Heat-resistant instrument cable for ships and manufacturing process of heat-resistant instrument cable

A technology of instrument cable and manufacturing process, applied in the field of wire and cable, to achieve the effect of small structure size, excellent electrical and mechanical properties, and beneficial to light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

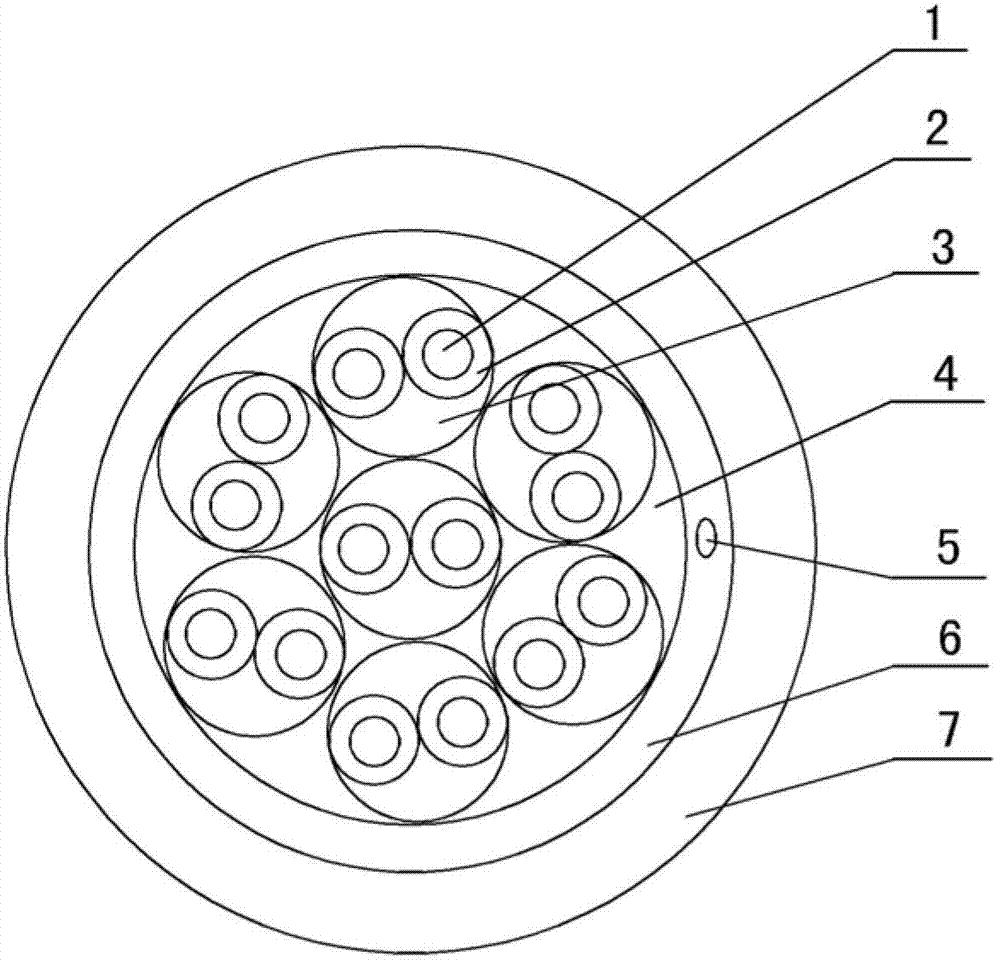

[0025] see figure 1 , the structure of the heat-resistant instrument cable for ships in this embodiment is set as:

[0026] The cable conductor 1 is twisted by a plurality of tinned copper wires drawn by copper rods, annealed and tinned, and an insulating layer 2 is extruded on the conductor 1 to form an insulated core, and two insulated cores form a twisted unit 3. The cable core 4 is formed by twisting a plurality of pair-twisted units 3; and the outer surface of the cable core 4 is sequentially provided with a longitudinal drain wire 5, a tinned copper wire braided shielding layer 6 and an extruded sheath layer 7; the insulating layer 2 and the outer sheath layer 7 are made of fluororesin extruded material.

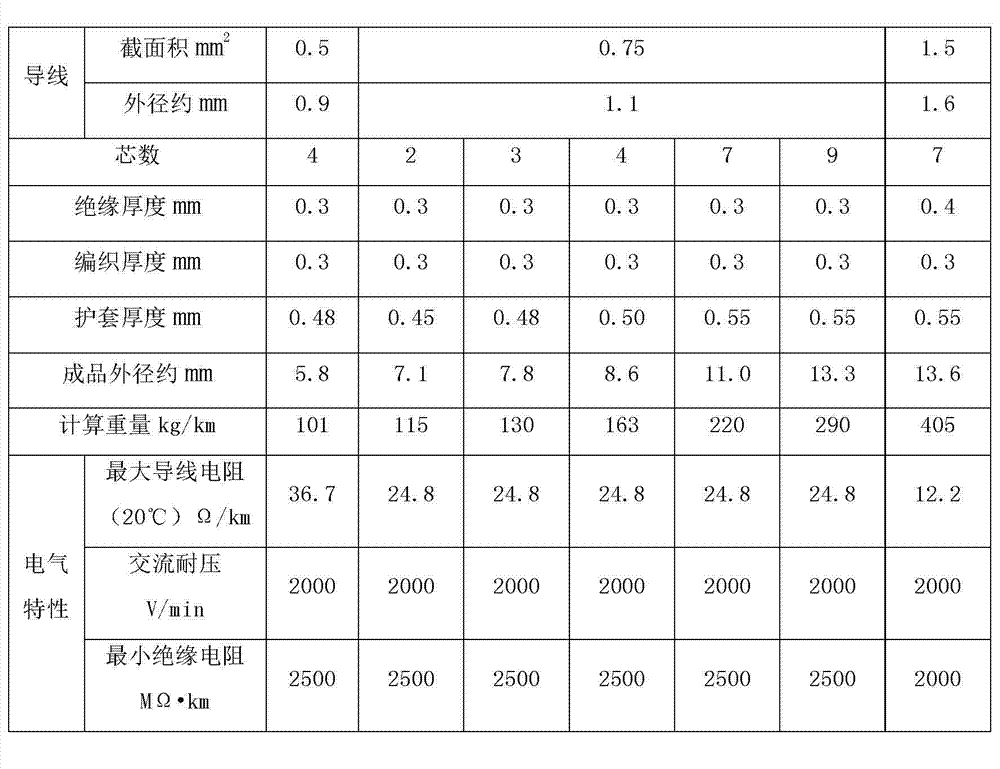

[0027] In specific implementation, the cross section of conductor 1 is 0.5 mm 2 , 0.75 mm 2 or 1.5mm 2 ;Conductor 1 is made of seven or nineteen tinned copper wires through regular twisting; insulating layer 2 and outer sheath layer 7 are made of meltable polytetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com