Cover view gripper

A gripper and container technology, which is applied in the field of cover seat inspection and labeling device, can solve the problems that the sealing element is not closed correctly, the sealing element is not seated correctly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the various figures, the same components are always identified by the same reference numerals, so that they are only described once.

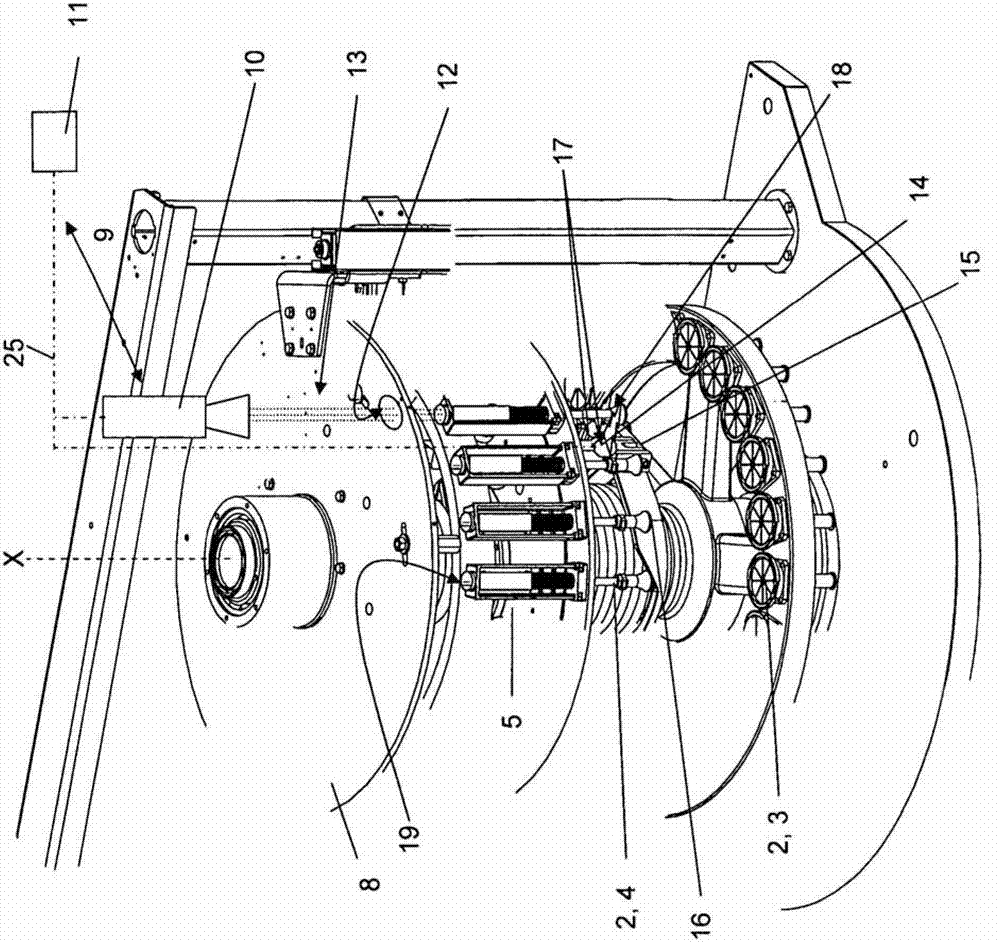

[0032] figure 1 A container handling device 1 is shown, in the exemplary embodiment as a labeling machine or a labeling carousel. The container handling device 1 has a plurality of centering devices 2 each having a standing surface 3 and a container gripper 4 .

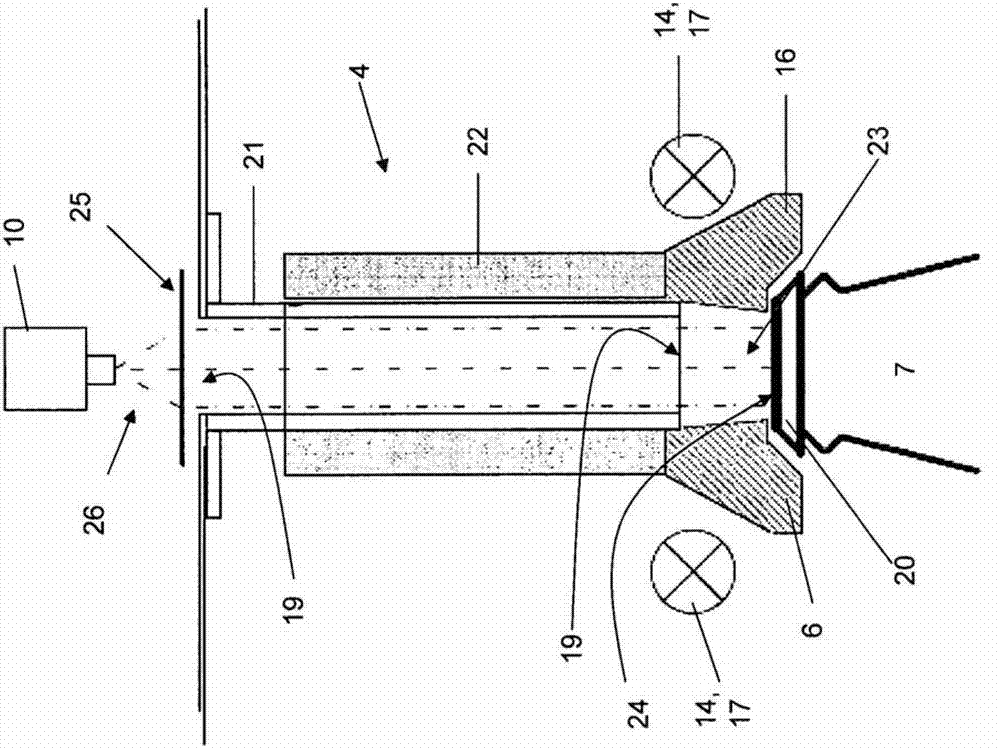

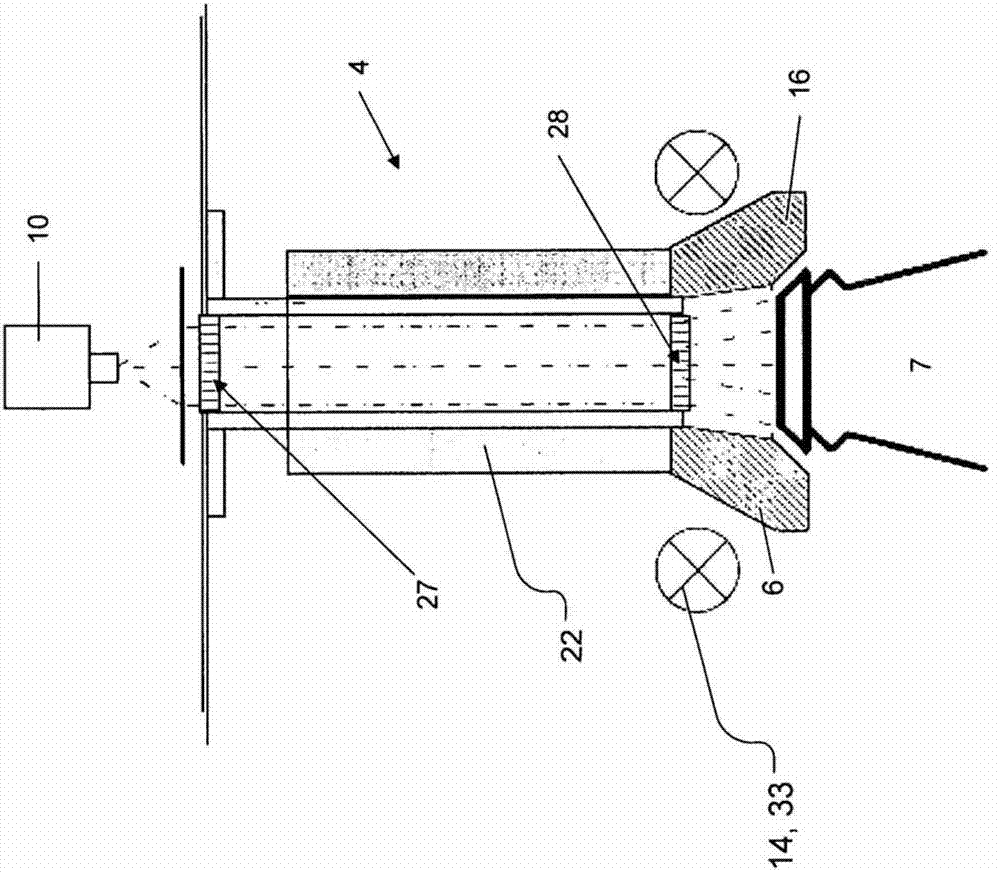

[0033] The standing surface 3 is provided in a known manner as a turntable 3 , wherein the container gripper 4 is mounted on a drive 5 so that the container gripper can be raised and / or lowered. The centering device 2 makes the container 7 ( Figures 2 to 4 ) eg the bottle is rotated about the central axis X of the container handling device 1 and the container is fed eg to a labeling machine. The container 7 stands with its bottom foot on the corresponding turntable 3 and the head of the container is held by means of the container gripper 4 . Figures 2 to 4 Only the neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com