Mold special for wire harness winding, winding device and lamp manufacturing process

A winding device and winding technology, which is applied to lighting devices, lighting device parts, transportation and packaging, etc., can solve problems such as low production efficiency, inconsistent spacing between illuminants, and increase production costs, and achieve strict inspection processes. The effect of improving wire harness winding quality and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

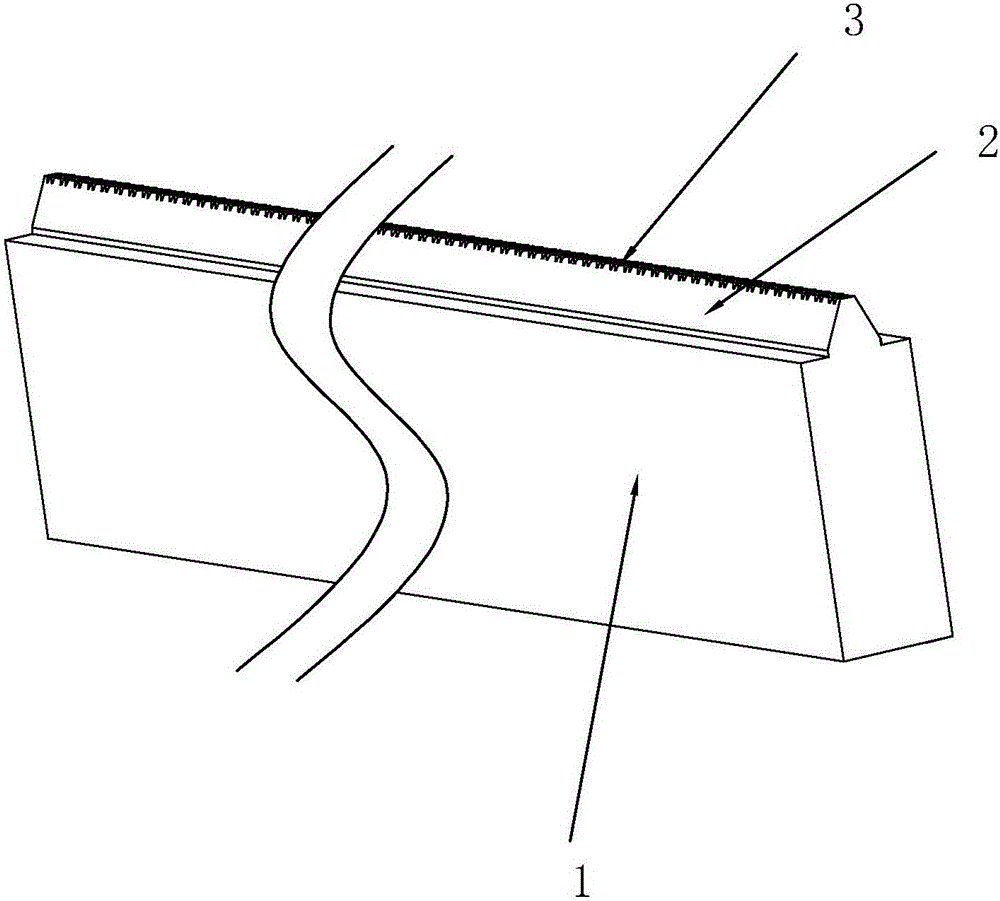

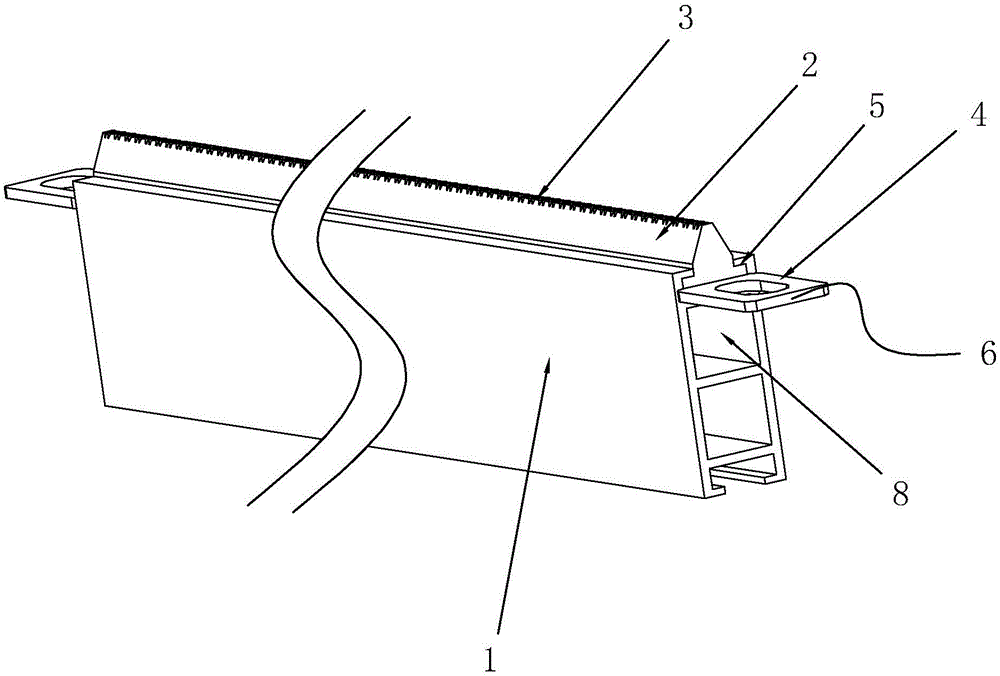

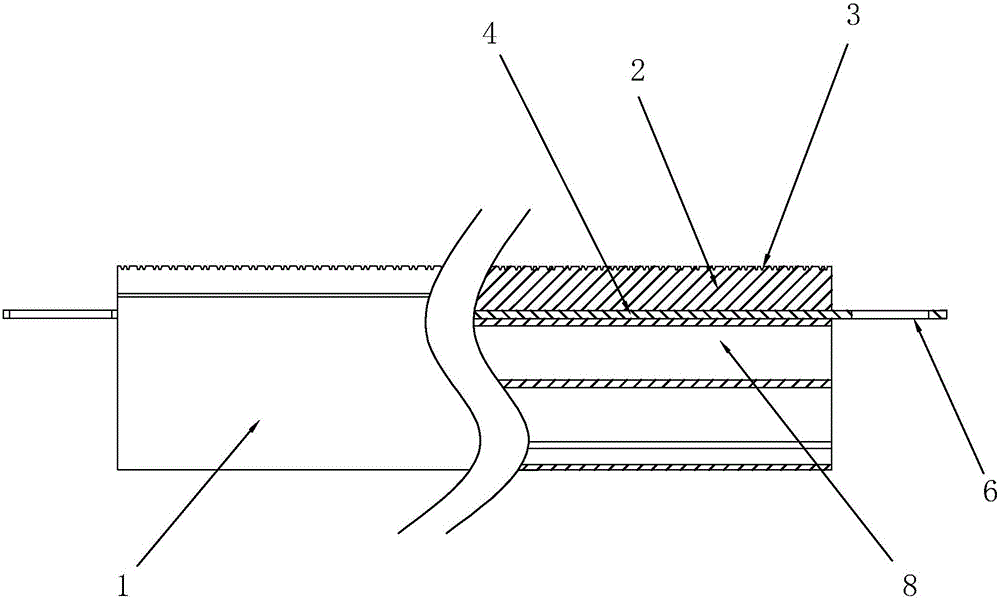

[0070] see figure 2 As shown, a special mold for wire harness winding includes a rectangular main template 1, a sliding groove 5 is provided on an outer wall of the main template 1, and the cross section of the sliding groove 5 is T-shaped, and the sliding groove 5 The length direction of the main template 1 is consistent with the overall length direction of the main template 1; it also includes a secondary template 2, which can be adapted to the sliding groove 5, and can realize sliding movement along the length direction of the sliding groove 5. On the side wall of the sub-formwork 2 away from the bottom of the sliding groove 5, there are a number of embedding grooves 3 distributed along a straight line, and the intervals between adjacent embedding grooves 3 are kept consistent;

[0071] Also, see figure 2 as well as image 3 As shown, between the sub-formwork 2 and the bottom of the sliding groove 5, a plug-in board 4 is inserted, and the shape of the plug-in board 4 is...

Embodiment 2

[0076] see Figure 4 as well as Figure 7 As shown, a winding device includes a frame 35, on which a special wire harness winding die, a traction mechanism 19, a first pressing part 9, and a second pressing part 12 are arranged on the frame 35; A pressing part 9 includes a cylindrical first pressing head 10 and a first driving assembly 11, the first driving assembly 11 may be an optional drive motor and the first driving assembly 11 is used to drive the first pressing head 10 to rotate in a circumferential direction ; The second pressing part 12 includes a second pressing head 13 coaxially arranged with the first pressing head 10, and a second driving assembly 14, and the second driving assembly 14 is used to drive the second pressing head 13 to approach or move away from The first pressing head 10 moves in the direction, the second pressing head 13 is rotatably connected to the second driving assembly 14, and the two ends of the wire harness winding die are respectively pres...

Embodiment 3

[0089] A lamp manufacturing process, comprising the following steps:

[0090] Step 1. Winding: Use the above-mentioned winding device to wind the series wires on the special mold for wire harness winding, in which it is required that each wire embedding groove 3 should be embedded with a series wire;

[0091] Step 2. Adhesive tape: Attach the tape along the length direction of the main template 1 to the wire harness winding mold with the serial wire wound in step 1. After the string wire winding is completed, the wire harness winding mold will display Spiral distribution, relying on the adhesive force of the tape, so that there will be no deformation between the spiral distribution series wires wound on the same wire bundle winding special mold;

[0092] Step 3. Grinding of serial wires: Use an abrasive belt grinder to grind the serial wires on the wire harness winding mold in step 2, and remove the outer insulating varnish of the serial wires located in the embedding groove 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com