Method for manufacturing gold tailings ash aggregates

A technology for gold tailings and a manufacturing method, applied in the field of building materials manufacturing, can solve the problems of gold tailings powder ceramsite blank, environmental pollution, development scale limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

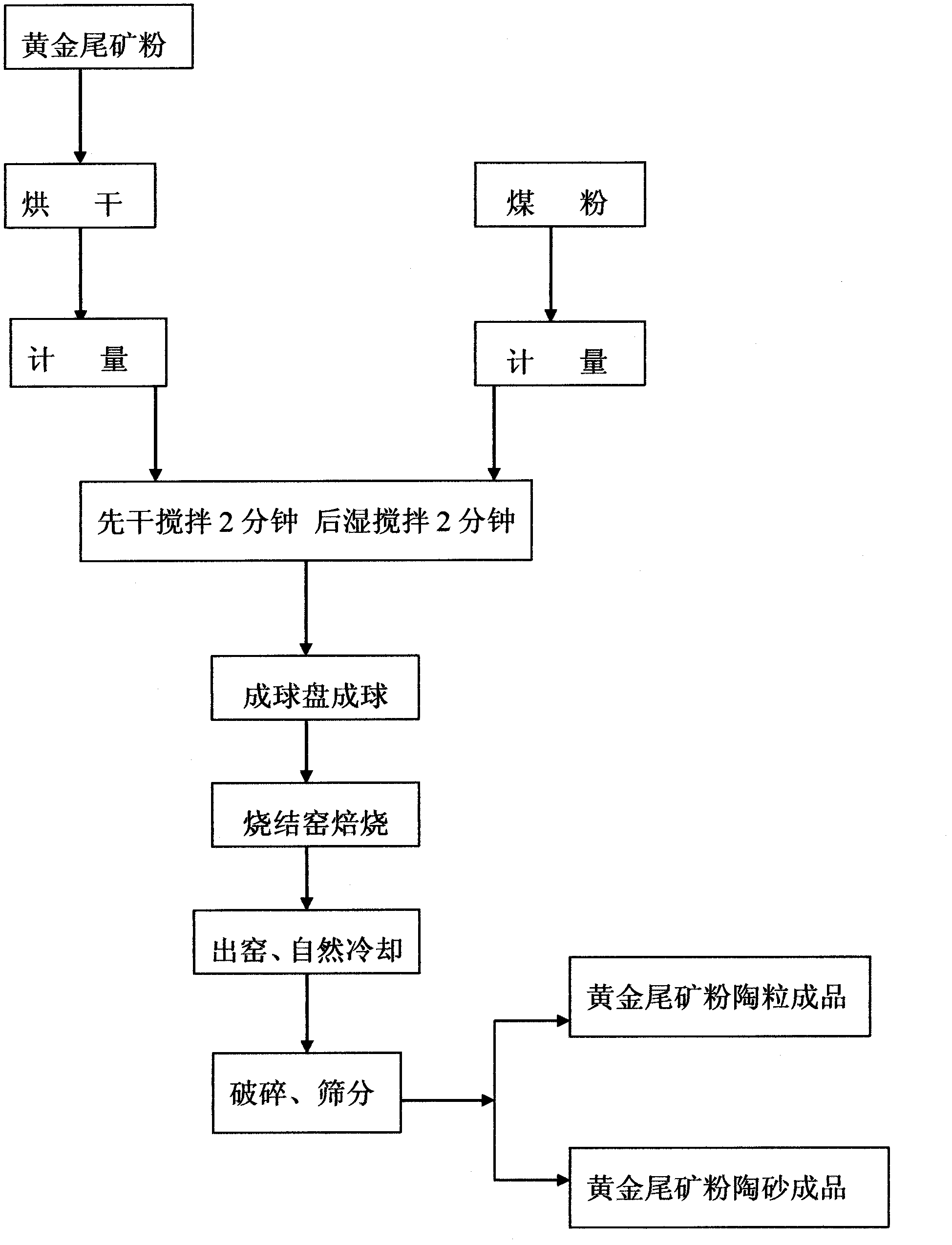

Image

Examples

Embodiment 1

[0023] Weight ratio: gold tailings powder 90%;

[0024] Coal powder 10%;

[0025] Manufacturing process:

[0026] 1. Dry the gold tailings powder first, and use a 0.30mm square hole sieve to sieve;

[0027] 2. Separately measure gold tailings powder and coal powder below 0.3mm after sieving;

[0028] 3. Put the measured two materials into the blender, first dry stir for about 2 minutes, then add 1 / 2 of water, and then wet stir for about 2 minutes;

[0029] 4. Send the stirred gold tailings powder mixture into the ball forming plate, add 1 / 2 of water, and rotate into balls;

[0030] 5. Put the gold tailings powder ceramsite raw meal balls into the static continuous ceramsite sintering kiln for roasting, the sintering temperature is 1220℃~1350℃, the sintering time is 2.0~2.5 hours, the gold tailings powder ceramsite raw meal balls are sintered In the kiln, it goes through three process stages of preheating, sintering and cooling in sequence, and cools down to below...

Embodiment 2

[0034] Weight ratio: gold tailings powder 92%;

[0035] Coal powder 8%;

[0036] Manufacturing process:

[0037] 1. Dry the gold tailings powder first, and use a 0.30mm square hole sieve to sieve;

[0038] 2. Measure the sieved gold tailings powder and coal powder below 0.3mm respectively;

[0039] 3. Put the measured two materials into the blender, first dry stir for about 2 minutes, then add 1 / 2 of water, and then wet stir for about 2 minutes;

[0040] 4. Send the stirred gold tailings powder wet mixture into the ball forming plate, add 1 / 2 of water, and rotate into balls;

[0041] 5. Put the gold tailings powder ceramsite raw meal balls into the static continuous ceramsite sintering kiln for roasting, the sintering temperature is 1220℃~1350℃, the sintering time is 2.0~2.5 hours, the gold tailings powder ceramsite raw meal balls are sintered In the kiln, it goes through three process stages of preheating, sintering and cooling in sequence, and cools down to bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com