Grease-containing waste clay ceramsite and preparing method thereof

A manufacturing method and technology of waste white clay, applied in the field of building materials manufacturing, can solve problems such as fire, spontaneous combustion, endangering groundwater quality, etc., and achieve the effect of improving the strength level and expanding the effect of waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weight ratio: waste clay powder containing oil 60%;

[0023] Fly ash 40%;

[0024] Manufacturing process:

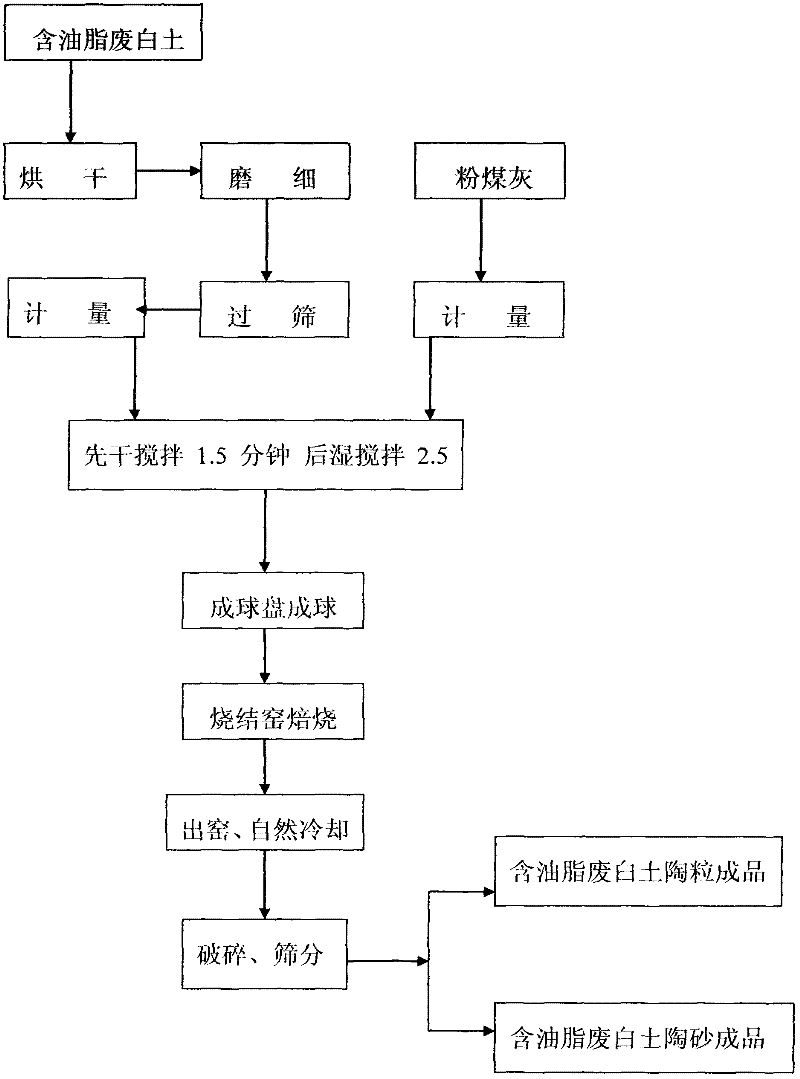

[0025] 1. After drying and grinding the waste white clay containing oil, sieve it with a 0.3mm square hole sieve, return the rest of the 0.3mm sieve and grind it again, and use the waste white clay powder containing oil at the bottom of the 0.3mm square hole sieve, As the main raw material for the production of ceramsite;

[0026] 2. Measure the sifted oil-containing waste clay powder and fly ash respectively;

[0027] 3. Put the measured two kinds of materials into the blender, first dry blend for about 1.5 minutes, then add 1 / 2 water, then wet blend for about 2.5 minutes;

[0028] 4. Send the stirred wet mixed powder into the ball forming tray, add 1 / 2 water, and spin and centrifuge to form balls;

[0029] 5. Put the grease-containing waste clay ceramsite raw meal balls into a static double-layer continuous fly ash ceramsite sintering kiln for roas...

Embodiment 2

[0034] Weight ratio: waste clay powder containing oil 70%;

[0035] Fly ash 30%;

[0036] Manufacturing process:

[0037] 1. After drying and grinding the waste white clay containing oil, sieve it with a 0.3mm square hole sieve, return the rest of the 0.3mm sieve and grind it again, and use the waste white clay powder containing oil at the bottom of the 0.3mm square hole sieve, As the main raw material for the production of ceramsite;

[0038] 2. Measure the sifted oil-containing waste clay powder and fly ash respectively;

[0039] 3. Put the measured two kinds of materials into the blender, first dry blend for about 1.5 minutes, then add 1 / 2 water, then wet blend for about 2.5 minutes;

[0040] 4. Send the stirred wet mixed powder into the ball forming tray, add 1 / 2 water, and spin and centrifuge to form balls;

[0041] 5. Put the grease-containing waste clay ceramsite raw meal balls into a static double-layer continuous fly ash ceramsite sintering kiln for roas...

Embodiment 3

[0045] Weight ratio: waste clay powder containing oil 80%;

[0046] Fly ash 20%;

[0047] Manufacturing process:

[0048] 1. After drying and grinding the waste white clay containing oil, sieve it with a 0.3mm square hole sieve, return the rest of the 0.3mm sieve and grind it again, and use the waste white clay powder containing oil at the bottom of the 0.3mm square hole sieve, As the main raw material for the production of ceramsite;

[0049] 2. Measure the sifted oil-containing waste clay powder and fly ash respectively;

[0050] 3. Put the measured two kinds of materials into the blender, first dry blend for about 1.5 minutes, then add 1 / 2 water, then wet blend for about 2.5 minutes;

[0051] 4. Send the stirred wet mixed powder into the ball forming tray, add 1 / 2 water, and spin and centrifuge to form balls;

[0052] 5. Put the grease-containing waste clay ceramsite raw meal balls into a static double-layer continuous fly ash ceramsite sintering kiln for roas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com