Glass engraving device and glass production method adopting glass engraving device

A technology for engraving equipment and glass, applied in decorative arts, painting tools, processing models, etc., can solve the problems of easy mutual adsorption of glass, unfavorable separation, low glass transfer efficiency, etc., to improve glass production efficiency, improve stability, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

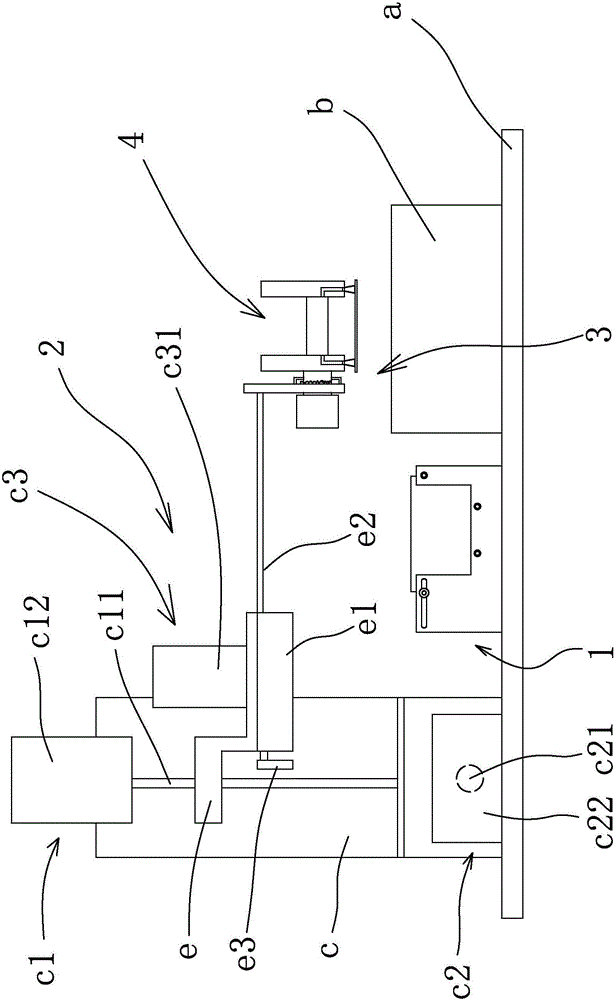

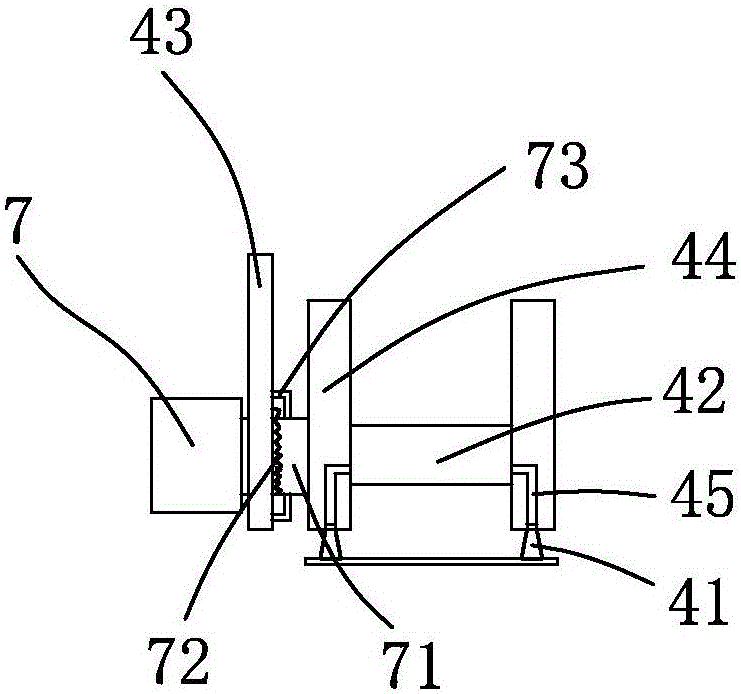

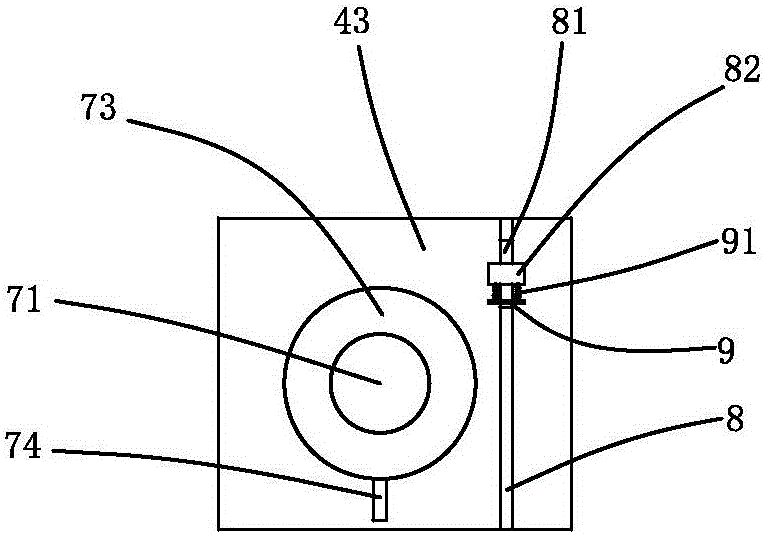

[0029] Such as Figure 1 to Figure 9 As shown, this solution includes a working platform a, which is characterized in that the working platform a is provided with at least one empty glass shelf 1 and at least one glass shelf 1 for placing glass to be processed, and two adjacent glass shelves 1 are arranged parallel to each other The glass shelf 1 is provided with a plurality of limiting grooves d for fixing the glass edges to prevent the glass from touching each other, and the glass shelf 1 is provided with a channel structure 53 for allowing the glass to pass in and out. The channel structure 53 runs through at least one side of the glass shelf 1, The working platform a is provided with a glass transfer mechanism 2 capable of transferring glass between the processing platform b and the glass shelf 1. The glass transfer mechanism 2 includes a pick-up assembly 3 capable of absorbing materials. The pick-up assembly 3 is connected with a working On the platform a, a driving assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com