Illumination system, light mixing chamber and dispaly device

A lighting system and display device technology, applied in the field of lighting systems, can solve the problems of insufficient illumination uniformity and insufficient light distribution of the display device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

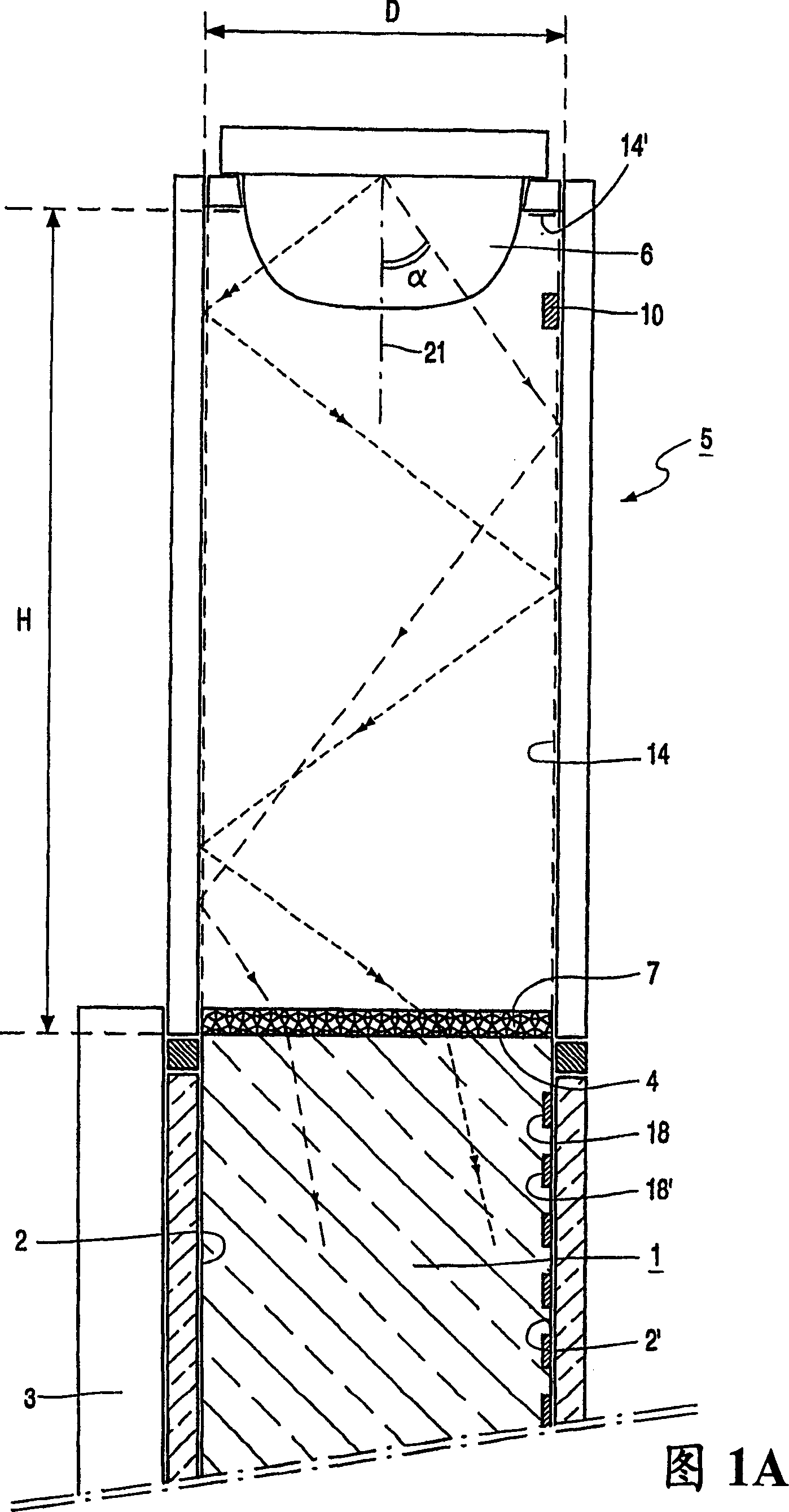

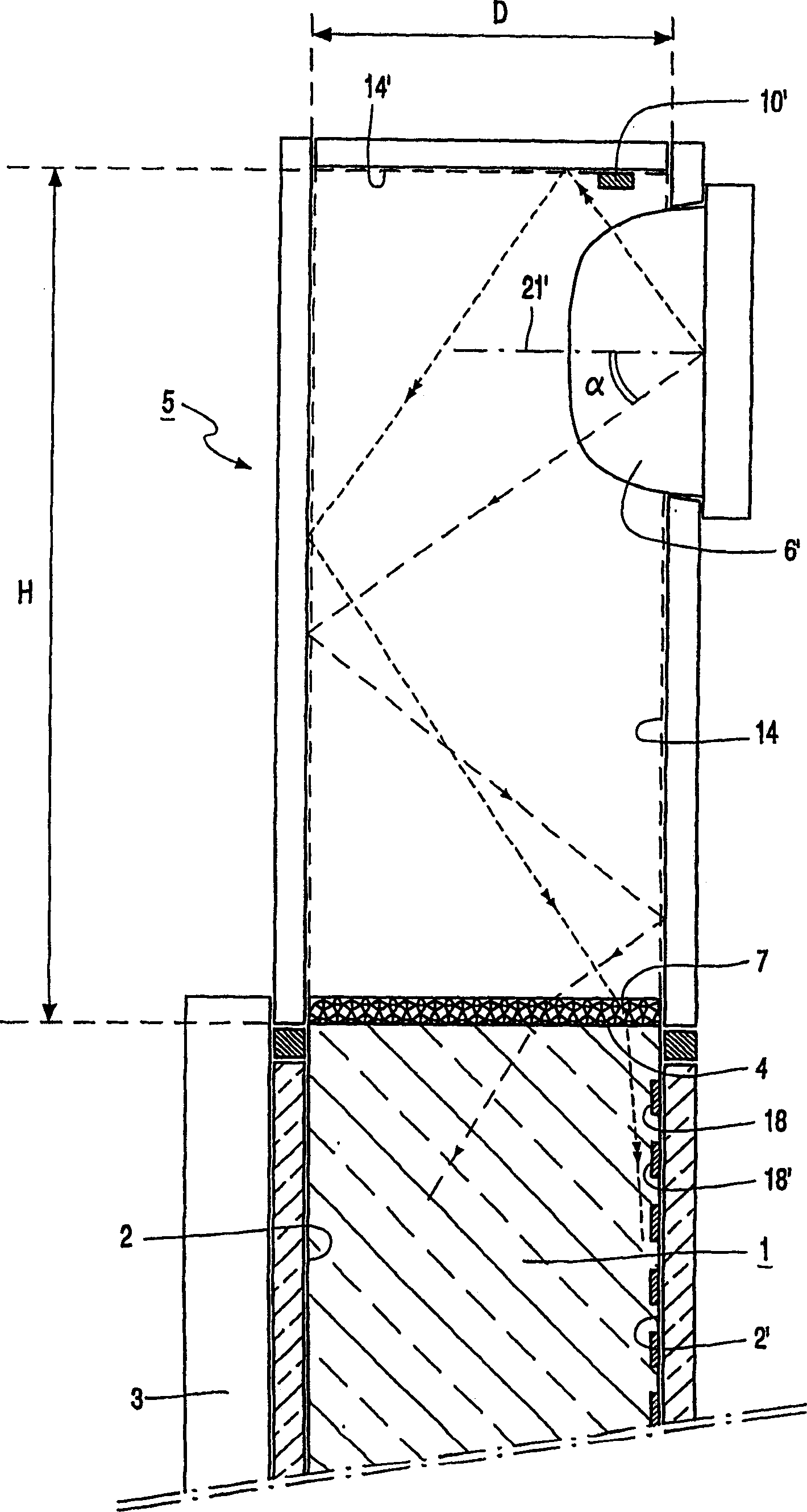

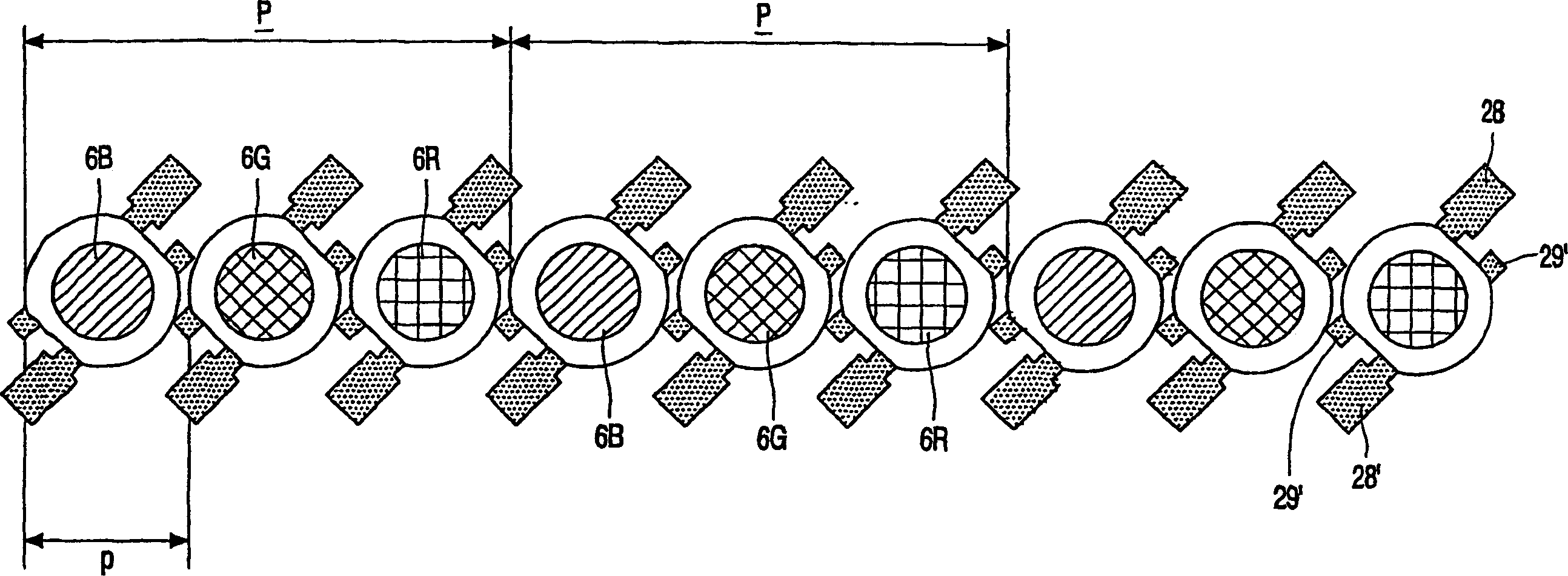

[0066] Figure 1A is a schematic cross-sectional view of an assembly of a lighting system and a display device, which includes an embodiment of a lighting system according to the present invention. The lighting system comprises a light-emitting panel 1 of light-transmitting material. For example, the plate 1 can be made of synthetic resin, acrylate, polycarbonate, PMMA (polymethyl methacrylate) such as Perspex, or glass. In operation, light propagates through the plate 1 under the effect of total internal reflection. The luminous panel 1 has a light emission window 2 and a rear wall 2' opposite the light emission window. Between the light emission window 2 and the rear wall there is a light coupling edge region 4 for coupling light into the luminous panel 1 . The lighting system also includes a longitudinal 15 (see image 3 ) of the light mixing chamber 5, and the lighting system is provided with a light source 6 having a longitudinal axis 21. The light mixing cavity 5 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com