Gravure and digital integrated printing machine

A technology of printing machines and gravure printing units, applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of gravure printing plate making and management costs, slow pattern design output process, large color difference, etc., to achieve Extend the scope of the design, make up for the effect of repeated overprinting and large amount of ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below, but the present invention is not limited to the following examples.

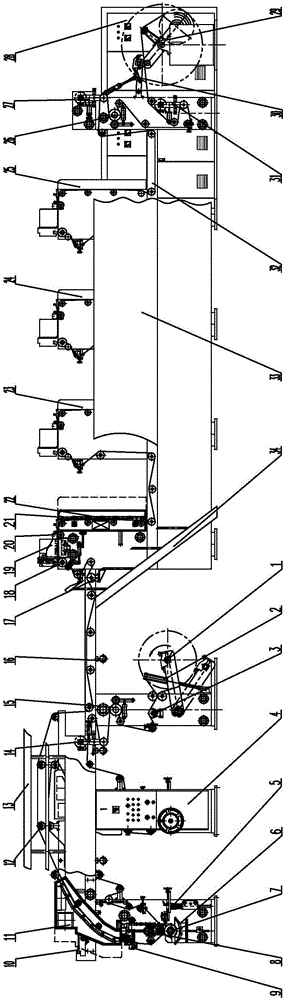

[0017] Such as figure 1 As shown, the concave number integrated printing machine provided by the present invention has at least one discharging part 1, combined printing unit, one receiving part 29 and one electric control part 28 (using industrial computer or electric control cabinet). The combined printing unit is composed of at least one gravure printing unit 4 (ie gravure printing unit) and at least one digital inkjet printing unit 22 arranged in a straight line. The discharging unit 1 , the gravure printing unit 4 , the digital inkjet printing unit 22 and the receiving unit 29 are all electrically connected to and controlled by the electrical control unit 28 . The gravure printing unit is provided with a drying unit, and the digital inkjet printing unit is provided with a digital drying unit 21 .

[0018] The gravure printing unit includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com