Four-axis linkage numerical control glass carving processing center control system

A control system, four-axis linkage technology, applied in the field of machinery, can solve the problems of dependence on imports, low efficiency, pollution, etc., to achieve the effect of enhancing flexibility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

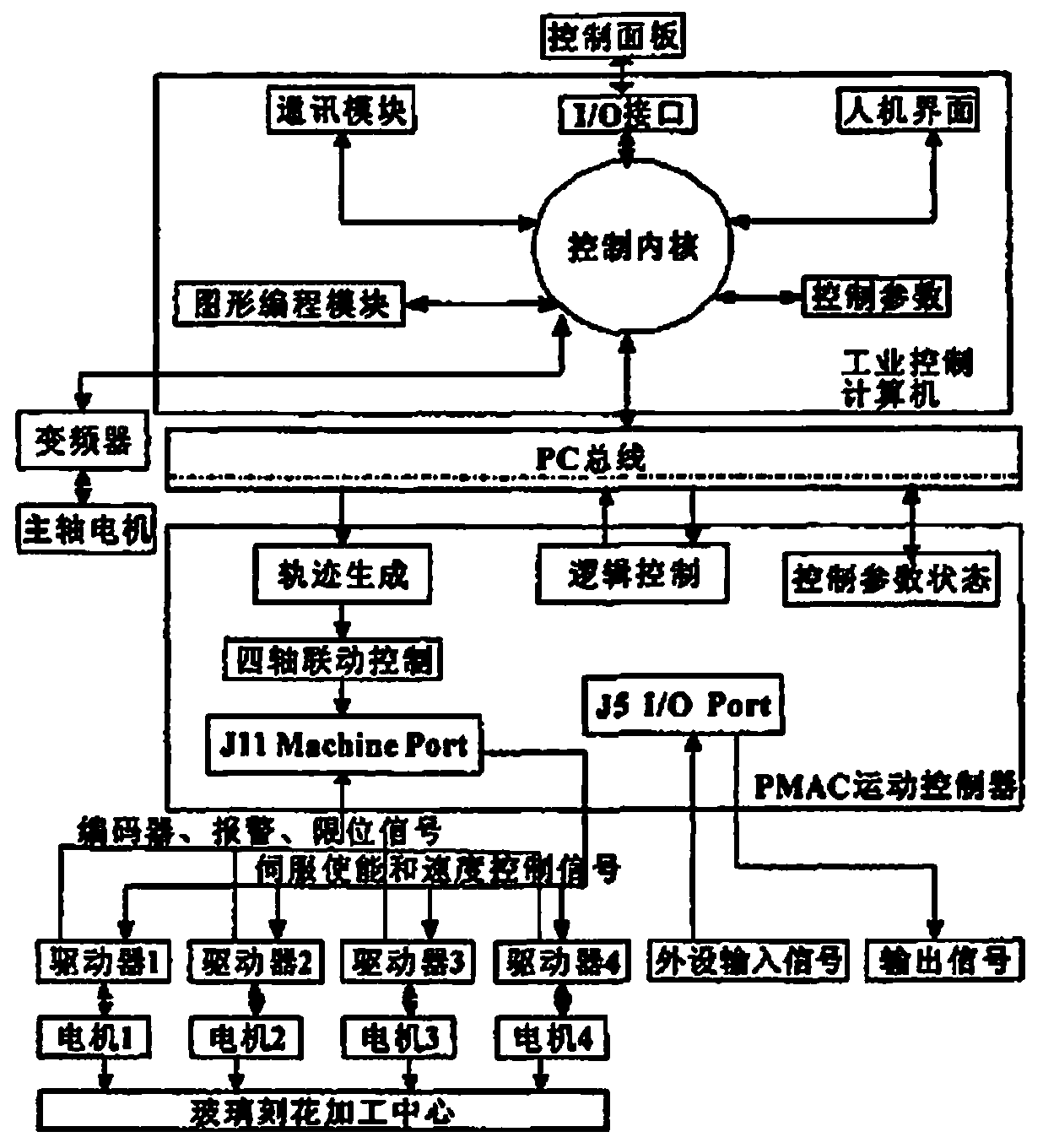

[0014] Such as figure 1 , The synchronous control of the motor is the focus and difficulty of the system control, because the axes of the synchronous control in the machine tool are far apart, if the synchronization performance is not good, the machining accuracy cannot be guaranteed, and in severe cases, it will cause damage to precision parts such as the screw.

[0015] The numerical control system adopts the dual-CPU open numerical control system based on the upper computer and the lower computer. The upper computer is an industrial control computer, which mainly completes non-real-time tasks such as NC programming, NC simulation, graphic interpolation, man-machine interface processing, and network functions. Real-time tasks such as programming logic control. The control kernel in the upper computer is the core of the whole numerical control system. It exchanges in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com