Processing table for glass engraving machine

A technology of engraving machine and processing table, applied in the field of CNC machine tools, can solve problems such as increasing production cost, and achieve the effect of strengthening fixation and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

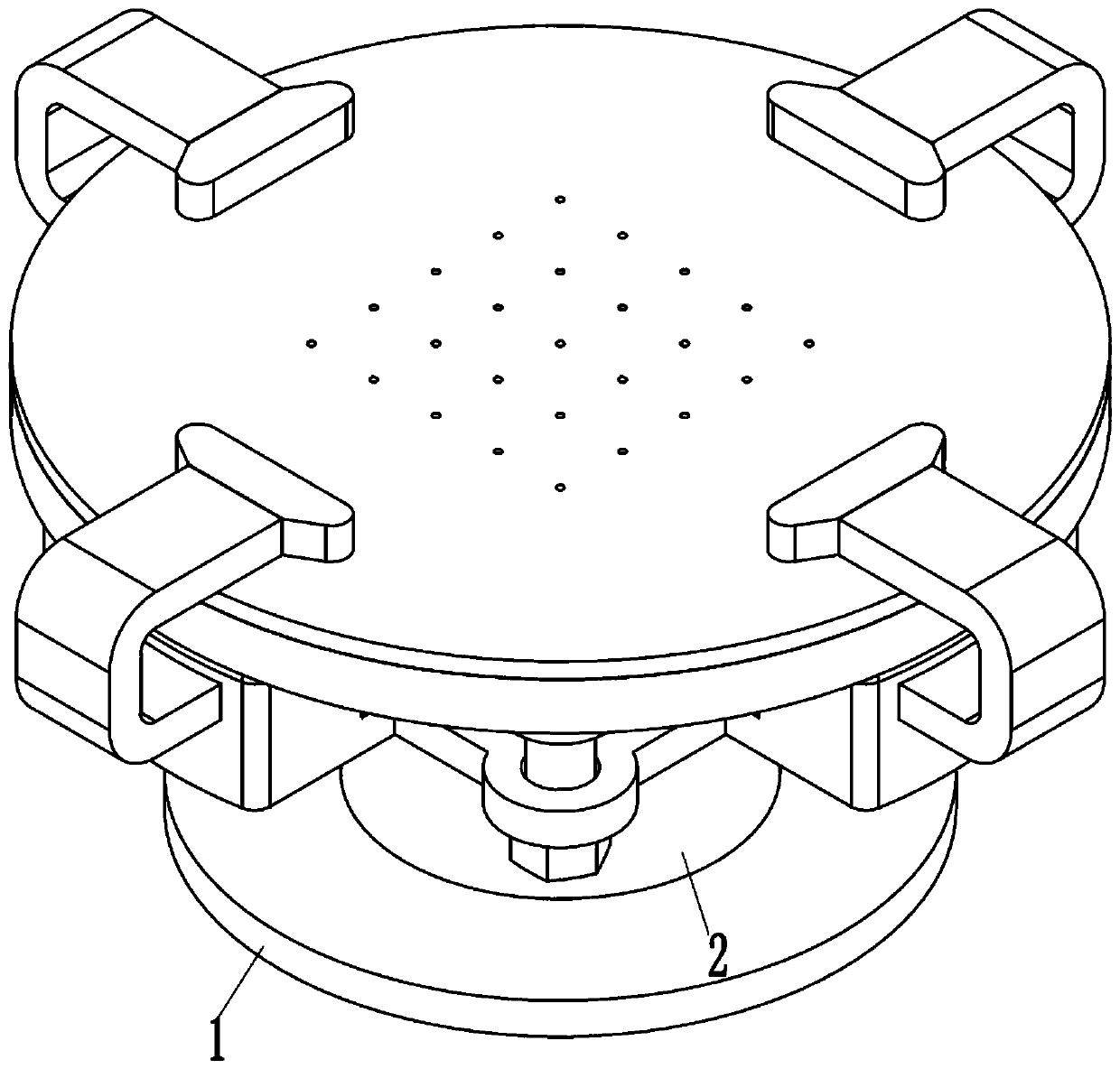

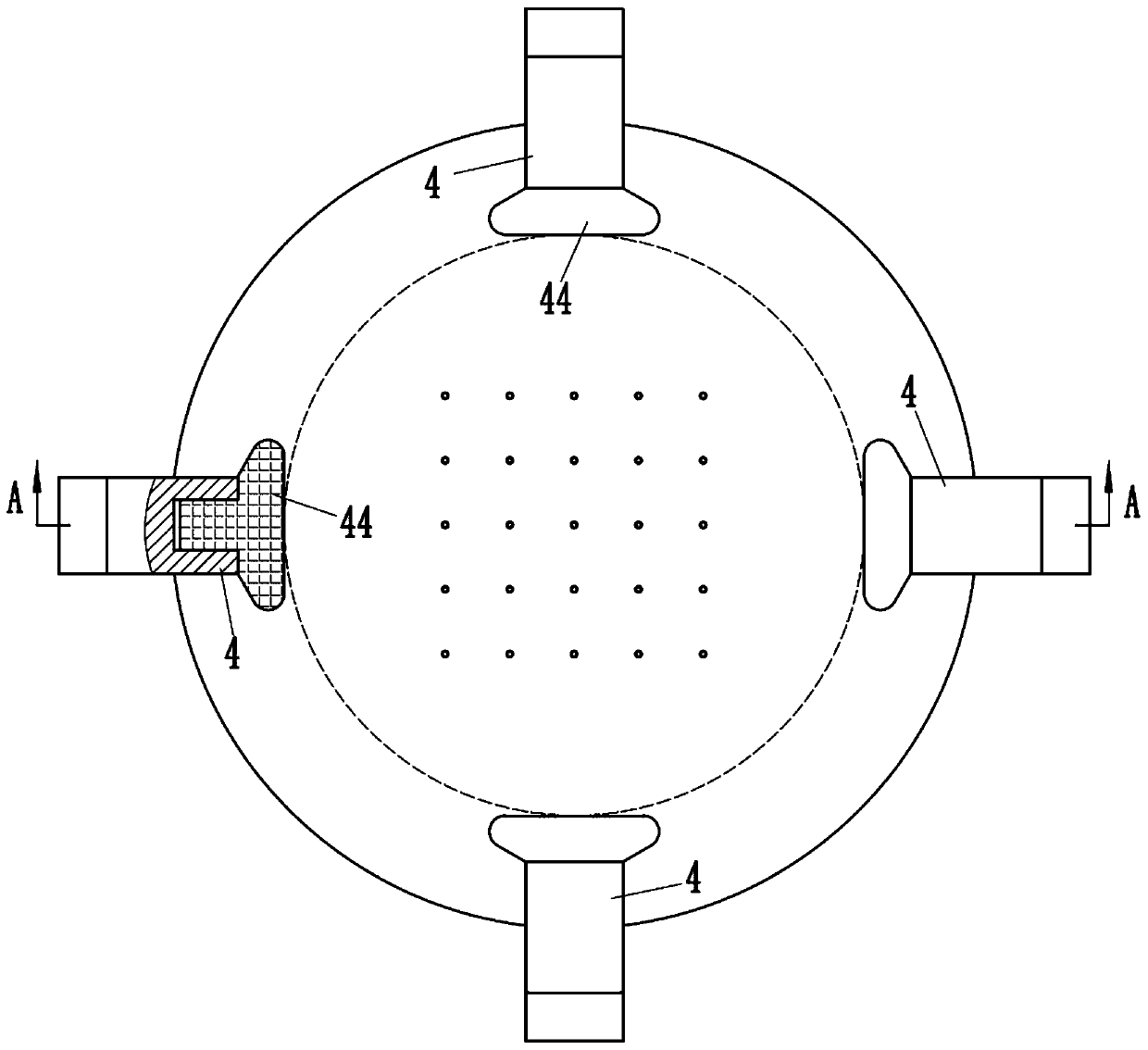

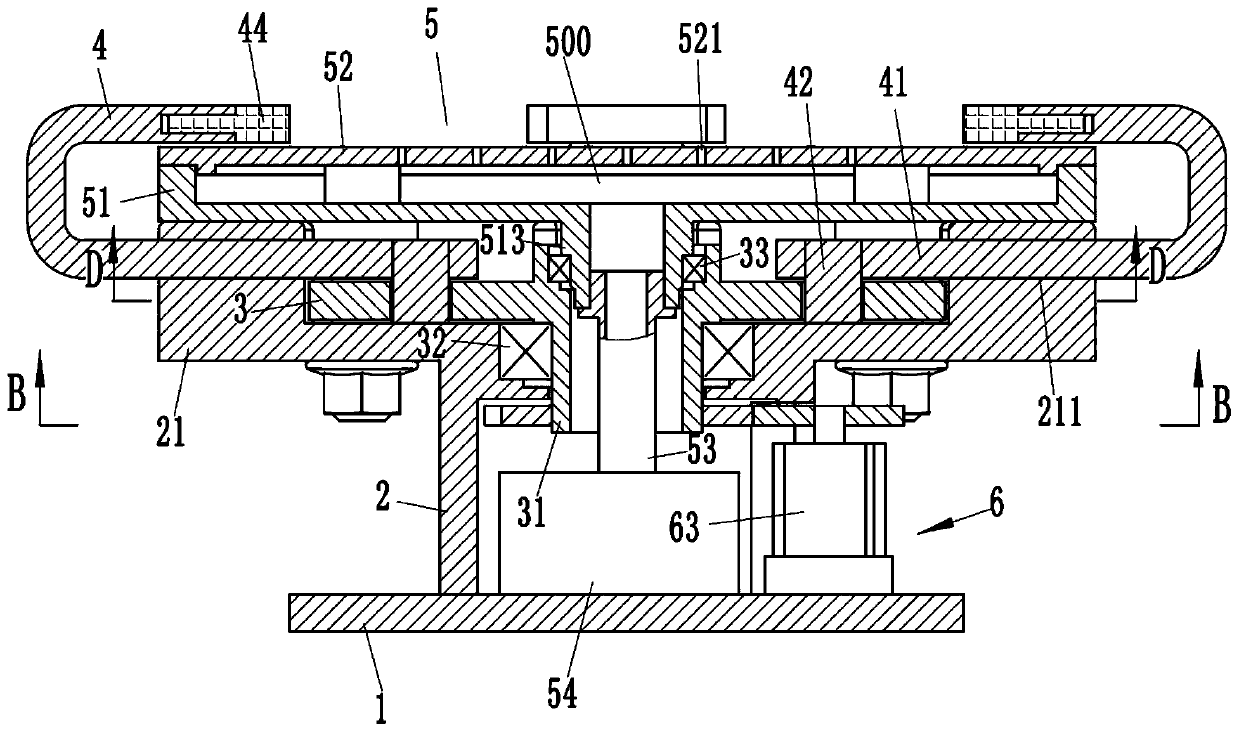

[0024] Examples such as Figure 1 to Figure 6 As shown, a processing table for a glass engraving machine includes a bottom plate 1, on which a hollow base 2 is fixed, the upper end of the base 2 is hinged with a drive plate 3, and the drive plate 3 is formed with four circumferential uniform The eccentrically arranged arc-shaped groove 31 of the cloth; the outer wall of the upper end of the base 2 is fixed with four uniformly distributed connecting arms 21, and the outer end of the connecting arm 21 is formed with a radially penetrating rectangular groove 211, each rectangular groove 211 is mated with the lower end rectangular plate 41 of a corresponding U-shaped splint 4, the lower end rectangular plate 41 passes through the inner protruding end of the rectangular groove 211 and is fixed with a drive rod 42, and the drive rod 42 is inserted into a corresponding arc In the shaped groove 31;

[0025] The upper ends of the four connecting arms 21 are fixed with an adsorption pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com