Multilayer semi-dry adherent culture device and culture method

An adherent culture and culture method technology, applied in the field of multi-layer semi-dry adherent culture devices, can solve the problem of uneven light intensity distribution, and achieve the effects of uniform illumination, easy harvesting and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

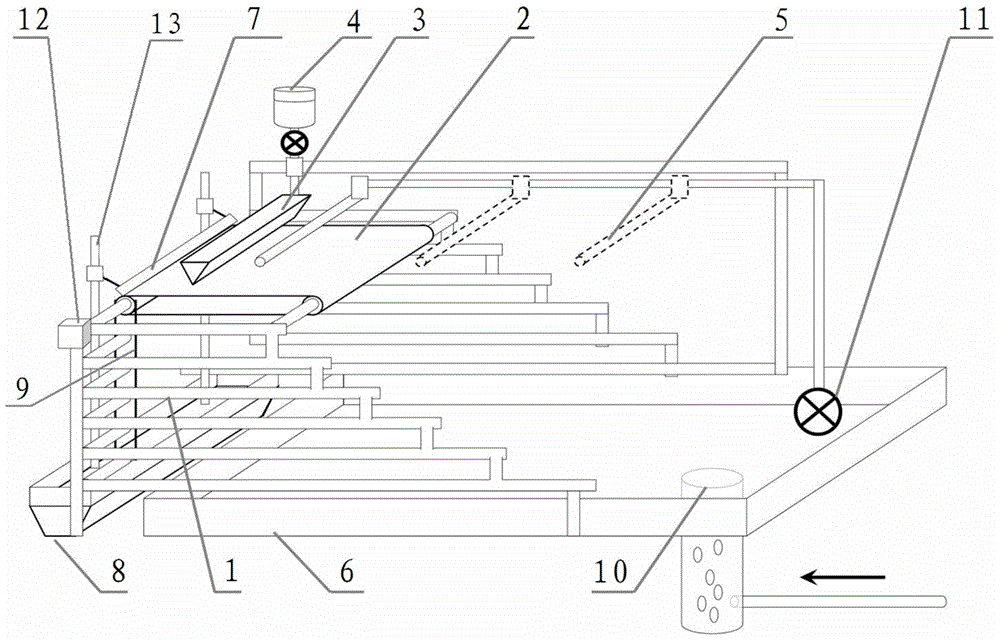

Embodiment 1

[0040] Place six adherent culture units 2 horizontally on the support system 1. The adherent culture units 2 are 1m wide and 5cm high, and the lengths from top to bottom are 1m, 1.2m, 1.4m, 1.6m, 1.8m, 2.0 m. All adherent culture units 2 are aligned near the side of the algae mud scraper 7, and the other side is distributed in steps, and the next layer is 0.2m wider than the upper layer, so that each layer of adherent culture units 2 has a part that can accept vertical The light on the ground is not blocked by other layers, the interlayer height of the adherent culture unit 2 is 0.1m, and the moving surface of the adherent culture unit 2 is a stainless steel wire mesh conveyor belt, which is driven by the same motor 12 to rotate . Ordinary towels are spread and fixed on steel wire mesh as the culture surface. The Spirulina medium used in this embodiment consists of 1 liter of medium containing: 16.80 grams of sodium bicarbonate, 0.5 grams of potassium hydrogen phosphate, 2.5 ...

Embodiment 2

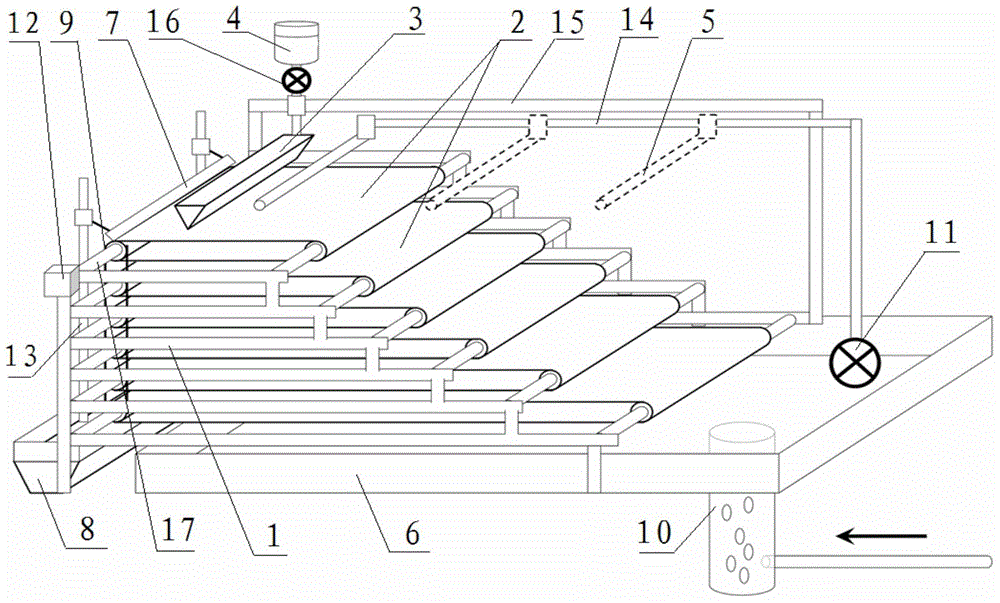

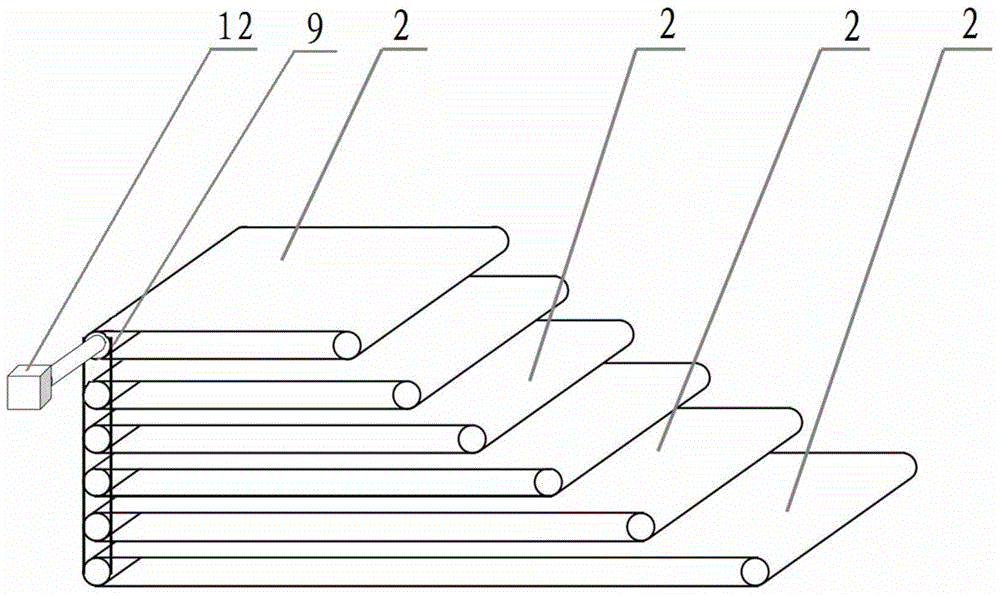

[0042] Place 3 adherent culture units 2 on the support system 1, each adherent culture unit 2 is composed of a fiber fabric belt group to form a closed conveyor belt with a width of 1m and a height of 5cm, and the lengths of the adherent culture units 2 from top to bottom are 1.0 m, 1.5m, 2.0m. All adherent culture units 2 are fixed on the support system 1 at an angle of 30 degrees with the horizontal, such as Figure 4 As shown, two adherent culture units are placed in parallel and obliquely, and a part of any layer directly receives the light perpendicular to the ground without being blocked by other layers. The distance between adjacent adherent culture units 2 is 0.1 m. One end of each adherent culture unit 2 is fixed with a drive sprocket, and multiple adherent culture units 2 are coupled with the drive chain 9 through the drive sprocket and rotate under the same motor 12 . The culture device is placed outdoors to receive natural light, and the light intensity of sunlig...

Embodiment 3

[0044] The culture device is the same as in Example 2, inoculate the seed liquid containing 900g (dry weight) spirulina on the same culture area, open the medium delivery pump 11 and adjust the flow to make the culture liquid drip onto the adherent culture unit 2 to keep the culture surface moist . After cultivating for 3 days, all the biomass of the spirulina was collected to obtain a dry weight of 1342 grams. After deducting the inoculated biomass of 900 grams, the device covers an area (based on the area of the largest adherent culture unit 2) of 1m×2m=2m 2 , equivalent to (1342-900) g / 2m yield per unit area of Spirulina 2 / 3d=73.7g / m 2 / d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com