Preparation method of 2,3-dimethyl-2-isopropyl butyronitrile

A technology of propyl butyronitrile and dimethyl, applied in 2, to achieve the effect of reducing cost, high yield and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

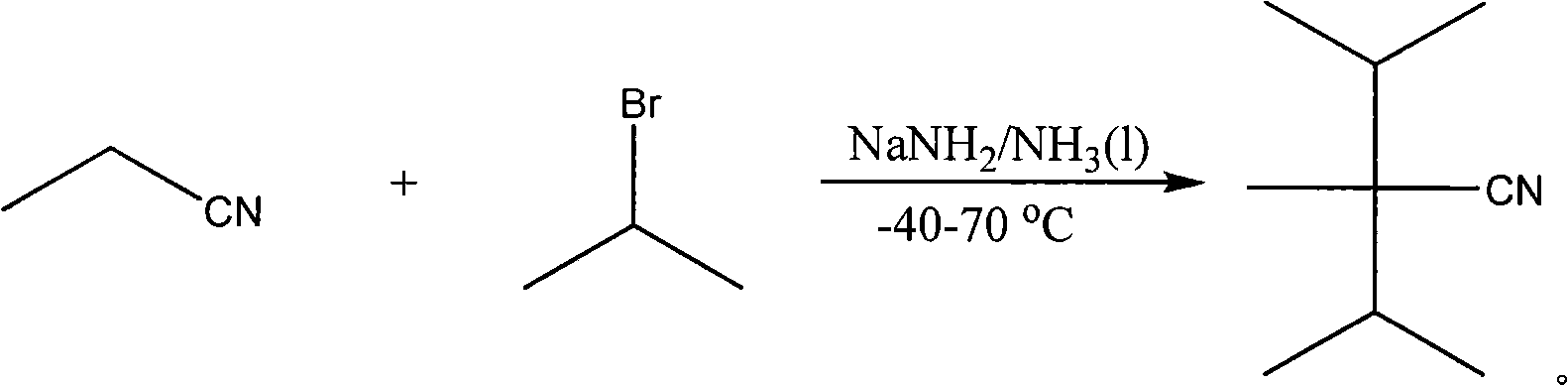

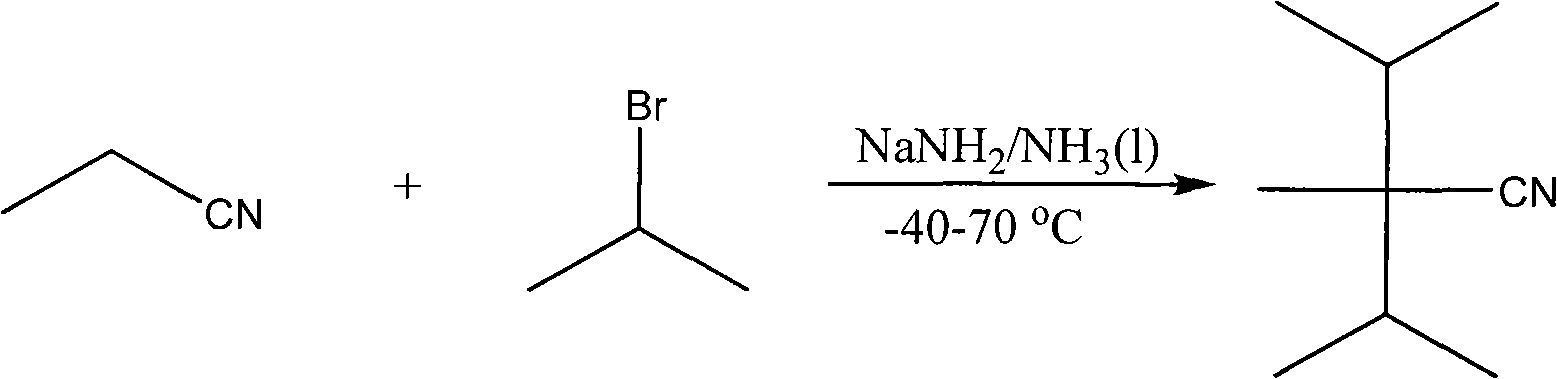

[0014] A kind of 2, the preparation method of 3-dimethyl-2-isopropylbutyronitrile of the present invention comprises the steps:

[0015] The first step is to cool the ammonia gas to a liquid state and add it to the low-temperature reaction kettle, then add sodium amide, start stirring to mix the materials in the kettle evenly, and adjust the temperature in the low-temperature reaction kettle to -40~-70°C; the liquid in the above process Ammonia is a solvent, and sodium amide is an alkali, and their respective weight percentages are respectively 30-40% and 10-18% of the reaction mixture solution.

[0016] In the second step, propionitrile and 2-bromopropane are added into a high-position stirring dropping tank and mixed evenly; the weight percentages of propionitrile and 2-bromopropane are respectively 6-10% and 35-45%.

[0017] In the third step, slowly drop the mixed liquid obtained in the second step into the low-temperature reaction kettle, adjust the temperature in the low...

Embodiment 1

[0021] First use low-temperature cooling, cool 800 kg of liquid ammonia and add it to a 3000L low-temperature reaction kettle, then add 350 kg of sodium amide, start stirring to make the kettle evenly stirred. Maintain the temperature in the reactor between -50 and -60°C. Add 150 kg of propionitrile and 850 kg of 2-bromopropane into the high-position stirring drop tank, and stir evenly. Then slowly drop the mixed solution into the low-temperature reactor, the dropping process is strongly exothermic, and the temperature in the reactor must be controlled not to be higher than -50°C during the dropping process. The dropwise addition time is 8 hours, after the dropwise addition is completed, the temperature is kept at low temperature for 10 hours, and the reaction temperature is set at about -50 degrees. After the reaction is completely finished, the liquid ammonia is recovered by evaporation, and the evaporation ends in about 2-4 hours. 100 kg of water was added dropwise to que...

Embodiment 2

[0023] First use low-temperature cooling, cool 800 kg of liquid ammonia and add it to a 3000L low-temperature reaction kettle, then add 350 kg of sodium amide, start stirring to make the kettle evenly stirred. Maintain the temperature in the reactor between -40. Add 150 kg of propionitrile and 850 kg of 2-bromopropane into the high-position stirring drop tank, and stir evenly. Then slowly drop this mixed solution into the low-temperature reaction kettle. During the dropping process, the heat is strongly exothermic. Be sure to control the temperature in the reaction kettle during the dropping process not to be higher than -40°C. The dropwise addition time is 8 hours, after the dropwise addition is completed, the temperature is kept at low temperature for 6 hours, and the reaction temperature is set at about -40 degrees. After the reaction is completely finished, the liquid ammonia is recovered by evaporation, and the evaporation ends in about 2-4 hours. Water was added dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com