Ceramic particles with iron tailing powder and manufacturing method thereof

A technology of iron tailings powder and a manufacturing method, applied in the field of building materials manufacturing, can solve the problems of decreasing, increasing the production cost of ceramsite, and being difficult to find in a region or city.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weight ratio: iron tailings powder 90%;

[0024] Coal powder 10%;

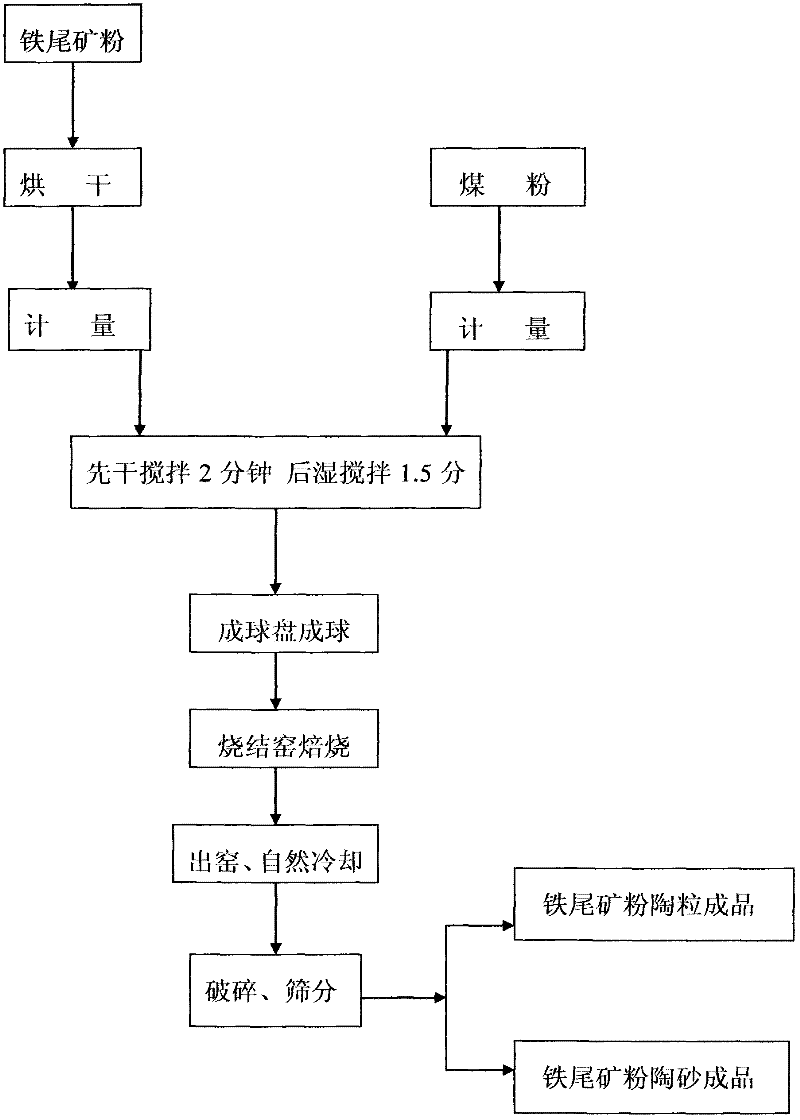

[0025] Manufacturing process:

[0026] 1. Dry the iron tailings powder first, and then sieve it with a 0.3mm square hole sieve. The rest of the 0.3mm sieve is used as fine aggregate for concrete products, and the 0.3mm sieve bottom part is used as the main raw material for the production of ceramsite ;

[0027] 2. Measure the sieved iron tailings powder and coal powder respectively;

[0028] 3. Put the measured two kinds of materials into the blender, first dry blend for about 2 minutes, then add 1 / 2 water, then wet blend for about 1.5 minutes;

[0029] 4. Send the stirred wet mixed powder into the ball forming plate, add 1 / 2 water, and rotate into balls;

[0030] 5. Put the iron tailings powder ceramsite raw meal balls into the static continuous sintering kiln for roasting, the sintering temperature is 1240℃~1320℃, the sintering time is 2.3~2.6 hours, the iron tailings powder ceramsite ra...

Embodiment 2

[0036] Weight ratio: iron tailings powder 93%;

[0037] Coal powder 7%;

[0038] Manufacturing process:

[0039] 1. Dry the iron tailings powder first, and then sieve it with a 0.3mm square hole sieve. The rest of the 0.3mm sieve is used as fine aggregate for concrete products, and the 0.3mm sieve bottom part is used as the main raw material for the production of ceramsite ;

[0040] 2. Measure the sieved iron tailings powder and coal powder respectively;

[0041] 3. Put the measured two kinds of materials into the blender, first dry blend for about 2 minutes, then add 1 / 2 water, then wet blend for about 1.5 minutes;

[0042] 4. Send the stirred wet mixed powder into the ball forming plate, add 1 / 2 water, and rotate into balls;

[0043] 5. Put the iron tailings powder ceramsite raw meal balls into the double-layer continuous ceramsite sintering kiln for roasting, the sintering temperature is 1240℃~1320℃, and the sintering time is 2.3~2.6 hours. The iron tailings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com