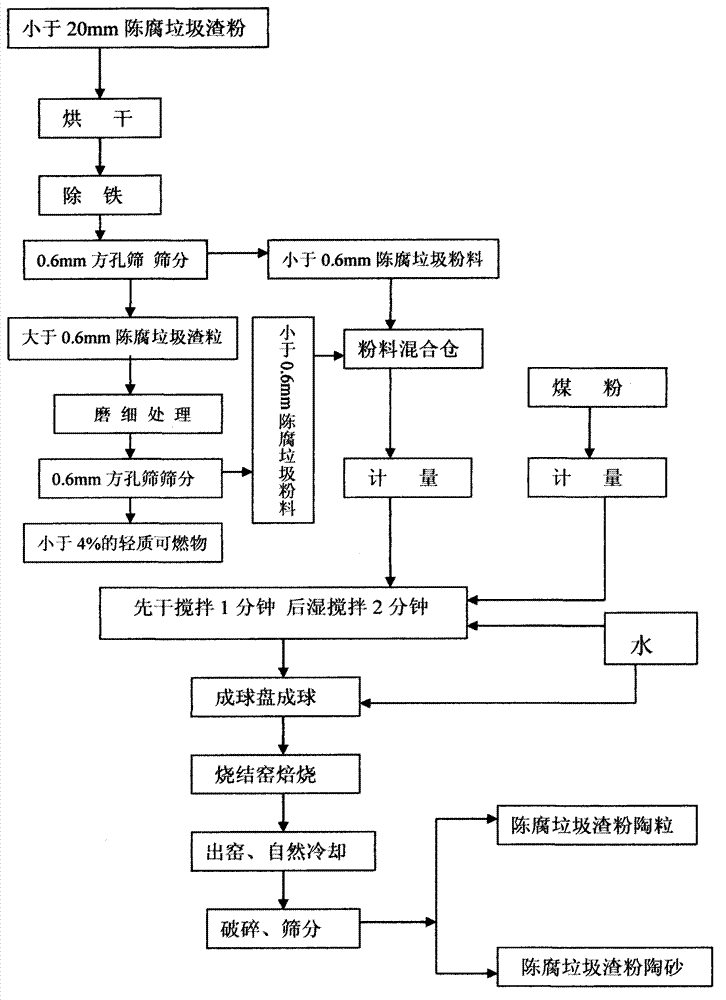

ActiveCN102775179AMaterial selection scienceReasonable ratioSolid waste disposalCeramicwarePelletizingCoal

The invention relates to stale refuse residue powder and fly ash ceramsite and a manufacturing method thereof. Materials, proportion and manufacturing process flow are included. The stale refuse residue powder and fly ash ceramsite comprises, by weight, 47%-56% of stale refuse powder, 34%-47% of fly ash and 6-10% of coal dust. The manufacturing process flow is that the stale refuse powder with the grain size smaller than 20mm is dried and screened through a 0.6mm square hole screen, and screen residue particles are levigated and screened through the 0.6mm square hole screen; the stale refuse powder, the fly ash and the coal dust which have the gain sizes of smaller than 0.6mm are respectively calculated; after dry mixing of the stale refuse powder, the fly ash and the coal dust for 1min, 1 / 3 of water is added, wet mixing is performed for 2min, the mixed wet powder is fed into a pelletizing tray, water is added to perform pelletizing, and the ceramsite raw material balls are placed in a double-layer continuous type ceramsite sintering kiln to be roasted, are taken out of the kiln to be cooled and undergo crushing separation. The stale refuse residue powder and fly ash ceramsite and the manufacturing method of the ceramsite have the advantages that materials are selected scientifically, the proportion is reasonable, the waste utilizing rate of the stale refuse residue powder and the fly ash is high, and the ceramsite meets the requirements of Lightweight Aggregate and Part 1 of Test Method thereof: Lightweight in the national standard.

Owner:BAOTOU ZHENGTANG ENVIRONMENTAL PROTECTION IND

Beef chip and making method thereof

The invention discloses a beef chip which is characterized by being made from the following components in parts by weight: 100 parts of mashed potatoes, 20 parts of oatmeal, 3 parts of beef extract powder, 2 parts of beef granules, 2 parts of red wine, 2 parts of celery, 2 parts of carrot, 2 parts of fragrant-flowered garlic, 1 part of hericium erinaceus, 1 part of hot pepper lyophilized powder, 0.5 part of circium japonicum, 0.3 part of wrinkled giant hyssop, 2 parts of ginger, 1.0 part of bicarbonate soda, 2 parts of salt, 10 parts of white sugar, 0.5 part of monosodium glutamate and a proper amount of water. Compared with the traditional chip, the beef chip has the advantages of special process and scientific material selection, and is non-frying so that the heat is reduced; meanwhile, the red wine, the celery, the carrot, the fragrant-flowered garlic, the hericium erinaceus and the hot pepper are rich in vitamins and are capable of improving the immunity function of a human body; hawthorn has a higher health function, can resist cancers, and is beneficial to the health; and the ginger, the hot pepper, the circium japonicum and the wrinkled giant hyssop are capable of invigorating the stomach and helping digestion. The beef chip accords with the demand of the human body and ensures that the health is maintained while people enjoy the food. The oatmeal is beneficial to the eating of a patient suffering from diabetes; and the bicarbonate soda can enable the chip to be bulked, thus the beef chip has good taste.

Owner:WUHU XIANGRONG FOOD

Paving method of epoxy terrazzo floor

The invention discloses a paving method of an epoxy terrazzo floor, and belongs to the field of epoxy floors. The hardness, the abrasive resistance, the impact resistance, or the like, of the epoxy floor paved by the disclosed method can hardly meet the application needs synchronously. The paving method of the epoxy terrazzo floor comprises the following steps: firstly, polishing the ground, removing the dust, and coating a priming paint; secondly, ultrasonically stirring epoxy resin, vinyl acetate, phospholipid, aggregate, and nanometer zinc oxide for 10-30 minutes, then adding sodium silicate, epoxy curing agent DMP-30, and defoaming agent therein for being uniformly stirred, and then applying the mixture onto the ground, thereby finishing paving the epoxy terrazzo floor after coarse polishing and fine polishing. The paving method of the epoxy terrazzo floor can be widely applied to the decoration construction of the floor of large-scale public buildings such as airports, hotels, conference centers, and exhibition halls.

Owner:哈尔滨中建璟园科技开发有限公司

Epoxy grout and preparation method thereof

ActiveCN105176465AImprove adhesionImprove performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolyamideSlurry

The invention discloses epoxy grout, comprising a component A and a component B by weight; the resin component A comprises bisphenol F epoxy resin, epoxy resin octyl group glycidyl ether, bisphenol A type 128 epoxy resin, a reactive diluent AGE, an organic silica coupling reagent, fumed silica, cement C35 type, silica powder, titanium dioxide, talcum powder and epoxy black slurry; the curing agent component B comprises the following components in ratio by weight: a polyamide curing agent, a cashew nut shell oil-modified curing agent, DMP-30 (Tris(dimethylaminomethyl)phenol), organobentonite, silica micropowder and superfine mica powder; a ratio of the resin component A to the curing agent component B is 3-6:1. The invention also discloses a preparation method of the epoxy grout. The compressive resistance and bonding strength of the expoxy grout after long-term curing are higher, and the water resistance is higher than that of expoxy grout on the market, and the expoxy grout is wide in ratio, has no solvent and non-transferability plasticizer and solvent and is excellent in comprehensive performance.

Owner:HUNAN QUANCHEN TECH

Tomato potato chips and preparation method thereof

The invention discloses tomato potato chips, which are prepared from the raw materials in parts by weight: 100 parts of smashed potato, 5 parts of cooked black soybean meal, 2 parts of tomato paste, 2 parts of lyophilized tomato powder, 1 part of lyophilized brassica chinensis powder, 1 part of red wine, 1 part of blueberry juice, 0.5 part of black pepper powder, 1 part of scallion, 2 parts of ginger, 1.0 part of baking soda, 2 parts of table salt, 10 parts of white sugar,0.5 part of monosodium glutamate and a proper amount of water. Compared with the traditional chips, the tomato potato chips are unique in a preparation process and scientific in raw material selection. The potato chips disclosed by the invention are non-fried, so that calories are reduced. The potato chips are prepared from the cooked black soybean meal, the red wine, the blueberry juice, the tomato paste and the lyophilized tomato powder, so that the potato chips contain rich vitamins, and are good to health, and the immune function of a human body can be improved; the ginger and the black pepper powder have the effect of invigorating the stomach; the formula is in line with the needs of the human body, so that the physical health is maintained when a person enjoys the potato chips; the tomato paste and the lyophilized tomato powder are used for adjusting tomato flavor, so that the original flavor of tomatoes can be maintained; and by adoption of the baking soda, the potato chips can be bulky, and have a good mouth-feel.

Owner:WUHU XIANGRONG FOOD

Low-warpage and high-hardness polymer and preparation method thereof

The invention discloses a low-warpage and high-hardness polymer. The low-warpage and high-hardness polymer is prepared from, by weigh, 40-80% of POK resin, 0.1-2% of compatilizer, 0.1-5% of processing aids and 20-60% of glass fibers. The steps of material preparation, mixing and extrusion are adopted. Material selection is scientific, the preparation method is precise; compared with conventional engineering plastic, the obtained polymer has more excellent impact resistance and chemical resistance and higher hardness and abrasion resistance, the hardness and the abrasion resistance are far higher than those of polymer POM (polyoxymethylene) which is the hardest at present, the warpage is low, and the low-warpage and high-hardness polymer is suitable for the occasions where the precision requirement is high.

Owner:5ELEM HI TECH CORP

Instant fried dumpling

An instant fried-in-oil damping of glutinous rice flour is prepared through preparing its stuffing from milk, honey, sugar, red jujube, walnut kernel, sesame and peanut, wrapping it by the wrapper made of glutinous rice flour, frying in oil, freezing and packing.

Owner:王来峰

Gastrodia tea and preparing method thereof

InactiveCN1419835APay attention to material selectionMaterial selection scienceTea substituesUnknown materialsGastrodiaZiziphus jujuba

A gastrodia tuber tea is prepared from gastrodia tuber, wolfberry fruit and wild jujube through respectively soaking in the extracted liquid of ganoderma, lily bulb and lotus flower three times, far infrared baking and mixing. Its advantages are sure nutritive and health-care effect and agreeable taste.

Owner:韦俊康

Potato chip with sesame flavor and preparation method thereof

The invention discloses a potato chip with a sesame flavor. The potato chip is prepared from the following raw materials in parts by weight: 100 parts of potato mud, 10 parts of coarse rice powder, 5 parts of glutinous rice powder, 2 parts of sesame paste, 2 parts of sesame oil, 1 part of chili powder, 2 parts of carrot lyophilized powder, 1 part of fresh mushroom lyophilized powder, 2 parts of ginger, 1.0 part of sodium bicarbonate powder, 2 parts of salt, 10 parts of white sugar, 0.5 part of gourmet powder, 3 parts of cabernet, 3 parts of xylitol and a proper amount of water. Compared with the known potato chip, the potato chip disclosed by the invention has the advantages that the preparation process is unique; the selection of the raw materials is scientific; the potato chip is not fried, so that heat is reduced; furthermore, coarse rice, sesame oil, carrot lyophilized powder and fresh mushroom lyophilized powder contain rich vitamins, so that the immunity function of a human body can be improved; the potato chip is beneficial to the health, and the ginger and the chili powder can invigorate the stomach; and the formula meets the demand of a human body, so that people can enjoy the food, and the body health is maintained.

Owner:WUHU XIANGRONG FOOD

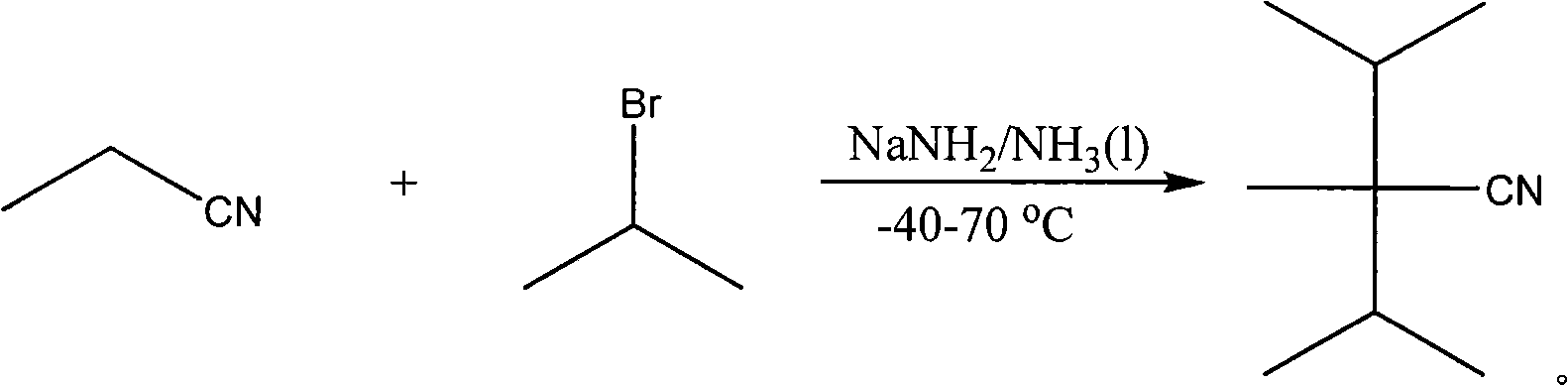

Preparation method of 2,3-dimethyl-2-isopropyl butyronitrile

InactiveCN101823983AReduce pollutionLow costCarboxylic acid nitrile preparationOrganic compound preparationPropionitrileEthyl acetate

The invention discloses a preparation method of 2,3-dimethyl-2-isopropyl butyronitrile. The preparation method comprises the following steps of: firstly, cooling ammonia to a liquid state, adding obtained liquid ammonia into a low-temperature reaction kettle and then adding sodamide; secondly, adding propionitrile and 2-bromopropane into a high-order stirring and dropping pot and uniformly mixing; next, slowly dropping a mixed liquor obtained in the second step into the low-temperature reaction kettle, regulating the temperature in the low-temperature reaction kettle, and after complete reaction, evaporating and recovering the liquid ammonia; and finally, adding ethyl acetate to extract a water phase in the third step, respectively washing the water phase by using clear water and a saline solution, drying, filtering and desolventizing a final organic phase and distilling in vacuum to prepare the 2,3-dimethyl-2-isopropyl butyronitrile after the desolventizing. The method has scientific material selection, proper proportioning and simplicity and is suitable for industrial production. Moreover, the reaction time is short, the yield is high, and the quality of the product is good.

Owner:JIANGSU GRANDCHEM IND

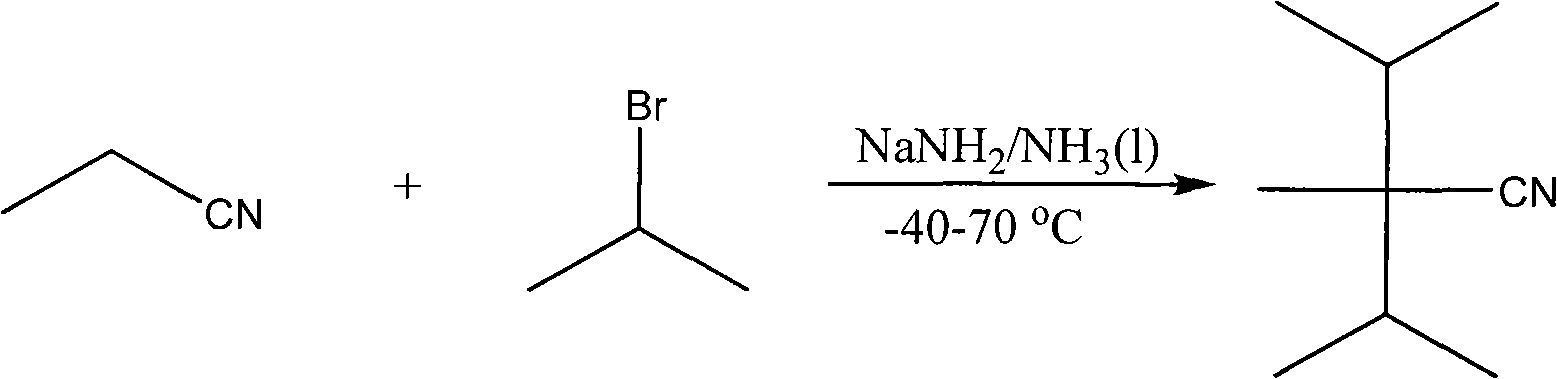

Copper tailing powder ceramsite manufacturing method

InactiveCN102344296AIncrease dosageMaterial selection scienceSolid waste disposalCeramicwareExpanded clay aggregateCopper

The invention relates to a copper tailing powder ceramsite manufacturing method. Raw materials adopted by the copper tailing powder ceramsite manufacturing method comprise 70 to 80% of copper tailing powder, 10 to 25% of fly ash and 5 to 10% of coal powder. The copper tailing powder ceramsite manufacturing method comprises the following steps of drying the copper tailing powder by an oven, sieving, carrying out metering processes respectively on the sieved copper tailing powder, the fly ash and the coal powder, feeding the sieved copper tailing powder, the fly ash and the coal powder into a mixer to carry out dry stirring for about 2 minutes, adding water into the mixture until the volume of the water is a half of that of the mixer, carrying out wet stirring for about 2 minutes, feeding the wet powder obtained by the wet stirring into a prilling disc, adding water into the wet powder to carry out prilling, putting the copper tailing powder ceramsite raw pellets obtained by the previous step into a static continuous sintering kiln to carry out sintering, taking out the sintered products from the static continuous sintering kiln, cooling, crushing, and screening. The copper tailing powder ceramsite manufacturing method is characterized in that the copper tailing powder subjected to drying, sieving and metering, the metered fly ash and the metered coal powder are dried and mixed in the mixer, then are subjected to wet stirring, and then are added with water to form the copper tailing powder ceramsite raw pellets; and the copper tailing powder ceramsite raw pellets are fed into the static continuous sintering kiln for sintering to form desired products after three processes of preheating, sintering and cooling. Copper tailing powder ceramsites obtained by the copper tailing powder ceramsite manufacturing method has the advantages of high waste copper tailing powder utilization rate, high strength and low water absorption.

Owner:齐齐哈尔中齐建材开发有限公司

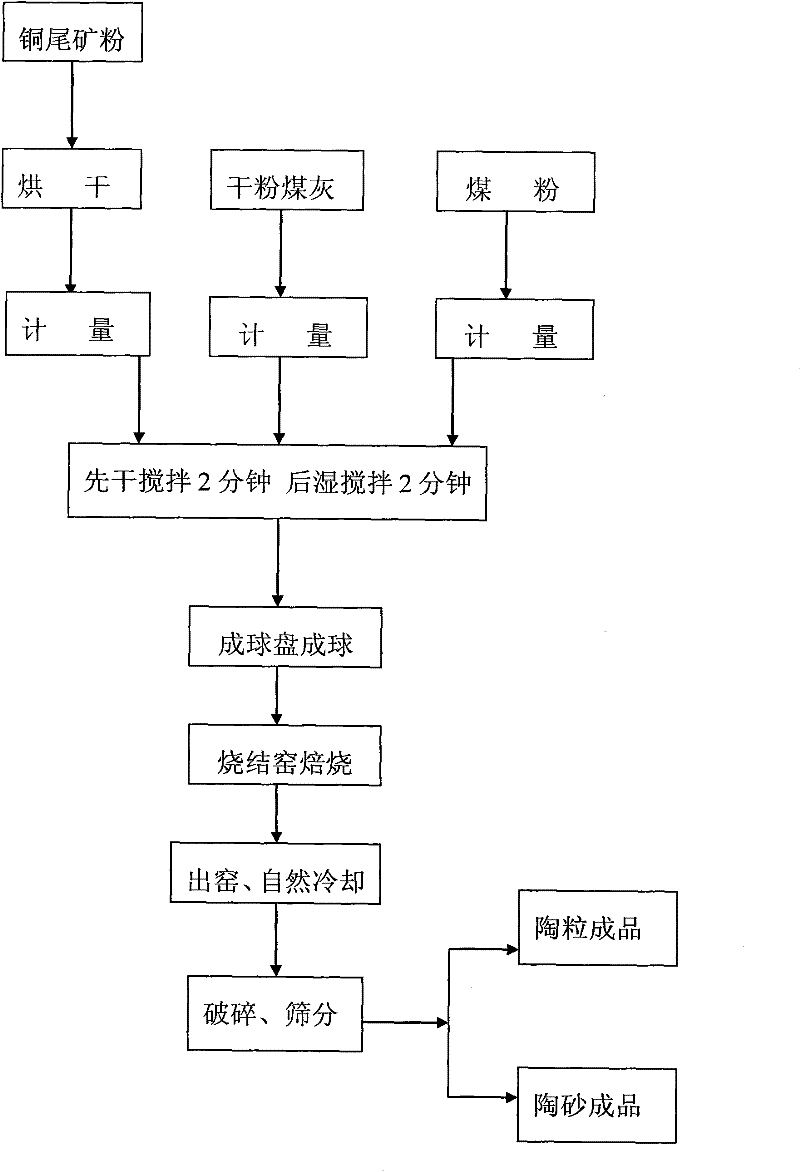

Method for manufacturing gold tailings ash aggregates

ActiveCN102503366AOvercoming obvious technical shortcomings in recyclingIncrease dosageCeramic materials productionClaywaresAbsorption rateCoal

The invention relates to a method for manufacturing gold tailings ash aggregates, which comprises materials and proportions, as well as a manufacturing process flow. The materials comprise 90 to 92 percent of gold tailings ash and 8 to 10 percent of pulverized coal. The process flow comprises the following steps of: baking the gold tailings ash, screening, and measuring; measuring the pulverized coal; conveying the gold tailings ash and the pulverized coal into a stirrer to be stirred in a dry state for about 2 minutes; adding half amount of water, and stirring in a wet state for about 2 minutes; feeding the stirred wet ash material into a balling pan, and adding the rest half amount of water to produce balls; putting raw gold tailings ash aggregate balls into a static continuous aggregate sintering kiln for roasting; and discharging from the kiln, cooling, crushing and separating. The method is characterized in that: the gold tailings ash and the pulverized coal are respectively measured after the gold tailings ash is baked and screened, are stirred in the stirrer in the dry state and the wet state and pelletized by adding water; the raw gold tailings ash aggregate balls are sentto the sintering kiln for being roasted; and the gold tailings ash has the advantages of high waste utilization, high aggregate strength and low water absorption rate through three sintering process steps, namely preheating, sintering and cooling.

Owner:范峪铭

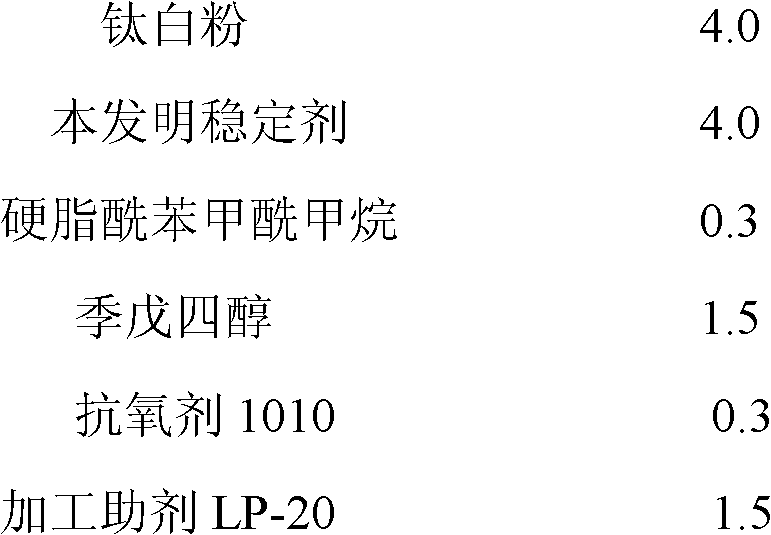

Epoxidized calcium-zinc oleate compound stabilizer and preparation method thereof

ActiveCN102504443AEasy to keepGood dispersibility in flakesOrganic chemistryDistillationReaction temperature

The invention relates to epoxidized calcium-zinc oleate compound stabilizer and a preparation method thereof, and belongs to the technical field of PVC processing agent. The stabilizer is prepared by the following steps that: oleic acid, glacial acetic acid or formic acid, concentrated sulfuric acid or p-toluene sulfo acid, and hydrogen peroxide are added into a reactor to conduct epoxidation reaction so as to obtain epoxidized oleic acid, wherein the reaction temperature is 45-65 DEG C, and the reaction time is 2-3 hours; alkali wash is carried out, that is, the prepared epoxidized oleic acid is subjected to alkali wash by diluted sodium bicarbonate solution and is then washed by water to the PH of 6-8, then reduced pressure distillation is conducted to remove water; metal ions and catalyst are added into the epoxidized oleic acid which is subjected to alkali wash for reaction, finally lubricant is added into the mixture, and then the mixture is discharged and cut into slices after being stirred uniformly so as to prepare the epoxidized calcium-zinc oleate compound stabilizer. The stabilizer has excellent plasticizer and stability, and the preparation method provided by the invention is excellent instability and is easy to operate.

Owner:SHANDONG RUIFENG CHEM

Orange potato chips and preparation method thereof

InactiveCN102754795AMaintain tasteAppropriate tasteFood preparationChipped potatoesMonosodium glutamate

The invention discloses orange potato chips, which are prepared from the following raw materials in parts by weight: 100 parts of mashed potato, 20 parts of green bean powder, 10 parts of xylitol, 10 parts of buckwheat powder, 3 parts of orange juice, 2 parts of grape seed oil, 2 parts of lyophilized garland chrysanthemum particles, 2 parts of lyophilized spinach particles, 2 parts of mashed mulberry, 1 part of condensed milk, 2 parts of ginger, 1 part of turmeric powder, 1.0 part of baking soda, 2 parts of salt, 10 parts of white sugar, 0.5 part of monosodium glutamate and a proper amount of water. The potato chips are prepared from the green bean powder, the xylitol, the buckwheat powder, the orange juice, the grape seed oil, the lyophilized garland chrysanthemum particles, the lyophilized spinach particles and the smashed mulberries, so that the potato chips contain rich vitamins, and are anti-oxidative and good to health, and the immune function of a human body can be improved; turmeric has the effect of invigorating the stomach, so that the potato chips have a health care function; and the formula is in line with the needs of the human body, so that the health is maintained when people enjoys the potato chips, and the potato chips belong to delicious food.

Owner:WUHU XIANGRONG FOOD

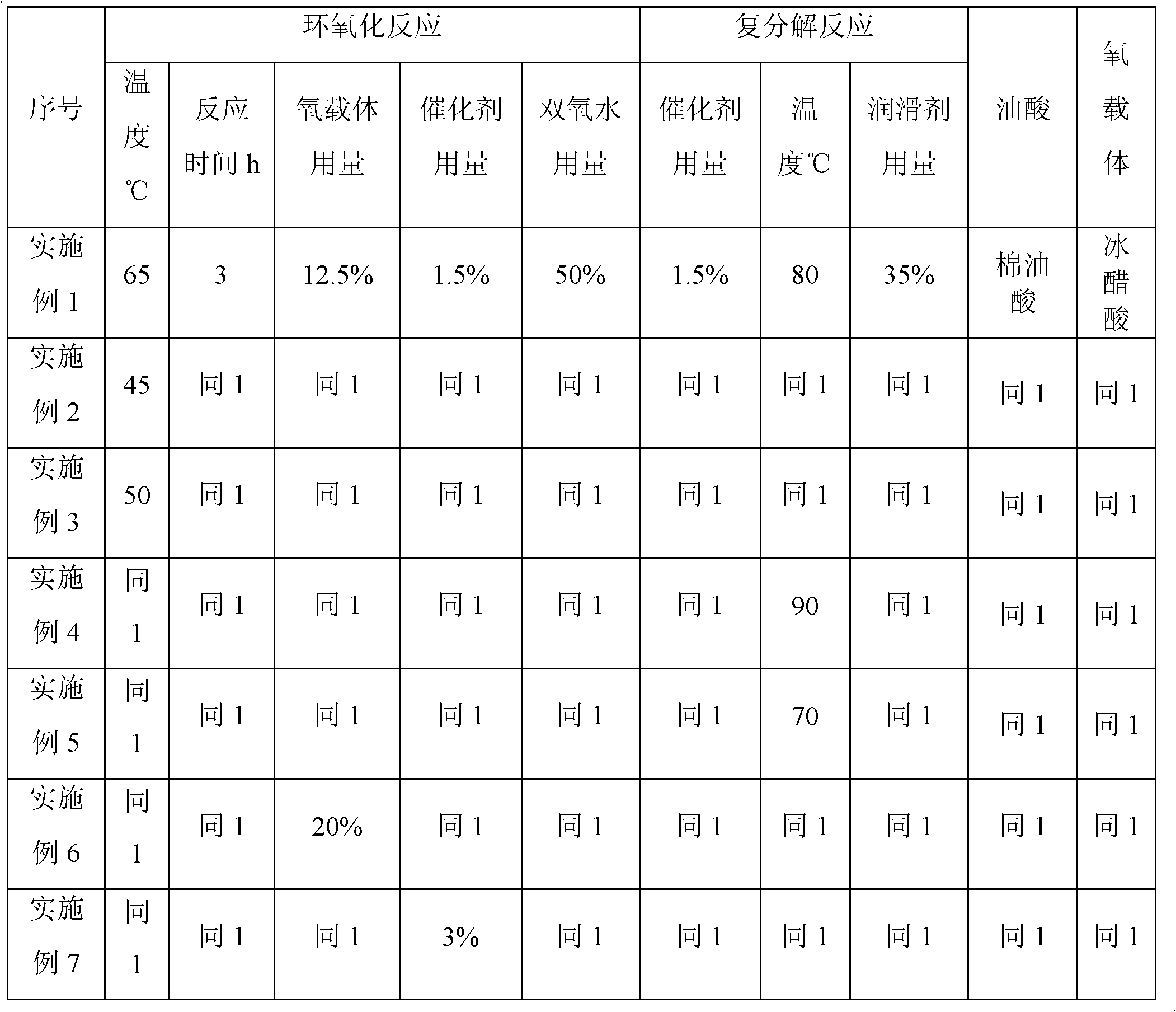

Grease-containing waste clay ceramsite and preparing method thereof

ActiveCN102503509AMaterial selection scienceReasonable ratioCeramic materials productionCeramicwareCircular economyNational standard

The invention relates to grease-containing waste clay ceramsite and a preparing method thereof. According to material proportion, the grease-containing waste clay ceramsite comprises 60%-80% of grease-containing waste clay powder and 20%-40% of pulverized fuel ash. The process flow is that stoving, levigating, sieving and metering the grease-containing waste clay powder, conveying the grease-containing waste clay powder and the pulverized fuel ash to a stirrer for dry stirring for about 1.5 minutes, adding 1 / 2 water for wet mixing for about 2.5 minutes, stirred wet powder materials are sent into a balling disc for balling by adding water again, placing waste clay ceramsite raw materials into a double-layer continuous pulverized fuel ash ceramsite sintering furnace for sintering, and finally cooling, crushing and selecting the waste clay ceramsite raw materials after drawing. The grease-containing waste clay ceramsite and the preparing method thereof are characterized in that combination of the grease-containing waste clay and the pulverized fuel ash solves problems of pollution to the environment caused by grease-containing waste clay solid waste and pulverized fuel ash solid waste, and ceramsite sintering needs no coal or soil, thereby saving energy and land. Ceramsite products prepared with the method meet national standard requirements, so that the grease-containing waste clay ceramsite and the preparing method thereof really achieve environmental improvement and development and utilization simultaneously, and meet development requirements for circular economy of our country.

Owner:BAOTOU ZHENGTANG ENVIRONMENTAL PROTECTION IND

Barbecue seasoning

The invention relates to a seasoning, especially a seasoning for barbecue. The barbecue seasoning comprises the following ingredients: 50-80 weight portions of chili powder, 50-80 weight portions of cumin, 20-30 weight portions of white pepper, 30-50 weight portions of salt, 20-25 weight portions of Chinese prickly ash, 20-25 weight portions of black pepper, 2-3 weight portions of fennel, 1-3 weight portions of bay leaf, 3-5 weight portions of cassia, and 5-10 weight portions of seafood powder. The food produced by using the seasoning has a unique taste. The seasoning adopts natural plants for combining according to the proportions and in the processes of grinding, disinfection.

Owner:彭武良

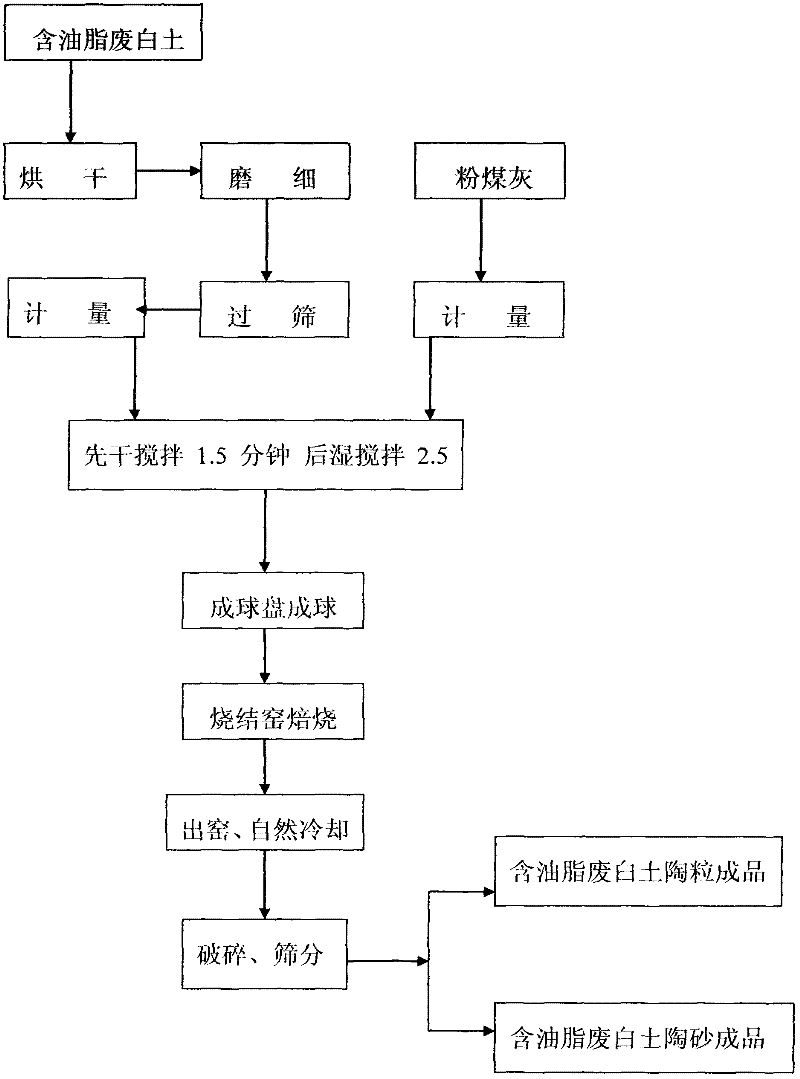

Manufacturing method for waste industrial molding sand dust ceramsite

InactiveCN102503530AOvercoming obvious technical shortcomings in recyclingMaterial selection scienceSolid waste disposalCeramicwareExpanded clay aggregateEnvironmental engineering

The invention relates to a manufacturing method for waste industrial molding sand dust ceramsite. The manufacturing method comprises material proportioning and manufacturing process flow, wherein the material proportioning is as follows: 90-92% of waste industrial molding sand dust and 8-10% of coal powder; and the process flow is as follows: respectively measuring the waste industrial molding sand dust and the coal powder; after conveying the waste industrial molding sand dust and the coal powder to a stirring machine, drily stirring for about 2 min, adding 1 / 2 water, and wetly stirring for 1 min; conveying the stirred wet powder into a ball pelletizing disk, and adding water to form a ball; placing the ceramsite raw material ball in a static continuous sintering kiln for calcination; preheating, sintering and cooling; and discharging from the kiln, cooling, smashing and separating to obtain the waste industrial molding sand dust ceramsite as a finished product. The waste industrial molding sand dust ceramsite has the advantages of high utilization rate and high strength.

Owner:齐齐哈尔中齐建材开发有限公司

Method for preparing monomethyl succinate

InactiveCN101823961AReduce pollutionMaterial selection scienceOrganic compound preparationCarboxylic acid esters preparationAcetic acidMENTHOL CRYSTALS

The invention discloses a method for preparing monomethyl succinate. The method comprises the following steps of: 1, adding menthol crystal into a reaction vessel, raising the temperature and stirring the menthol crystal until the solid substance in the reaction vessel is melted completely, and adding succinic anhydride to perform heat preservation reaction; 2, after the reaction is finished, adding water to perform reflux, standing the reaction product to separate liquid from the reaction product, adding ethyl acetate to perform extraction, combining organic phases, drying, filtering and desolventizing; and 3, adding petroleum ether to be used as a recrystallizing solvent, dissolving and recrystallizing the mixture, and filtering the recrystallized product to obtain a monomethyl succinate product. The method has the advantages of scientific material selection, proper proportion, simpleness, suitability for industrial production, short reaction time, high yield and good quality of products.

Owner:JIANGSU GRANDCHEM IND

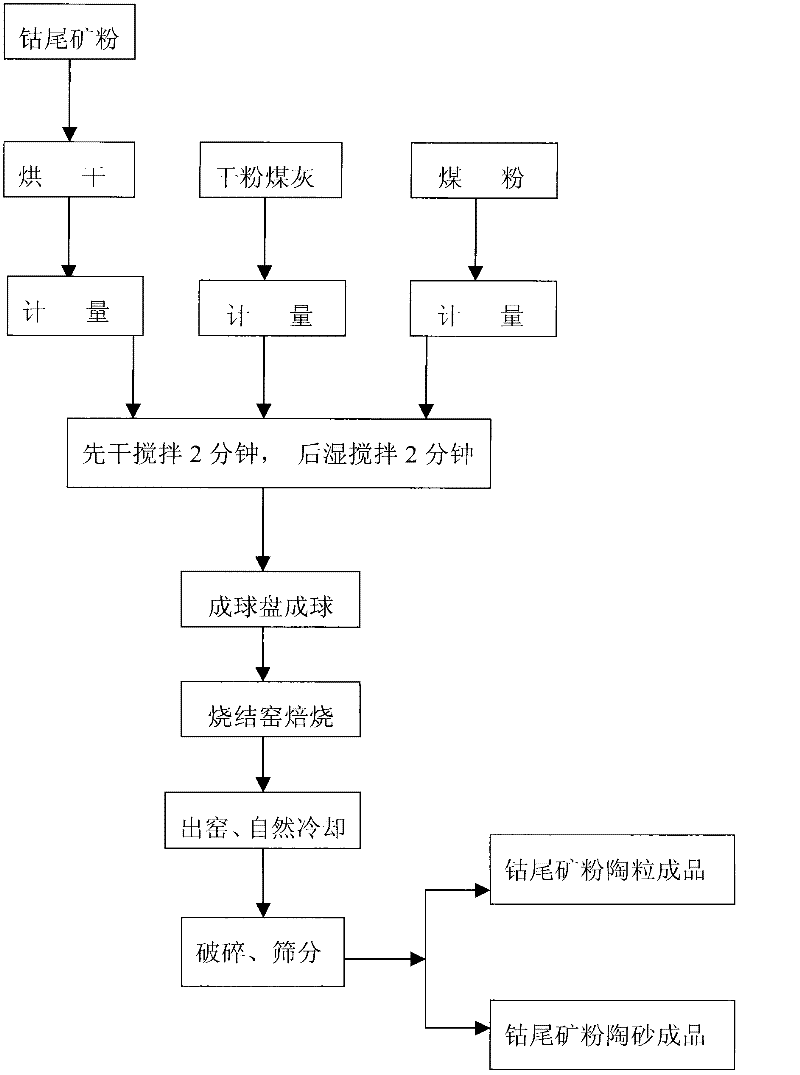

Method for manufacturing cobalt tailings ash aggregates

ActiveCN102503367AIncrease dosageMaterial selection scienceCeramic materials productionClaywaresPulverized fuel ashUltimate tensile strength

The invention relates to a method for manufacturing cobalt tailings ash aggregates, which comprises materials and proportions, as well as a manufacturing process flow. The materials comprise: 70 to 80 percent of cobalt tailings ash, 10 to 25 percent of pulverized fuel ash, and 5 to 10 percent of pulverized coal. The process flow comprises the following steps of: baking the cobalt tailings ash, screening, and measuring; respectively measuring the pulverized fuel ash and the pulverized coal; conveying the cobalt tailings ash, the pulverized fuel ash and the pulverized coal into a stirrer to be stirred in a dry state for about 2 minutes; adding half amount of water, and stirring in a wet state for about 2 minutes; feeding the stirred wet powder material into a pelletizing pan, and adding water to produce balls; putting the raw cobalt tailings ash aggregate balls into a static continuous sintering kiln for roasting; and discharging from the kiln, cooling, crushing and separating. The method is characterized in that: the cobalt tailings ash and the pulverized fuel ash and the pulverized coal are respectively measured after the cobalt tailings ash is baked and screened, are stirred in the stirrer in the dry state and the wet state and pelletized by adding water; the raw cobalt tailings ash aggregate balls are sent to the sintering kiln for being roasted; and the cobalt tailings ashhas the advantages of high waste utilization, high strength and low water absorption rate through three sintering process steps, namely preheating, sintering and cooling.

Owner:BAOTOU ZHENGTANG ENVIRONMENTAL PROTECTION IND

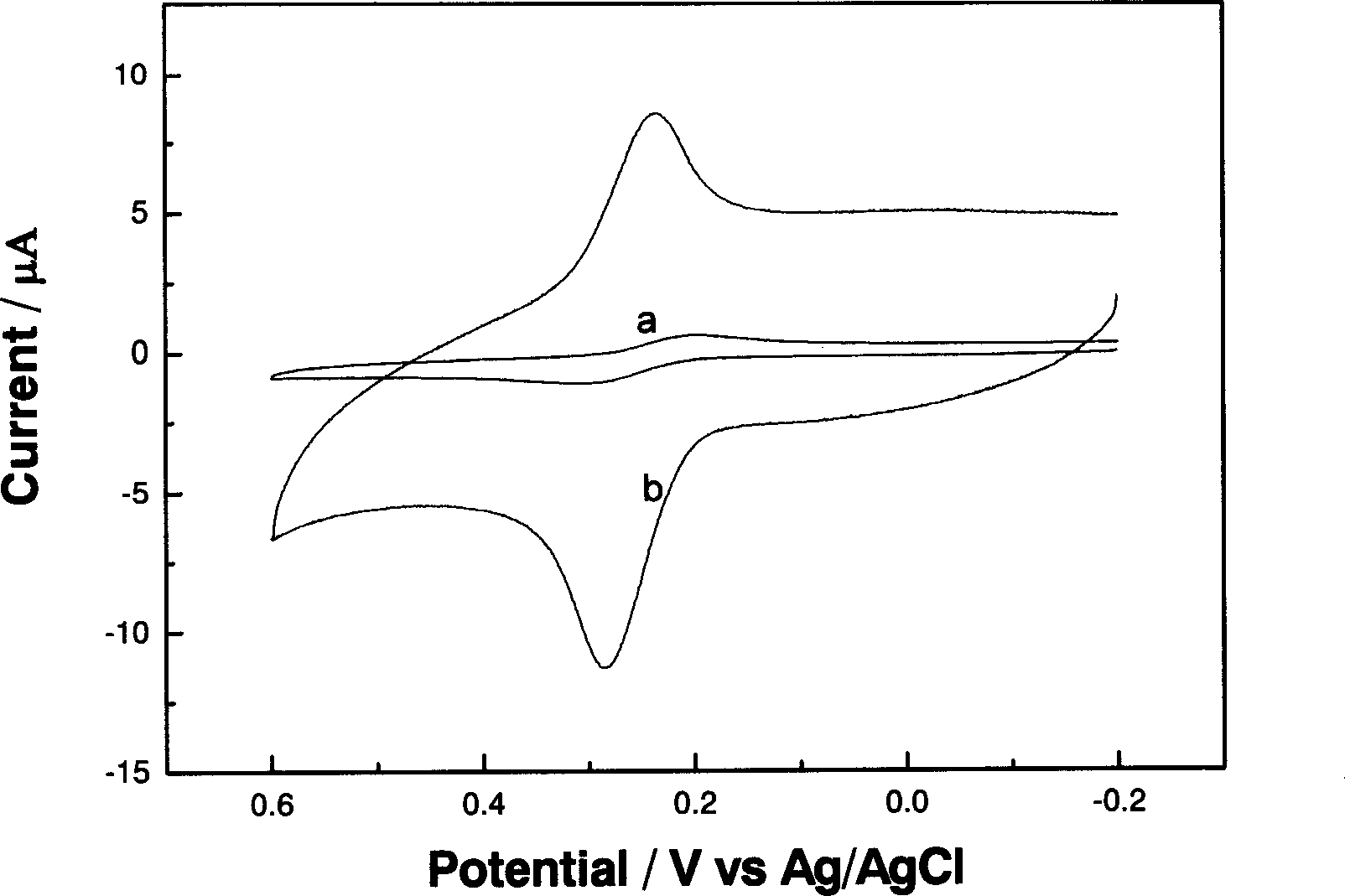

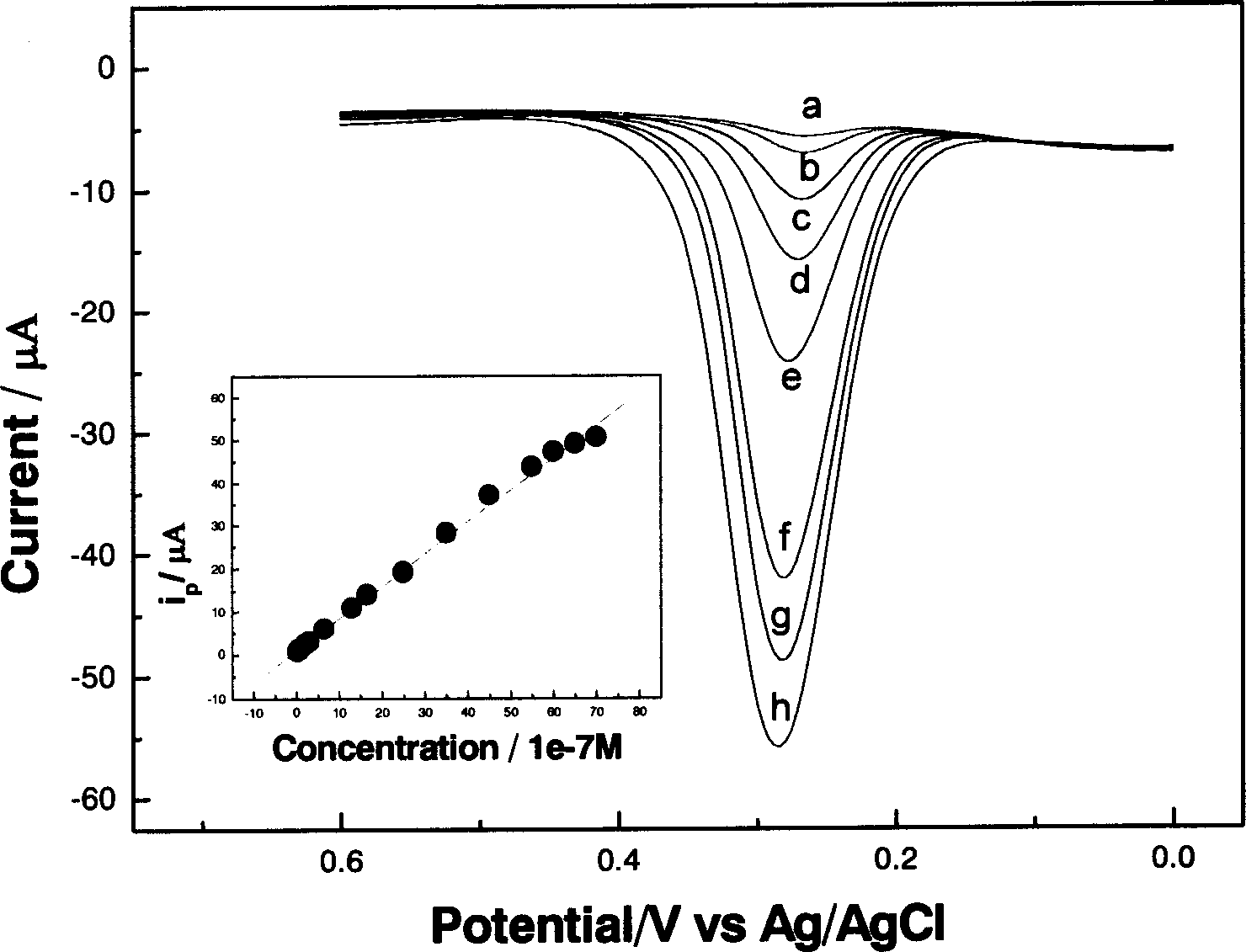

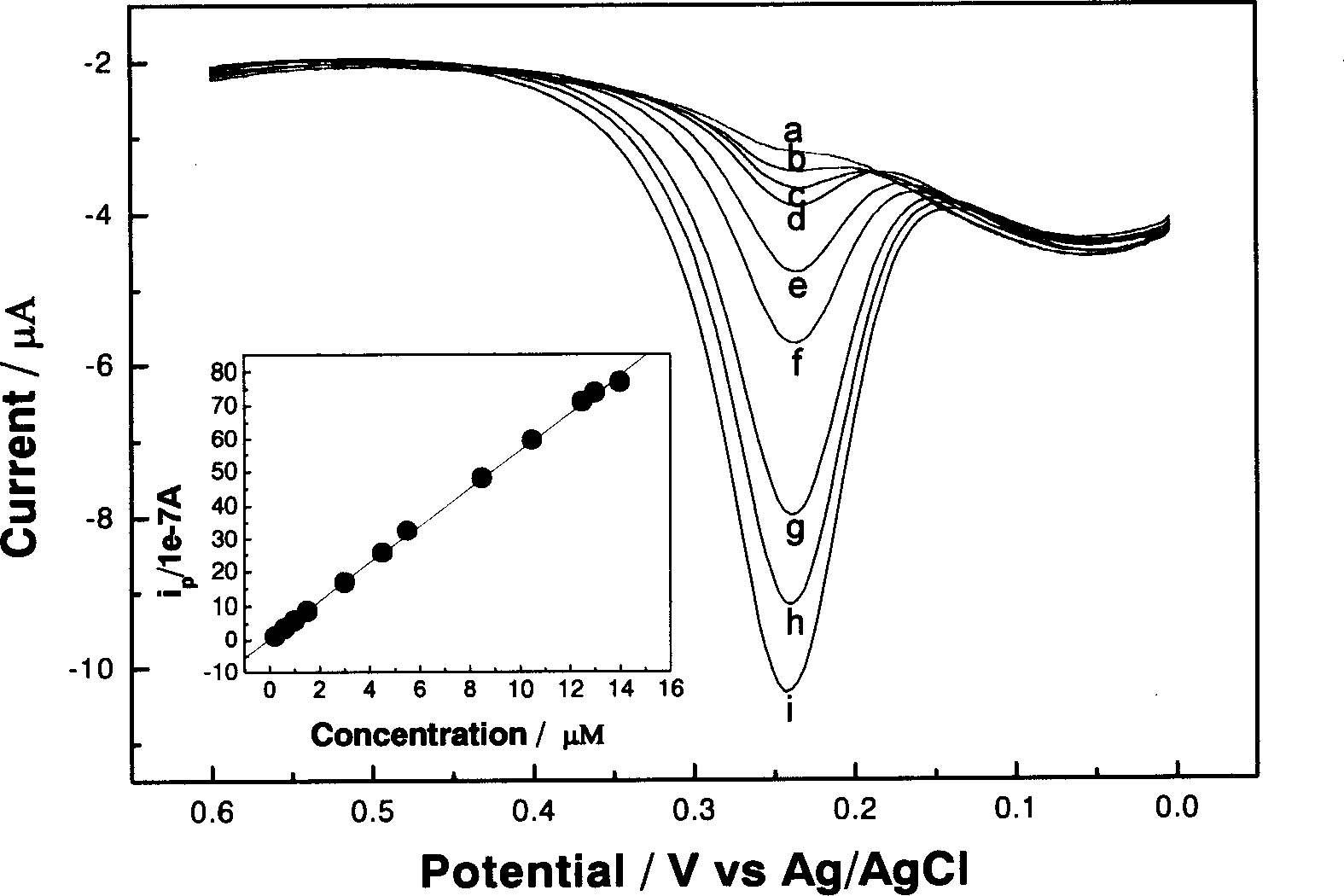

Process for preparing O-carboxymethyl chitosan covalent binding chemical modification electrode

InactiveCN1865967ALow costHigh detection sensitivityMaterial electrochemical variablesO carboxymethyl chitosanDistilled water

The disclosed preparation method for an electrode chemical modified by O-carboxylmethychitose covalence bond comprises: dipping glass-carbon electrode into O-carboxylmethychitose-formic acid solution for modification, taking out to clean with formic acid and distilled water. This invention can improve detection sensitivity for DA, can eliminate effect of AA and UA, and has long lifetime.

Owner:YANGZHOU UNIV

Preparation method for kelp flavored seafood seasoning

ActiveCN104286808AReduce soaking pretreatment timeRetain nutrientsProtein composition from fishAnimal proteins working-upMonosodium glutamateActivated carbon

The invention relates to a preparation method for a kelp flavored seafood seasoning. The preparation method comprises the following steps: selecting dry swimming bladders as the raw material, carrying out the ultrasonic treatment after cleaning, crushing and soaking, adding papayotin for enzyme-controlled enzymolysis after beating, adding activated carbon for carbon removing after enzyme inactivating, and filtering through a filtering cloth to obtain an enzymolytic filtering solution; selecting kelp to be cut into pieces, adding water for heating and insulation extracting, and filtering to obtain a kelp extracting solution; mixing the enzymolytic filtering solution and the kelp extracting solution, adding monosodium glutamate, salt, disodium nucleotide and potassium sorbate for mixing to obtain a seasoning solution; subpacking the seasoning solution into bottles to obtain the finished liquid kelp flavored seafood seasoning, or carrying out spray drying on the seasoning solution to obtain the powdery kelp flavored seafood seasoning. The preparation method is reasonable in technology, controllable in operation, scientific in ingredient selection and short in preparation time; the prepared kelp flavored seafood seasoning is rich in kelp flavor, delicious in seafood taste, strong in natural sense, abundant in nutritions and easy to digest and absorb by a human body.

Owner:威海市桢昊生物技术有限公司

Chinese herbal external cream for preventing and treating radiation and preparation method thereof

InactiveCN102166301AWide range of indicationsSimple and fast operationAerosol deliveryOintment deliveryBarbed Skullcap HerbNuclear radiation

The invention relates to a Chinese herbal external cream for clinically preventing and treating radiation and a preparation method thereof, belonging to the technical field of medicine. The Chinese herbal external cream is prepared from the following materials in parts by weight: 10-30 parts of cactus juice, 30-50 parts of waxberry juice, 10-30 parts of Chinese medical extracting solution, 10-15 parts of waxberry kernel oil, 2-12 parts of emulsifier and 0-1 part of preservative, wherein the Chinese medical extracting solution is prepared by decocting and refining 13-19 parts of radix adenophorae, 13-19 parts of ophiopogon root, 13-19 parts of winter mulberry leaf, 8-15 parts of barbed skullcap herb, 8-19 parts of red peony root and 13-19 parts of honeysuckle. The invention has the advantages of scientific material selection and reasonable formula, and the technical method for preparing the Chinese herbal external cream is simple and advanced. The prepared Chinese medical compound external preparation for preventing and treating nuclear radiation injury to the skin has the advantages of wide application range and obvious treatment effect, is simple and convenient to operate, is economical and safe, and is an ideal external medicament for preventing and treating nuclear radiation injury to the skin.

Owner:YANGZHOU UNIV

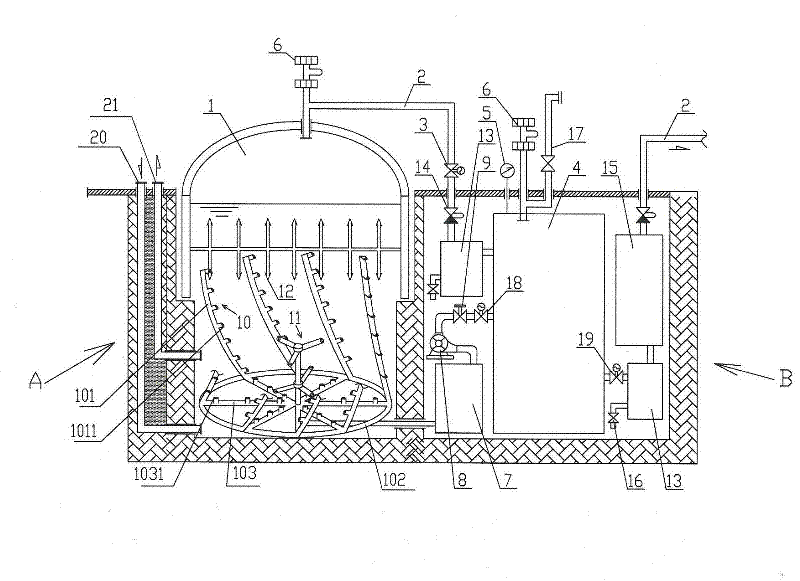

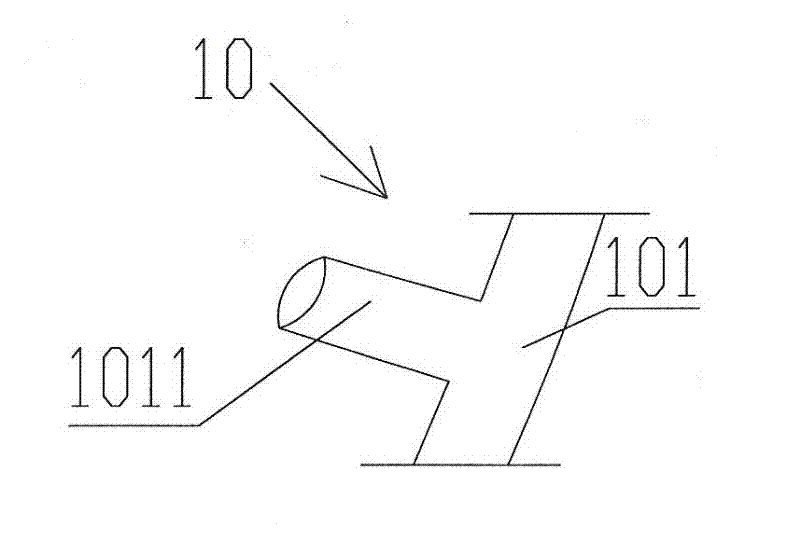

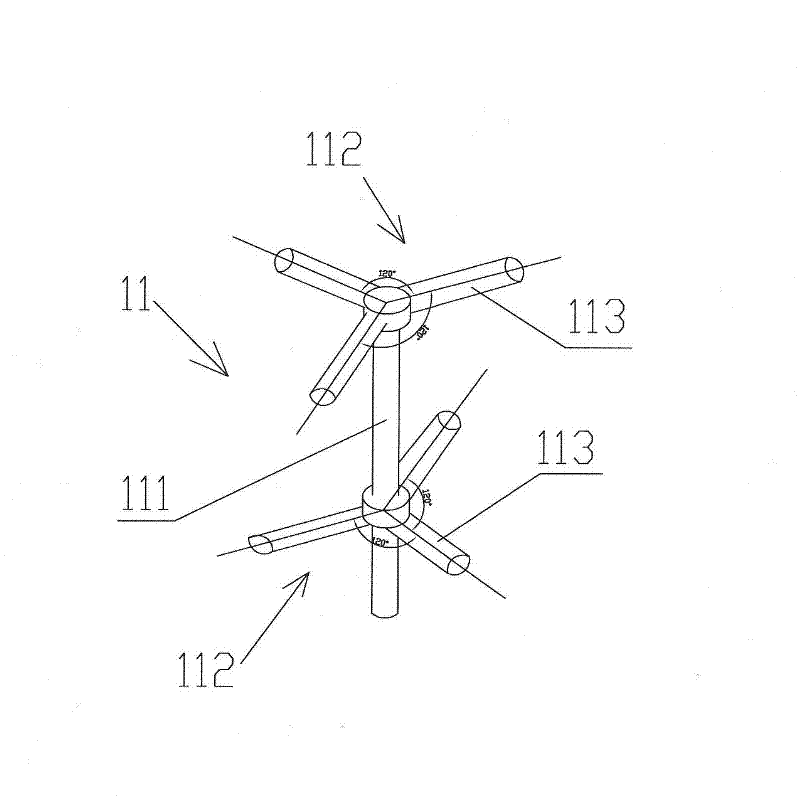

Biogas generator applicable to cold regions

InactiveCN102225832ARealize the purpose of heat preservation and temperature increaseBeneficial generationWaste based fuelBiological sludge treatmentProduction rateFiber

The invention discloses a biogas generator applicable to cold regions, which is mainly characterized in that: a guiding stirrer and a scrambler are arranged inside a biogas fermentation tank of a biogas pool, the guiding stirrer is located at the periphery of the biogas fermentation tank, the scrambler is located at the center of the biogas fermentation tank, the guiding stirrer and the scramblerare communicated, the guiding stirrer and the scrambler are communicated with a heat-insulation and heating controller, the heat-insulation and heating controller is connected with a gas collection tank through a gas pump, an adjusting valve and an electromagnetic valve and a shell breaking cone is located at the top of a floating cover of the biogas fermentation tank; the heat-insulation and heating controller can control the temperature of the fermented liquid, thus achieving the heat insulation and heating of the fermented liquid, protecting the fermented liquid from the outside temperature influence, reaching the optimum temperature for bacterium fermentation and facilitating the production of the biogas; and the guiding stirrer, the scrambler and the shell breaking cone utilize a gasdisturbing mode to carry out strong forced movement on the fermented liquid and reach a turbulent state, thereby destroying the crusting of plant fibers, completely decomposing the fermentation raw materials and increasing the gas production rate of the raw materials.

Owner:JILIN JIANZHU UNIVERSITY

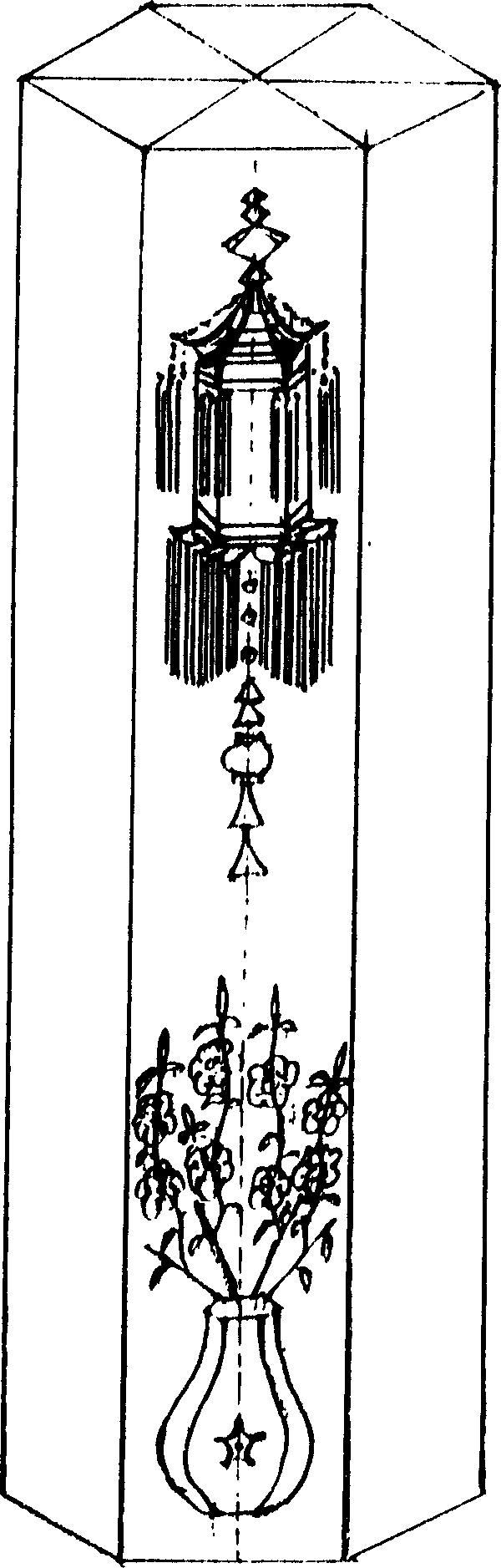

Glass engraving fabricating technique

InactiveCN1565869AConducive to carry forwardAdvanced technologyDecorative surface effectsSpecial ornamental structuresEngineeringPrism

Disclosed is a process of carving patterns on a regular three prism includes preparing a transparent regular three prism made of organic glass or crystal glass, carving symmetric patterns on one arris of the prism, carving patterns matchable to the symmetric patterns on the two side surfaces relative to the carved arris, then making the carved three prism into a craftwork. The invented process is advanced, simple, and the carved three prism has beautiful appearance and can be used widely.

Owner:丁志富

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com