Patents

Literature

86results about How to "Evenly illuminated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

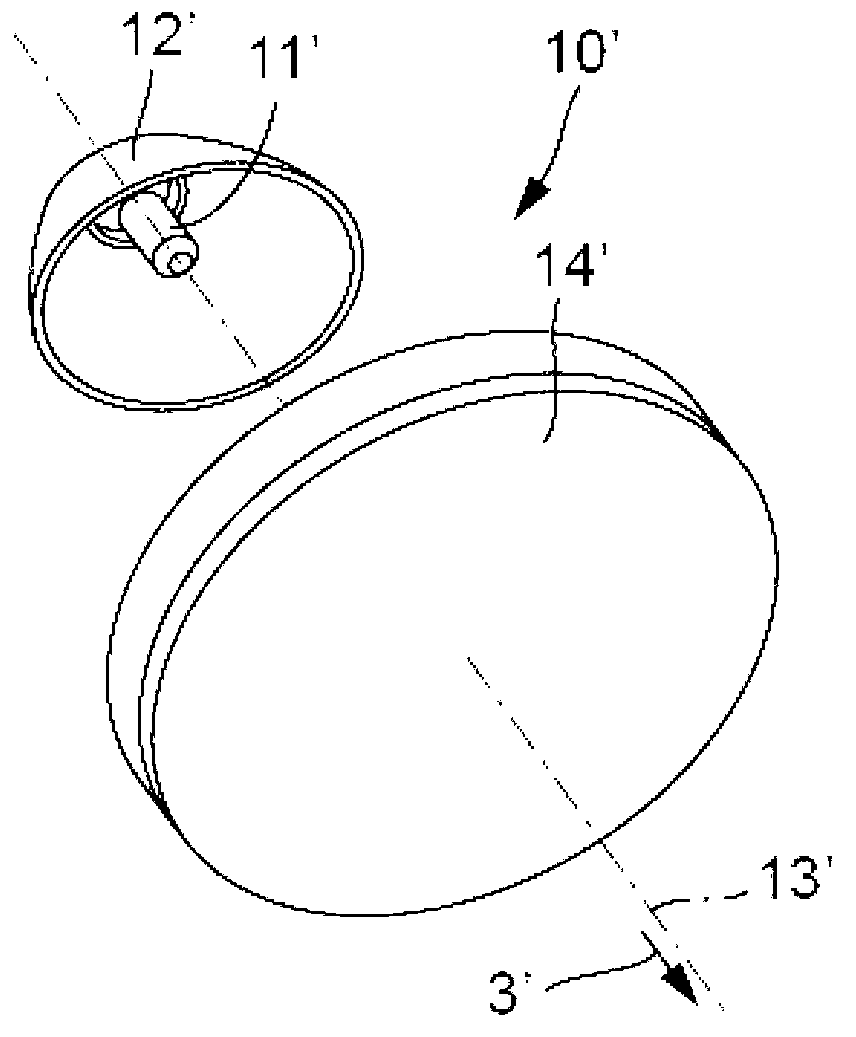

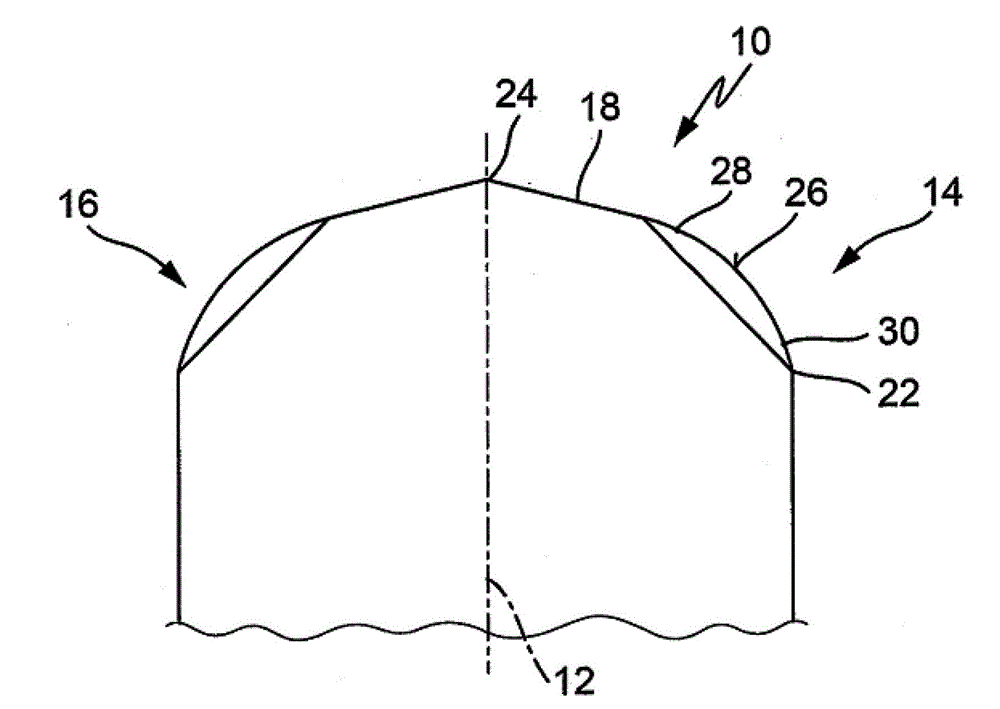

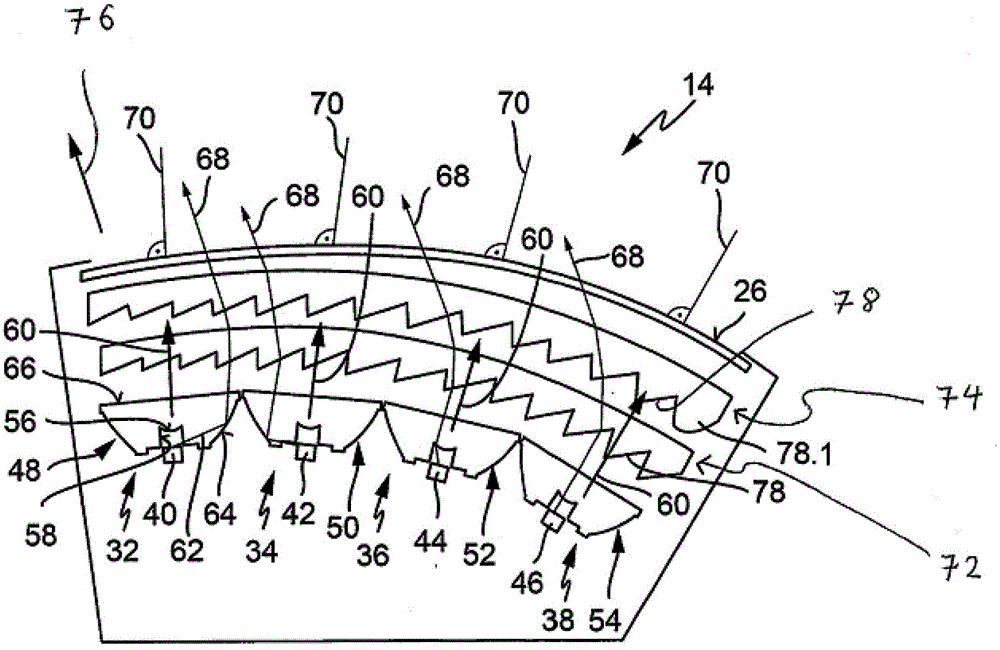

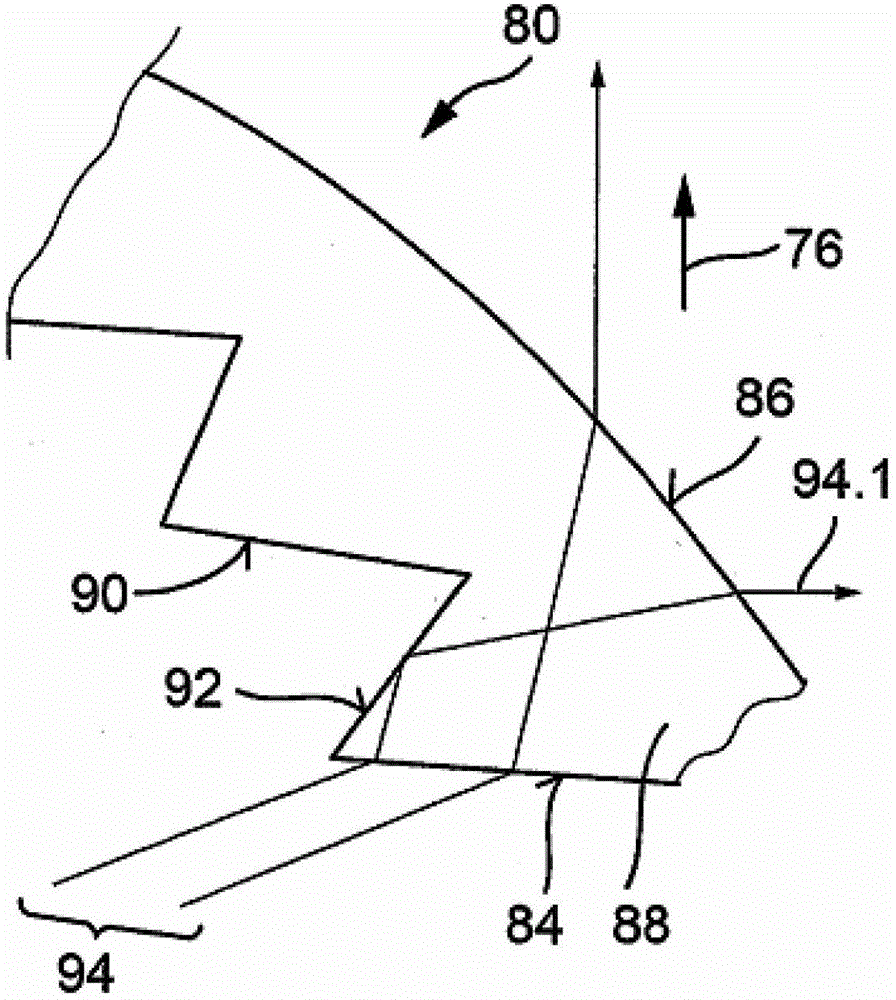

Headlight projection module for a motor vehicle

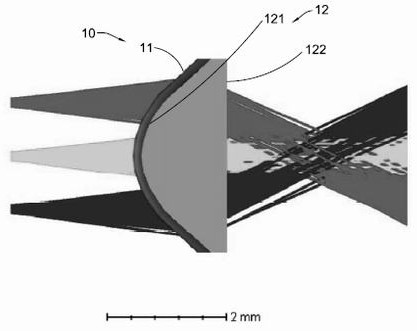

ActiveCN103090286AIncrease designEasy to illuminateVehicle headlampsPoint-like light sourceStructural elementOptical pathlength

The invention relates to a headlight projection module (10) for a vehicle, which is used for generating preset light distribution. The headlight projection module (10) has a light source (11) for emitting light, a primary lens (12) for concentrating a part of the emitted light, and a secondary lens (14) for projecting a part of the concentrated light in a light emitting direction (3) of the projection module. In order to enable the headlight projection module (10) to realize maximally effective structure and to illuminate a non-circular secondary optical unit (14) as uniform as possible with the whole surface, it is suggested that an optically active micro-structure (24) that refracts light be arranged in the beam path of the concentrated light in a virtual object position of the secondary optical unit (14). The micro-structure (24) has dimensions of the function-determining structural elements (26, 27) in the micrometer range, especially a height difference of the single structural elements (26, 27).

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

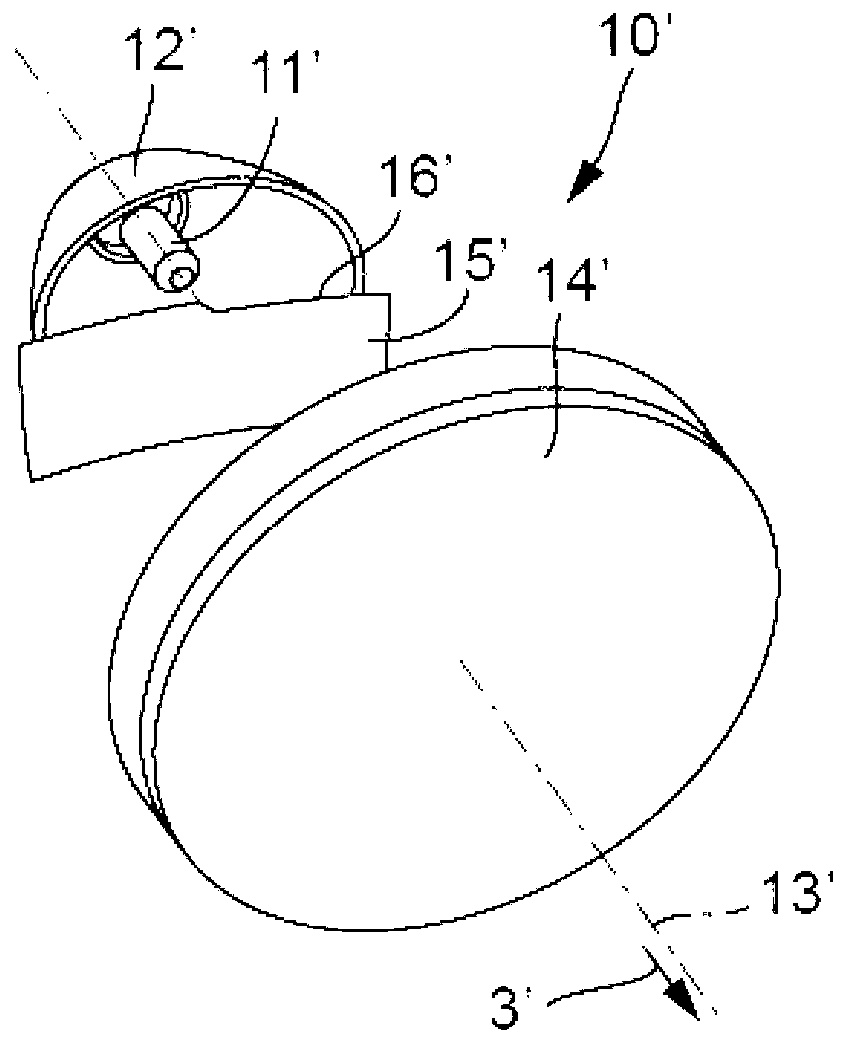

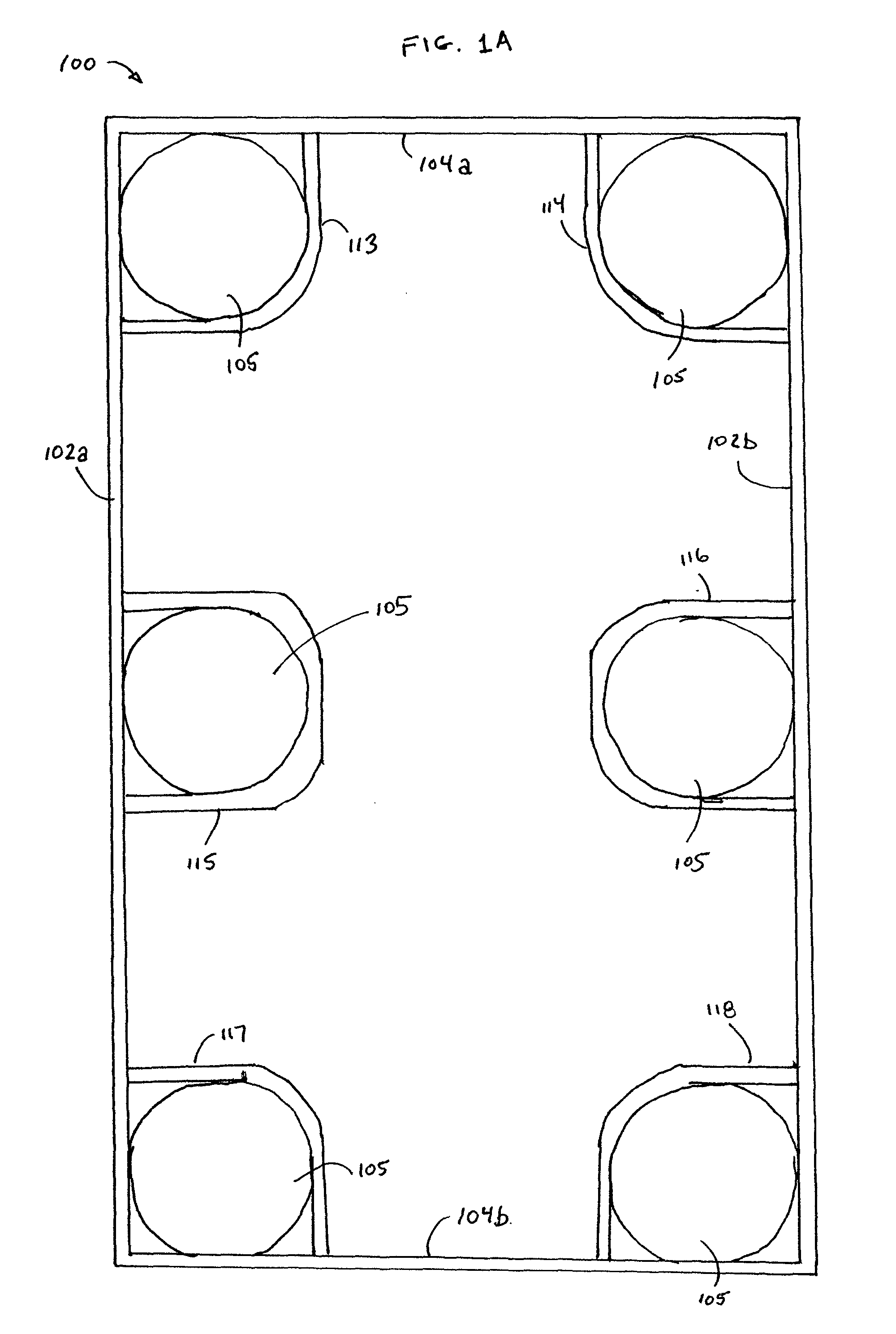

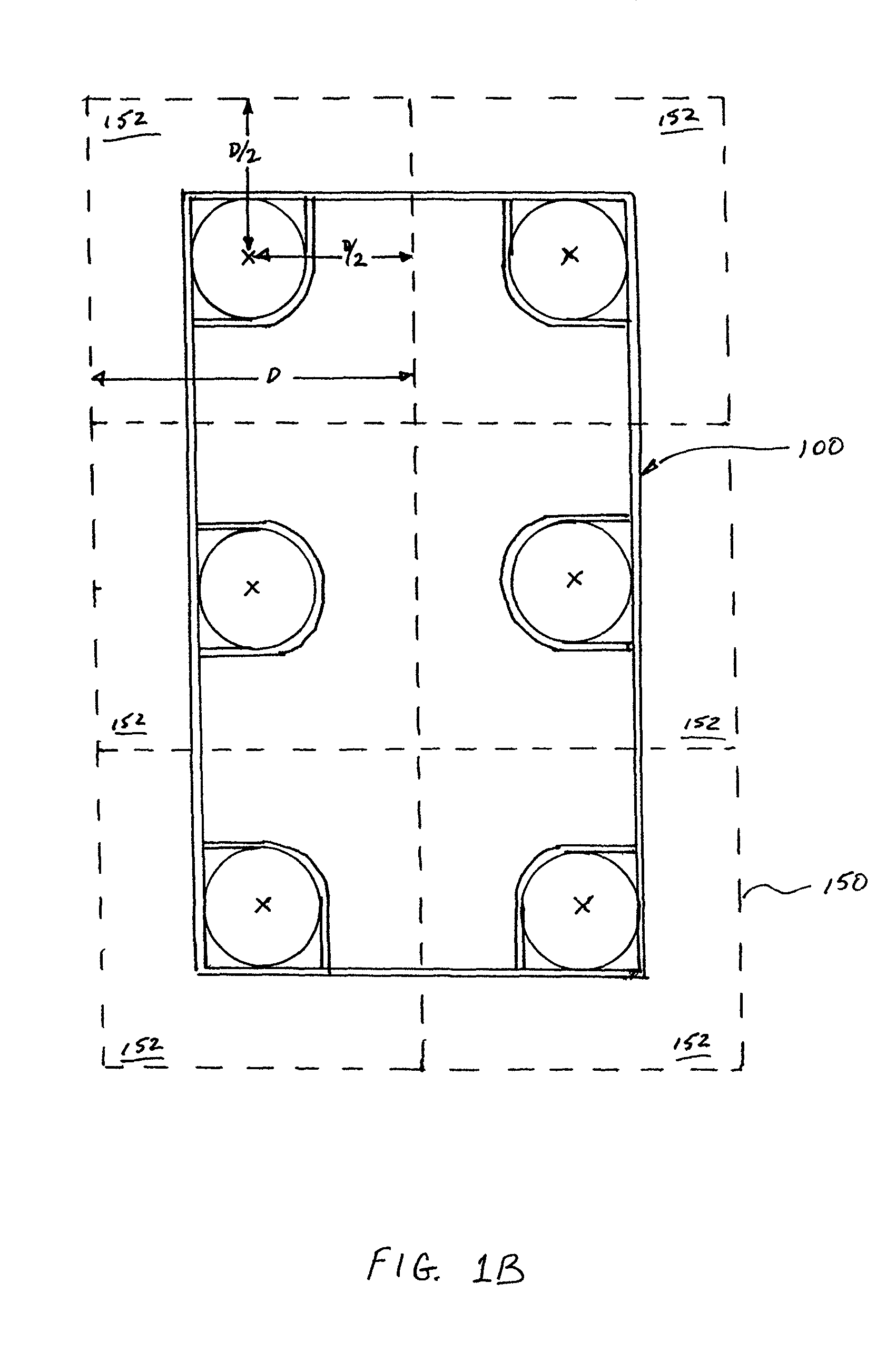

Versatile illumination system

InactiveUS20080079906A1Increase flexibilityImprove versatilityLighting applicationsMechanical apparatusModular fixtureEffect light

A lightweight, modular expandable multiple par lamp fixture configurable to form various sizes and intensities of high output area lighting or projected soft light. A high efficiency par lamp includes a high output globe and lightweight reflector, optional collar, and lens. Individual modular fixtures comprising high efficiency par lamps may be stacked to create larger units. The par lamps may be arranged in pods which can be assembled into larger units. A diffusion frame and fabric cover can be attached to the fixture in front of the par lamps to create a soft, deeply projected light. The diffusion frame may have an internal semi-translucent baffle to spread light through diffusive sidewalls.

Owner:FINN BRUCE L

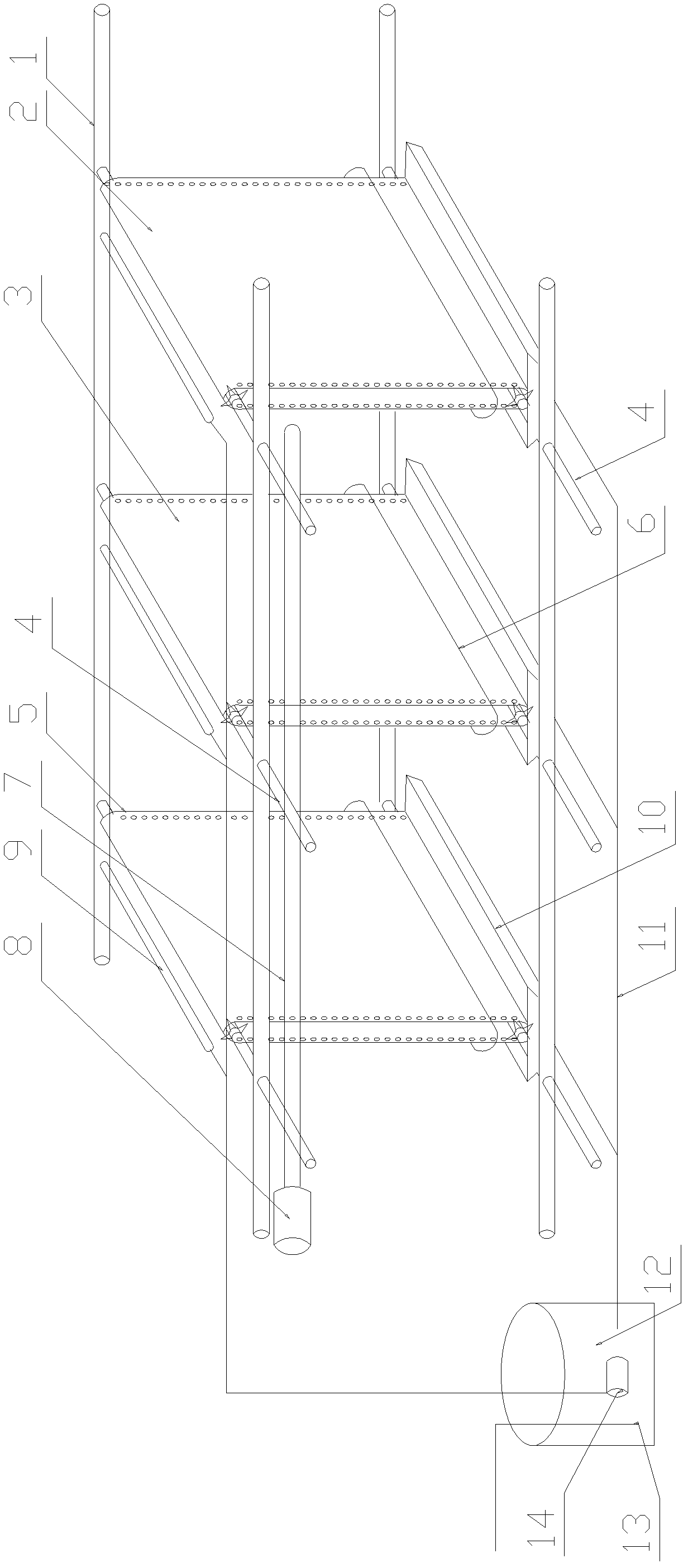

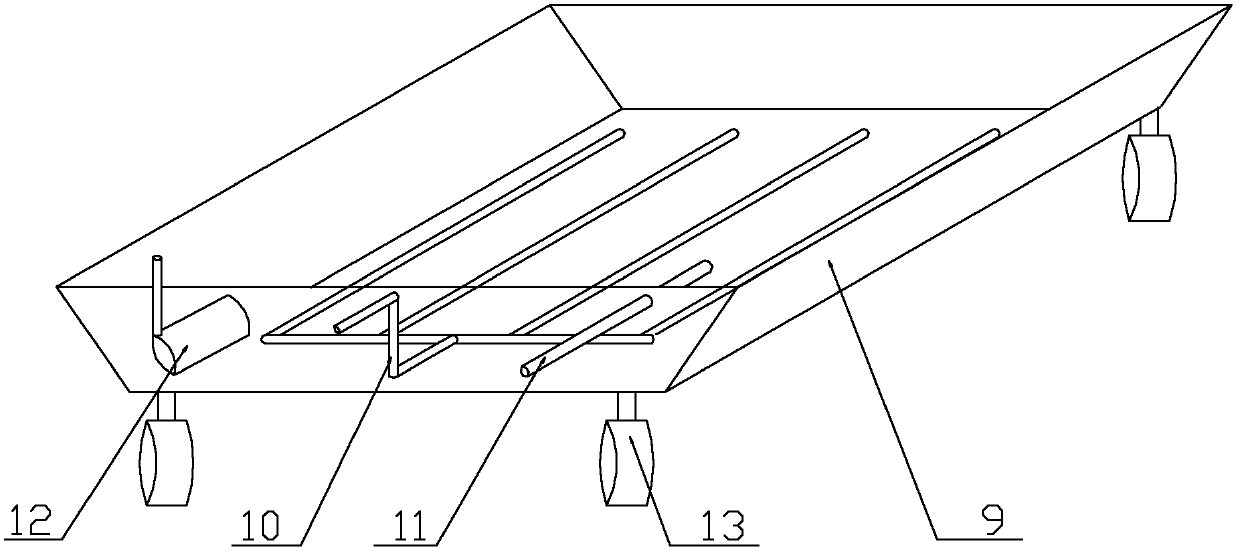

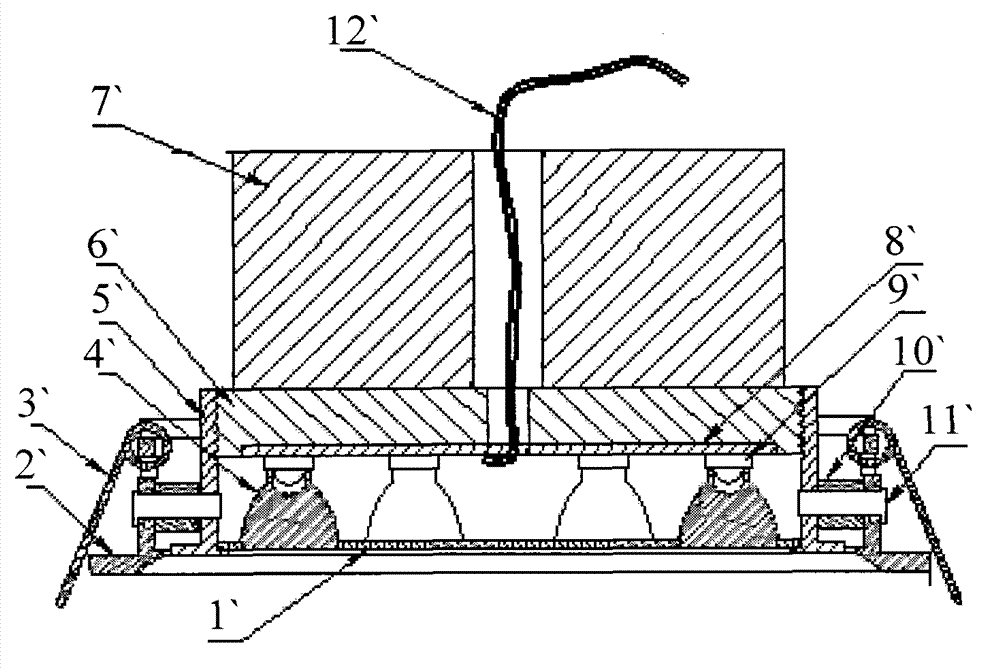

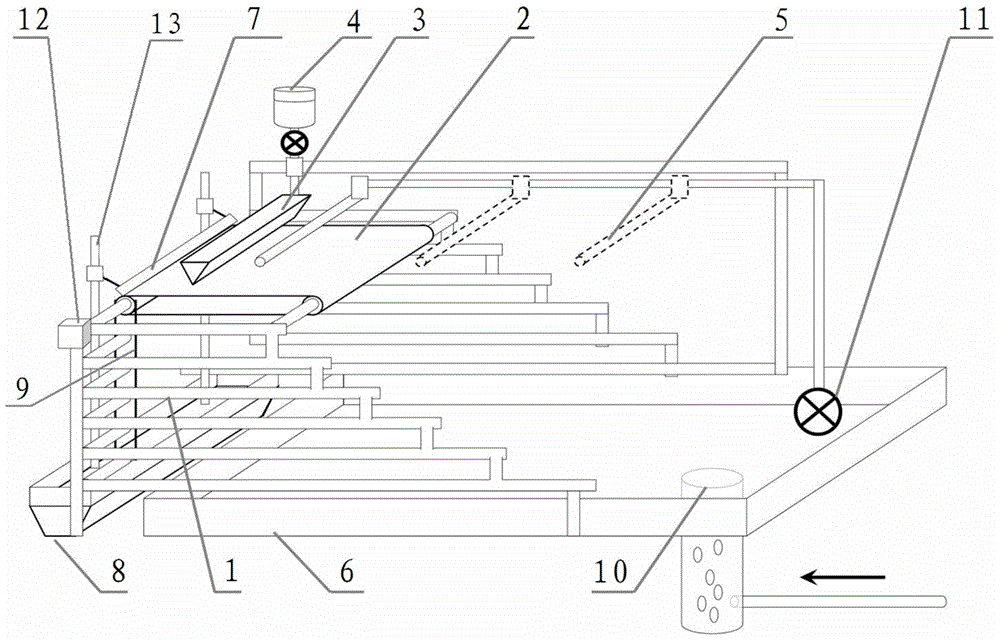

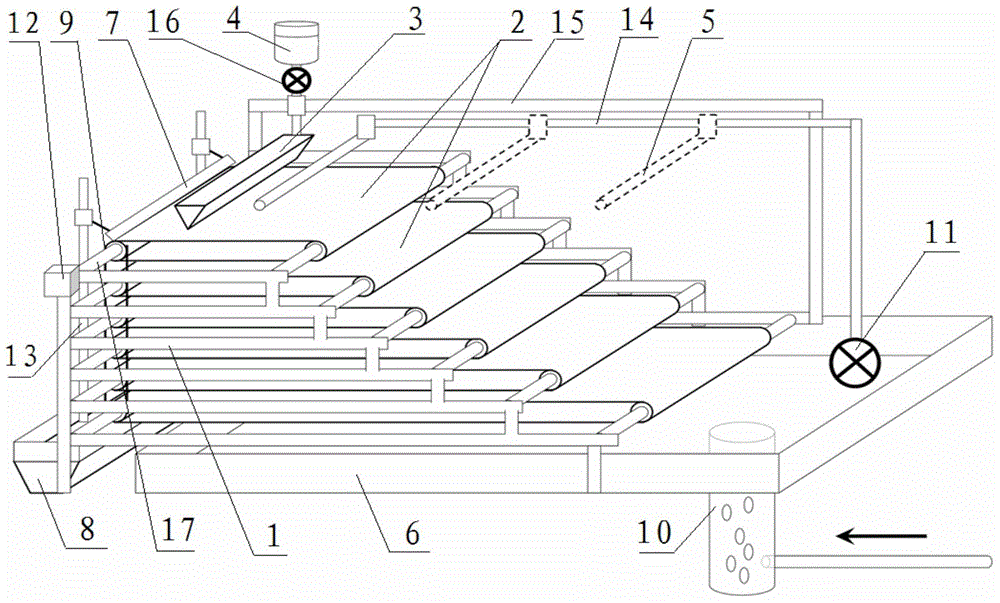

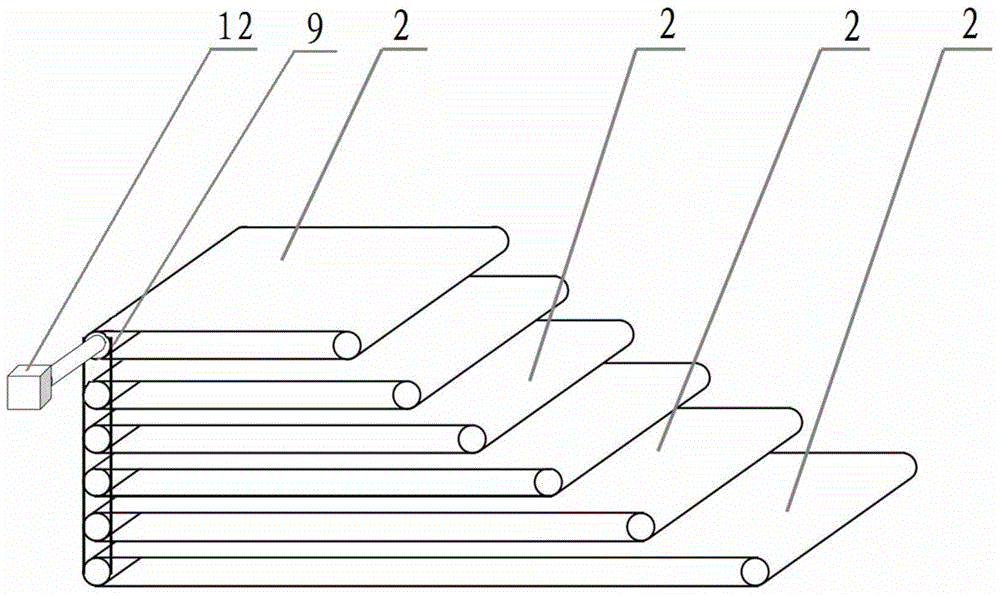

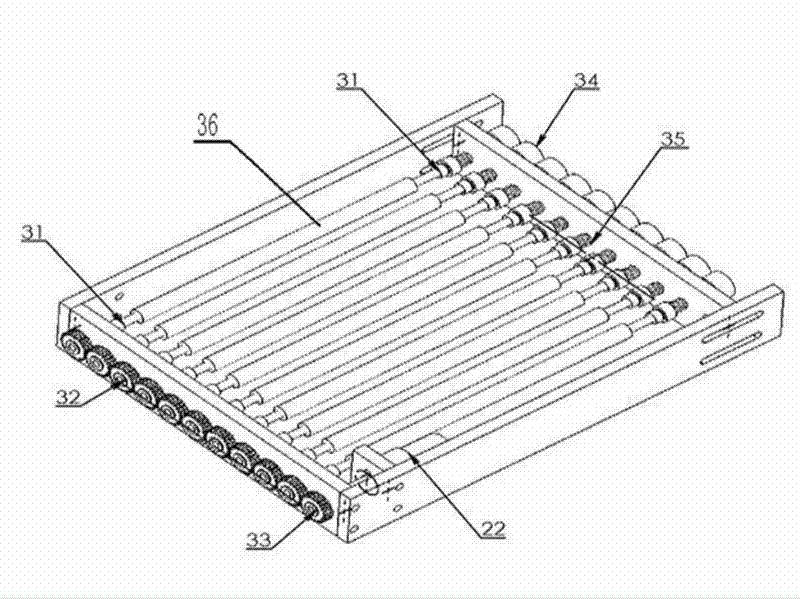

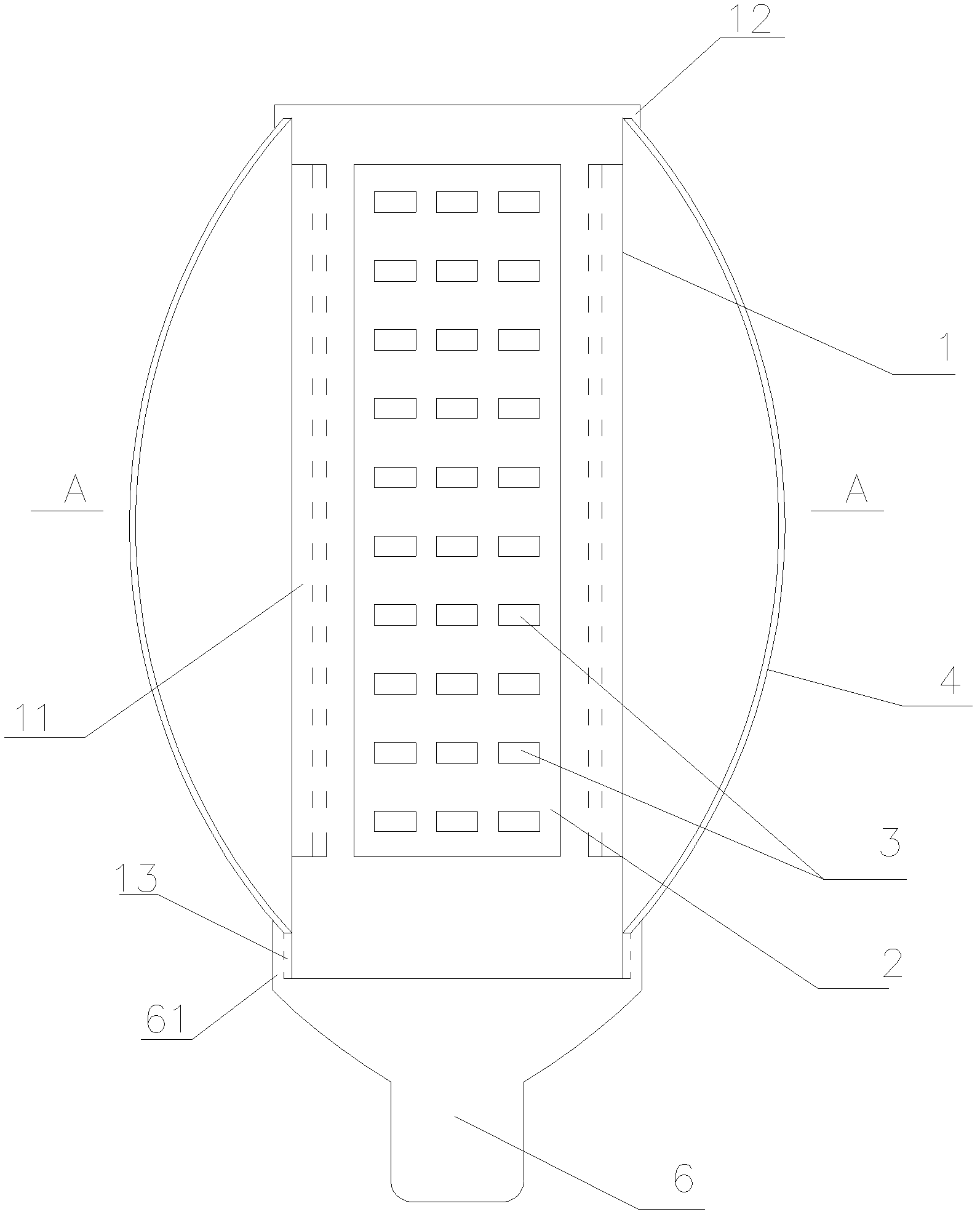

Half-dry solid-state adherent culture device for microalgae industrial production

ActiveCN103289887AReduce water consumptionAchieve ultra-high density cultureSolid phase fermentation bioreactorsSecondary metaboliteLiquid storage tank

The invention belongs to the field of microalgae culture, and in particular relates to a half-dry solid-state adherent culture device for microalgae industrial production. The half-dry solid-state adherent culture device comprises a bracket system, adherent culture units, a supporting shaft transmission system, a speed regulating motor, liquid supplementation pipes, collection grooves and a culture medium liquid storage tank, wherein at least one adherent culture unit is arranged on the bracket system and is connected with the speed regulating motor through the supporting shaft transmission system; the liquid supplementation pipes are respectively arranged above the adherent culture unit and are communicated with the culture medium liquid storage tank through pipelines; the collection grooves are respectively formed below the adherent culture unit and are communicated with the culture medium liquid storage tank through liquid collection pipes; a liquid circulating pump and a carbon supplementation device are arranged in the culture medium liquid storage tank. The half-dry solid-state adherent culture device can be used for producing microalgae biomass and secondary metabolites on a large scale; the yield in unit floor area is effectively improved; the culture period is shortened; the culture water consumption is greatly reduced; the cost of the culture device and the operation cost are reduced; the industrial magnification is facilitated.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Microalgae half-dry solid state adherent cultivation device for alternate illumination of bright and dark light

ActiveCN103289886AReduce water consumptionAchieve ultra-high density cultureSolid phase fermentation bioreactorsCirculating pumpBiology

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

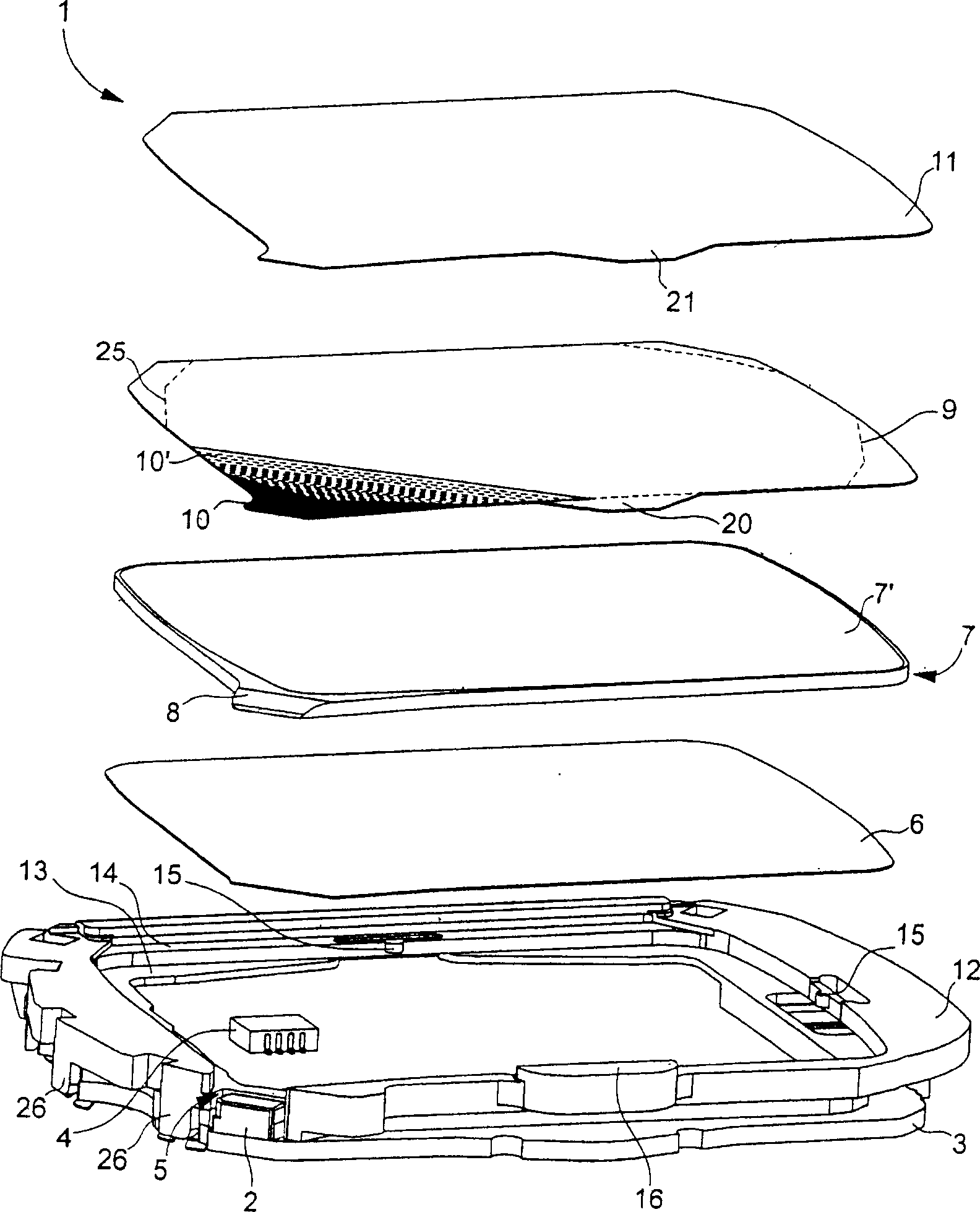

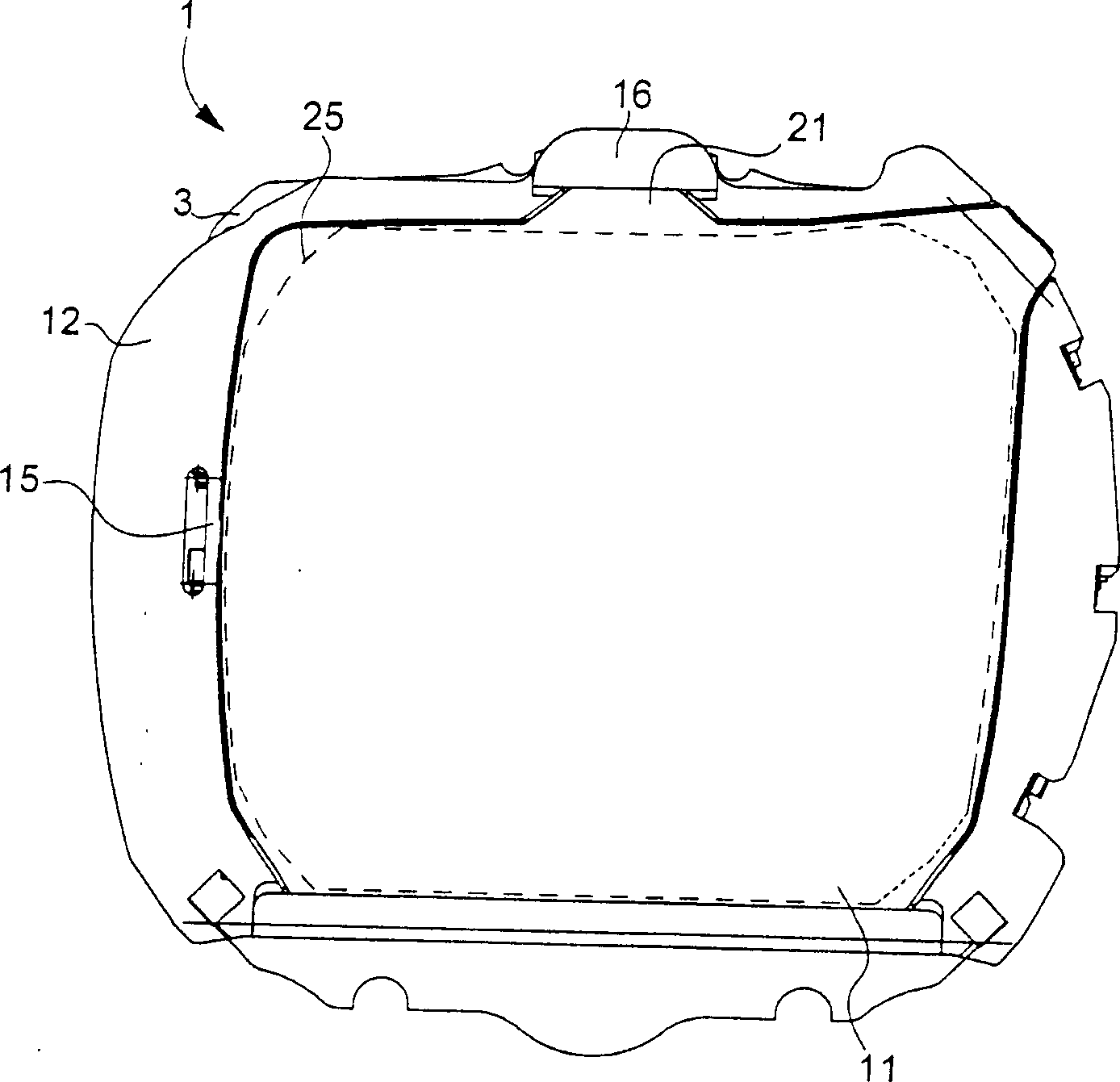

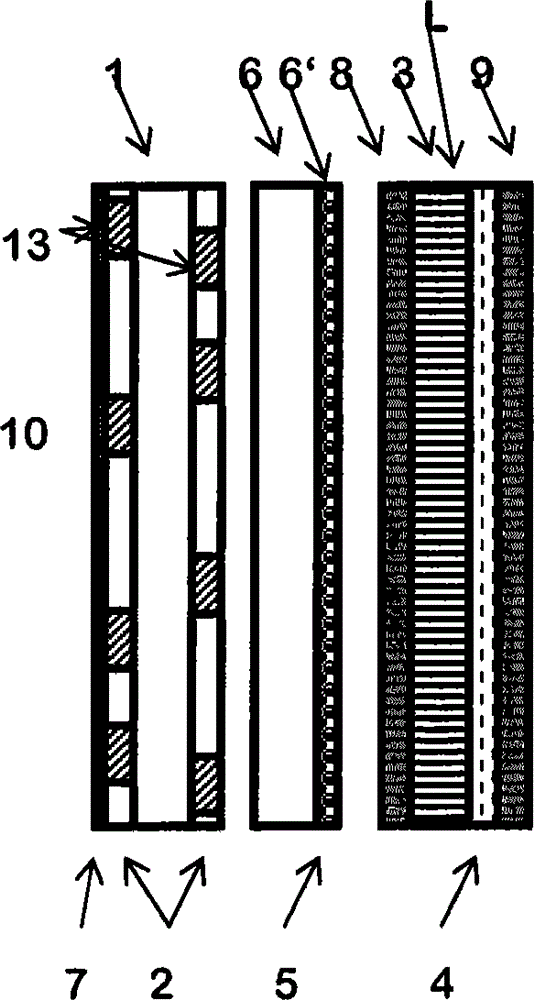

Backlighting device for an information display element of a portable object

The backlighting device ( 1 ) enables an information display element of a portable object such as a wristwatch to be illuminated from the back. This device comprises a light guide plate ( 7 ) having a front face and a rear face, a light reflector ( 6 ) located on the rear face of the light guide plate, a light diffuser film ( 9 ) and a rectifier film ( 11 ) located on the front face of the light guide plate and a source of visible light ( 2 ). This light source, such as a light emitting diode ( 2 ), feeds light beams to the edge of the light guide plate, which spread in the light guide plate between its two faces. A layer, such as a diffuser film, has a zone ( 10 ') with opacity decreasing from a limit ( 25 ) located close to the boundary area of the light guide plate, which receives the light beams of the light source, in order to attenuate the intensity of the light crossing said zone. This zone with decreasing opacity is, for example, a shading white or black dye disposed on the diffuser film.

Owner:ETA SA MFG HORLOGERE SUISSE

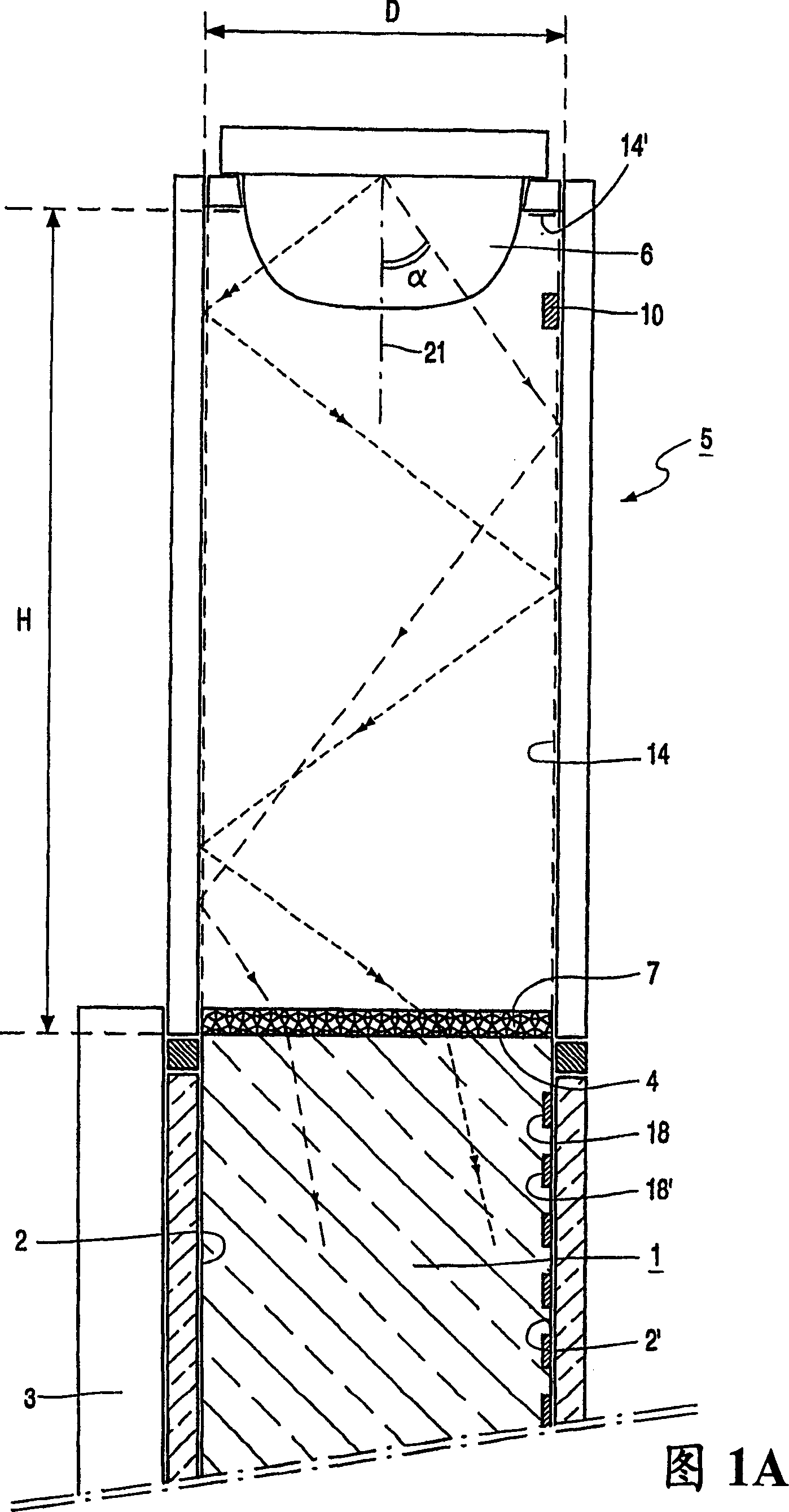

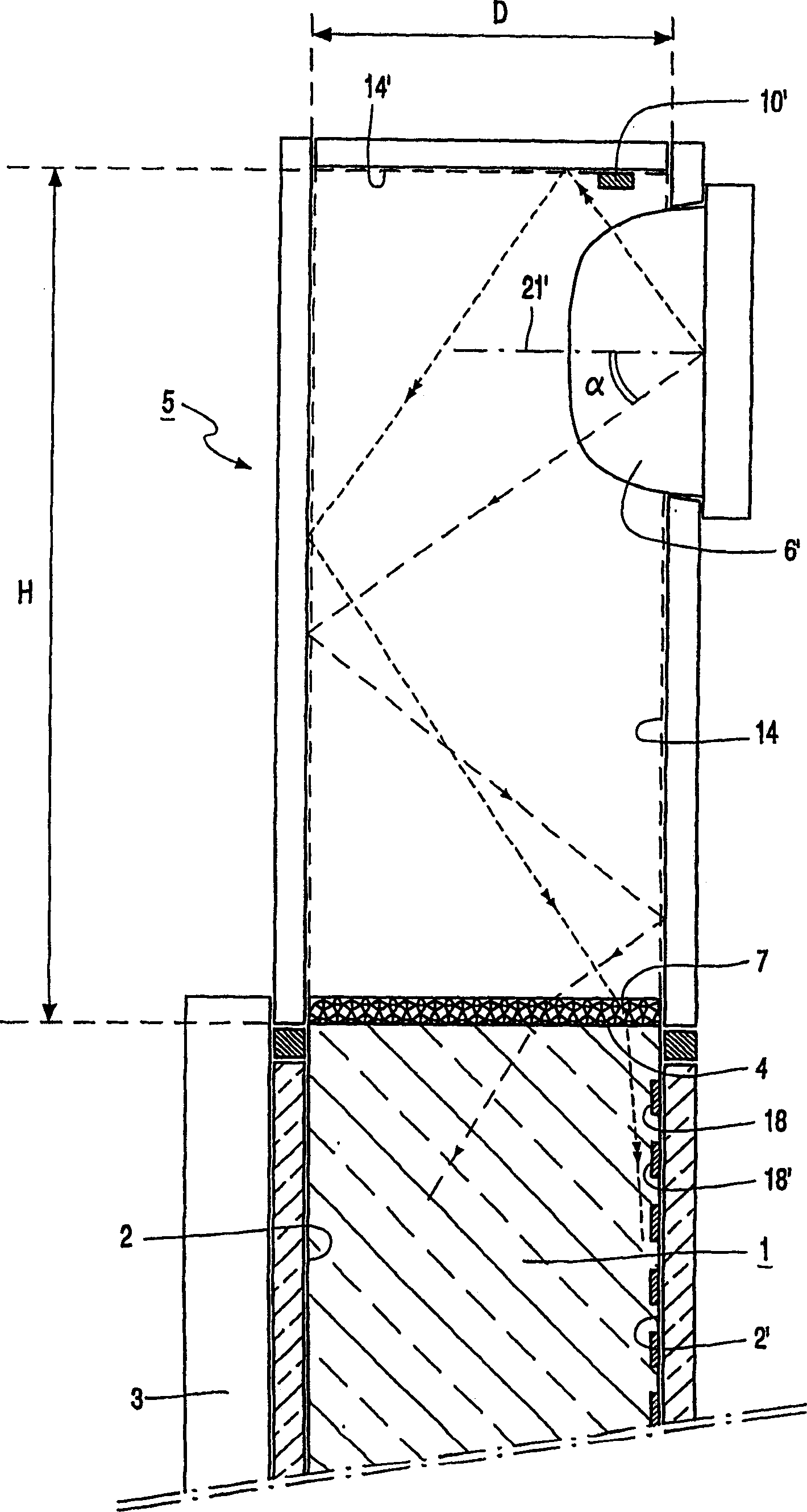

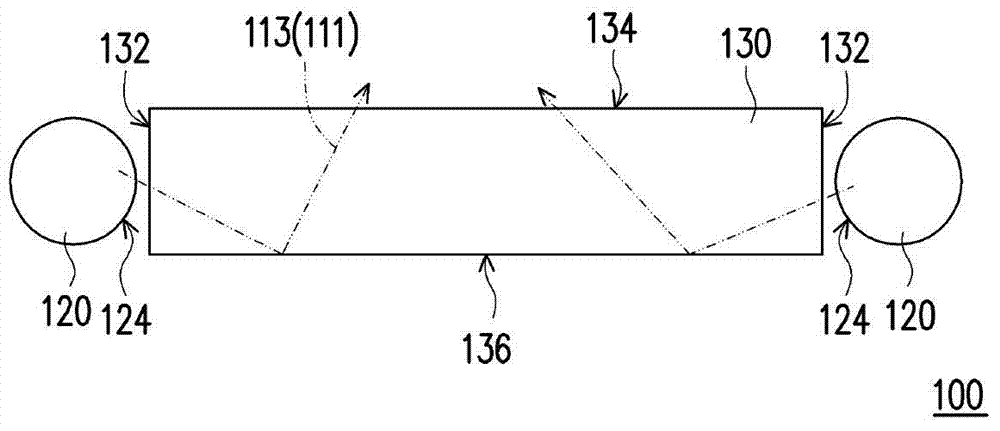

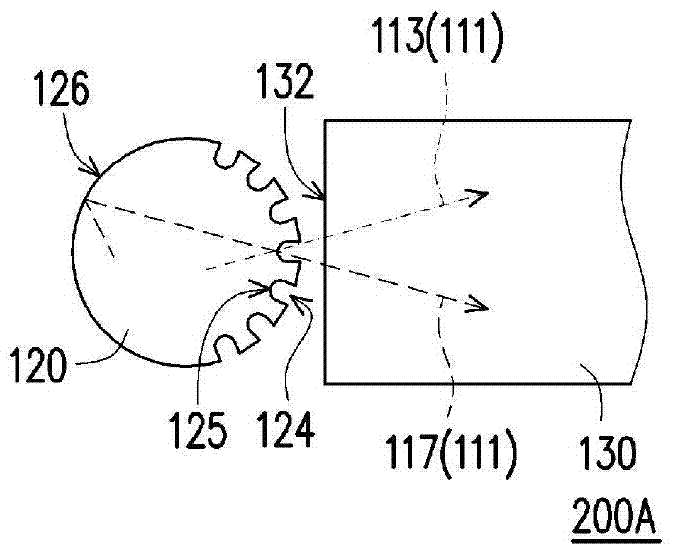

Illumination system, light mixing chamber and dispaly device

InactiveCN1383498AWell mixedEvenly illuminatedMechanical apparatusElectric circuit arrangementsEdge surfaceDisplay device

A backlight system for illuminating a display device (3) comprises a luminous panel (1) having a light emission window (2) and at least one edge face (4) coupling light into the luminous panel (1). The backlight system also includes a light mixing cavity (5) equipped with a light source (6). The light mixing cavity (5) is connected to the edge surface (4). According to the invention, the light source (6) comprises a plurality of clusters of light emitting diodes (LEDs) having different light emission wavelengths, the clusters being arranged at a distance P between each other. The ratio of the height H of the optical mixing cavity (5) to the cluster pitch P satisfies the relationship 0.1≤H / P≤10, preferably 0.2≤H / P≤2. Each cluster preferably includes one blue, one green and one red LED or one blue, two green and one red LED. Preferably each LED has a luminous flux of at least 5 lumens. The backlight system of the present invention has a very uniform light distribution, so that the display device is evenly illuminated.

Owner:LUMILEDS HLDG BV

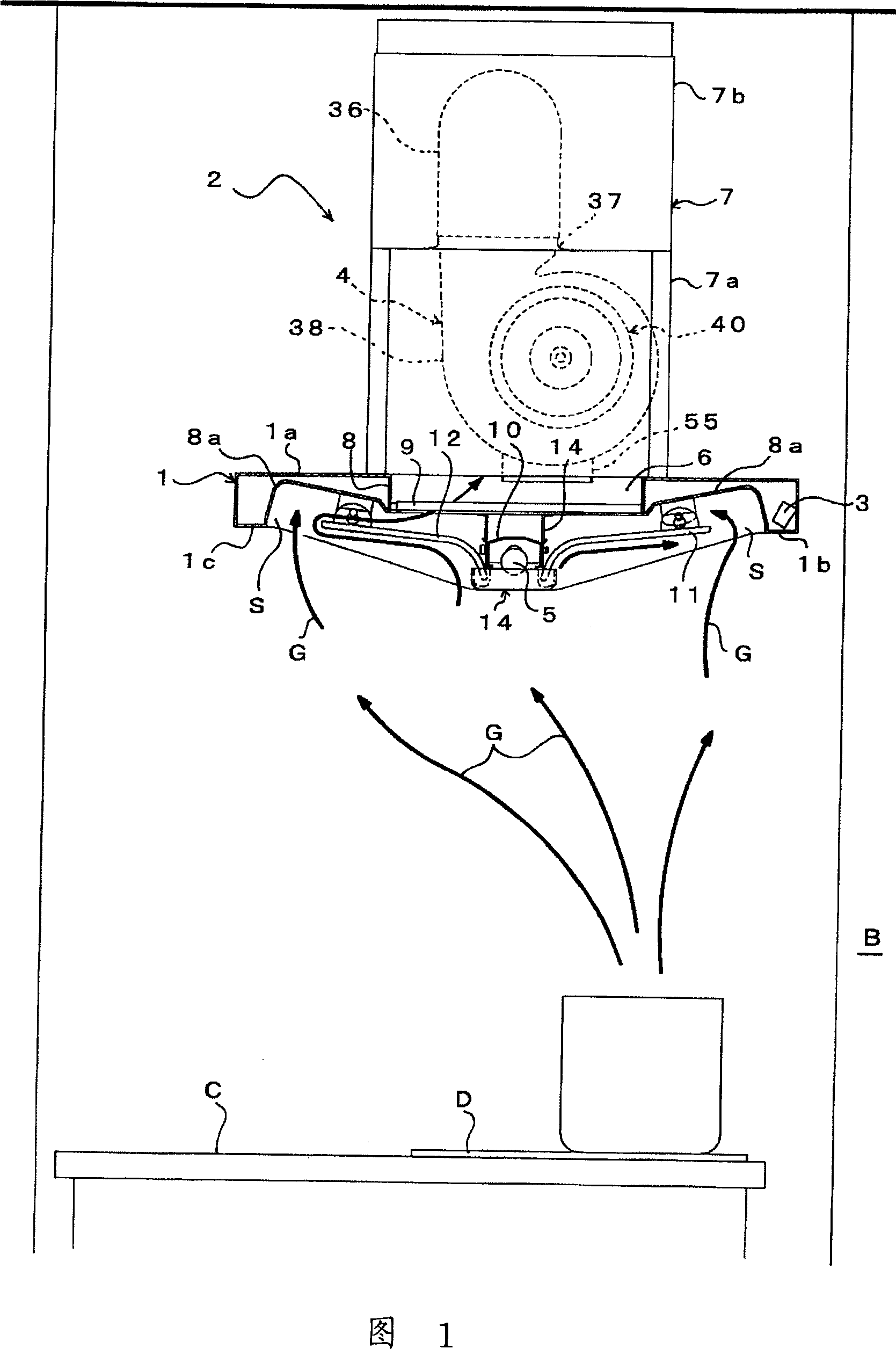

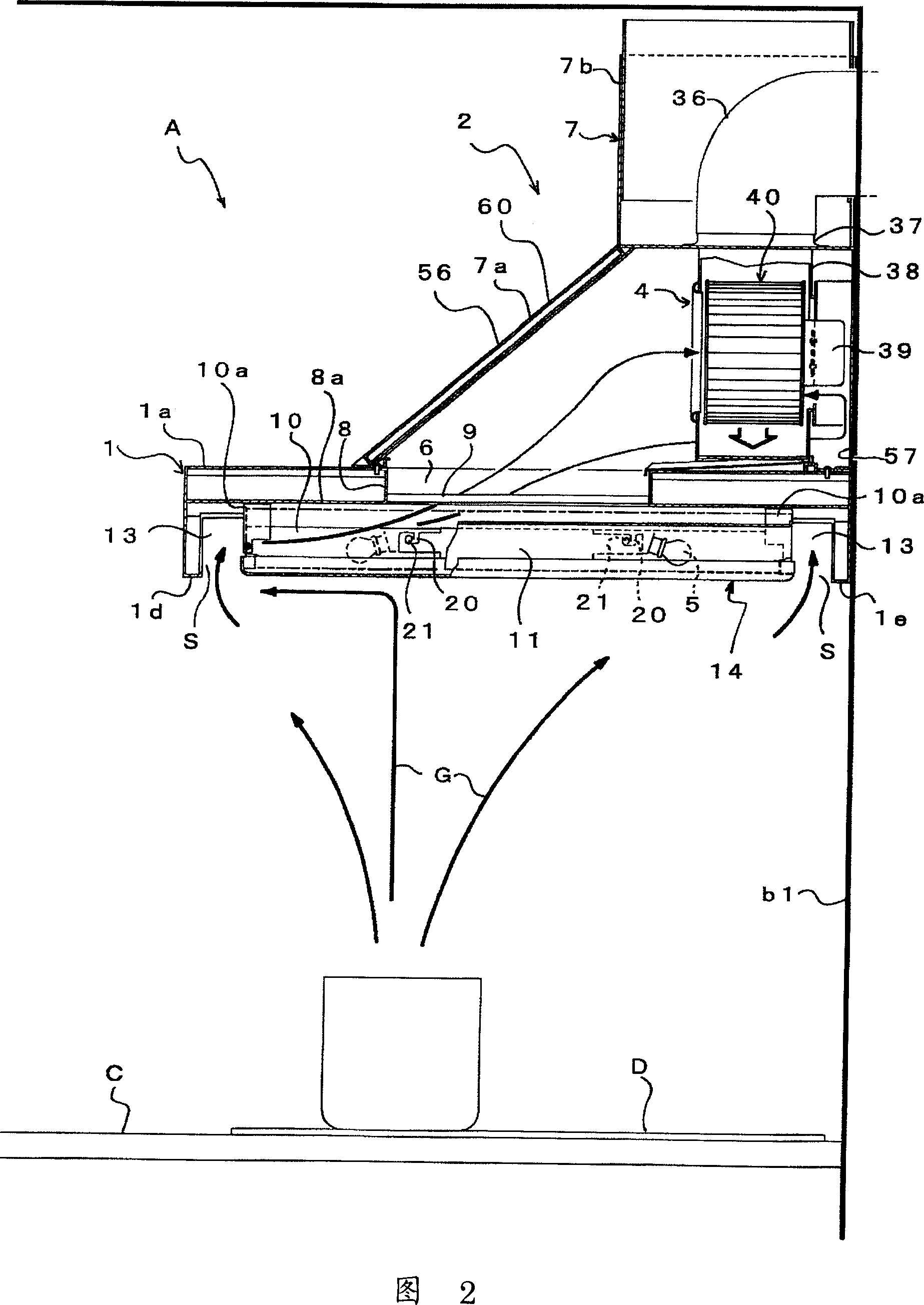

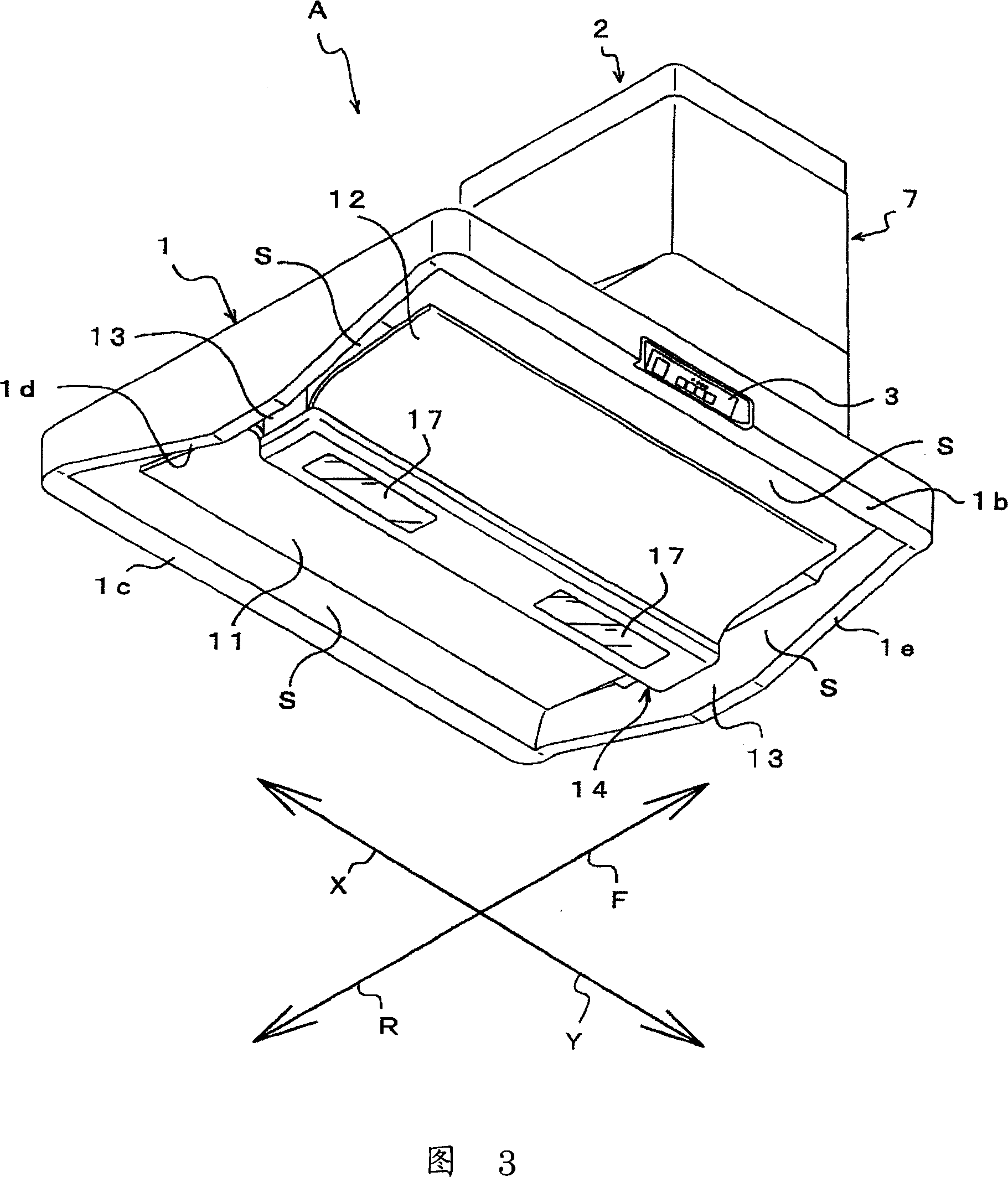

Oil smoke suction machine

ActiveCN101126516AContinuous and stable exhaust capacitySuppression of reduction in capture efficiencyDomestic stoves or rangesLighting and heating apparatusExhaust gasPollutant

The invention relates to an oil and smoke exhauster which can attract the pollutants like the exhaust gas when in the cooling process and exhausts the pollutants like the exhaust gas into the atmosphere. A support component is arranged at the central opening of a thin case which has a downward rectangular opening, and the support component spans two opposite edges of the opening and is suspended from a top plate of the case; also the invention has a central shield that can be assembled or disassembled freely; furthermore, a clearance between the central shield and the edge of the downward opening of the casing is guaranteed, and a large perforated plate and a small perforated plate are formed between the central shield and the another opposite edges of the opening. In addition, the support component is provided with an illuminating device and the central shield is provided with an oil-collecting device which can respectively collect the dripped oil on the perforated plate, furthermore the invention is provided with an illumination board to protector the illuminating device.

Owner:FUJI IND

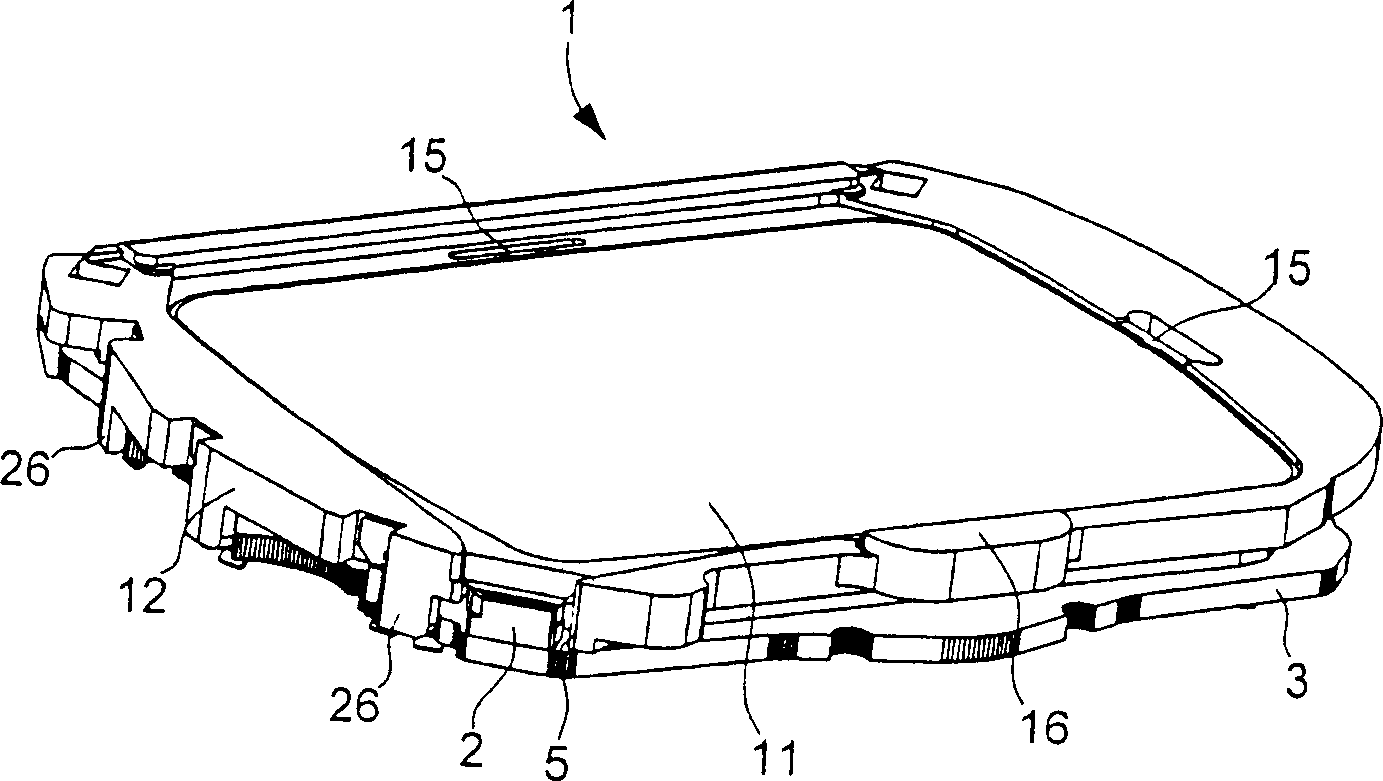

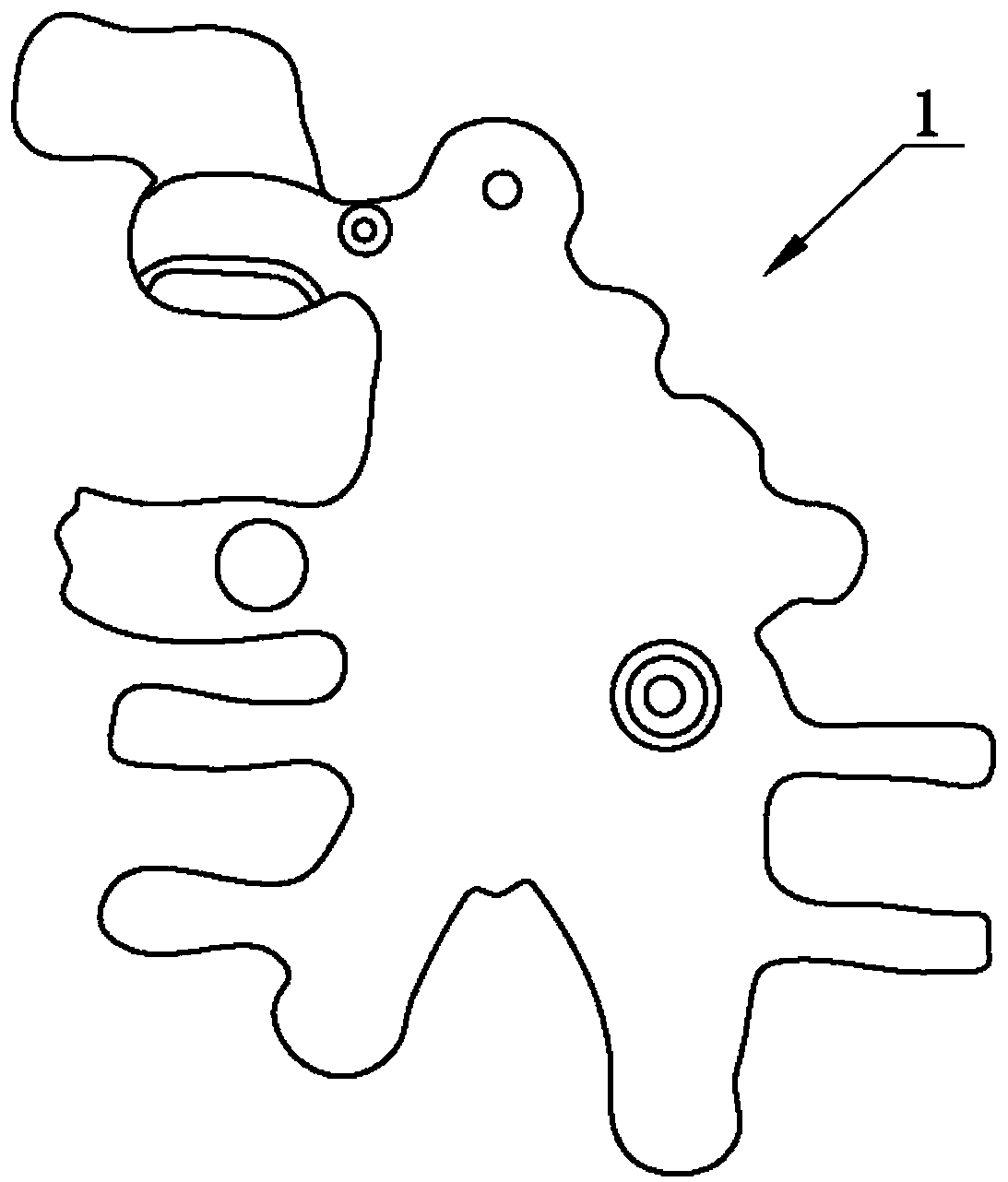

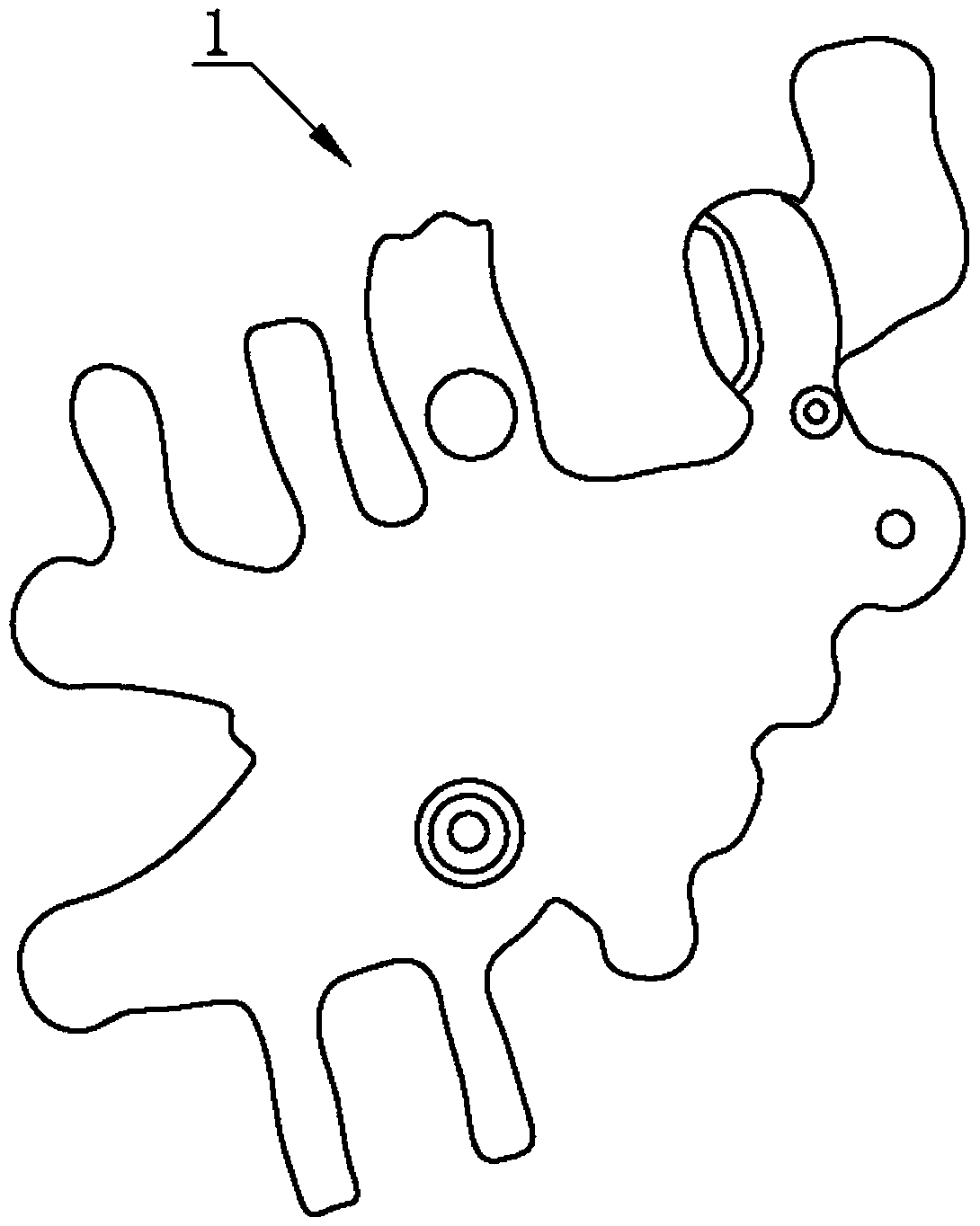

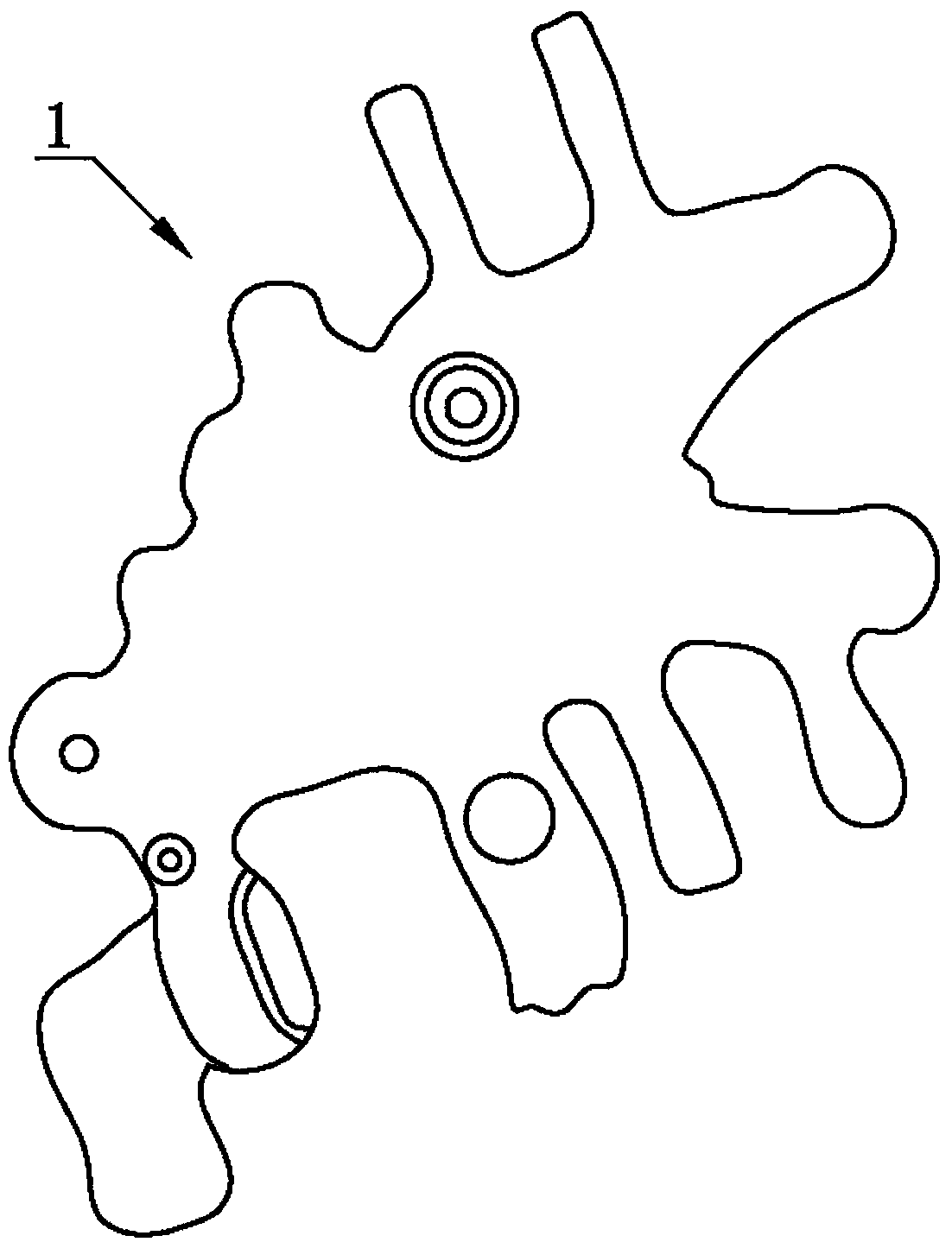

Cover view gripper

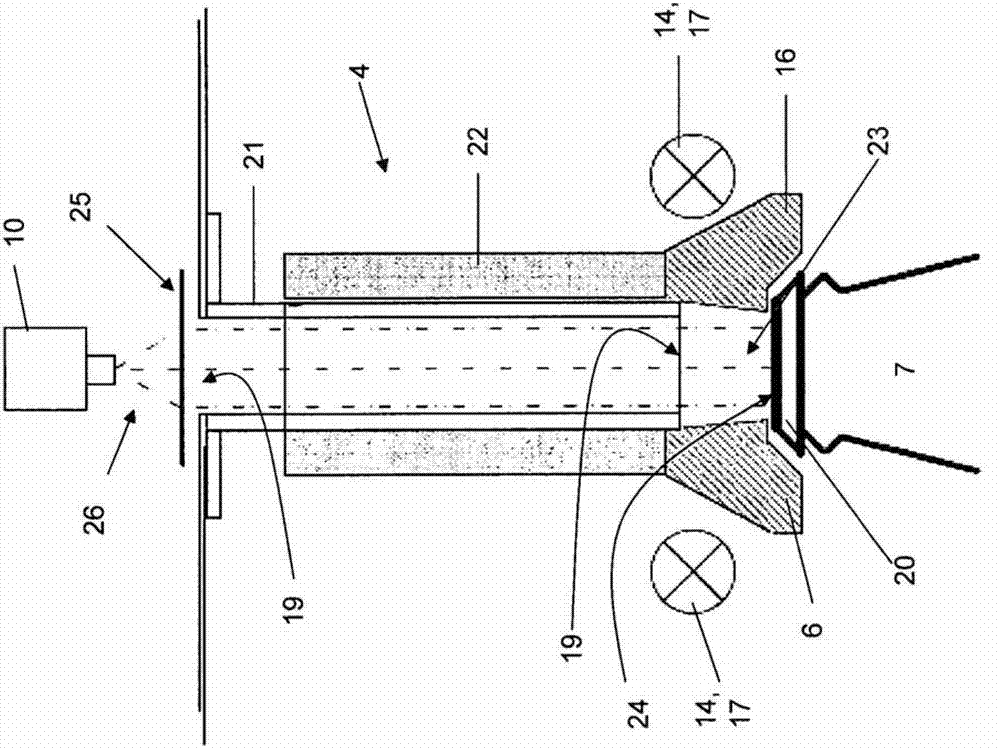

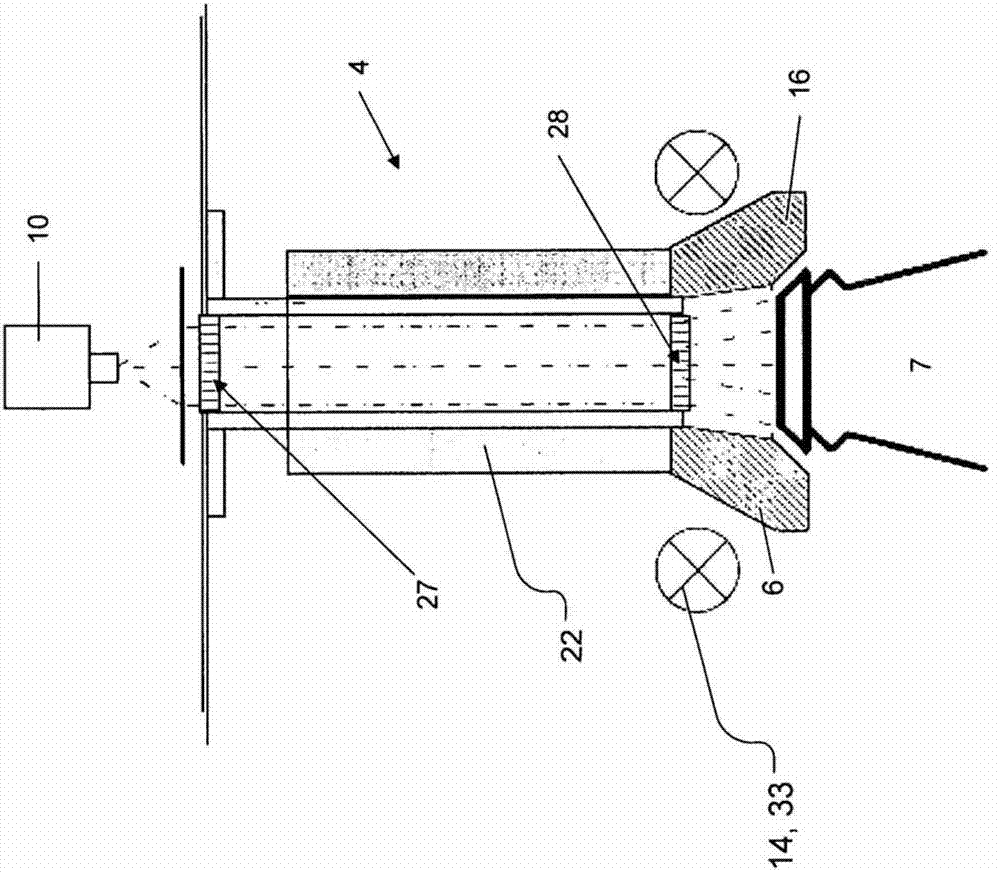

InactiveCN102781783AFavorable construction spaceEvenly illuminatedCapsCapping machinery safety/controlControl systemBottle

The invention relates to container handling device (1), in particular a labeling device for bottles, containers, et cetera, which comprises at least one centering device (2), which has a standing surface (3) and a bottle gripper (4), wherein at least one detection and control system (9) having at least one optical system (10) is provided. The bottle gripper (4) has inspection openings (19) both on the head side and on the foot side, wherein at least one light source (14, 17; 14, 33) is provided, and the bottle gripper (4) is at least partially light-conducting or comprises or contains light-conducting elements (6; 30) so that a surface, in particular a cover side (24), can be inspected can be inspected through the optical system and through the bottle gripper (4) and by means of the light-conducting design or light-conducting elements (6; 30) an illuminated inner area (23) can be inspected.

Owner:KHS GMBH

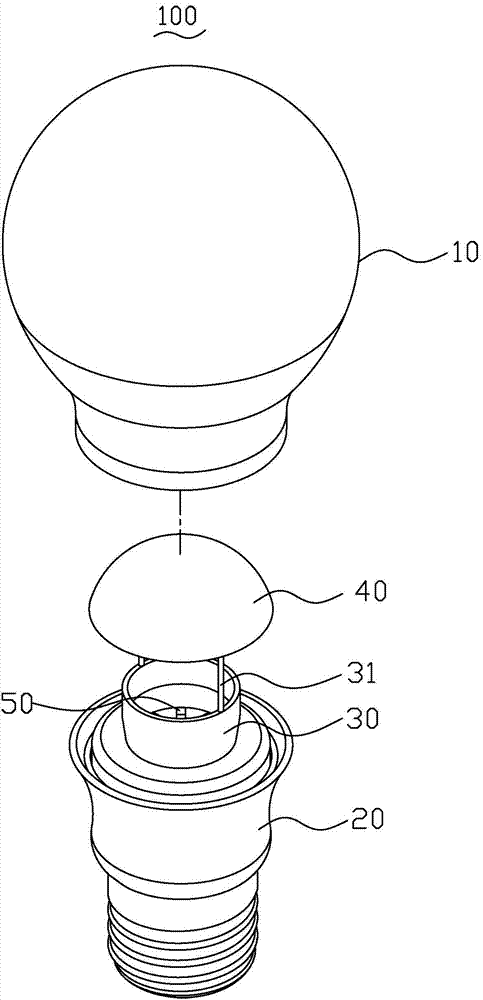

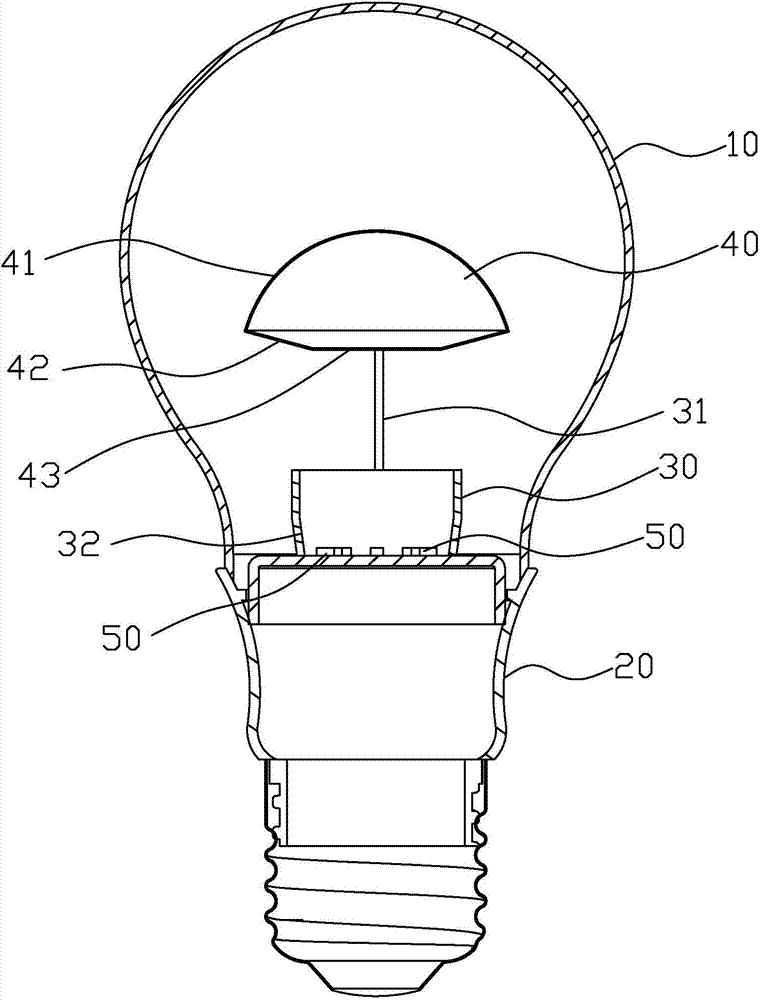

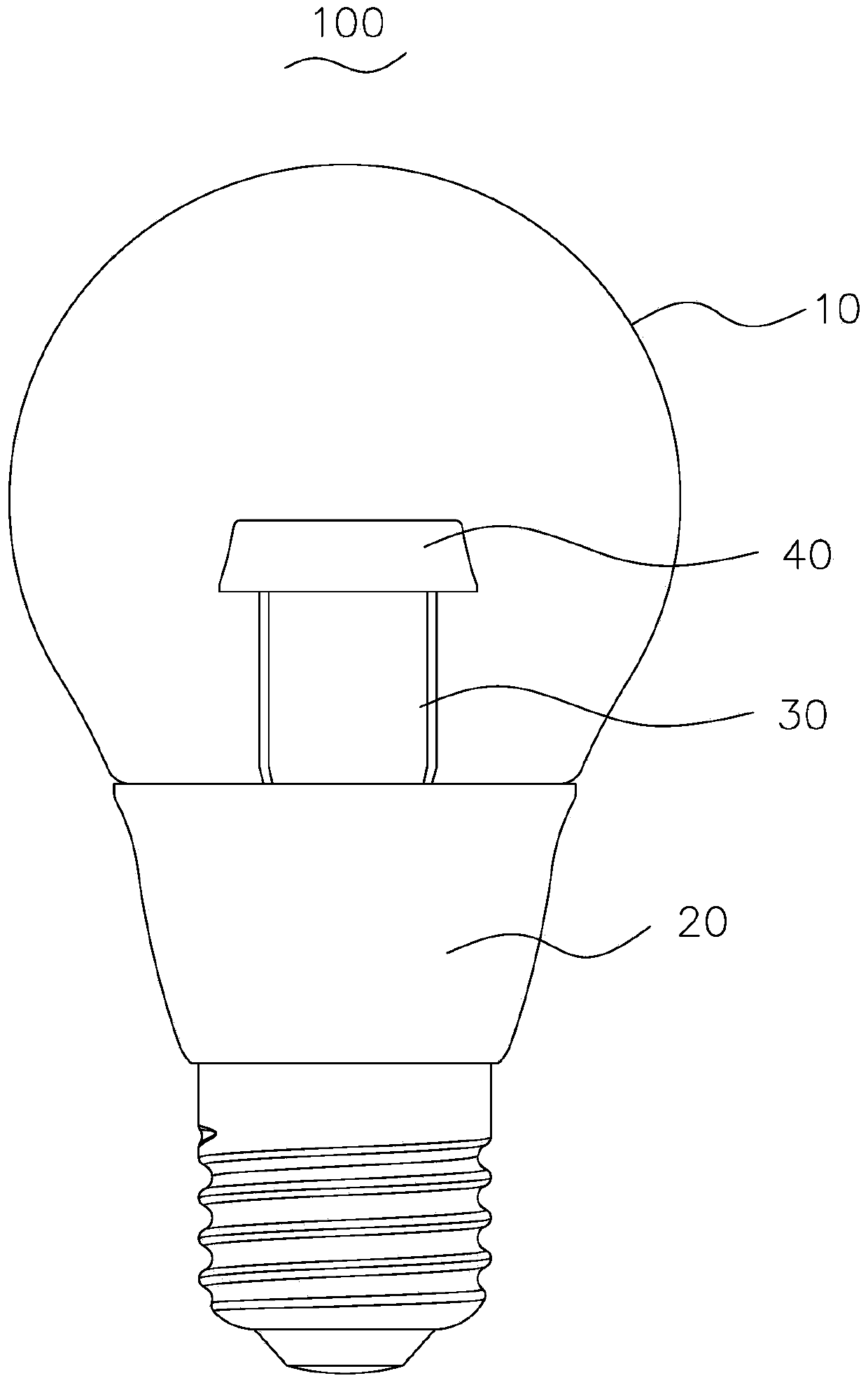

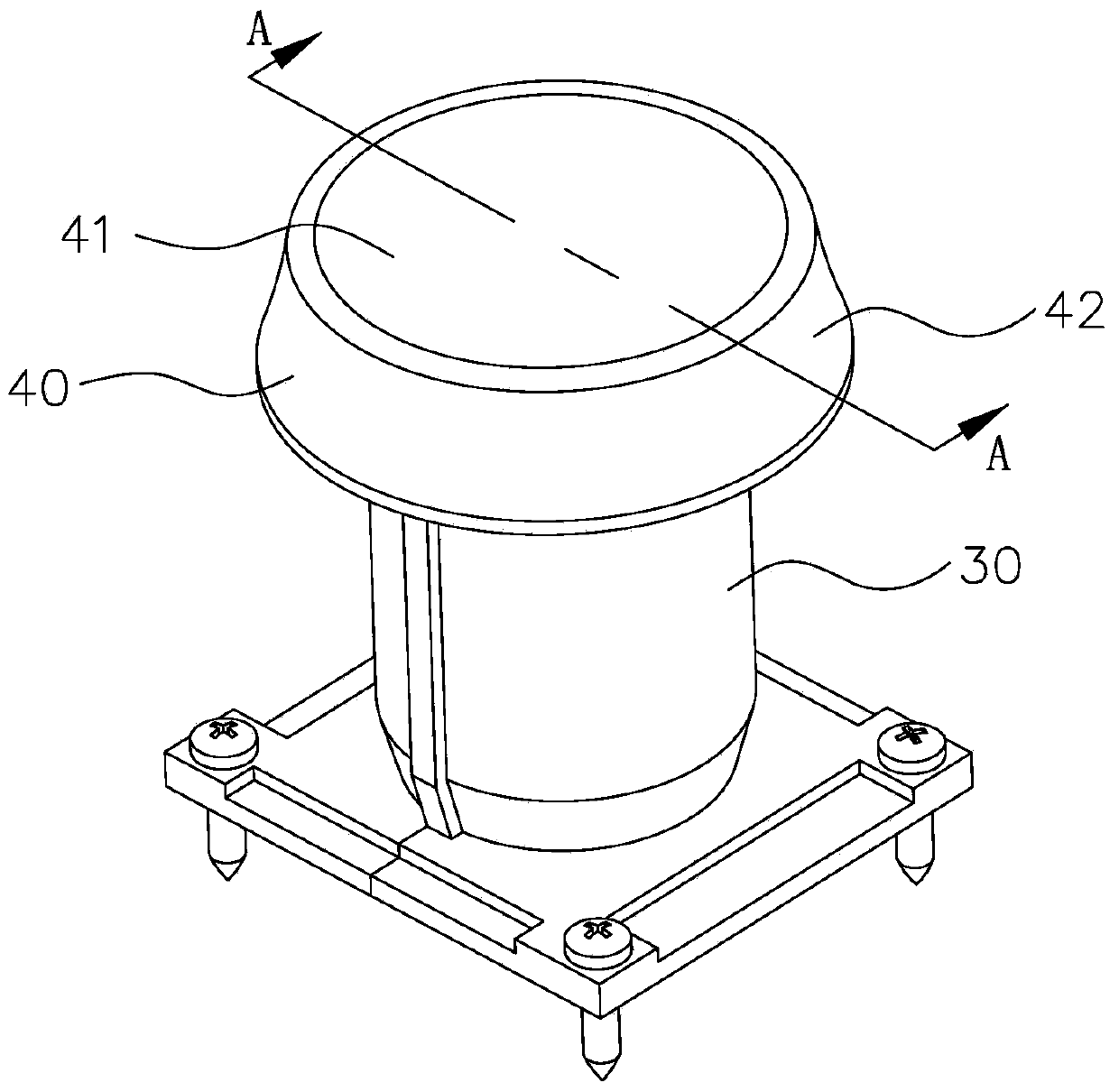

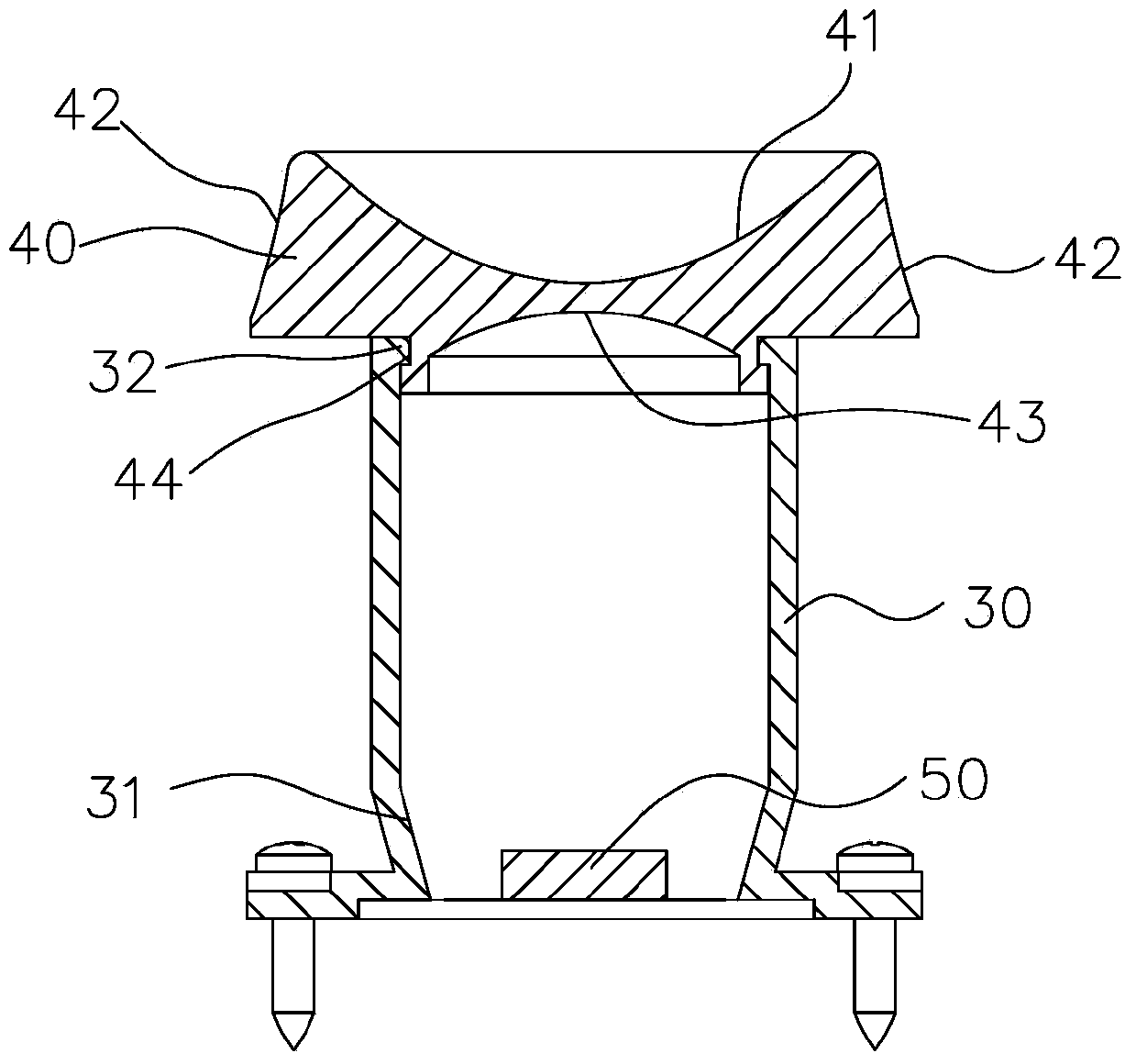

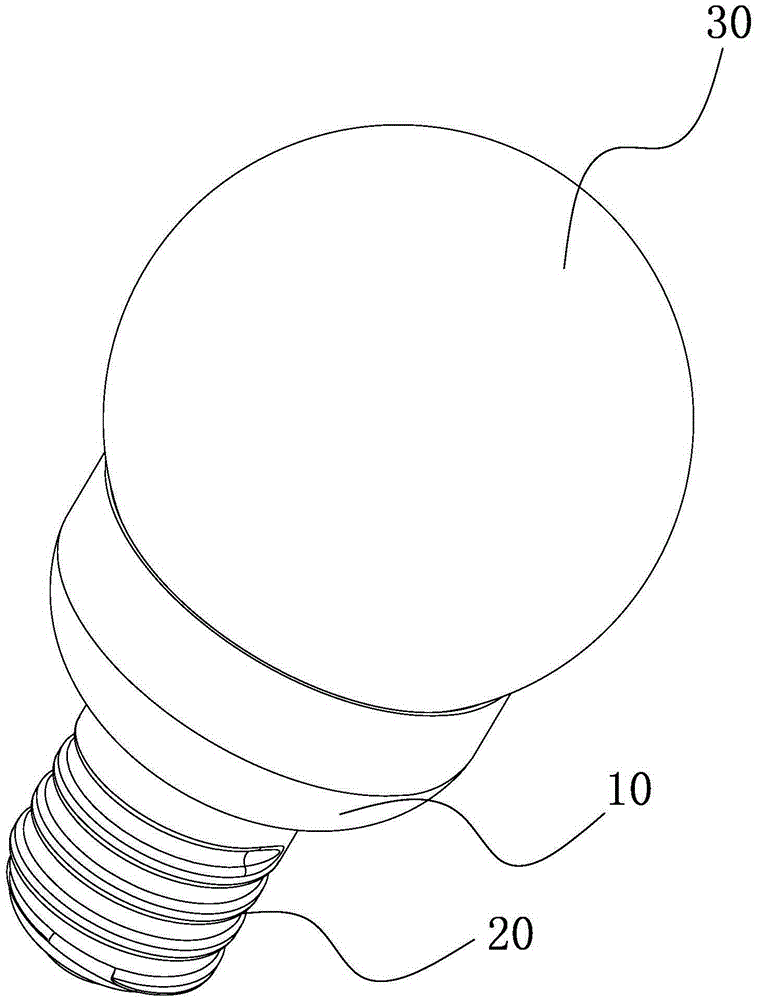

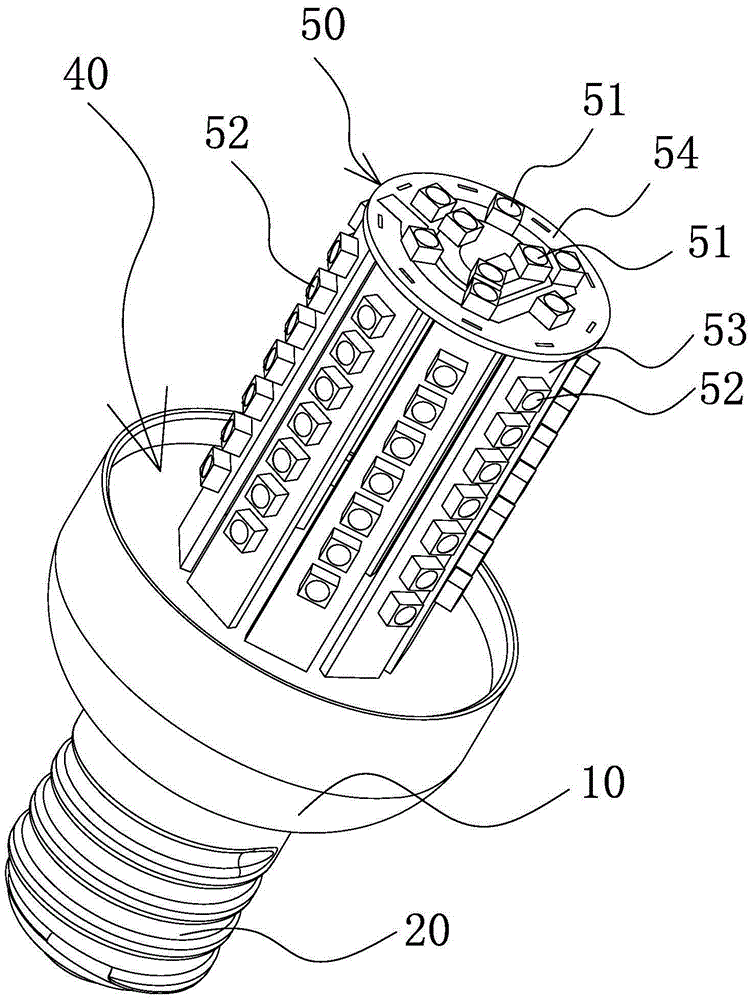

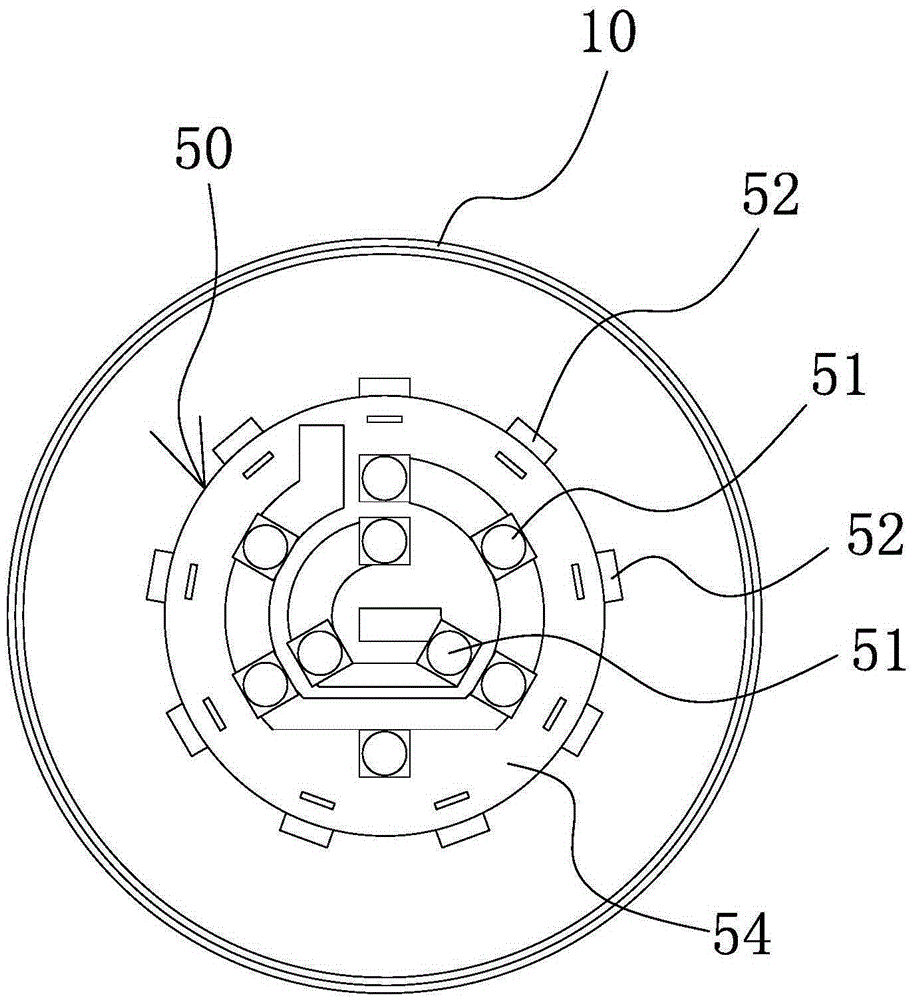

LED (Light Emitting Diode) lamp

ActiveCN103574359AEvenly illuminatedEvenly distributedPoint-like light sourceElectric lightingEngineeringLED lamp

The invention relates to an LED (Light Emitting Diode) lamp, which comprises a lamp cap body, a bulb shell, an LED light source and a light distribution member, wherein the LED light source is arranged on the top surface of the lamp cap body, and the bulb shell is arranged at the top end of the lamp cap body to accommodate the LED light source; the light distribution member is arranged above the LED light source, and comprises a light emitting part and a reflecting part, and the light emitting part is arranged on the reflecting part; the reflecting part is of an inverted frustoconical shell structure, and the outer side wall of the reflecting part is a reflecting surface; a through hole is formed in the middle of the reflecting part, and the light emitting part is made of a transparent or translucent material and projects towards the direction away from the reflecting part; the light emitting part is arranged opposite the through hole of the reflecting part, and the reflecting surface of the reflecting part is used for reflecting light emitted by the LED light source to the bottom of the bulb shell. The LED lamp has the advantages of simple structure and uniform light distribution.

Owner:XIAMEN LEE BROS CO LTD

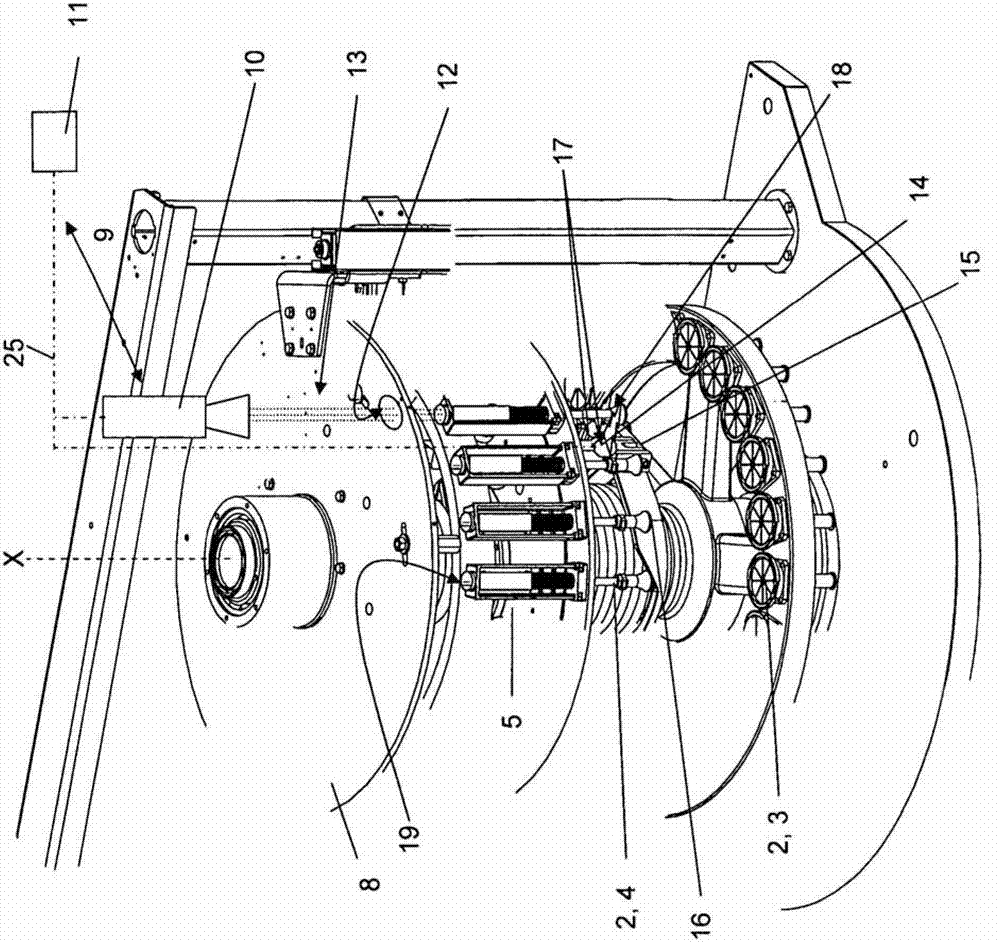

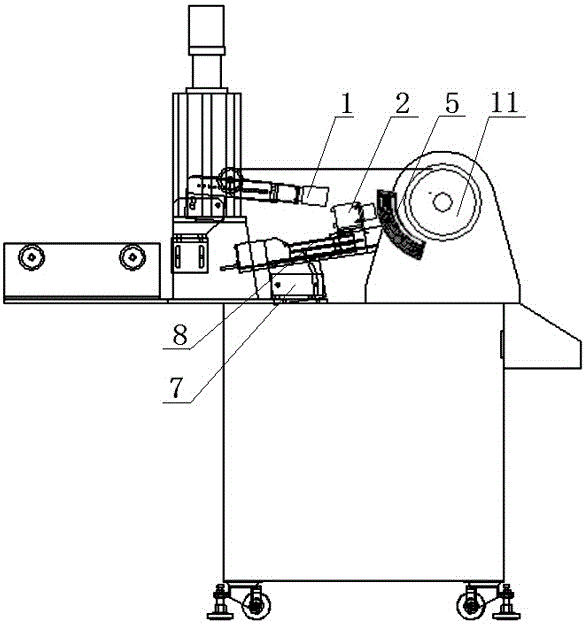

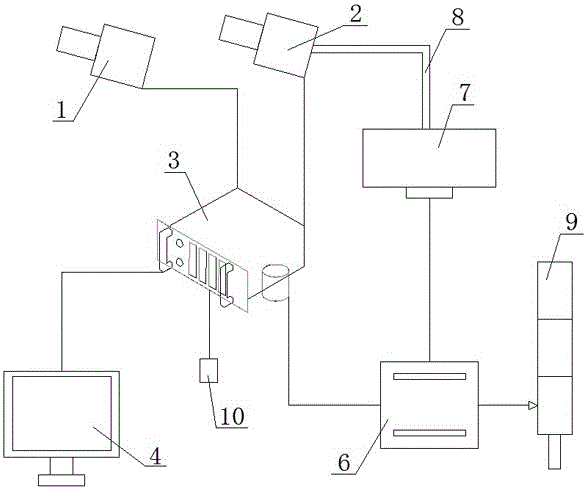

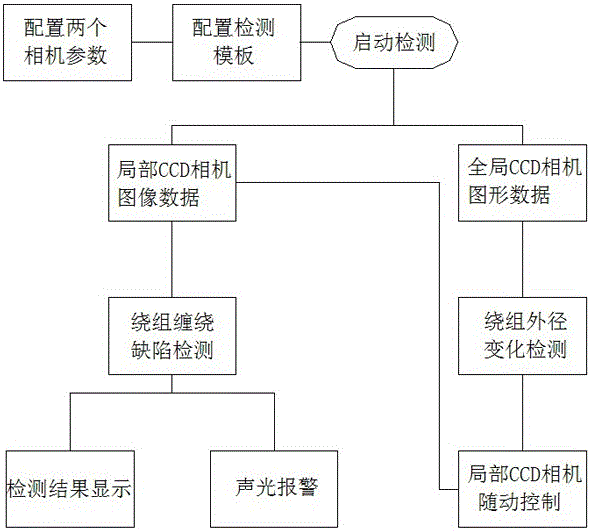

Real-time fiber winding defect visual inspection device based on double CDDs

InactiveCN105954008AImprove winding qualityImprove winding efficiencyOptical apparatus testingFiberVisual inspection

The present invention discloses a real-time fiber winding defect visual inspection device based on double CDDs. The device comprises a visual detection unit which comprises a global CCD camera which has a fixed position and is used for collecting a whole fiber winding image and a local CCD camera which has an adjustable position and is used for collecting a fiber winding local image. Both the global CCD camera and the local CCD camera are connected to an industrial computer. The industrial computer is connected to the local CCD camera through an electrical transmission unit and is connected to a display screen. According to the device, the double-CCD camera automatic online detection technology is used, the working position of the local CCD camera is adjusted through tracking fiber winding wire diameter change by the global CCD camera, thus the local CCD camera carries out online monitoring on a fiber winding in real time, the improvement of the fiber winding quality and defect detection efficiency is facilitated, the production cost is reduced, at the same time, the improvement of the degree of automation of fiber winding defect detection is facilitated, in an online real-time detection process, the fiber winding defect image information is recorded, and the problem backtracking is helped.

Owner:江南工业集团有限公司

Light-emitting diode (LED) lamp

InactiveCN103470977AEvenly illuminated at large anglesSimple structureMechanical apparatusPoint-like light sourceScattered lightEngineering

A light-emitting diode (LED) lamp comprises a lamp cap body, a bulb casing, an LED light source, a light guide pillar and a lens. The bulb casing covers the top end of the lamp cap body, the LED light source is arranged on the top surface of the lamp cap body, the light guide pillar is arranged above the LED light source, and the lens is arranged above the light guide pillar and comprises a concave lens part and a side light outlet part. The concave lens part comprises an upper concave surface and a lower concave surface, the side light outlet part surrounds the concave lens part and is connected with the upper concave surface and the lower concave surface, the lower concave surface is arranged above the light guide pillar, the light guide pillar is used for enabling light emitted by the LED light source to be guided to the lower concave surface of the concave lens part, and the upper concave surface and the side light outlet part are used for scattering light which enters the lower concave surface. The LED lamp can achieve large-angle light emitting and has the advantages of being simple in structure and uniform in light distribution.

Owner:LEEDARSON GREEN LIGHTING

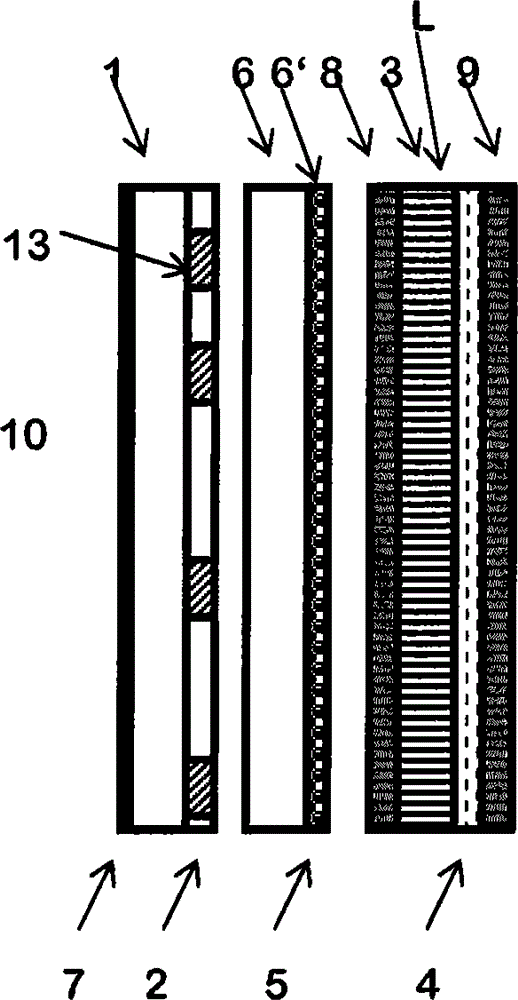

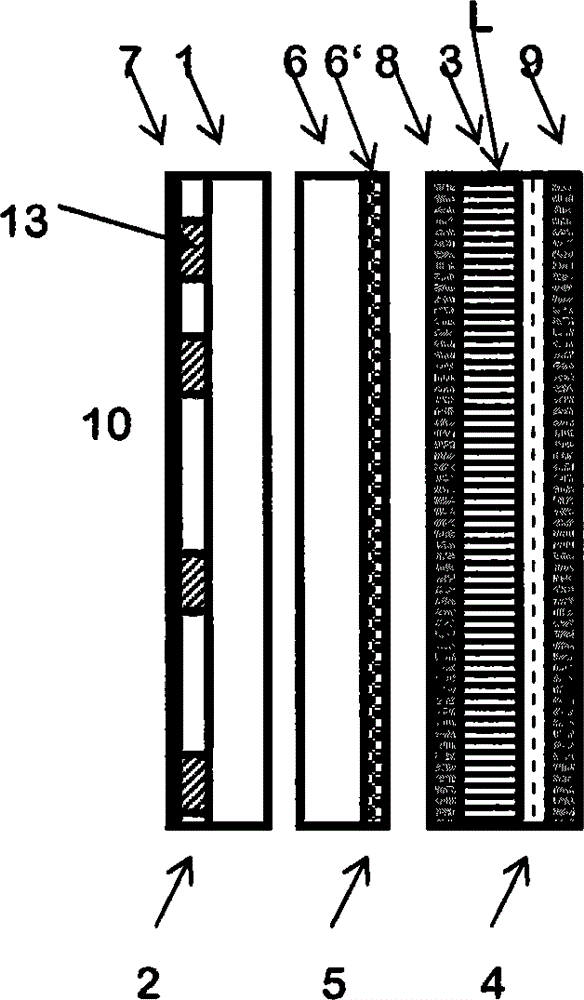

Light guide plate comprising decoupling elements

InactiveCN104871051AEvenly illuminatedEasy to produceMechanical apparatusLight guides for lighting systemsLight guideDisplay device

The invention relates to a planar light distribution module for a display, comprising a light guide plate through which light coupled in via at least one side face can propagate by means of total reflection, and at least one out-coupling device (2), which is applied on one or both of the main faces of the light guide plate (1), is in optical contact therewith and has a multiplicity of holographic optical elements (13) formed therein, which are configured in such a way that they can couple light out of the light guide plate (1), the light distribution module being characterized in that the holographic optical elements (13), independently of one another, have an extent of at least 300 μm in at least one spatial axis extending parallel to the surface of the out-coupling device (2). The invention furthermore relates to an optical display, in particular an electronic display.

Owner:COVESTRO DEUTSCHLAND AG

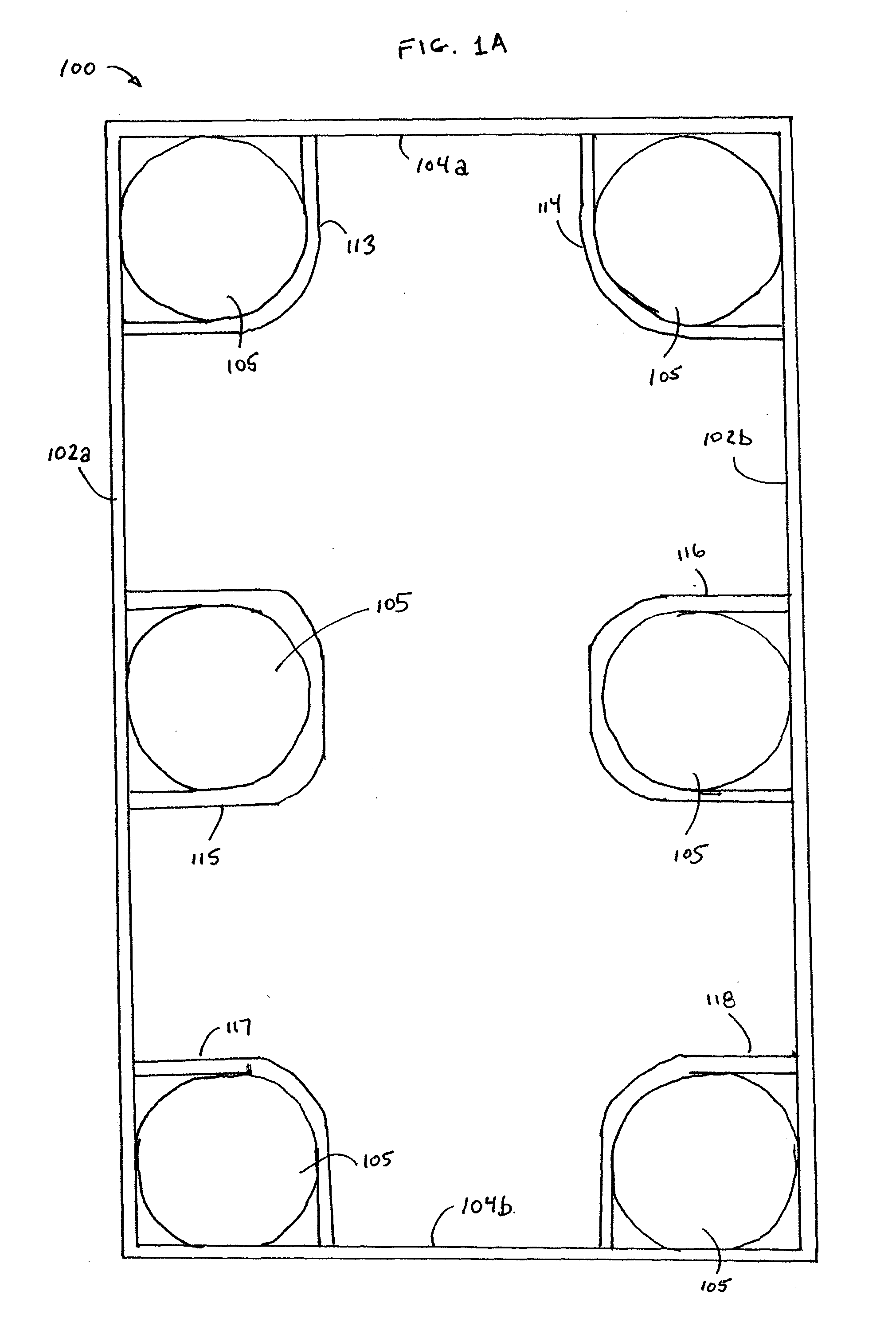

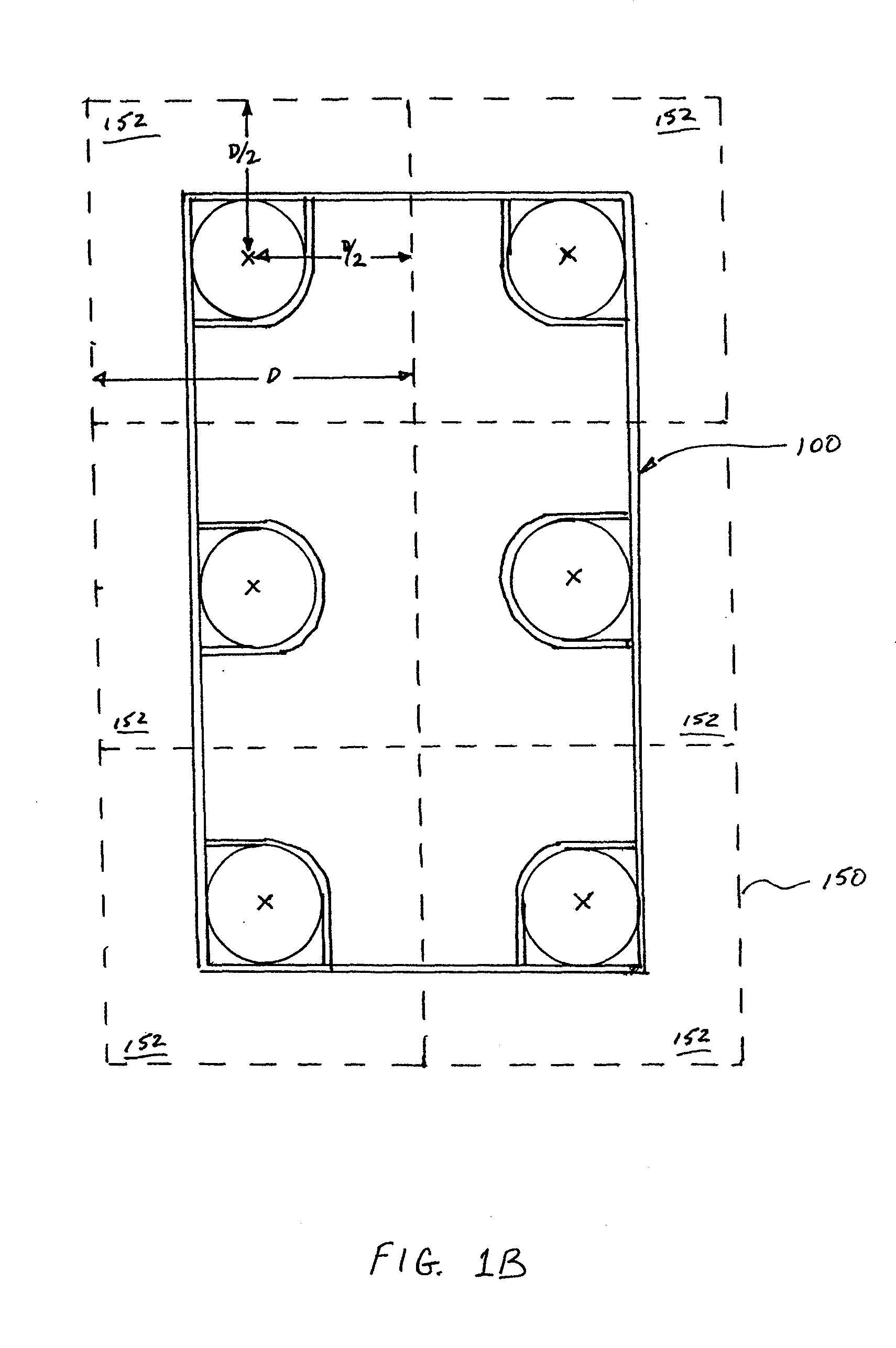

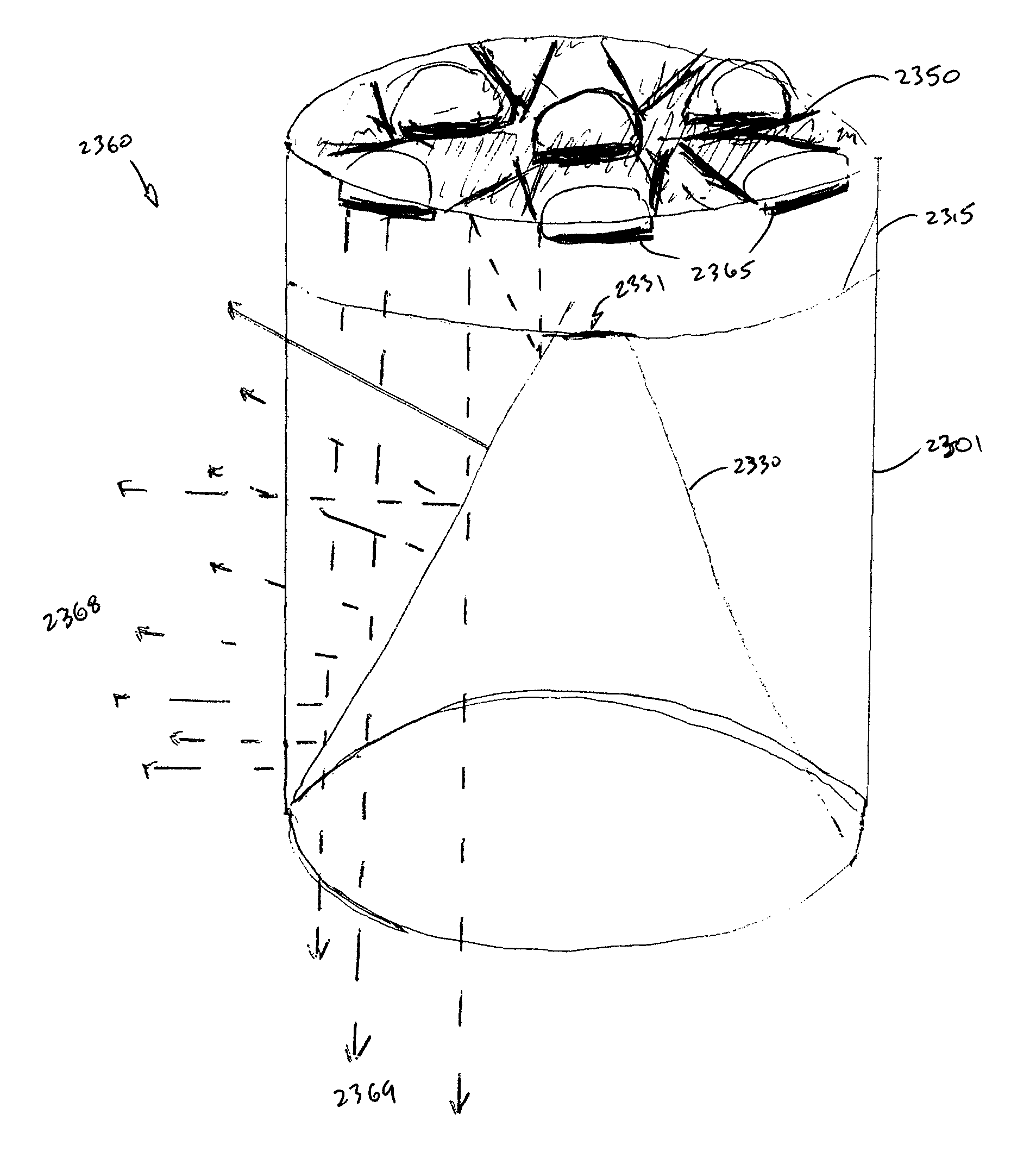

Versatile illumination system

InactiveUS7963673B2Increase in sizeIncrease flexibilityLighting applicationsMechanical apparatusModular fixtureModularity

A lightweight, modular expandable multiple par lamp fixture configurable to form various sizes and intensities of high output area lighting or projected soft light. A high efficiency par lamp includes a high output globe and lightweight reflector, optional collar, and lens. Individual modular fixtures comprising high efficiency par lamps may be stacked to create larger units. The par lamps may be arranged in pods which can be assembled into larger units. A diffusion frame and fabric cover can be attached to the fixture in front of the par lamps to create a soft, deeply projected light. The diffusion frame may have an internal semi-translucent baffle to spread light through diffusive sidewalls.

Owner:FINN BRUCE L

Illumination device used for motor vehicle and provided with dustproof cover extending opposite to traveling direction

InactiveCN102865538AEvenly illuminatedHigh strengthOptical signallingVehicle lighting systemsEngineeringOptical pathlength

The present invention relates to an illumination device used for a motor vehicle and provided with a transparent dustproof cover, wherein the dustproof cover has a shape that is equipped to fit the arrow-shaped outermost shape in a part of a body component of a motor vehicle, at least two light source elements are arranged in the interior of the illumination device along a line which follows the arrow-shaped outermost shape, light are transmitted towards the dustproof cover preferably in a normal direction, in a light path between the light source components and the dustproof cover is orderly provided with two light diffusion glass, such that the glass enables the light transmitted from the light source components to deflect as follows: an angle include by the deflected light and a motor vehicle longitudinal axis is smaller than that included by un-deflected light and the motor vehicle longitudinal axis.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

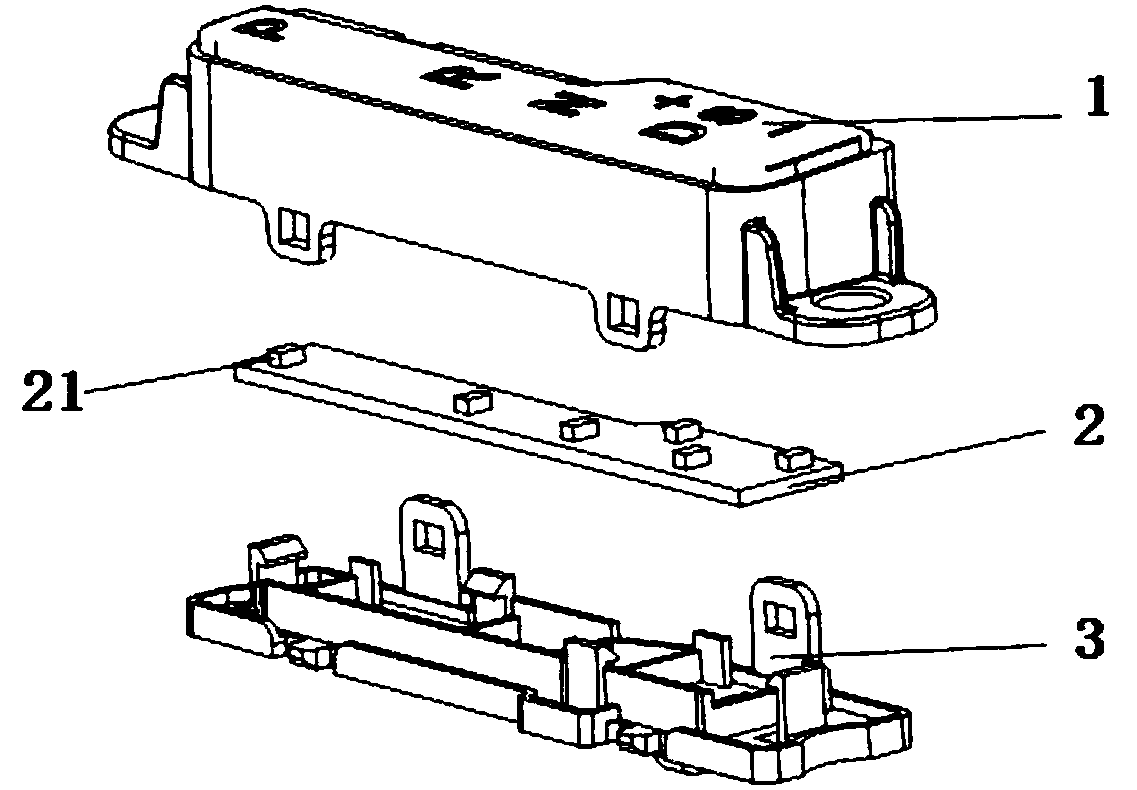

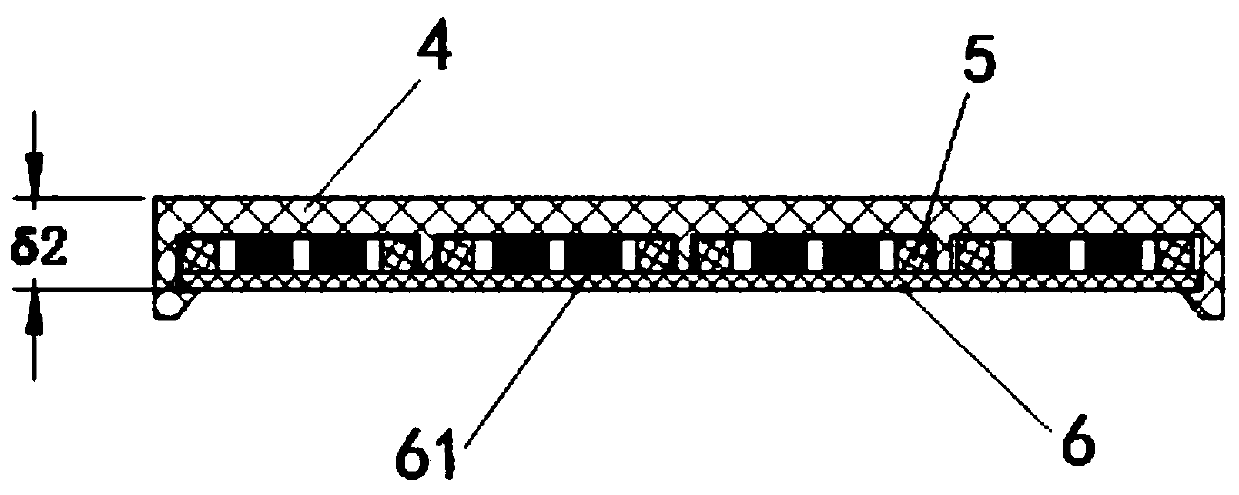

Multi-color gear indicator lamp structure

InactiveCN109555855AEvenly illuminatedReduce volumeGearing controlOptical light guidesLight guideEngineering

The invention relates to a multi-color gear indicator lamp structure. The multi-color gear indicator lamp structure comprises a cover plate, a PCB and a plurality of LED lamps arranged on the PCB, andis characterized in that a plurality of light guide plates are arranged on the PCB, and the plurality of light guide plates are in one-to-one correspondence with gears; grooves are formed in the sidefaces of the light guide plates, the plurality of LED lamps are located at the positions of the grooves correspondingly, and the thickness of the light guide plates is 0.1 mm larger than the height of the LED lamps; reflecting paper is attached to the upper surface and the lower surface of each light guide plate, the upper surface of the cover plate is provided with and displays gear characters,the lower surface of the cover plate is provided with a plurality of light isolation plates, and the plurality of light isolation plates are used for separating the gear characters from one another, so that light is prevented from being mixed; and a plurality of clamping legs are arranged on the edge of the cover plate, the cover plate covers the PCB, and the plurality of clamping legs are fastened to the edge of the PCB. According to the structure, the gear characters can be uniformly illuminated, the structure is compact and small in occupied space, and the gear indicator lamps of 1-8 colorscan be arranged according to the requirement of the displayed gears.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

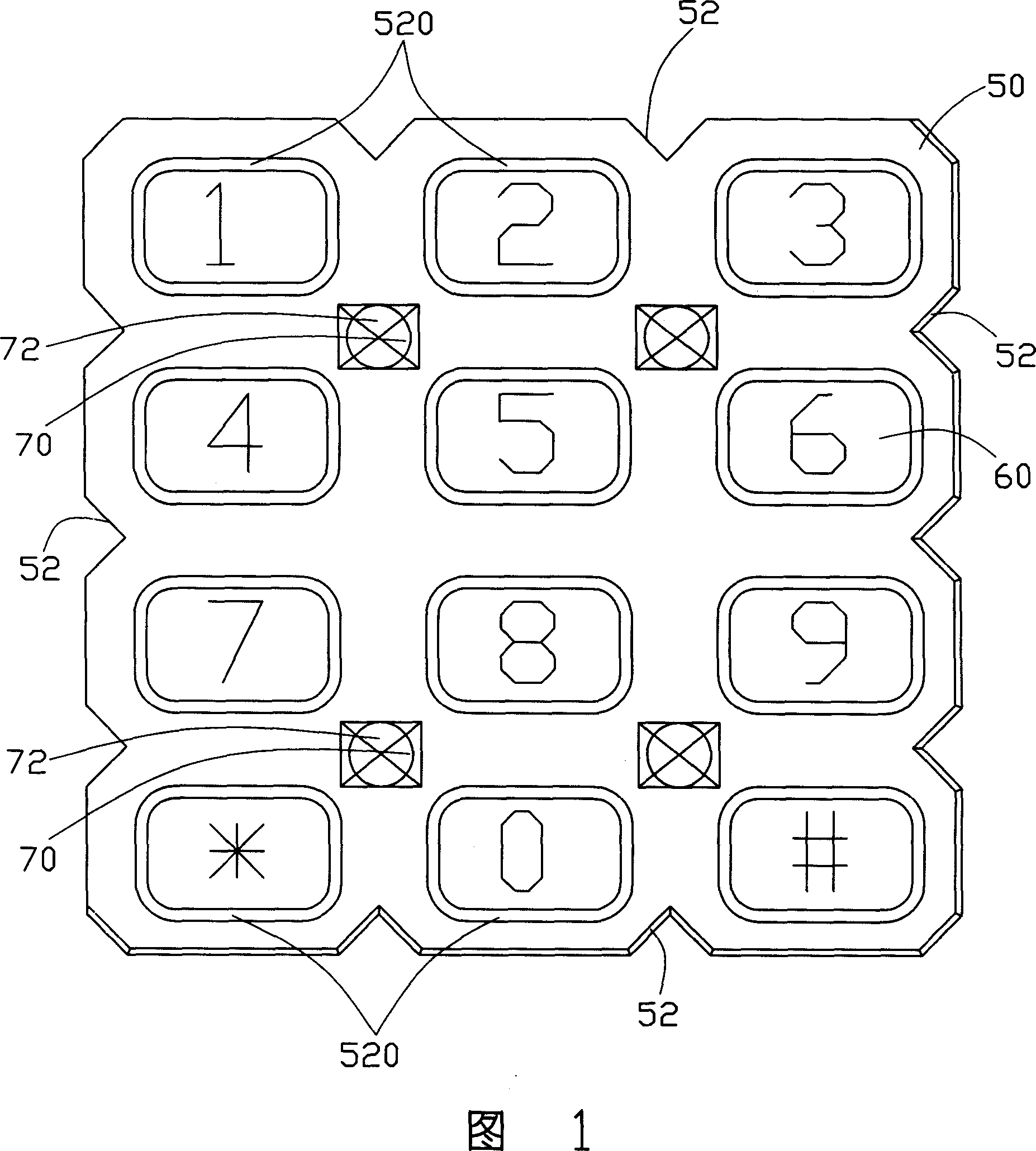

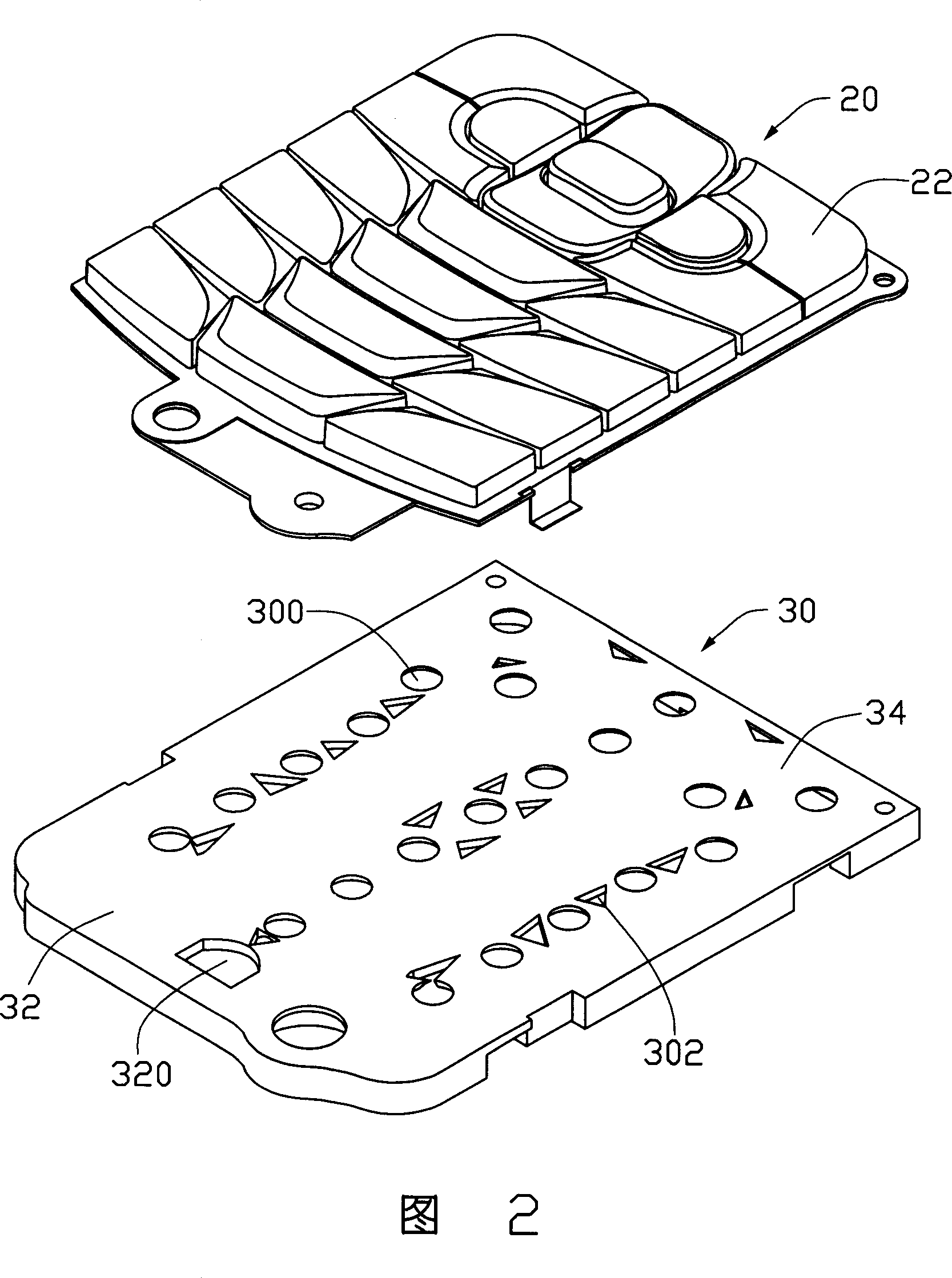

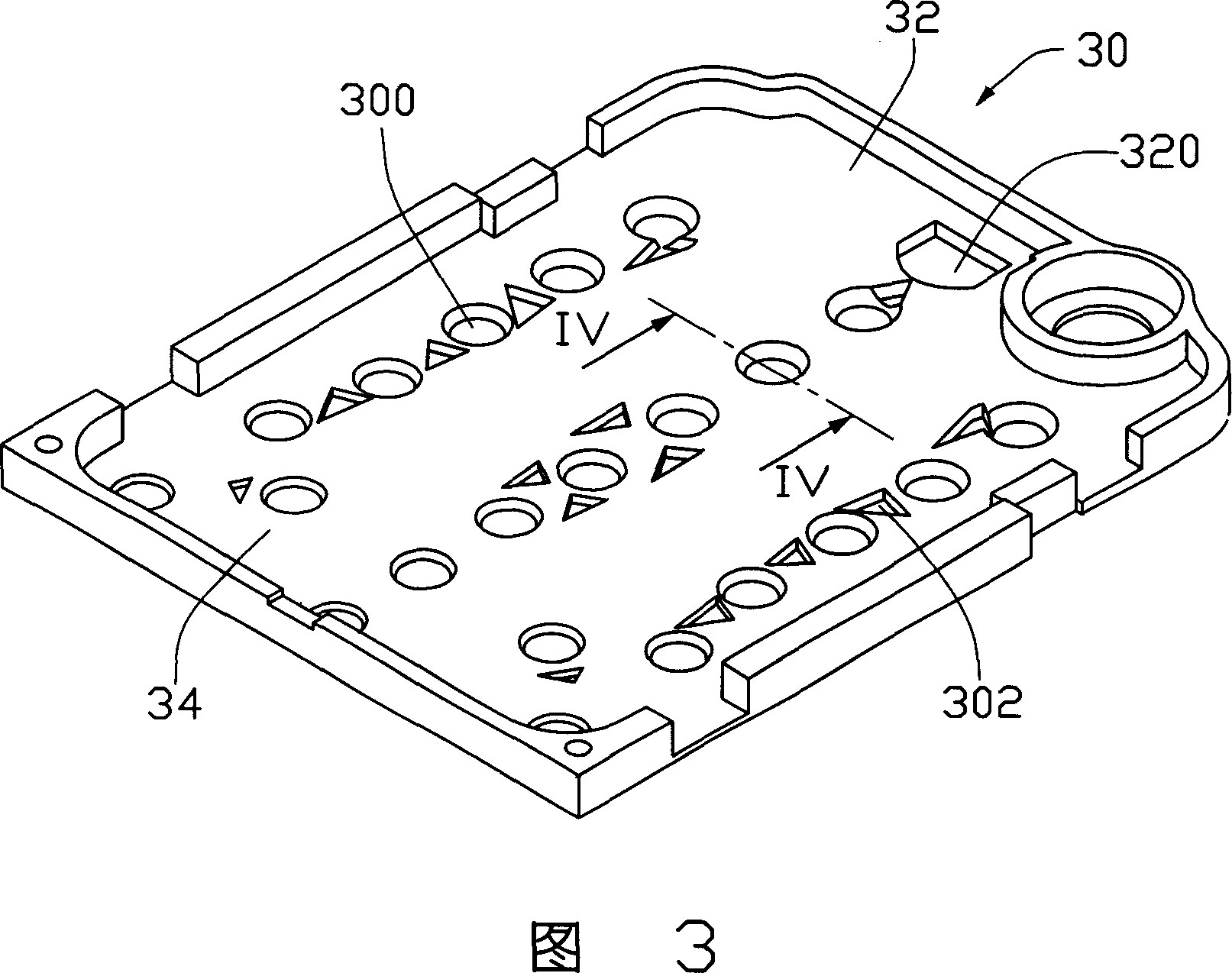

Light conducting plate and electronic products using the said plate

A light board used for leading light for a keyboard is provided in the invention. The keyboard includes several keys. The light board includes many bores corresponding to the key and a permitting place area which includes permitting hole to receive the light source. Because at least one direction of thickness of the light board decreases following the direction far from the permitting place area. The permitting hole is in the permitting place area. So the light send from the light is leaded to the bottom of the key, so one light source can make all keys illuminate, it can decrease the light source number and decrease the energy cost.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

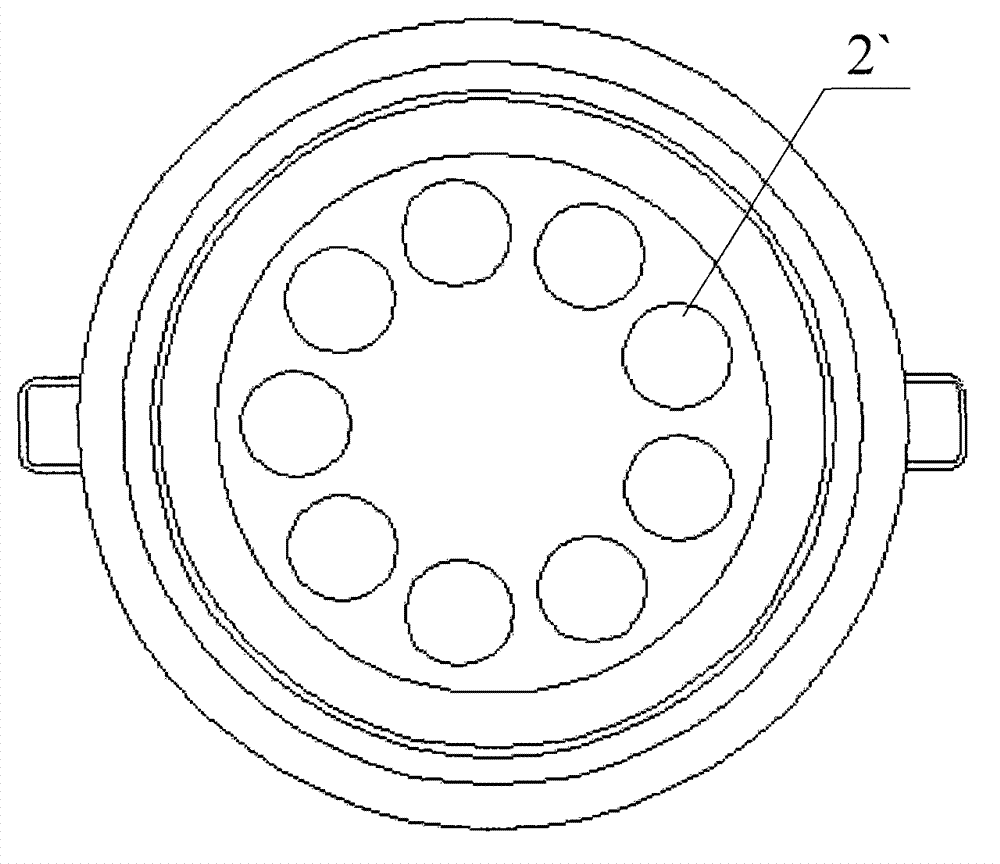

Light emitting diode (LED) ceiling lamp

InactiveCN103162196AReduce volumeUniform sizePoint-like light sourceLight fasteningsLight spotEngineering

The invention provides a light emitting diode (LED) ceiling lamp which is provided with nine condensing lenses and a surface cover which is covered on the condensing lenses, wherein the diameters of the condensing lenses range from 11.6mm to 12mm, and the diameter of the surface cover ranges from 96mm to 100mm. An inner circle distribution line and an outer circle distribution line are installed on the surface cover, three condensing lenses are evenly installed on the inner circle distribution line, and six condensing lenses are evenly distributed on the outer circle distribution line. By means of light condensation and reflection technology of transparent plastic, the diameters of the condensing lenses range from 11.6mm to 12mm, the nine condensing lenses are distributed on an inner circle and an outer circle of the surface cover through the inner circle distribution line and the outer circle distribution line of the surface cover, and therefore, the size of the surface cover is reduced. By means of adjustment of the sizes and reasonable distribution positions of the condensing lenses, the LED ceiling lamp has the small size, LED lamp beads emit light and irradiate uniformly, good illuminating effects are obtained, no light spot is produced, and cost is lowered.

Owner:NINGBO QICHI ILLUMINATION LAMP

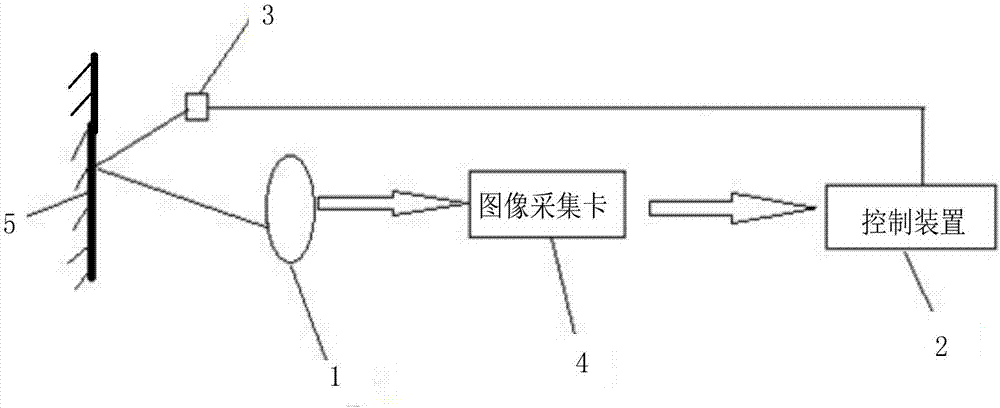

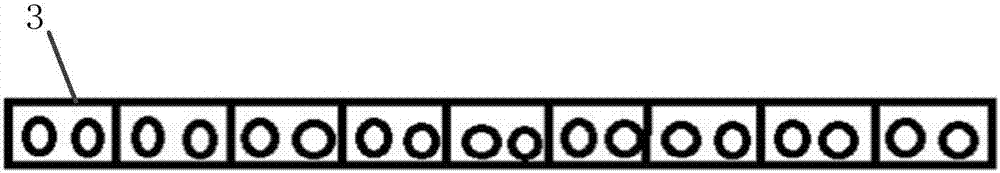

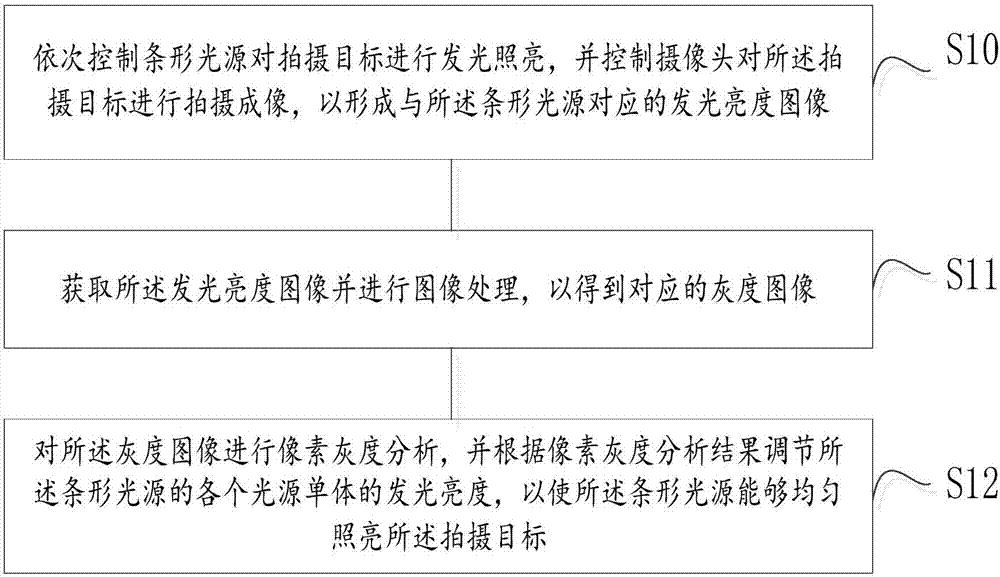

Light source brightness control system and control method

PendingCN107959801AEvenly illuminatedUniform brightnessTelevision system detailsColor television detailsControl systemEngineering

The invention discloses a light source brightness control system and a light source brightness control method. The light source brightness control system comprises a camera, a control device and at least one strip-shaped light source. The strip-shaped light source comprises a plurality of light source monomers which are arranged in a straight line and are used for emitting the light to a shootingtarget. The camera is used for carrying out shooting and imaging on the shooting target so as to form a light-emitting brightness image corresponding to the strip-shaped light source. The control device is used for sequentially controlling the strip-shaped light source to emit the light during the brightness adjustment of the light source, and carrying out image treatment on the light-emitting brightness image. In this way, the light-emitting brightness of each light source monomer of the corresponding strip-shaped light source is controlled according to the image treatment result, so that thestrip-shaped light source can uniformly illuminate the shooting target. According to the invention, the brightness of a shot image can be more uniform.

Owner:GUANGZHOU UNIVERSITY

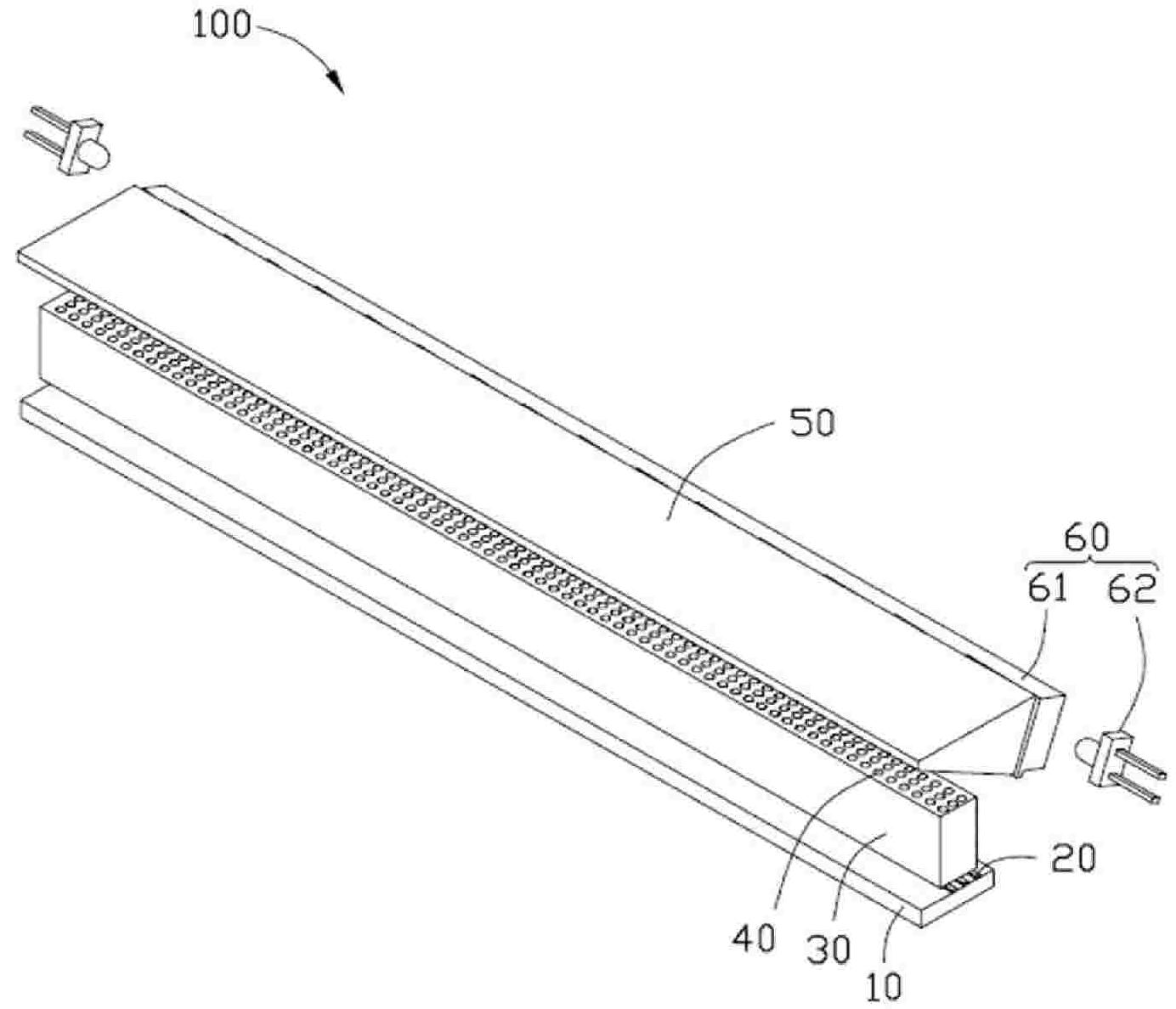

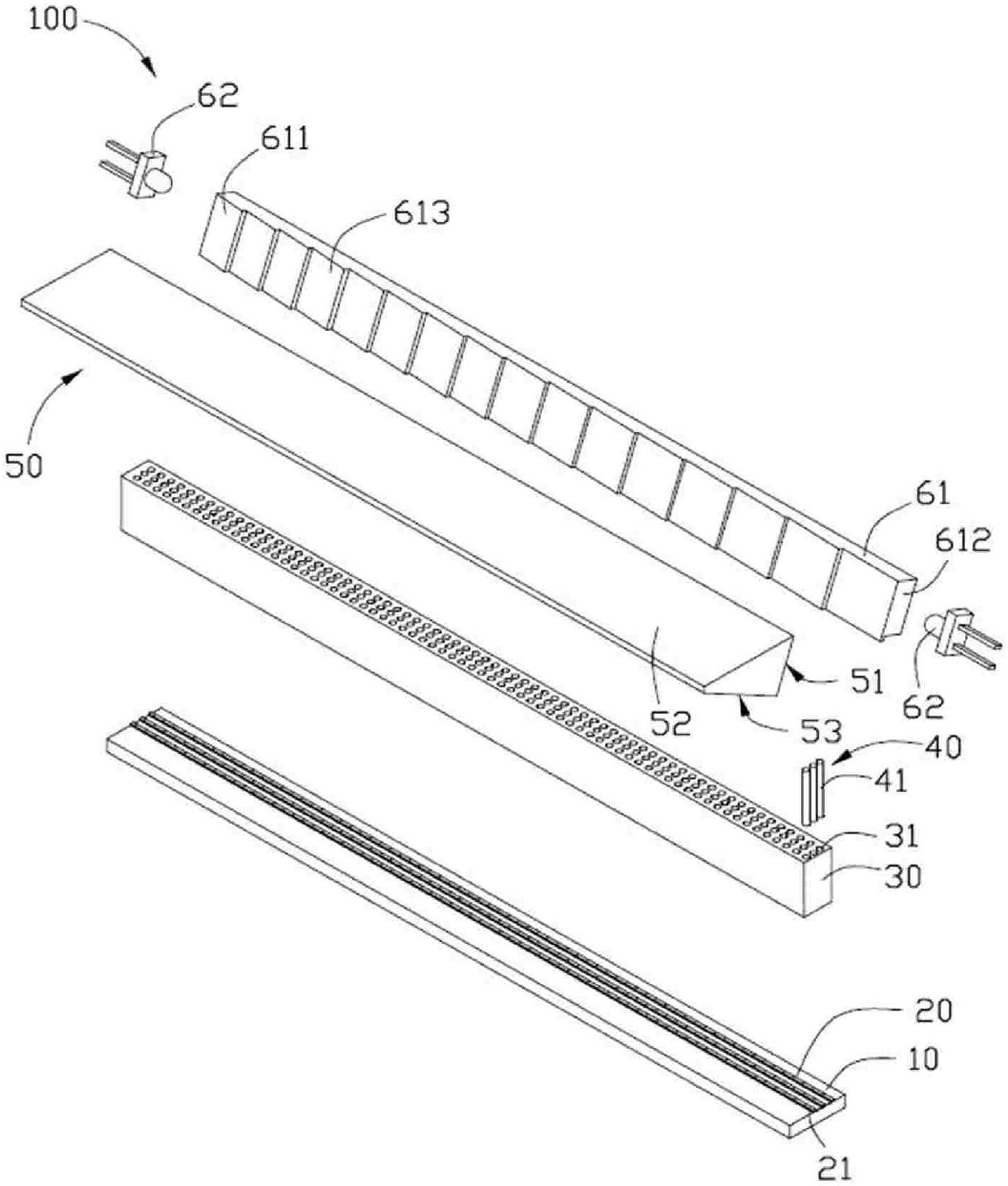

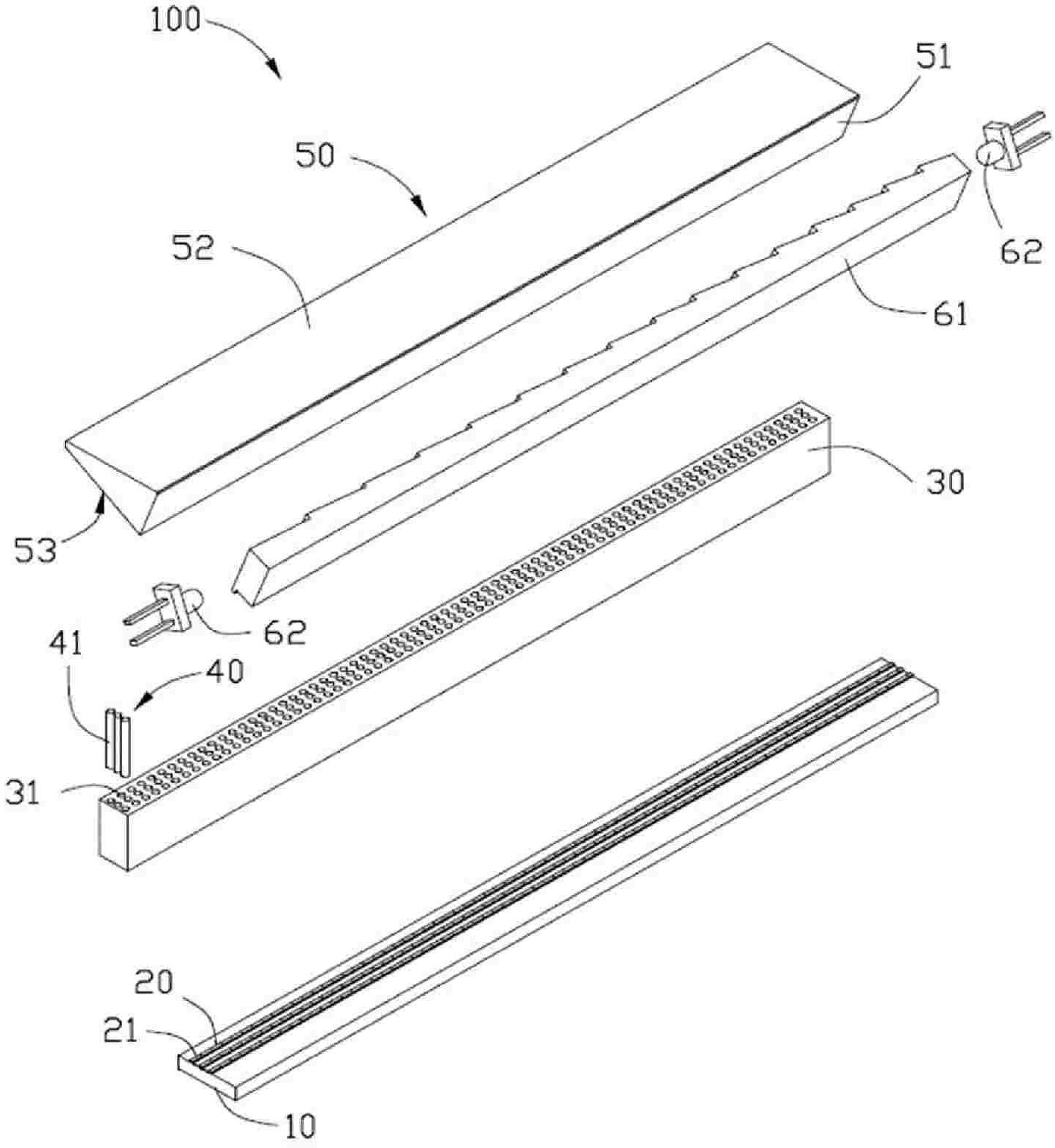

Light source module and display device

InactiveCN104747937AEvenly illuminatedImprove picture qualityMechanical apparatusElectric lightingLight guideLight beam

A light source module that includes a light guide strip, at least one light-emitting device, and a light guide plate (LGP) is provided. The light guide strip includes at least one light-incident end and a light-emitting surface. The light-emitting surface is at least one portion of a side surface of the light guide strip, and the side surface is adjacent to the light-incident end. The light-emitting device is located beside the light-incident end and configured to emit light that enters the light-incident end. The LGP is located beside the light guide strip and has a first surface, a second surface, and a light-incident surface. The second surface is opposite to the first surface, and the light-incident surface is connected to the first surface and the second surface and faces the light-emitting device. The light guide strip surrounds the light-incident surface. A display device is also provided.

Owner:E INK HLDG INC

Irregular part detection and positioning method

InactiveCN109631763AEvenly illuminatedEasy to analyzeUsing optical meansContour matchingComputer graphics (images)

The invention belongs to the field of visual inspection technologies and relates to an irregular part detection and positioning method. The method includes the following steps that: step 1, the template image of a part is collected, a contour matching algorithm for the template image is established; step 2, a transfer device transfers a part to be tested to a position under a photographing device;step 3, a strip light source lamp is turned on so as to perform auxiliary illumination; step 4, the image is binarized; step 5, contour matching algorithm operation is performed on the image, so thatposition information can be obtained; step 6, the position information is transmitted to an external device, and numerical display algorithm operation is performed on the position information, so that a readable position numerical value and angle numerical value are obtained. Therefore, the influence of ambient light can be eliminated, at the same time, an entire workpiece can be uniformly illuminated, and therefore, high-contrast image information can be obtained, so that software analysis can be facilitated; and therefore, with the above equipment, steps and algorithms adopted, manufacturing use costs can be controlled, and the accuracy of detection and positioning can be ensured.

Owner:东莞中科蓝海智能视觉科技有限公司

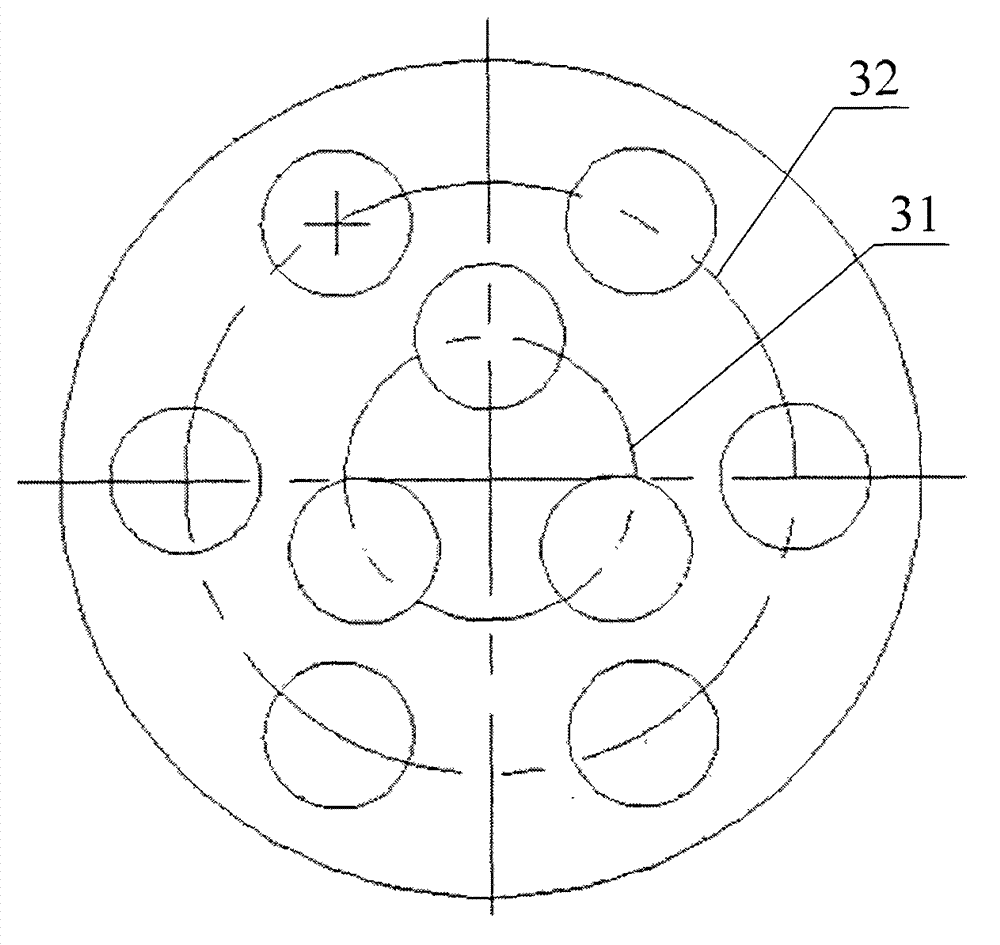

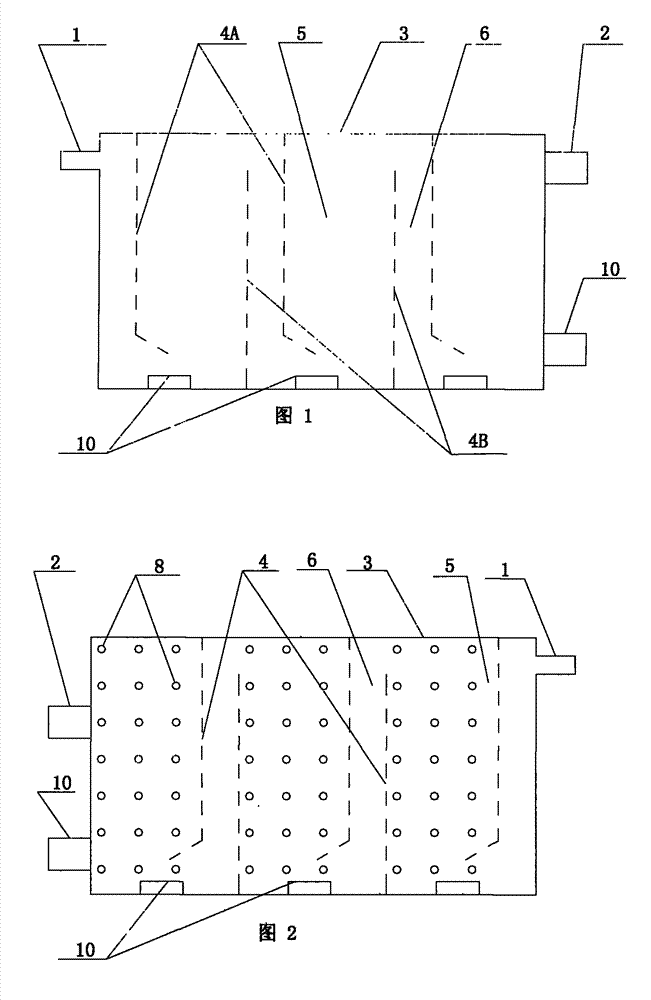

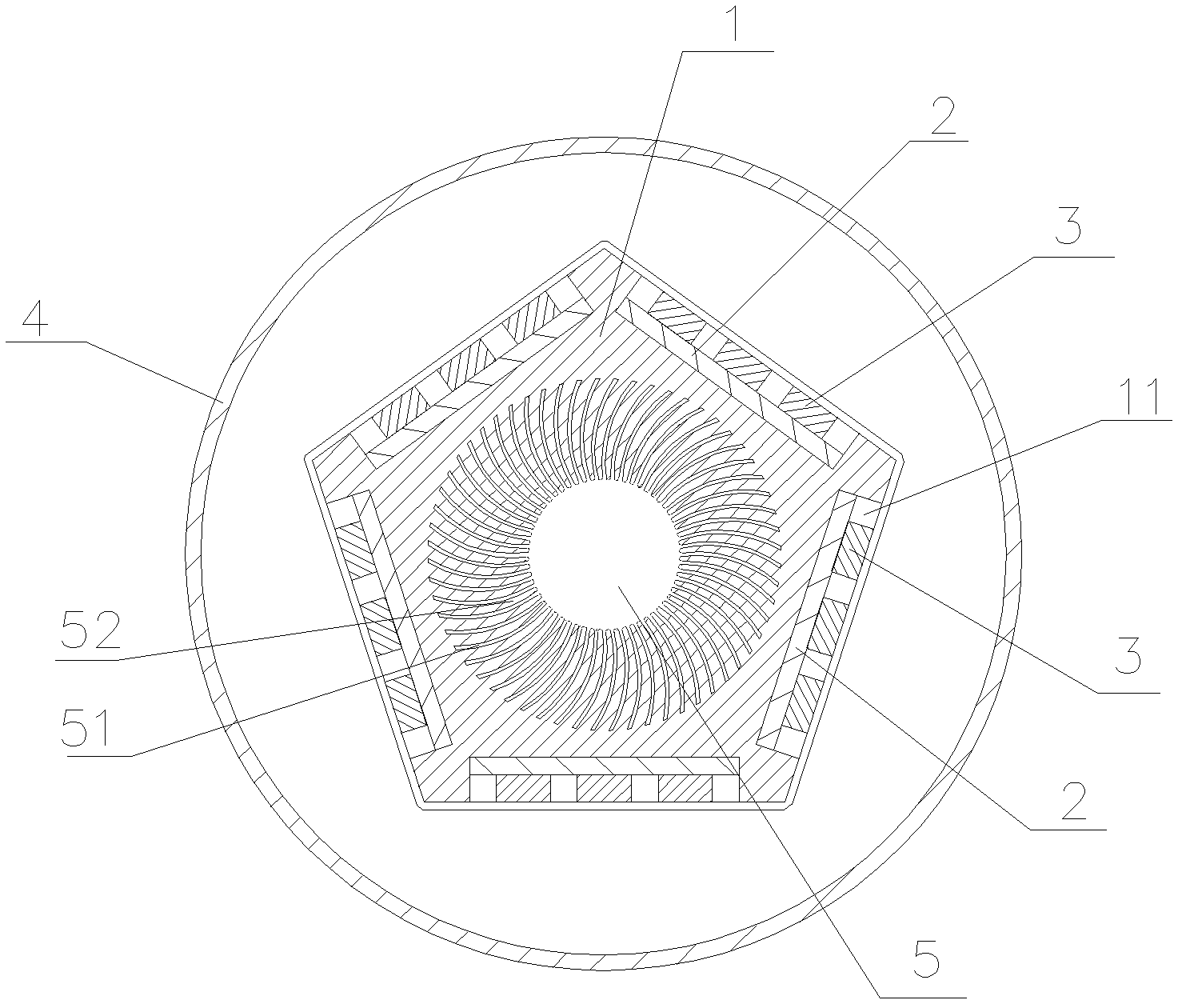

Continuous hydrogen production reactor with photosynthetic bacteria

InactiveCN101845387BExtended service lifeEasy to operateGas production bioreactorsMicroorganism based processesEngineeringPhotosynthetic bacteria

The invention relates to a continuous hydrogen production reactor with photosynthetic bacteria, which comprises a shell. The shell is provided with a feeding opening at one end and a discharging opening at the other end, the inner wall of the shell is alternately provided with an upper baffle plate and a lower baffle plate in a direction perpendicular to the flowing direction of feed liquid, a gap is formed between the lower end of the upper baffle plate and the bottom wall of the shell, a gap is formed between the upper end of the lower baffle plate and the top wall of the shell, the upper baffle plate and the lower baffle plate are longitudinally arranged to alternately divide the shell into an ascending area and a descending area, an illumination device is arranged in the shell corresponding to the ascending area, and an air collecting hole is arranged at the top of the shell. Due to the structure of the continuous hydrogen production reactor with photosynthetic bacteria, feed liquid flowing in the shell alternately passes by the descending area and the ascending area to alternately pass by a black environment (the descending area) and an illumination environment (the ascending area) so that the illumination device is needless to switch on or off occasionally, the operation process is greatly simplified, and the service life of the illumination device is prolonged.

Owner:HENAN AGRICULTURAL UNIVERSITY

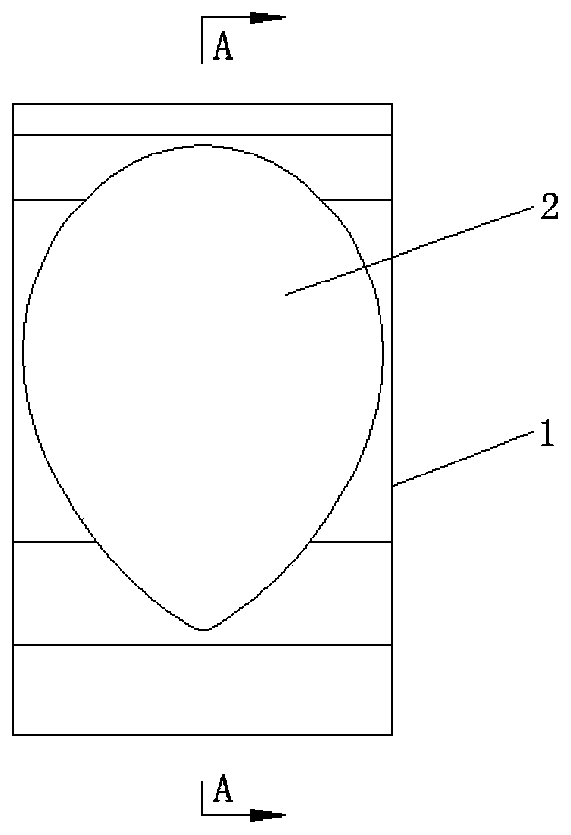

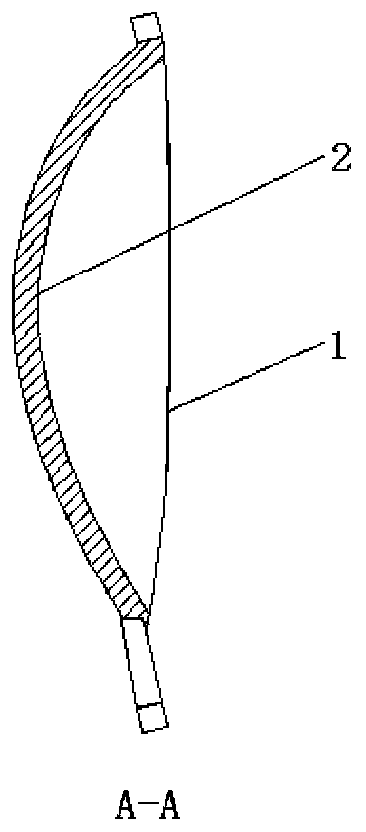

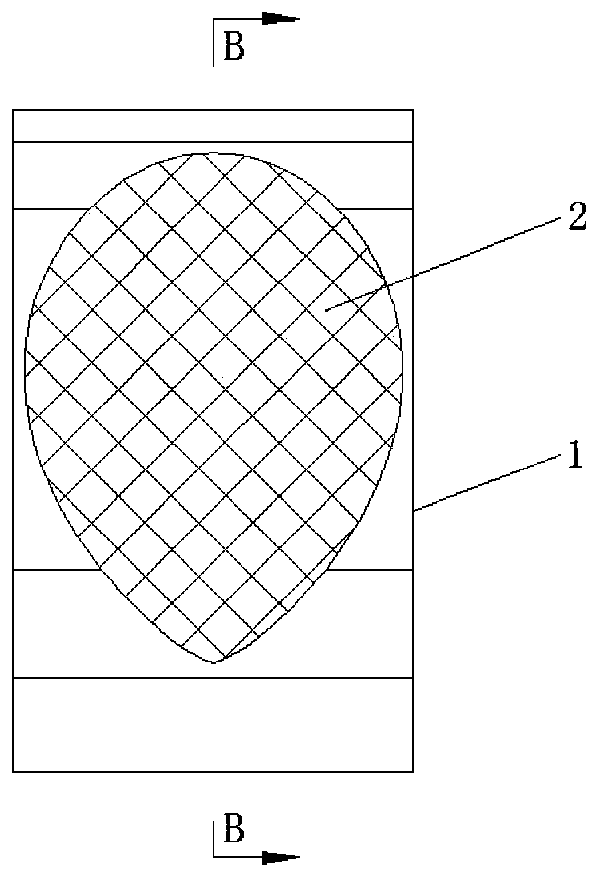

Special lens and glare-free blackboard lamp lighting system

PendingCN110242899AImprove lighting uniformityReduce macularLighting support devicesSemiconductor devices for light sourcesPhysicsLighting system

The invention discloses a special lens and a glare-free blackboard lamp lighting system, and relates to the technical field of classroom lighting devices. The special lens comprises a lens body, and a reflecting concave surface is arranged in the lens body; the outline of the outer edge of the reflecting concave surface is in a water drop shape. An arc part and a sharp part of the reflecting concave surface are respectively arranged at an upper end and a lower end of the reflecting concave surface. The glare-free blackboard lamp lighting system comprises a plurality of strip-shaped reflecting bowls which are positioned obliquely above a blackboard, one surface, close to the blackboard, of each strip-shaped reflecting bowl is provided with a plurality of the special-shaped lenses, and the glare-free blackboard lamp lighting system also comprises a PCB which is arranged close to the special-shaped lenses and is parallel to the blackboard, and a plurality of LED light sources which are in one-to-one correspondence with the reflecting concave surfaces of the special-shaped lenses are arranged on the PCB. The invention has the advantages of simple structure, no glare pollution and good illumination uniformity.

Owner:成都瀚德胜邦光学有限公司

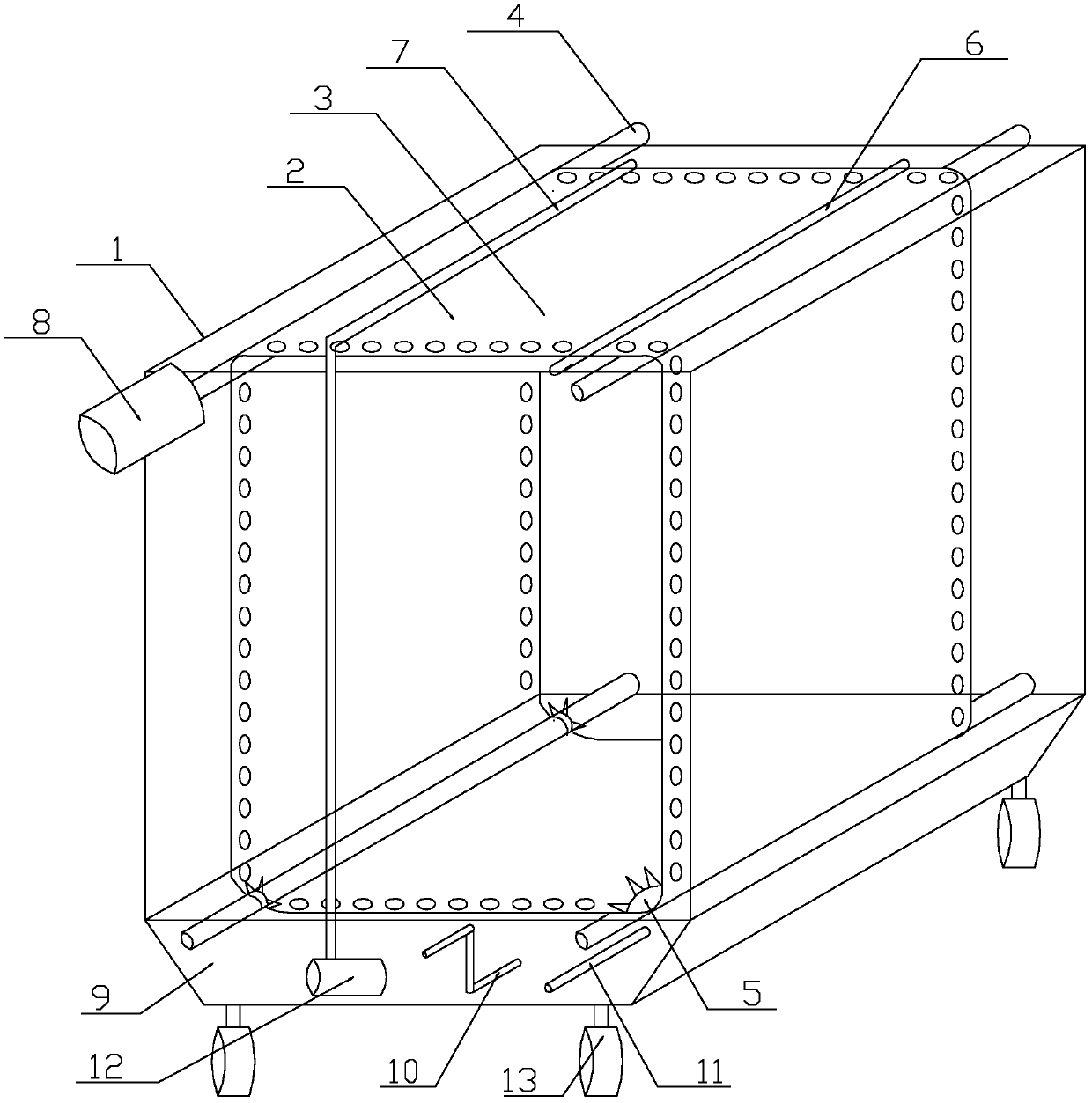

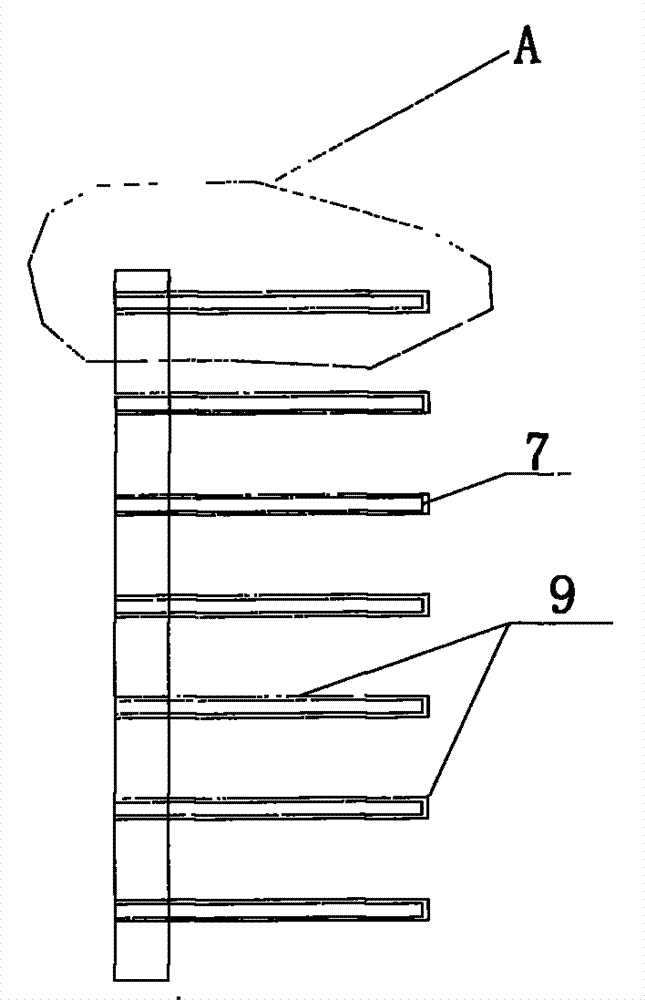

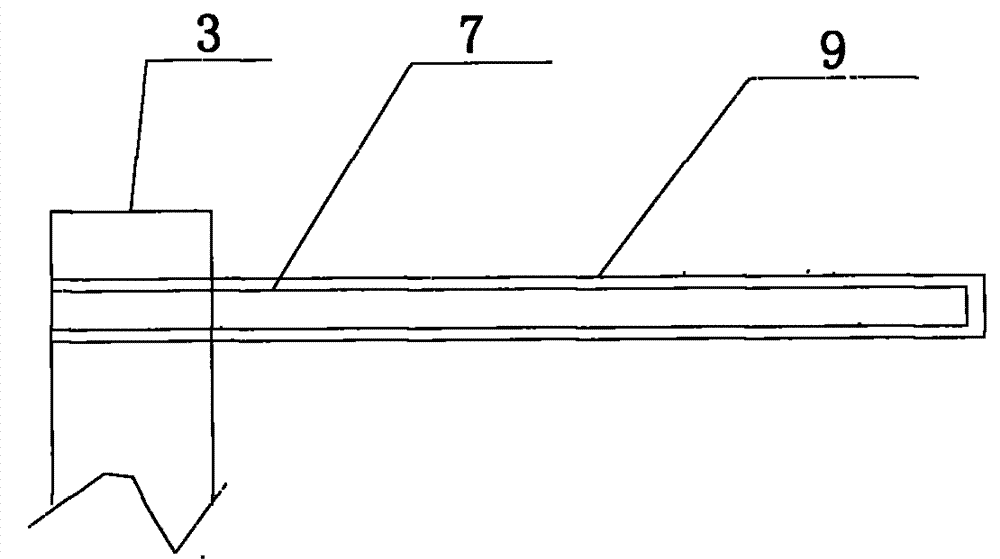

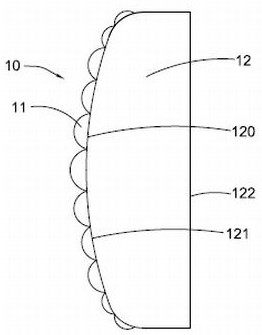

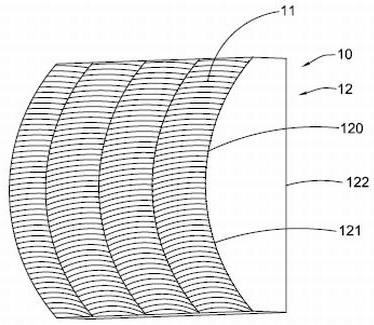

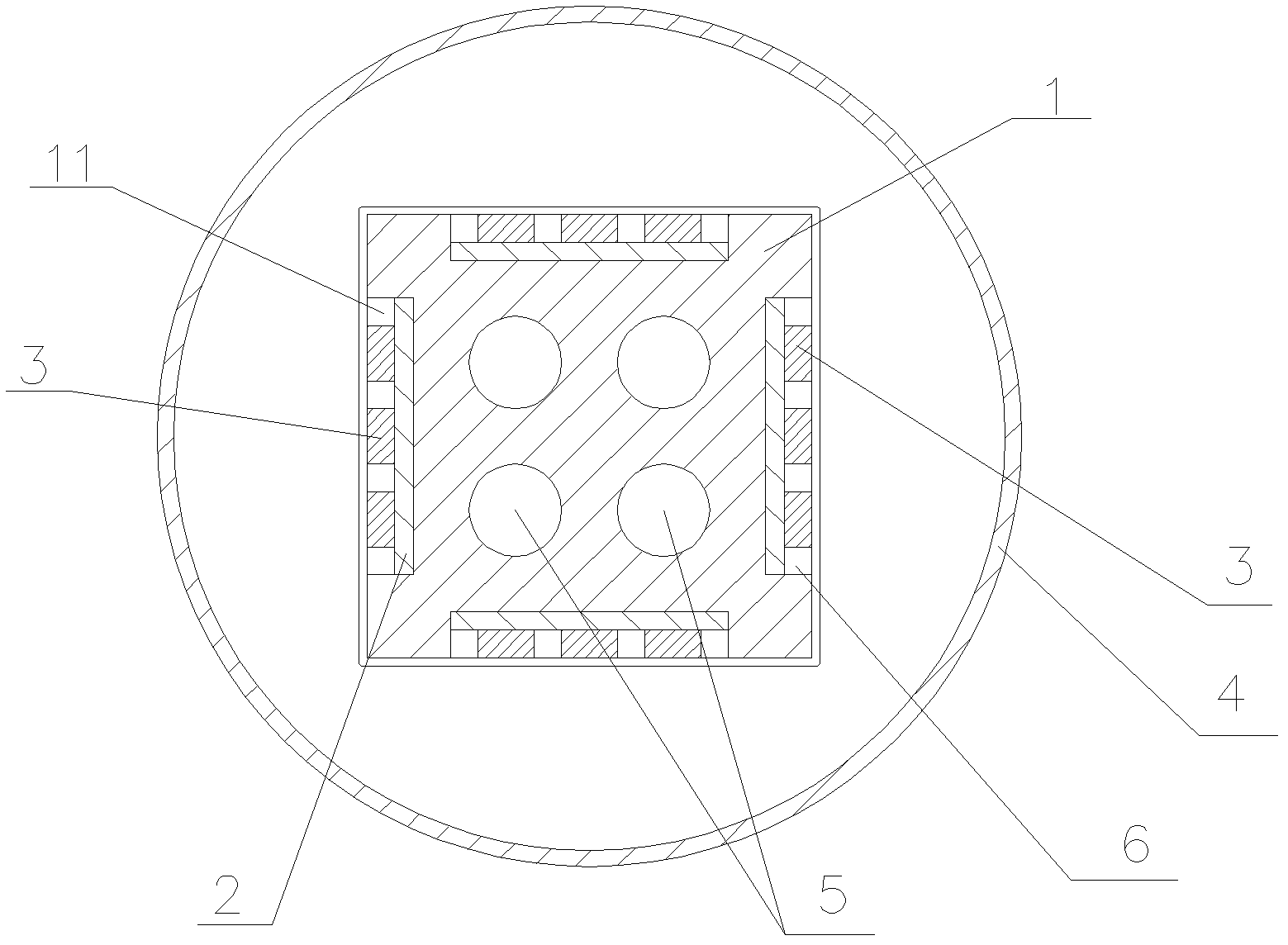

Multilayer semi-dry adherent culture device and culture method

InactiveCN105018330AReduce water consumptionAchieve ultra-high density cultureBioreactor/fermenter combinationsBiological substance pretreatmentsFisheryDistributor

The invention belongs to the field of microalgae culture and specifically relates to a multilayer semi-dry adherent culture device provided with multilayer adherent culture units. The adherent culture units are arranged horizontally or arranged forming a certain inclination angle from the horizontal plane, and one end of each multilayer adherent culture unit is aligned and the multilayer adherent culture units are parallelly arranged on a bracket system. Lengths of the multilayer adherent culture units are progressively increased successively from top to bottom, and the multilayer adherent culture units are driven by a motor to rotate. During operation of the device, a microalgae seed solution is firstly sprayed through a microalgae inoculators onto each layer of the adherent culture unit successively; a medium drips onto culture surfaces of all the adherent culture units through a medium distributor, and the surplus liquid returns back to a medium collecting tank under the action of gravity so as to be repeatedly used; and when an algae mud scraper is used for harvesting algae mud, the blade sticks close to the surfaces of the adherent culture units, and algae mud is scrapped off into an algae mud collecting tank with rotating of the adherent culture units. According to the invention, the problem of uneven light distribution is solved, the device is convenient for inoculation and harvesting, and efficient utilization of luminous energy is realized.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Light field modulator and modulation method thereof

ActiveCN111679439AEvenly illuminatedIncrease profitUsing optical meansLensLight energyMaterials science

The invention discloses a light field modulator and a modulation method thereof. The light field modulator comprises at least one dodging element and a curved-surface light-transmitting substrate. Thecurved-surface light-transmitting substrate is provided with at least one curved surface; and the dodging element is correspondingly arranged on the curved surface of the curved-surface light-transmitting substrate, so that the microstructure of the dodging element is arranged along the curved surface of the curved-surface light-transmitting substrate and is used for homogenizing light emitted bya light source, and the light can uniformly and efficiently illuminate the corresponding target area; and the utilization rate of light energy is improved.

Owner:SHANGHAI NORTH OCEAN PHOTONICS CO LTD

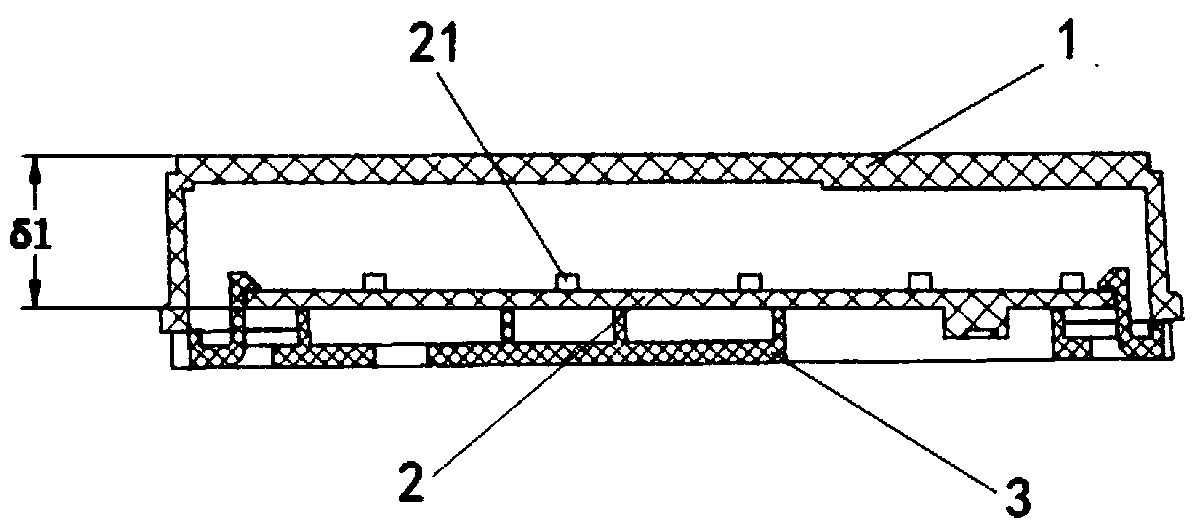

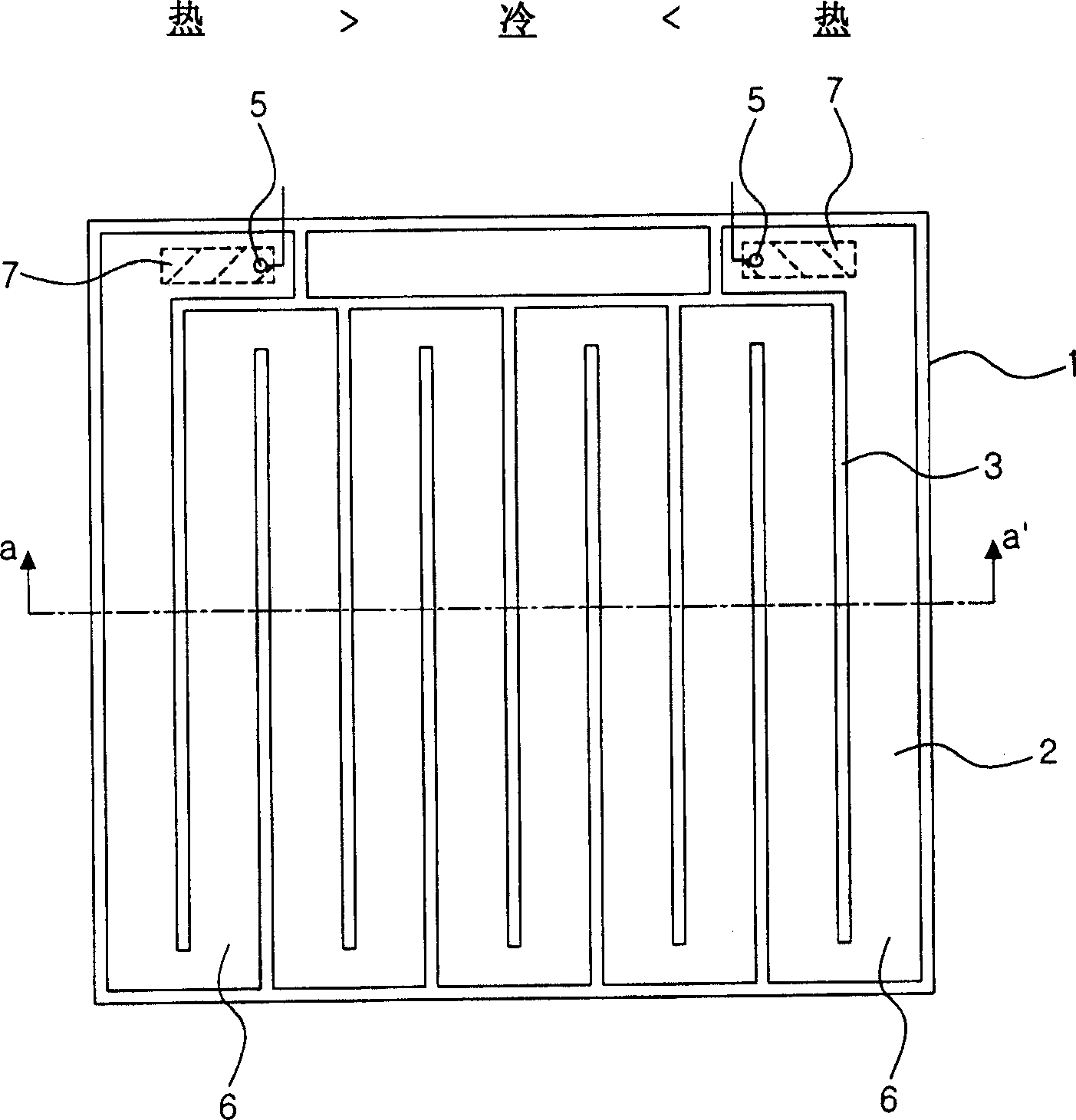

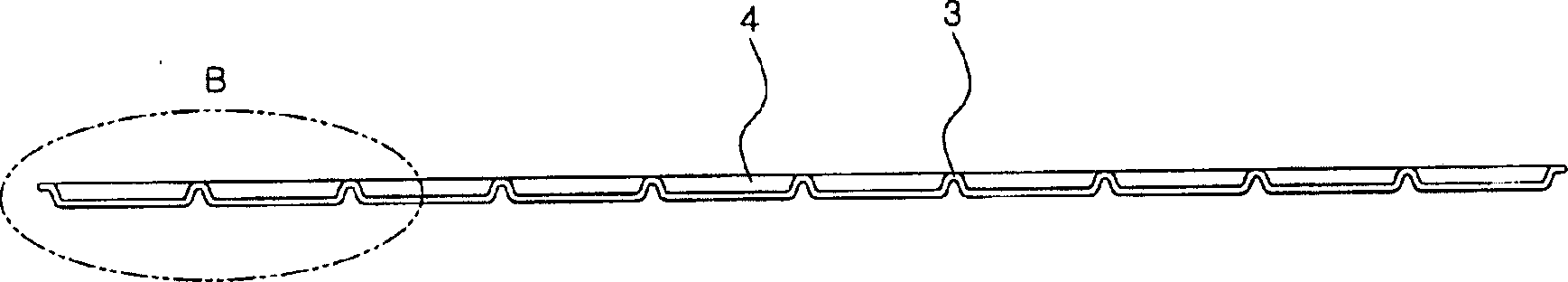

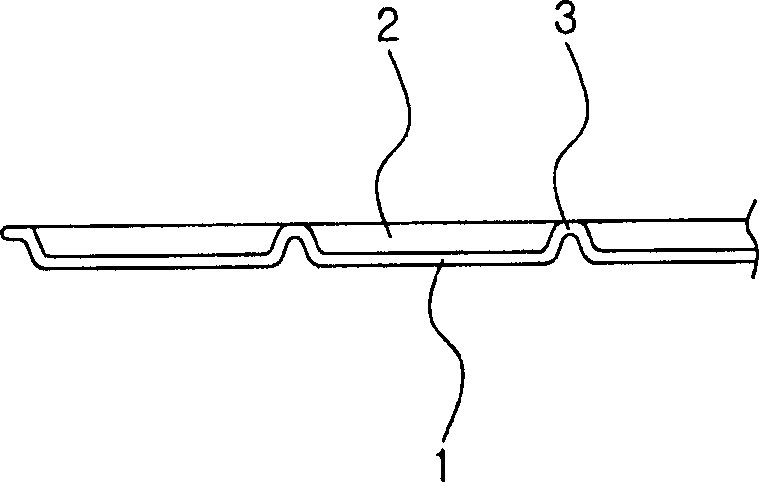

Channel structure of flat fluorescent lamp

InactiveCN1902536AIncrease brightnessImprove light efficiencyGas discharge lamp detailsNon-linear opticsLight sourceEngineering

A channel structure of a flat fluorescent lamp is disclosed. The channel structure of the flat fluorescent lamp is configured such that the lamp is suitable for being used as a backlight unit for flat displays, such as LCDs, or as a widerange light source to evenly illuminate wide flat surfaces, such as wide rectangular surfaces. In the channel structure of the flat fluorescent lamp, a sealed discharge space having a continuous serpentine shape and being partitioned into a plurality of communicating discharge channels by a plurality of partition walls is defined, with one or more electrodes provided in the discharge space. The discharge channels have different widths which are reduced in a direction away from a hot electrode.

Owner:MEDICAL RESEARCH COUNCIL

Improved bulb light

InactiveCN105402617AImprove corrosion resistanceExtended service lifeElectrical apparatusElectric circuit arrangementsAnode voltageEffect light

The invention provides an improved bulb light and belongs to the technical field of lighting. The improved bulb light comprises a light base, a light cap arranged below the light base, a spherical lightshade, a light-emitting mechanism and a control panel, wherein the lampshade and the light base form a containing cavity in a defining mode; the light-emitting mechanism is arranged inside the containing cavity; the light-emitting mechanism comprises multiple horizontally arranged first light-emitting light sources and multiple vertically arranged second light-emitting light sources; the light-emitting light sources are sequentially connected in series to form a single loop; the control panel is detachably installed at the bottom of the light base and provided with a control circuit which is electrically connected with the light cap and the loop where the light-emitting light sources are located; the control circuit comprises a first signal input module, a second signal input module, a signal processing module, a signal output module, an anode voltage input end and a cathode voltage input end. The improved bulb light has the advantages of being reasonable in design and good in lighting effect.

Owner:NINGBO DUOLIPU IND & TRADE CO LTD

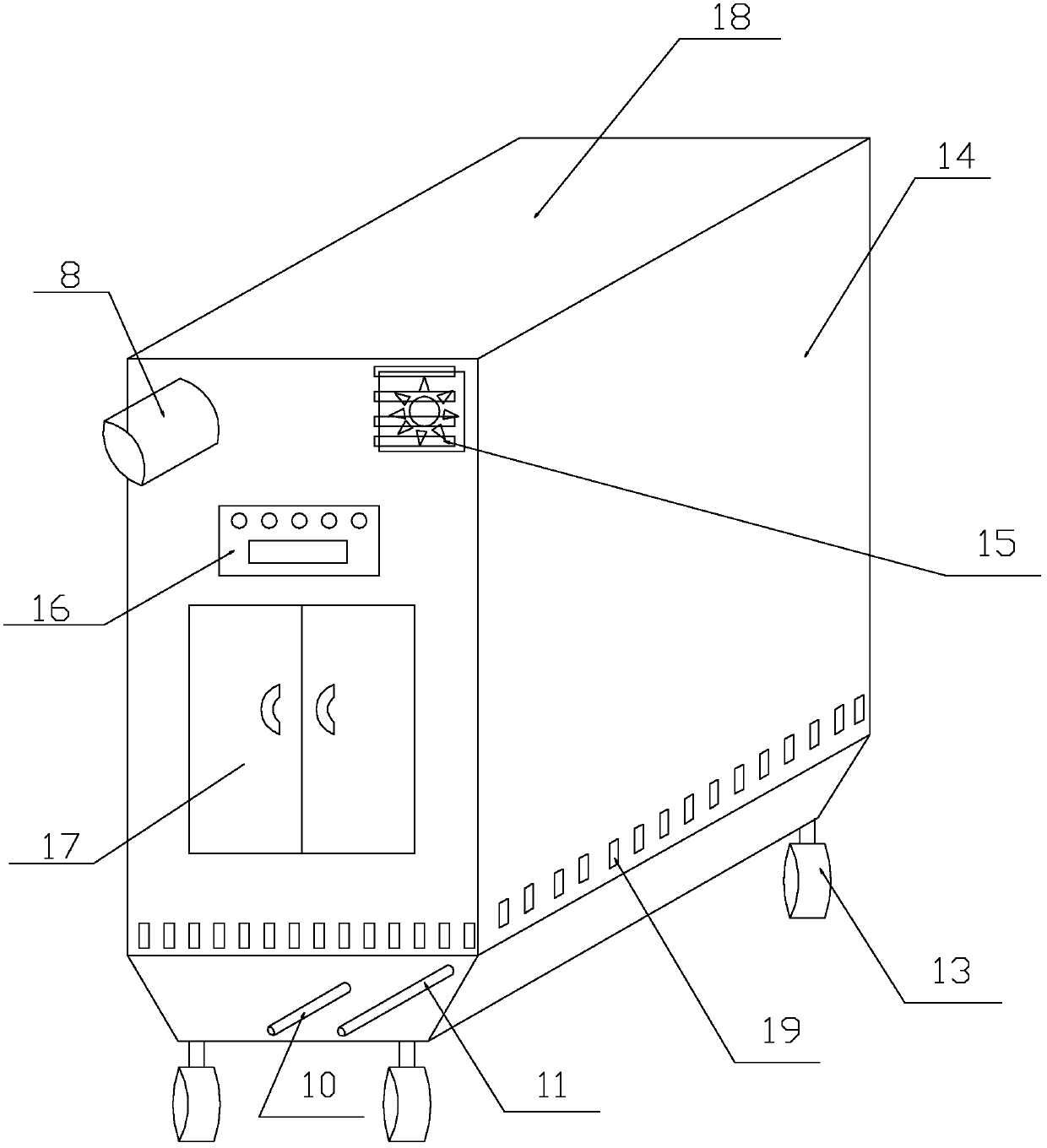

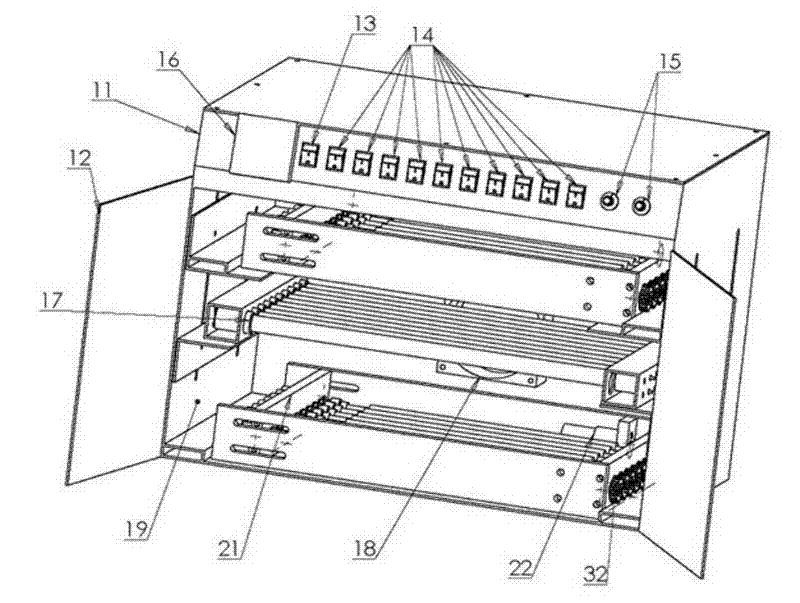

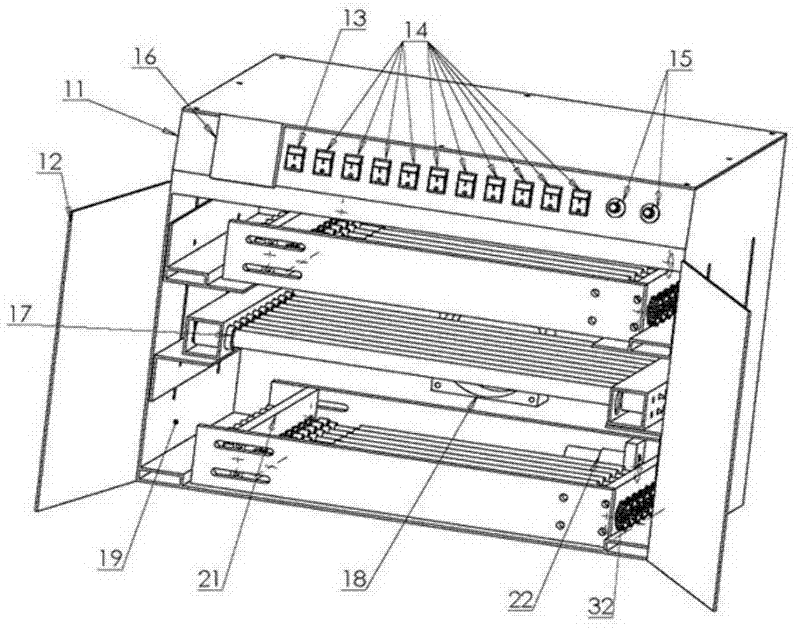

Continuous uniform rotating illumination device for surface treatment of rubber rollers

The invention discloses a continuous uniform rotating illumination device for surface treatment of rubber rollers. The illumination device comprises a box shell, a light source, a rubber roller rotating bracket, an electric control device and a fan; a box door and the electric control device are arranged at the front side of the box shell, and the fan is arranged at an exhaust port at the rear side of the box shell; the light source is fixedly arranged at the inner middle part of the box shell, and the rubber roller rotating bracket capable of being freely pulled out or pushed is arranged above or / and below the light source; and centers on which a plurality of rubber rollers can be arranged are arranged in pairs in the rubber roller rotating bracket, and the center at one end is in transmission connection with the output shaft of a motor through a transmission mechanism. The illumination device has the advantages of small volume, high efficiency, simplicity and convenience in operation and uniformity in illumination of the surfaces of the rubber rollers. After the illumination device works, operators can leave the site; and after the exhaust fan works for certain time and the ozone is basically exhausted, the operators enter to work. By the design, the operators can be fully protected from being injured by ultraviolet light and high-concentration ozone.

Owner:BEIJING LASER HI TECH CO LTD

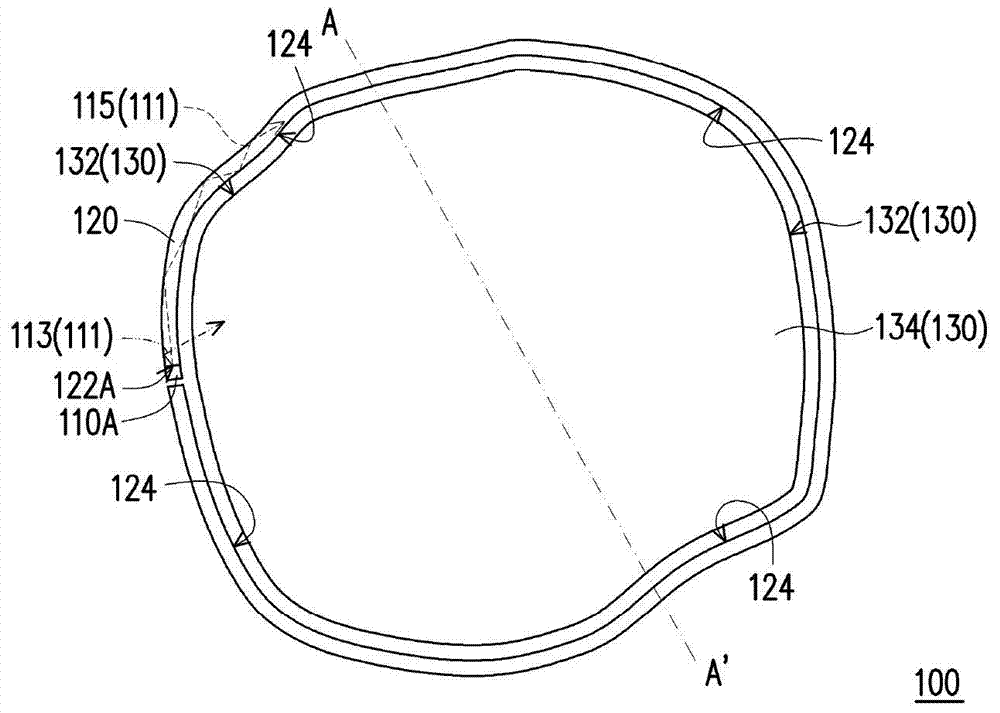

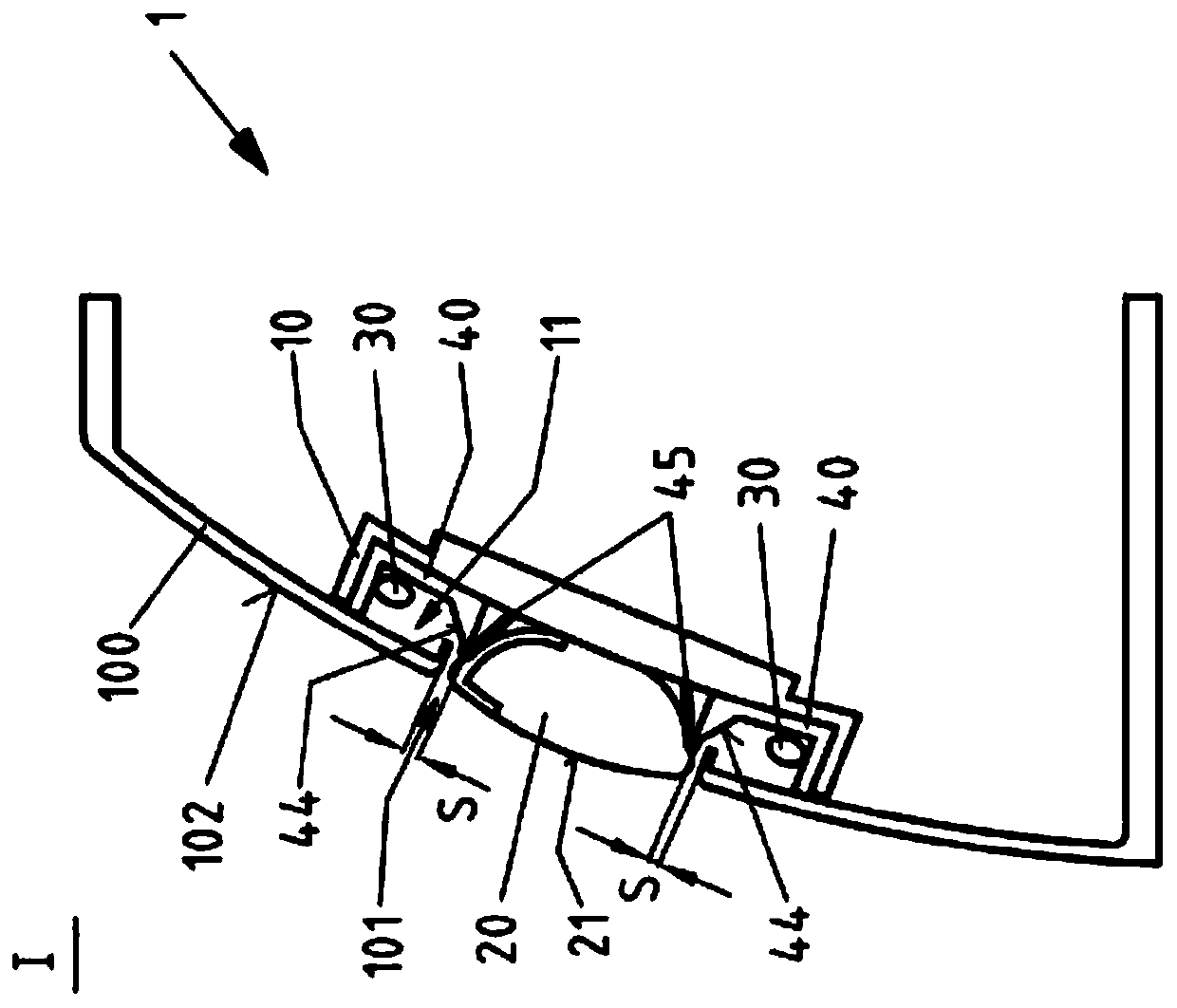

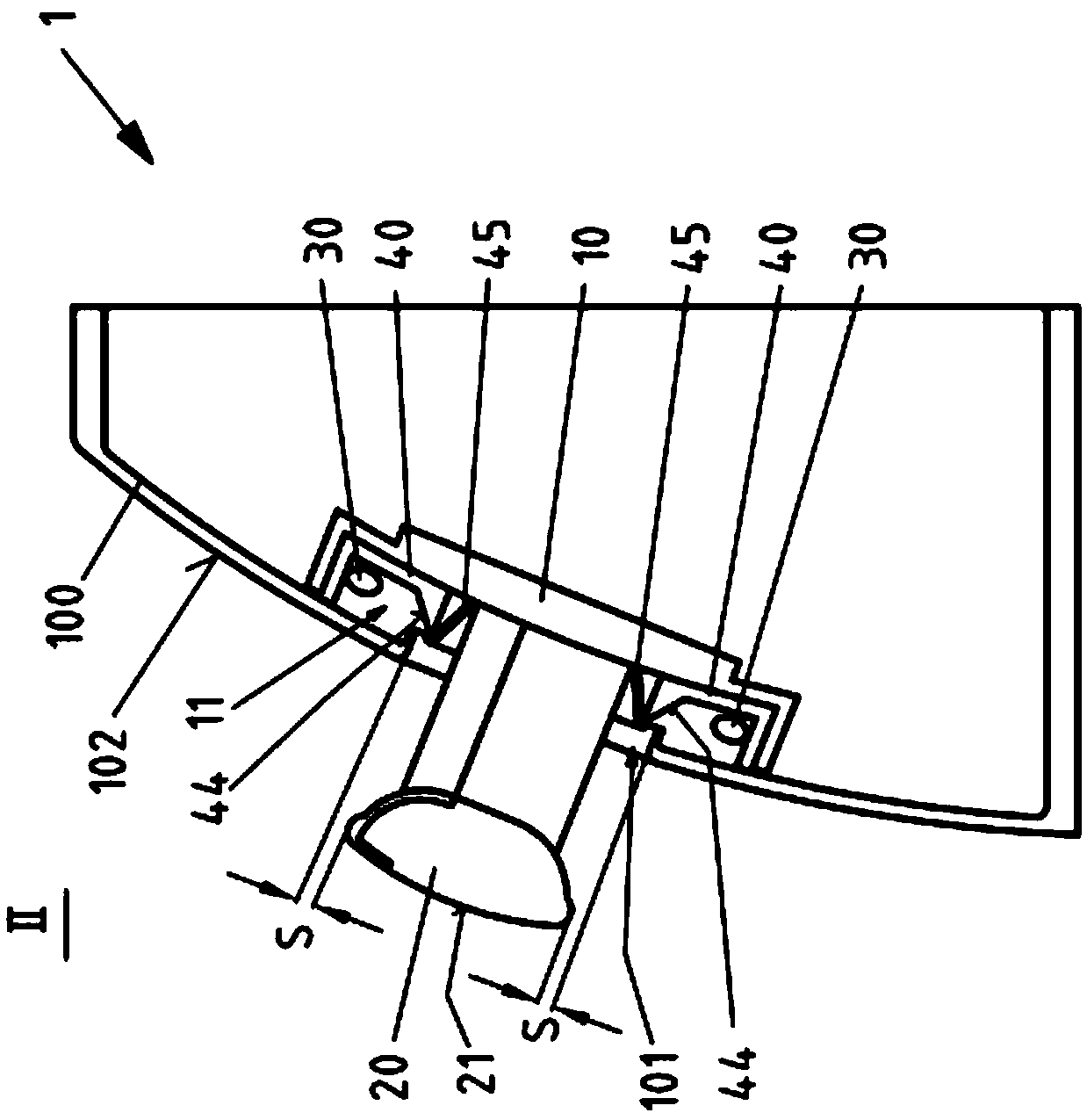

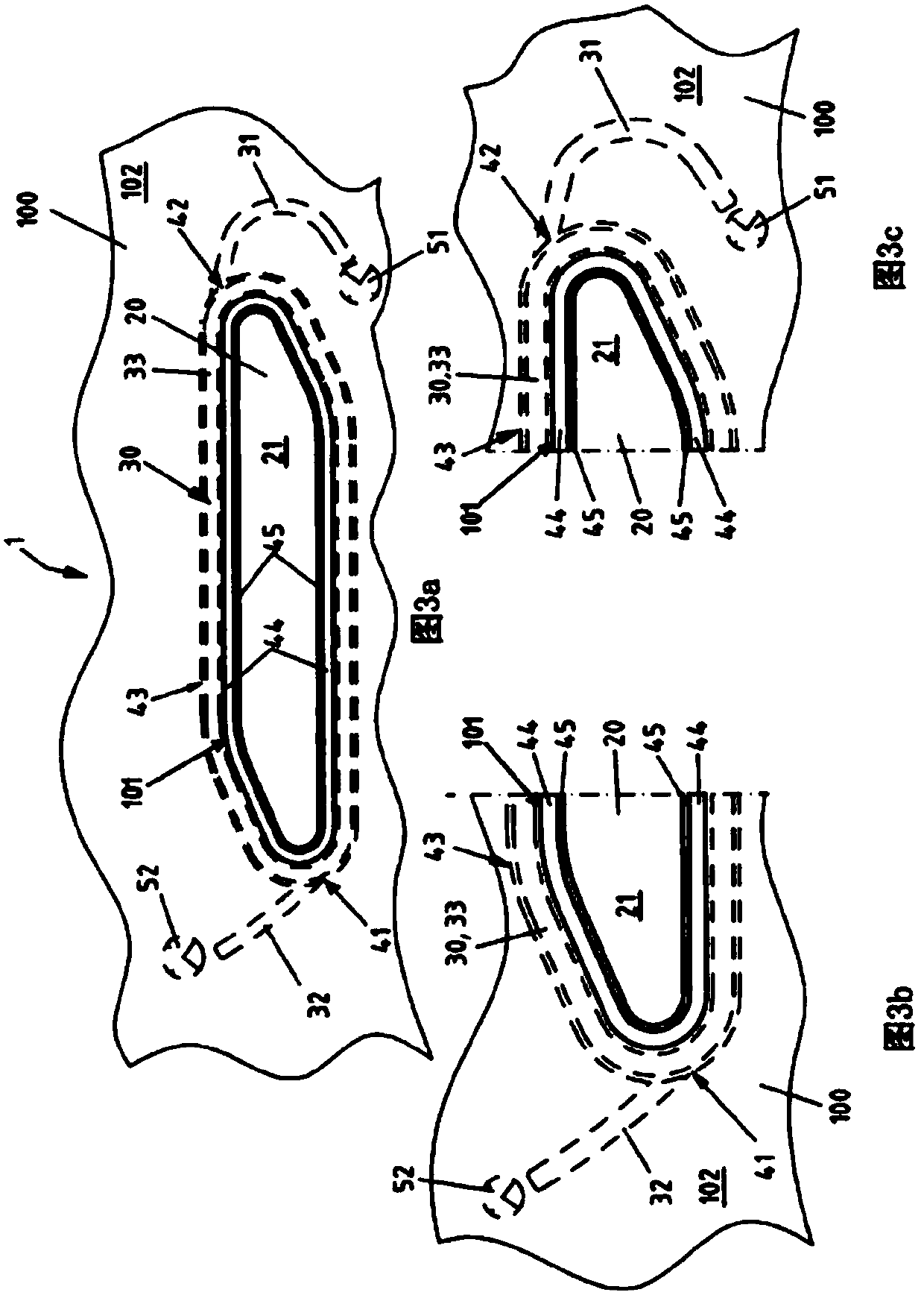

Handle device

ActiveCN109642441AReduce light intensityAchieve lightingVehicle locksLighting and heating apparatusElectrical and Electronics engineeringCar door

The invention relates to a handle device (1) for a movable part (100), in particular a motor vehicle door (100) of a motor vehicle, which is implemented with a carrier element (10), wherein a receptacle (11), which can be arranged on an opening (101) in the removable part (100), is formed on the carrier element (10), wherein an in particular surface-flush door handle (20) for actuating the movablepart (100) is movably mounted on the carrier element (10), and wherein the door handle (20) is formed in such a way that a front-side gap (S) is adjustable between the opening (101) in the movable part (100) and the door handle (20). To this end, according to the invention, an optical fiber (30) is arranged on the carrier element (10), in order to illuminate the door handle (20) indirectly through the gap (S).

Owner:HUF HULSBECK & FURST GMBH & CO KG

Contact image sensing module

InactiveCN102098409ACompact structureSmall footprintPictoral communicationLight-emitting diodeGlass sheet

The invention discloses a contact image sensing module, which comprises a contact image sensing element, a lens group, a glass plate and a light-emitting diode (LED) light source. The glass plate has a wedge-shaped cross section and comprises an incident plane, a first emergent plane and a second emergent plane; the LED light source is arranged on one side of the incident plane of the glass plate; the lens group is positioned between the second emergent plane of the glass plate and the contact image sensing element; light rays emitted from the LED light source enter the glass plate from the incident plane of the glass plate; one part of light rays entering the glass plate from the incident plane are directly emitted from the first emergent plane of the glass plate so as to irradiate an object to be scanned; and the other part of light rays entering the glass plate from the incident plane are reflected through the second emergent plane and are emitted from the first emergent plane so as to irradiate the object to be scanned. The contact image sensing module is compact in structure and smaller in occupied space, and can uniformly irradiate the object to be scanned in a wide range.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Heat-dissipating led lamp with multiple light-emitting surfaces

InactiveCN102287652AImprove luminous performanceIncrease usagePoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

The invention discloses a heat-dissipation-type LED (light-emitting diode) lamp with multiple light-emitting surfaces. The heat-dissipation-type LED lamp comprises a heat sink, an aluminium base plate, a lampshade and a lamp bead arranged on the aluminium base plate, wherein the heat sink is a polygonal column body, and the aluminium base plate is correspondingly arranged on each side of the heat sink; and the lampshade is an olivary convolution body, the upper and lower ends of the lampshade are provided with locating holes which are matched and fixed together with the heat sink by virtue of fasteners, and the heat sink is internally provided with an outer through heat dissipation channel. The LED lamp provided by the invention has the advantages of wide irradiating surface, good heat dissipation effect, long service life and the like.

Owner:OUTRACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com