Positioning device of CNC engraving and milling machine

A positioning device and fine carving machine technology, applied in the field of fine carving machines, can solve the problems of inconvenient multi-segment carving, increase of production cost, difficult positioning, etc., and achieve the effect of improving carving quality, easy operation and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

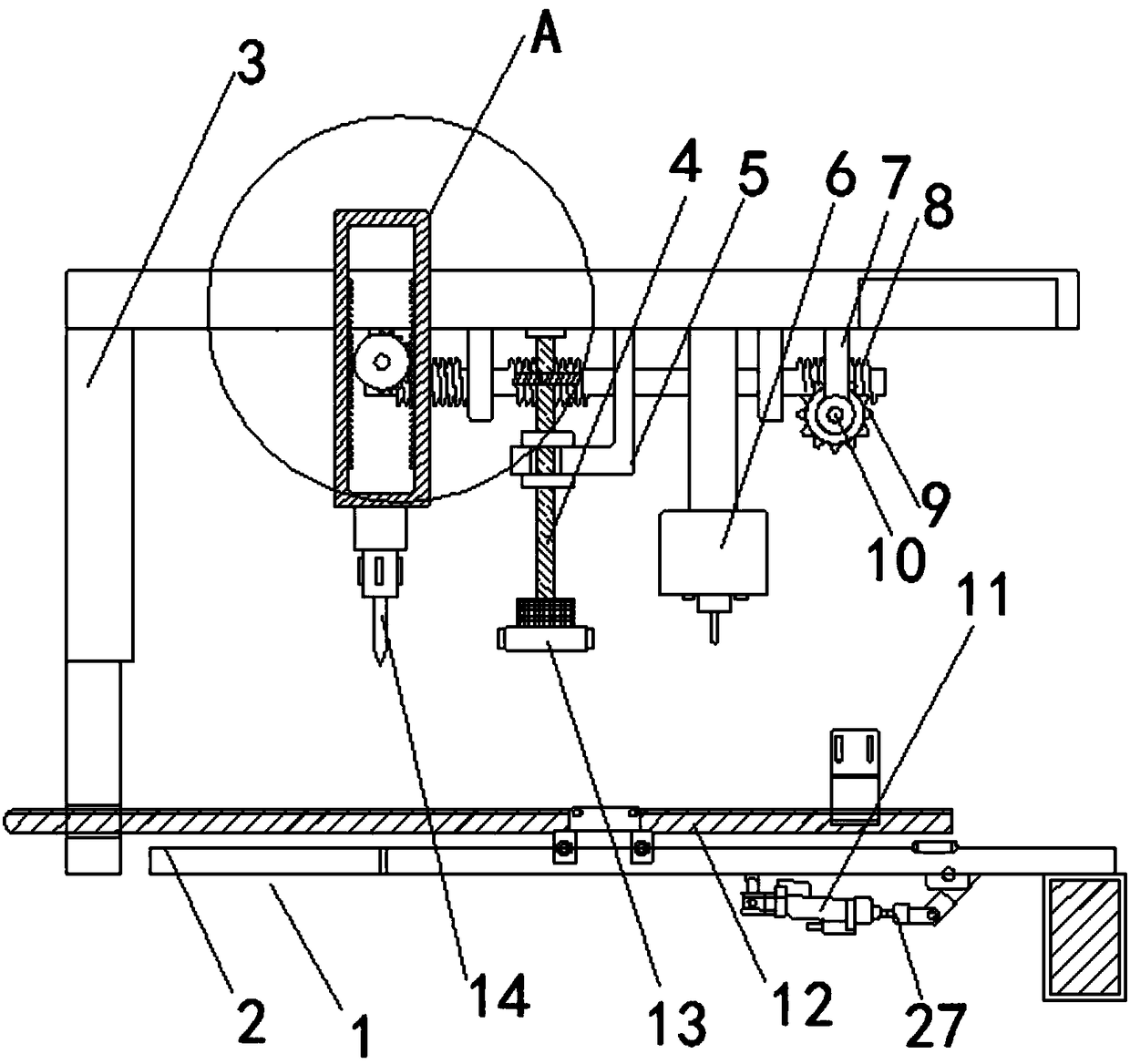

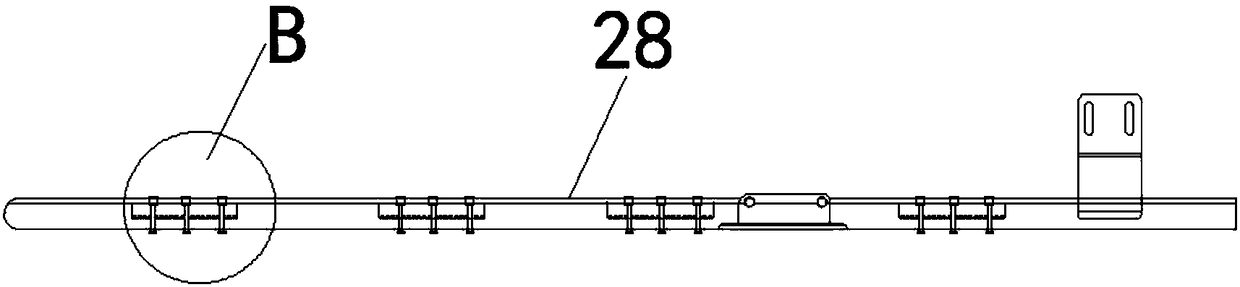

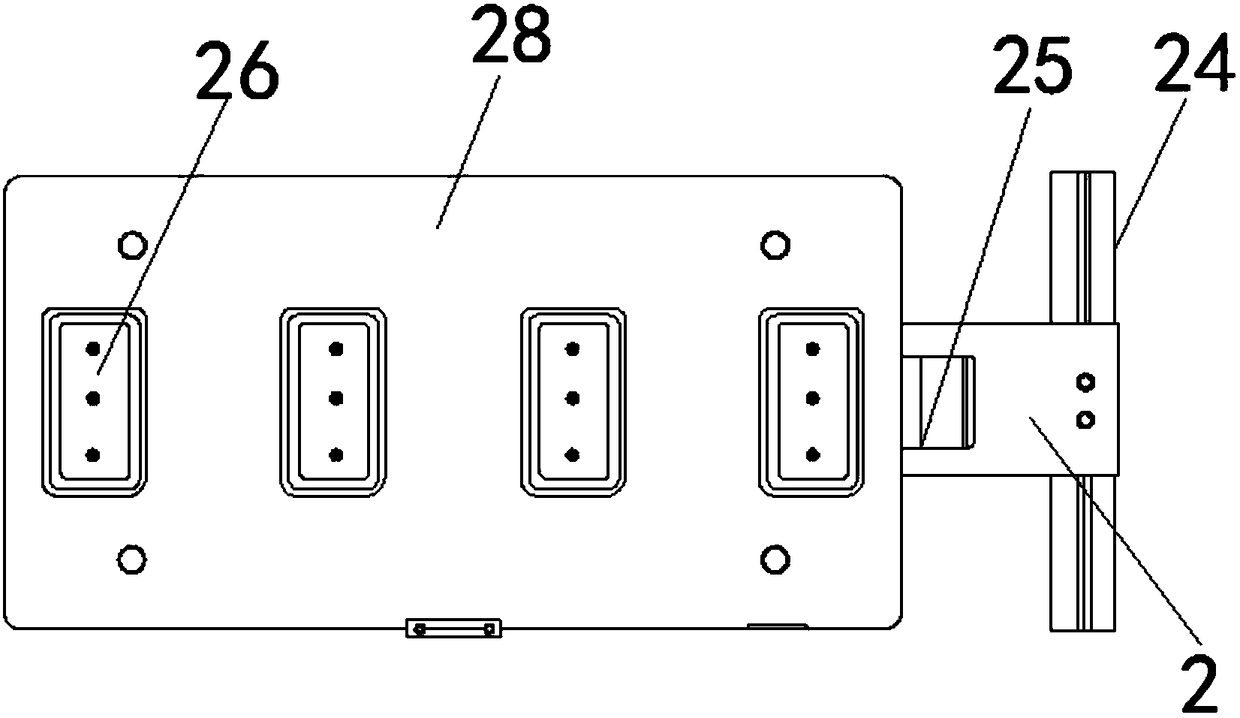

[0023] like Figure 1-8 As shown, the present invention provides a positioning device for fine engraving machines, including a device body 1, a base 2 is provided at the bottom of the device body 1, a load-bearing frame 3 is provided at the top of the device body 1, and a bearing frame 3 is installed on the top of the device body 1. Frame 20, the inside of frame 20 is equipped with lifting gear 21, the inner wall of frame 20 is provided with several lifting teeth 19, the bottom end of frame 20 is provided with engraving mechanism 14, one end of lifting gear 21 is provided with worm 8, one end of worm 8 A connecting rod 7 is installed, the bottom end of the connecting rod 7 is provided with a transmission gear 9, and one end of the transmission gear 9 is provided with a motor 10, and a carved mechanism 6, a fixed rod 5 and a lifting rod 4 are installed between the frame 20 and the connecting rod 7 , the bottom end of the lifting rod 4 is provided with a small motor 23, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com