LED (Light Emitting Diode) lamp

A technology of LED lights and LED light sources, applied in the field of LED lighting, can solve the problems of cumbersome assembly, complex structure of high-efficiency, large-angle LED bulbs, etc., and achieve the effect of simple structure and uniform light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

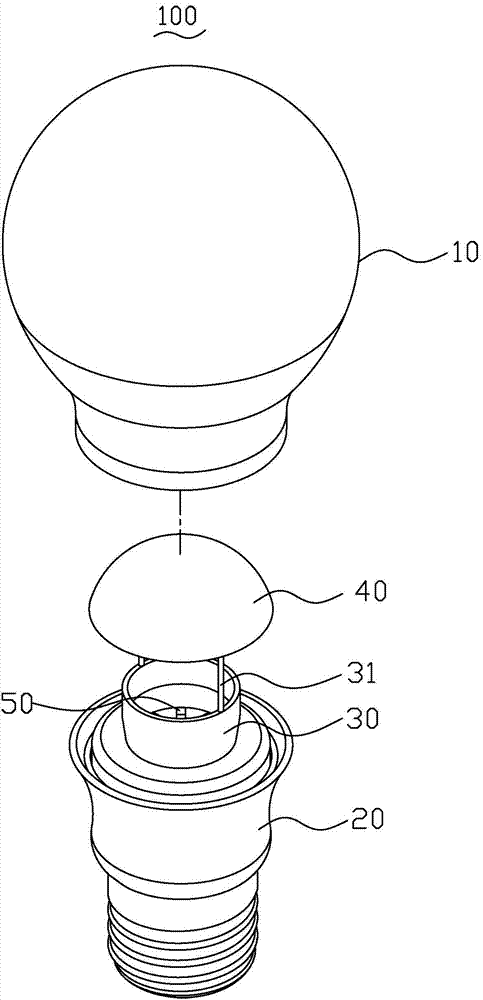

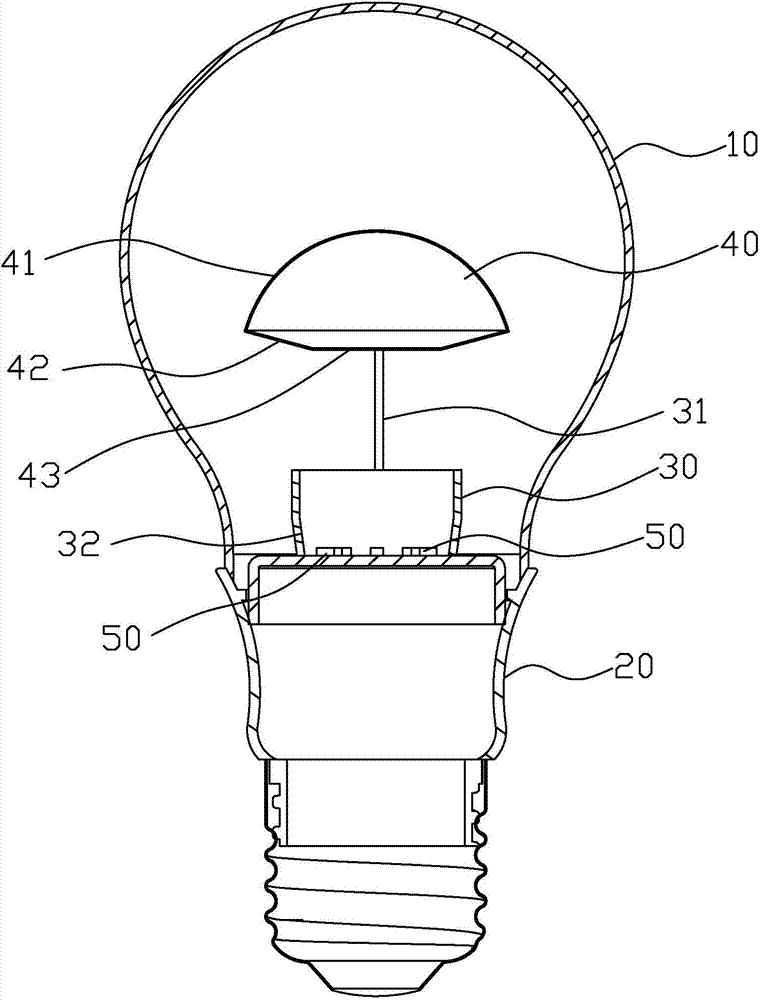

[0014] figure 1 It is a three-dimensional exploded view of the LED lamp according to the first embodiment of the present invention. The LED lamp 100 includes a lamp body 20, a bulb case 10, a plurality of LED light sources 50, and a light distribution member 40. These LED light sources 50 are arranged on the top of the lamp body 20. On the other hand, the bulb housing 10 is covered on the top of the lamp body 20 to accommodate the LED light sources 50 .

[0015] Please refer to figure 1 and figure 2 , these LED light sources 50 are arranged in a circular shape around the center of the top surface of the lamp body 20 , and the light distribution member 40 is arranged above these LED light sources 50 . The light distribution element 40 includes a light emitting portion 41 and a reflective portion 42 , and the light emitting portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com