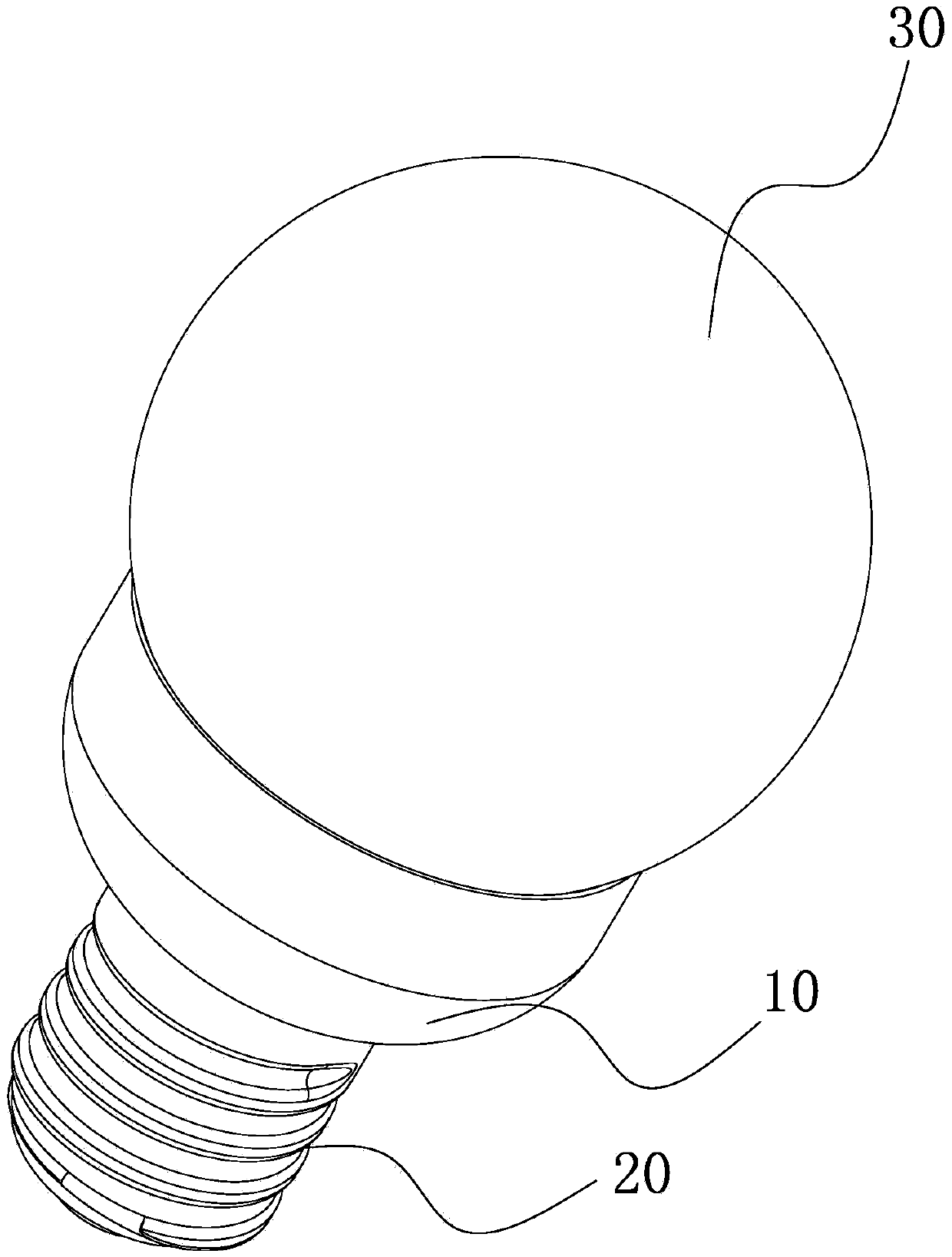

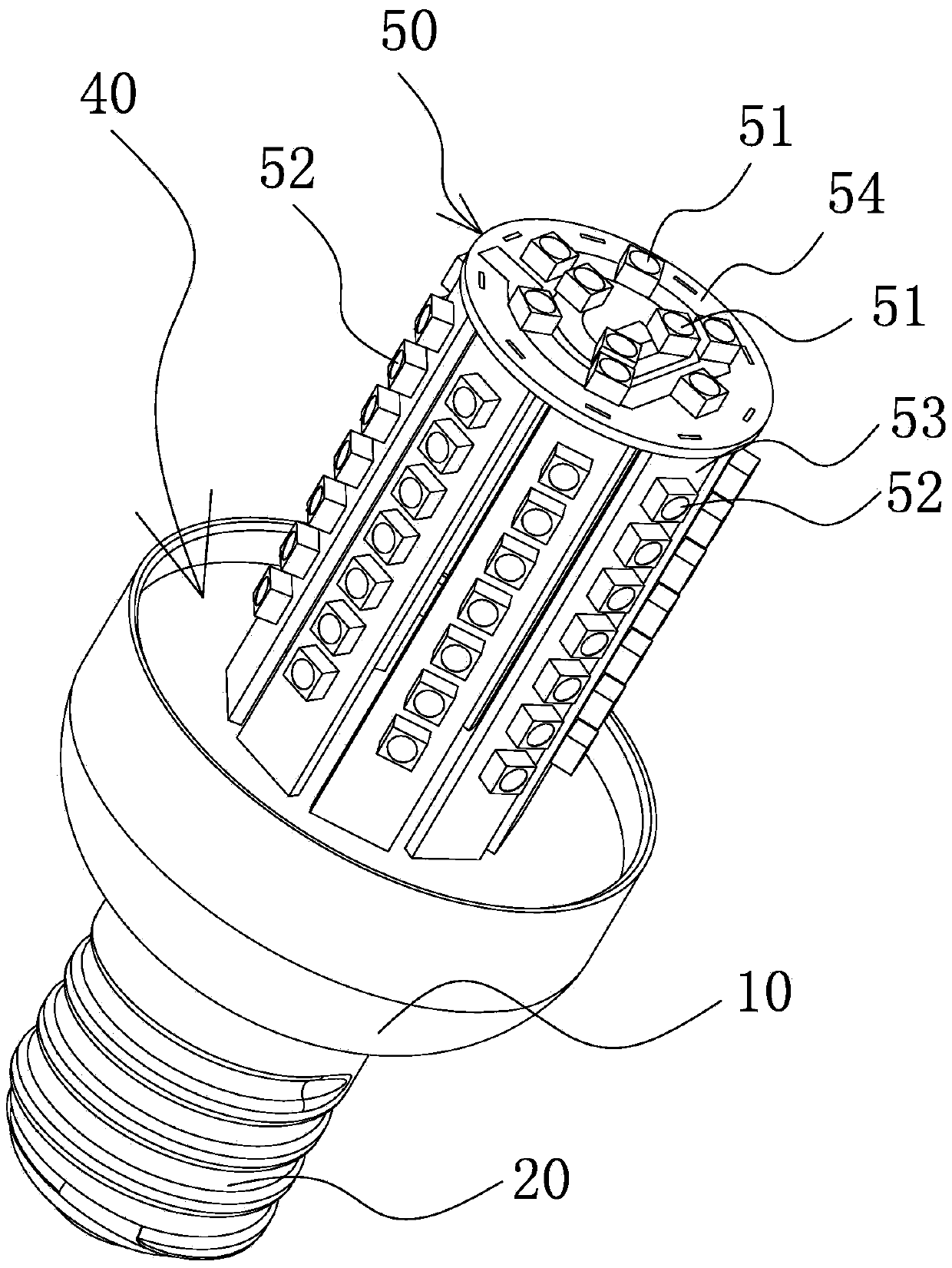

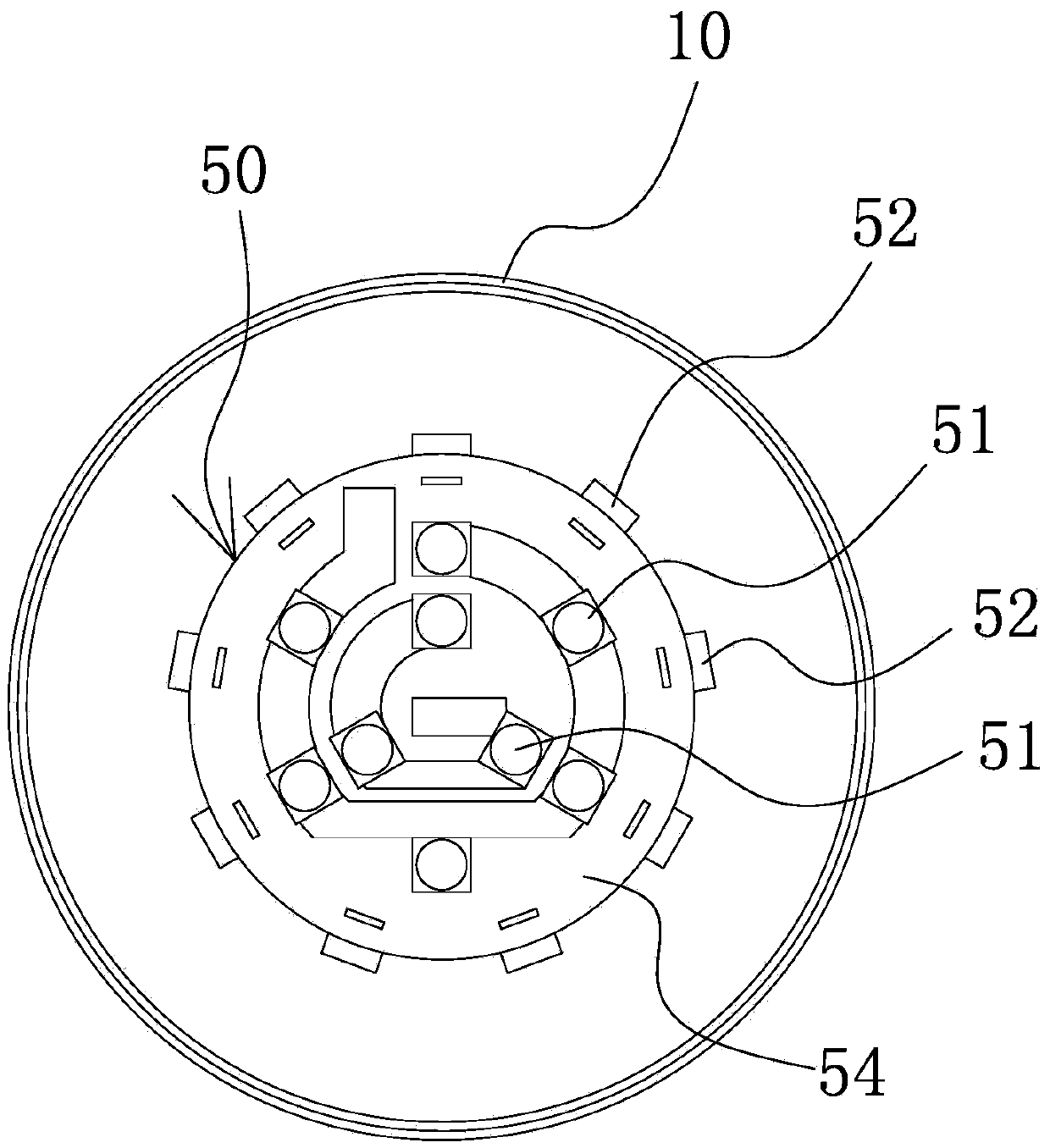

Convenient bulb lamp

A bulb lamp, a convenient technology, applied in the field of lighting, can solve the problems of unsatisfactory lighting effect, unable to meet the needs of high-quality life, etc., and achieve the effect of improving the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] According to the composition and parts by weight of Example 1 in the above Table 1, batching and smelting, smelting into molten aluminum, deslagging, degassing and refining, and deslagging after standing for a preset time; the above-mentioned molten aluminum after deslagging Pour it into the pressing chamber, fill it into the cavity of the mold at the preset injection speed and pour it, so that the aluminum liquid is solidified and formed into a lamp cap blank under the preset injection pressure, wherein: the above injection speed is 120L / min, The injection pressure is 110MPa; the finished lamp cap blank is subjected to post-treatment and surface treatment in sequence to obtain the finished product, wherein: the above-mentioned surface treatment is plasma micro-arc oxidation treatment, and the above-mentioned post-treatment includes homogenization annealing treatment, and homogenization annealing The treatment temperature is 500°C, and the holding time is 13h.

Embodiment 2

[0108] According to the composition and parts by weight of Example 2 in the above Table 1, batching and smelting, smelting into molten aluminum, deslagging, degassing and refining, and deslagging after standing for a preset time; Pour it into the pressing chamber, fill it into the cavity of the mold at the preset injection speed and pour it, so that the aluminum liquid is solidified and formed into a lamp cap blank under the preset injection pressure, wherein: the above injection speed is 130L / min, The injection pressure is 90MPa; the finished lamp cap blanks are subjected to post-treatment and surface treatment in sequence to obtain finished products, wherein: the above-mentioned surface treatment is plasma micro-arc oxidation treatment, and the above-mentioned post-treatment includes homogenization annealing treatment, and homogenization annealing The treatment temperature is 515°C, and the holding time is 14.5h.

Embodiment 3

[0110] According to the composition and weight parts of Example 3 in the above Table 1, batching and smelting, smelting into molten aluminum, deslagging, degassing and refining, and deslagging after standing for a preset time; the above-mentioned molten aluminum after deslagging Pour it into the pressing chamber, fill it into the cavity of the mold at the preset injection speed and pour it, so that the aluminum liquid is solidified and formed into a lamp cap blank under the preset injection pressure, wherein: the above injection speed is 140L / min, The injection pressure is 100MPa; the finished lamp cap blanks are subjected to post-treatment and surface treatment in sequence to obtain finished products, wherein: the above-mentioned surface treatment is plasma micro-arc oxidation treatment, and the above-mentioned post-treatment includes homogenization annealing treatment, and homogenization annealing The temperature of the treatment is 510° C., and the holding time is 14 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com