Continuous hydrogen production reactor with photosynthetic bacteria

A technology for hydrogen production reactors and photosynthetic bacteria, applied in photobioreactors, gas production bioreactors, biochemical instruments, etc., can solve problems such as light penetrating reactor volume limitations, prolong service life and simplify operation The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

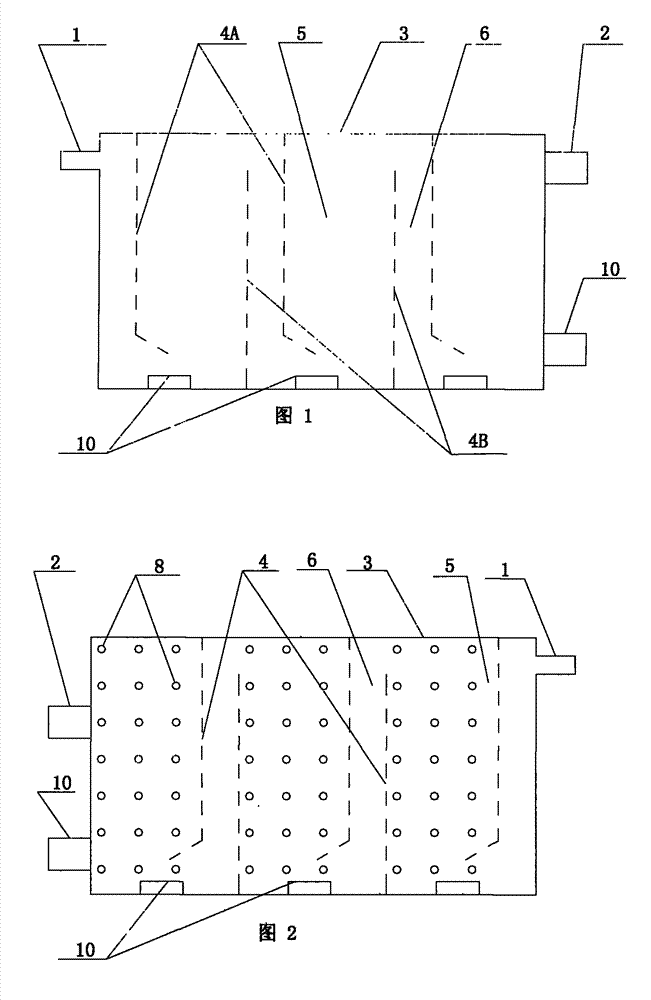

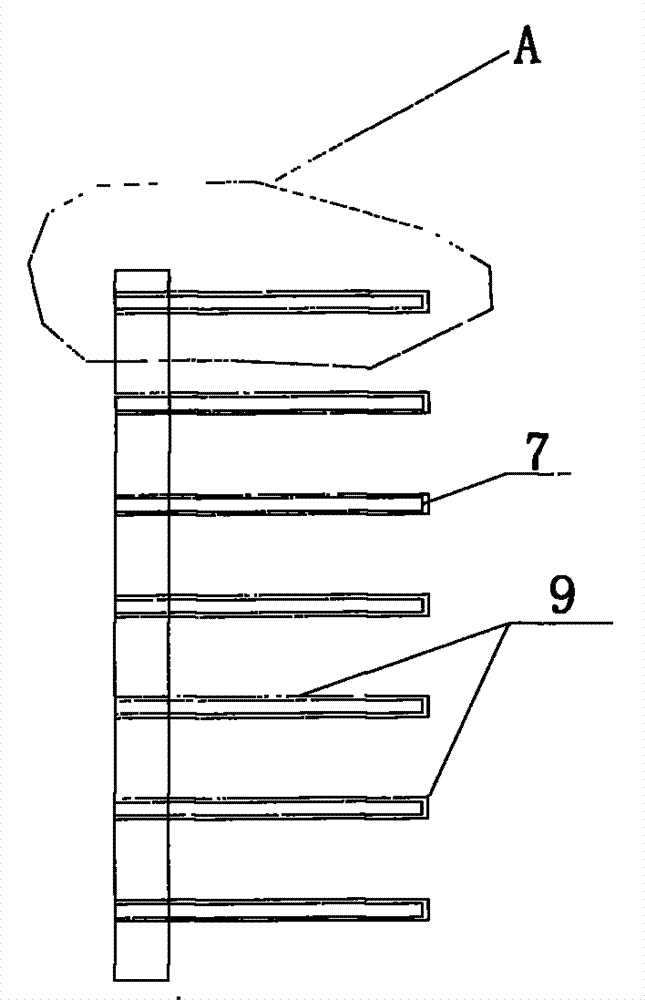

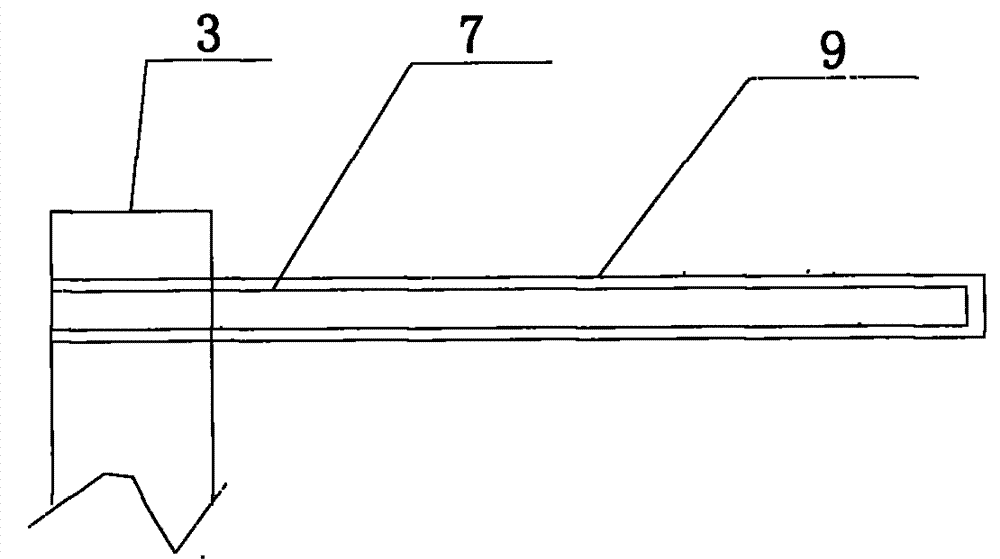

[0021] Such as figure 1 , figure 2 and Figure 5 As shown, the photosynthetic bacteria continuous hydrogen production reactor of the present invention includes a shell 3, a gas collection hole 12 is arranged on the top of the shell 3, and the aspect ratio of the shell 3 is greater than 1 / 2 and less than 1 / 1. One end of the housing 3 is provided with a material inlet 1 and the other end is provided with a material outlet 2. On the inner wall of the housing 3, upper baffles 4A and lower baffles 4B are alternately arranged perpendicular to the flow direction of the feed liquid. The upper baffles The lower end of 4A is bent at an angle of 120 degrees and a gap is provided between the bottom wall of the housing 3, and a gap is also provided between the upper end of the lower baffle 4B and the top wall of the housing 3. The upper and lower baffles 4A, 4B is sealed with the housing 3, so that the upper and lower baffles 4A, 4B arranged vertically divide the inner space of the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com