Automatic material taking and placing mechanism of engraving and milling machine

An automatic pick-and-place, engraving machine technology, applied to conveyor objects, furnaces, stone processing tools, etc., can solve problems such as low work efficiency, increased enterprise costs, and the inability of engraving machines to achieve streamlined operations, to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

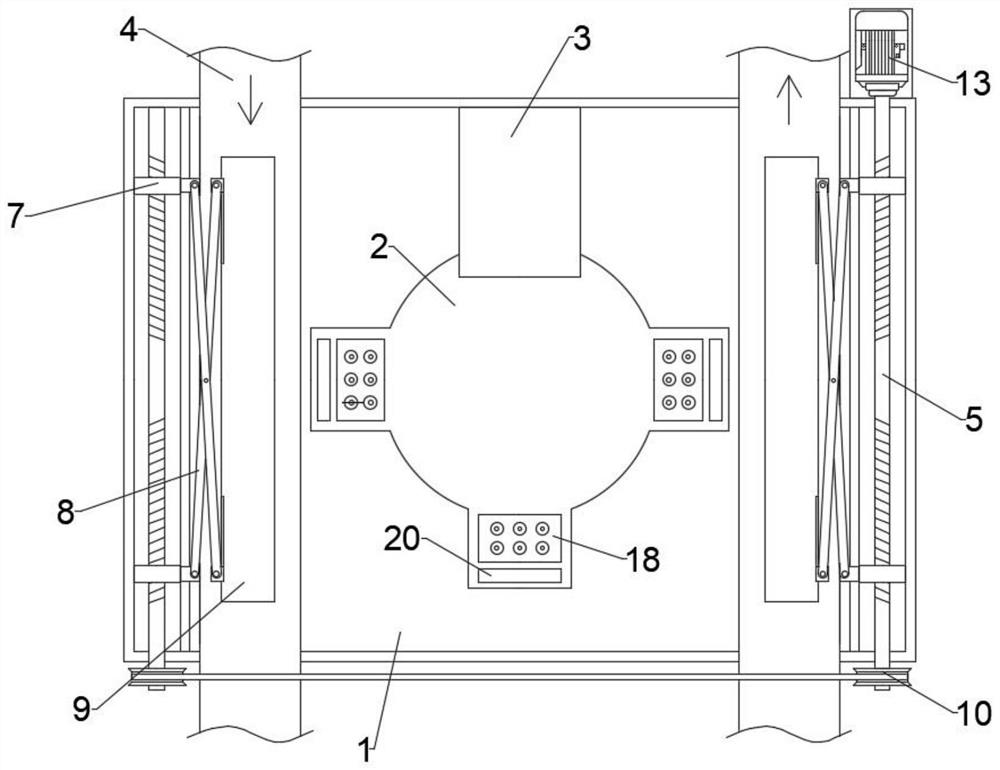

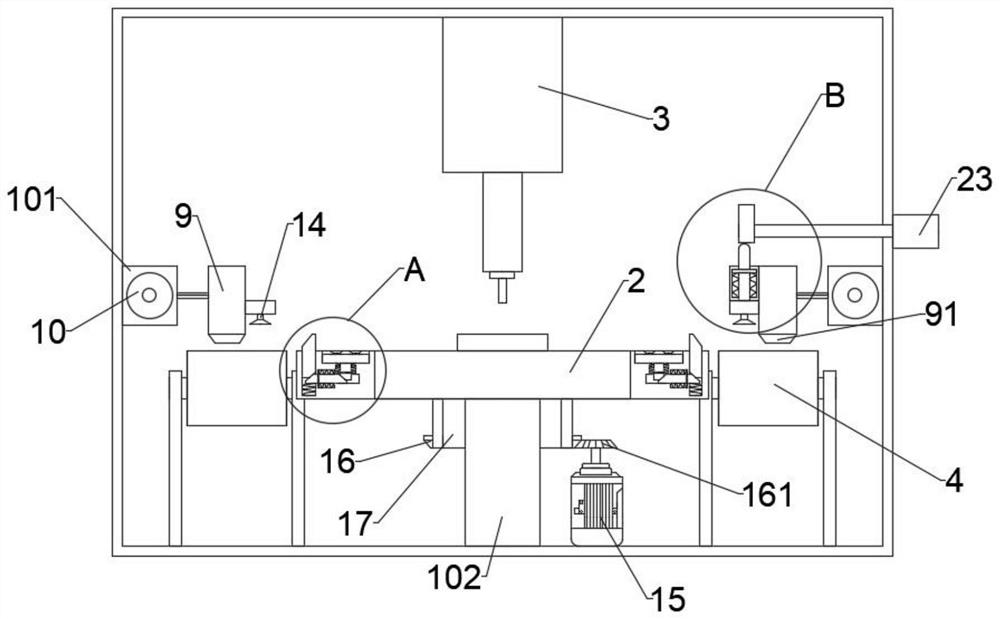

[0023] Such as Figure 1-3 As shown, the automatic loading and unloading mechanism of a fine carving machine proposed by the present invention includes a box body 1, the box body 1 is provided with an inner cavity, and the top cavity wall of the box body 1 is provided with an engraving and milling mechanism 3, and the left and right sides of the inner cavity Both parts are provided with a conveying mechanism 4 for conveying workpieces, the walls of the left and right ends of the inner cavity are equipped with auxiliary feeding mechanisms, the lower part of the inner cavity is provided with a rotating column 102, and the top of the rotating column 102 is provided with a processing turntable 2, The bottom wall of the processing turntable 2 is provided with a hollow sleeve 17, and the outer end of the hollow sleeve 17 is provided with a bevel gear ring 16. The bottom cavity wall of the inner cavity is detachably provided with a second motor 15, and the top of the second motor 15 i...

Embodiment 2

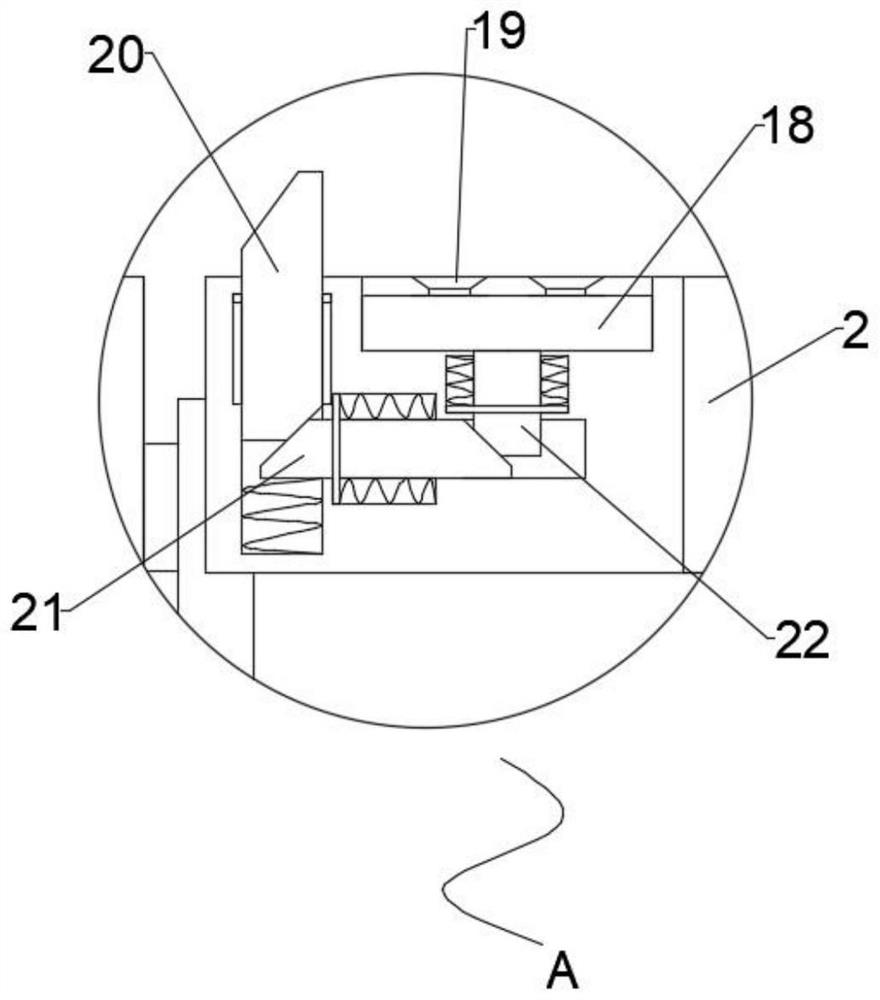

[0026] Such as Figure 2-5 As shown, the automatic loading and unloading mechanism of a fine carving machine proposed by the present invention, compared with the first embodiment, this embodiment also includes a limit mechanism including a positioning plate 18, a suction cup group 19 and a first tilting member 20, The top of the processing turntable 2 is provided with a cross-shaped rectangular groove, and a positioning plate 18 is embedded in the rectangular groove. The top of the positioning plate 18 is provided with a suction cup group 19, and the processing turntable 2 is provided with a first rectangular cavity below the rectangular groove. The second spring is evenly installed in the first rectangular cavity, and the second inclined part 22 is arranged, and the top of the second inclined part 22 is connected with the positioning plate 18, and the second rectangular cavity is arranged below the first rectangular cavity, and the second rectangular A third spring is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com