Material for laser etching and preparation method thereof

A laser engraving and raw material technology, applied in the field of laser engraving, can solve the problems of aging resistance, poor engraving effect, and poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

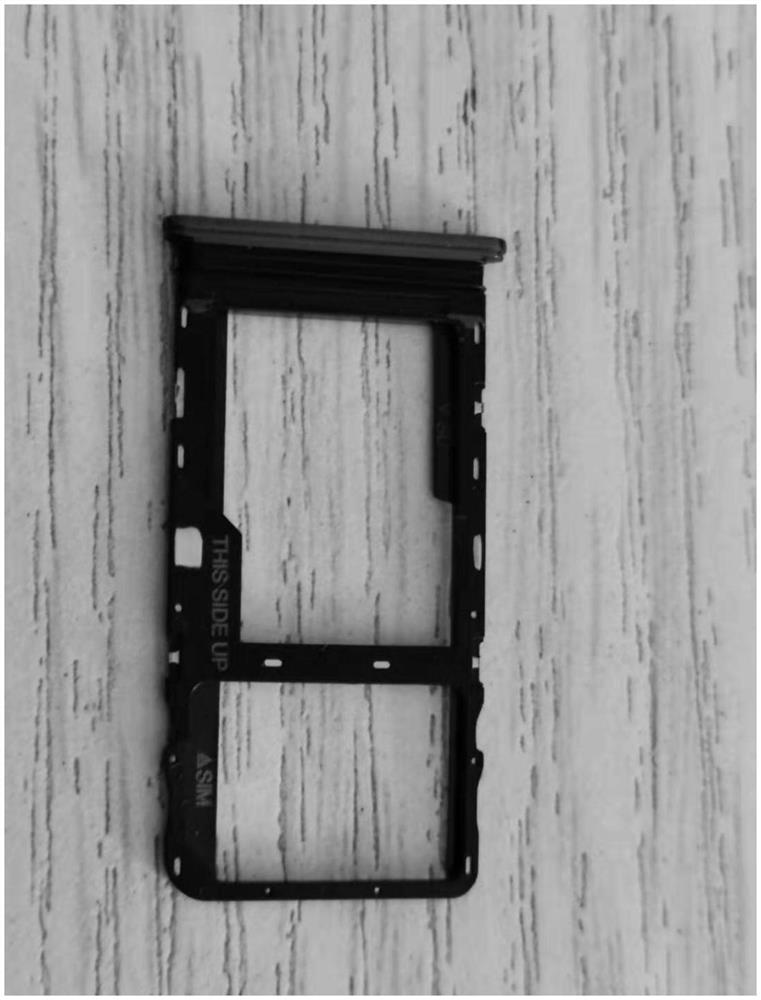

Image

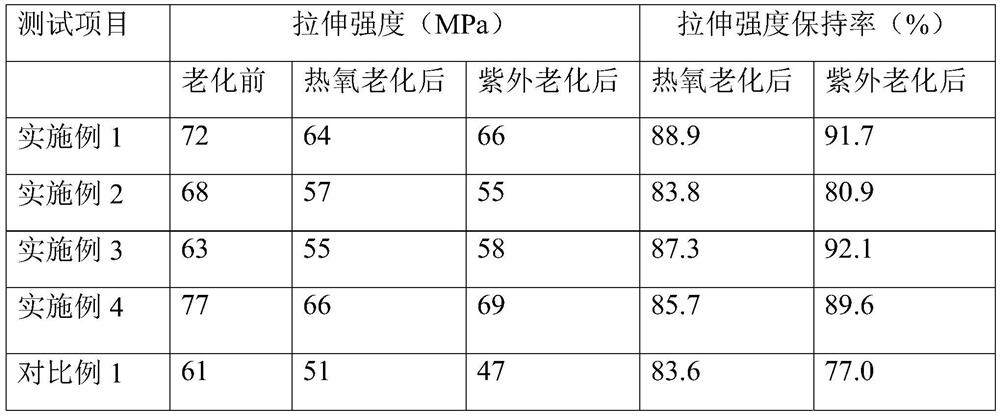

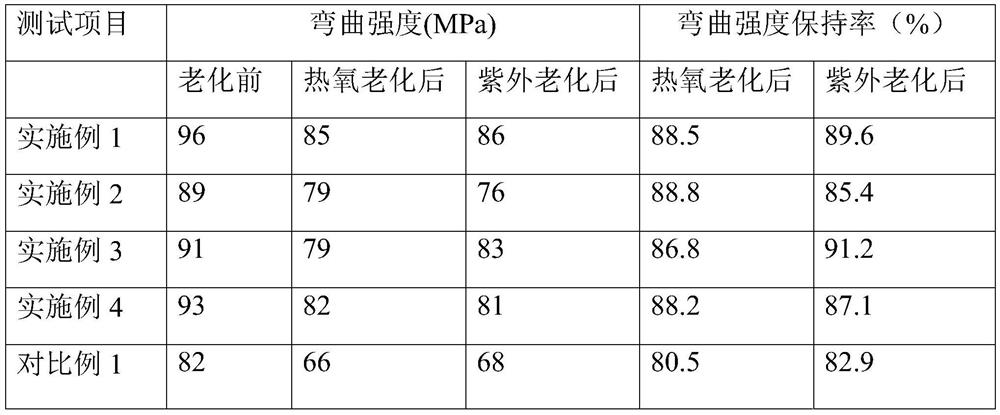

Examples

Embodiment 1

[0019] A material for laser engraving, comprising the following raw materials in parts by weight: 85 parts of PC, 10 parts of glass fiber, 12 parts of ABS resin, 15 parts of inorganic filler, 2.5 parts of laser engraving auxiliary agent, 18 parts of compatibilizer, antioxidant 1 part of additive, 17 parts of synergist and 4 parts of color masterbatch.

[0020] Further, the glass fibers are alkali-free glass fibers. The color masterbatch is preferably but not limited to Cabot UN2014 color masterbatch. The laser engraving auxiliary agent is preferably but not limited to the laser engraving auxiliary agent LaserAT-7762.

[0021] Further, the inorganic filler is composed of calcium carbonate, talc and silicon dioxide in a weight ratio of 1.8:0.6:1. The particle size of the inorganic filler is 50-150nm.

[0022] Further, the compatibilizer is composed of maleic anhydride grafted ethylene-octene copolymer and maleic anhydride-ethylene-acrylate terpolymer in a weight ratio of 1:1....

Embodiment 2

[0030] A material for laser engraving, comprising the following raw materials in parts by weight: 80 parts of PC, 8 parts of glass fiber, 8 parts of ABS resin, 12 parts of inorganic filler, 1.5 parts of laser engraving auxiliary agent, 15 parts of compatibilizer, antioxidant 0.5 parts of additive, 15 parts of synergist and 3 parts of color masterbatch.

[0031] Further, the inorganic filler is composed of calcium carbonate, talc powder and silicon dioxide in a weight ratio of 1.5:0.5:1.

[0032] Further, the compatibilizer is composed of maleic anhydride grafted ethylene-octene copolymer and maleic anhydride-ethylene-acrylate terpolymer in a weight ratio of 2:1.

[0033] Further, the antioxidant is composed of antioxidant BHT, antioxidant 1010 and antioxidant 168 in a weight ratio of 2:0.6:1.

[0034] Further, each part of the synergist includes the following raw materials in parts by weight: 10 parts of PVDF resin, 6 parts of vinyl tris (β-methoxyethoxy) silane, 5 parts of E...

Embodiment 3

[0040] A material for laser engraving, including the following raw materials in parts by weight: 90 parts of PC, 14 parts of glass fiber, 15 parts of ABS resin, 18 parts of inorganic filler, 3 parts of laser engraving auxiliary agent, 25 parts of compatibilizer, antioxidant 2 parts of agent, 22 parts of synergist and 7 parts of color masterbatch.

[0041] Further, the inorganic filler is composed of calcium carbonate, talc and silicon dioxide in a weight ratio of 2:1:1.

[0042] Further, the compatibilizer is composed of maleic anhydride grafted ethylene-octene copolymer and maleic anhydride-ethylene-acrylate terpolymer in a weight ratio of 1.5:1.

[0043] Further, the antioxidant is composed of antioxidant BHT, antioxidant 1010 and antioxidant 168 in a weight ratio of 3:1.2:1.

[0044] Further, each part of the synergist includes the following raw materials in parts by weight: 15 parts of PVDF resin, 9 parts of vinyl tris (β-methoxyethoxy) silane, 8 parts of EPDM rubber, hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com