A rotary displacement glass engraving machine

A technology of rotary displacement and precision engraving machine, which is applied in the direction of engraving, work accessories, manufacturing tools, etc., can solve the problem of high equipment cost, and achieve the effect of simple structure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

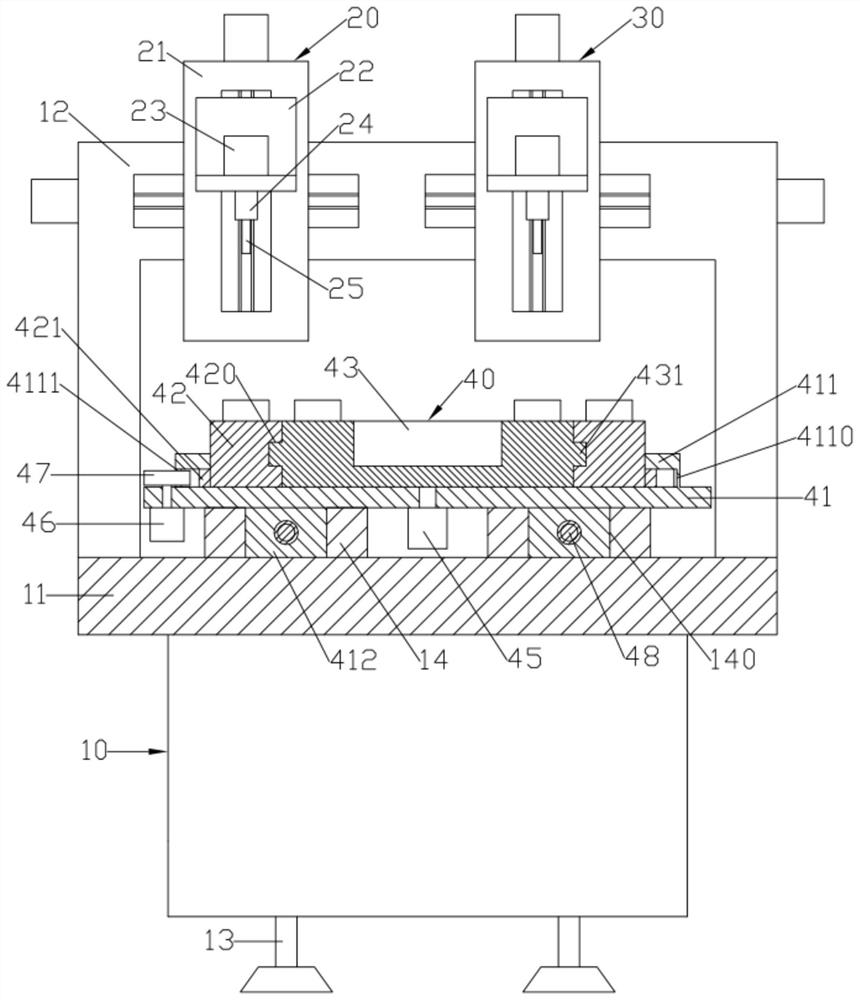

[0014] Such as figure 1 As shown, a rotating and shifting glass engraving machine includes a chassis 10 and a workbench unit 40; a manipulator is arranged on the front side of the chassis 10; a working plate 11 is fixed on the upper end of the chassis 10, and several supporting feet are arranged on the lower end surface 13. The rear end of the working board 11 is provided with a "凵"-shaped rear support frame 12 with the opening facing downward; the front end surface of the horizontal part of the rear support frame 12 is moved left and right to be provided with an outer engraving device 20 and an inner engraving device 30; The engraving device 20 and the inner engraving device 30 all include a vertical support plate 21 that moves left and right and is arranged on the front end face of the horizontal portion of the rear support frame 12; Straight-moving support base 22; vertically movable support base 22 is fixed with engraving motor 23; the output shaft of engraving motor 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com