Technology for reducing scratches of glass optical lenses during engraving

A glass lens and glass technology, applied in engraving, glass manufacturing equipment, glass cutting devices, etc., can solve problems such as scratches and rising production costs, and achieve the effects of reducing contact opportunities, improving productivity, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

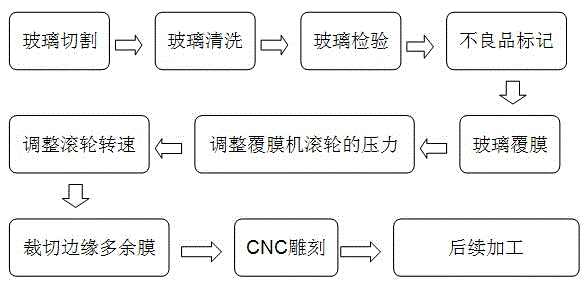

[0015] Such as figure 1 As shown, a process for reducing glass lens scratches during engraving, the steps are as follows:

[0016] The first step, glass cutting: gently place the glass on the cutting machine, cut it with a diamond tool according to the specified product size, avoid scratches during the cutting process, and ensure that the edge of the cut glass is flat, which is convenient for subsequent glass coating. For the cutting of excess film on the edge, in order to ensure the smooth progress of glass engraving, the size of the cut glass is required to be 0.5-0.7mm larger than the final product size, so as to ensure that the product has a certain amount of removal during engraving. Insert the cut glass into the washing rack;

[0017] The second step, glass cleaning: Since glass cutting is to use a diamond tool to cut on the glass surface, and add a small amount of kerosene to lubricate, at this time, there will inevitably be broken glass on the glass surface. First, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com