Real-time fiber winding defect visual inspection device based on double CDDs

A visual inspection device and visual inspection technology are applied in the direction of measuring devices, optical instrument testing, and machine/structural component testing. It can solve the problems of slippage, long winding time, and low precision, so as to reduce production costs and improve optical fiber winding. The effect of improving the quality and defect detection efficiency and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

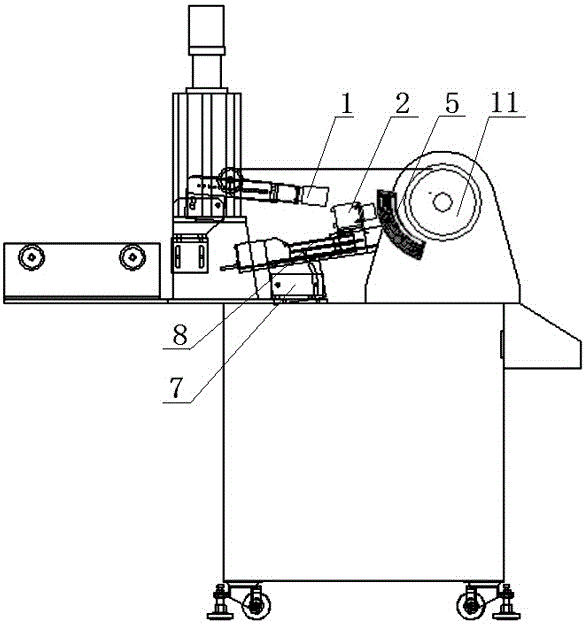

[0021] In the present invention, a visual detection unit is installed on the console of the original optical fiber winding 11 to detect the winding quality of the optical fiber. The optical fiber winding 11 to be detected is spindle-shaped, and the optical fiber winding 11 moves left and right during winding.

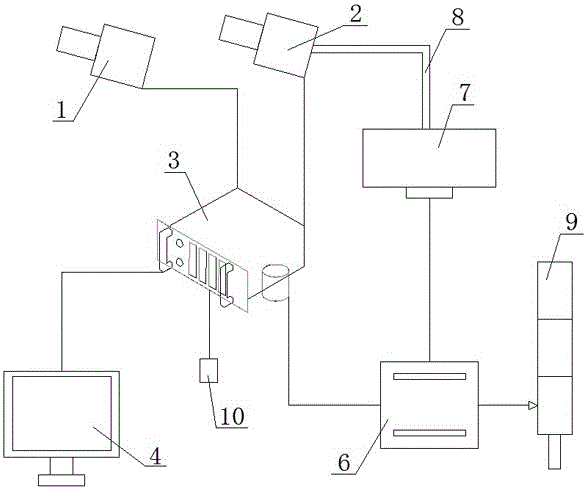

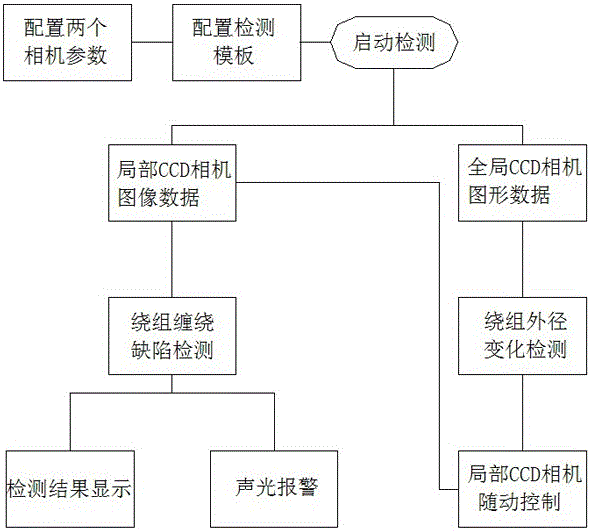

[0022] like Figure 1 to Figure 2 As shown, an embodiment of the present invention includes a visual detection unit, and the visual detection unit includes a global CCD camera 1 with a fixed position for collecting images of the entire fiber winding 11 and a position-adjustable global CCD camera 1 for collecting partial images of the fiber winding 11. A local CCD camera 2, the global CCD camera 1 and the local CCD camera 2 are electrically connected to the industrial computer 3 through a network cable, the industrial computer 3 is connected to the local CCD camera 2 through an electric drive unit, and the industrial computer 3 is connected to the display screen at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com