Light guide plate comprising decoupling elements

A technology of output coupling and light guide plate, which is applied in the field of planar light distribution modules, can solve problems such as precise orientation, increased production cost, and high cost, and achieve the effects of uniform illumination, simple production, and low structural height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

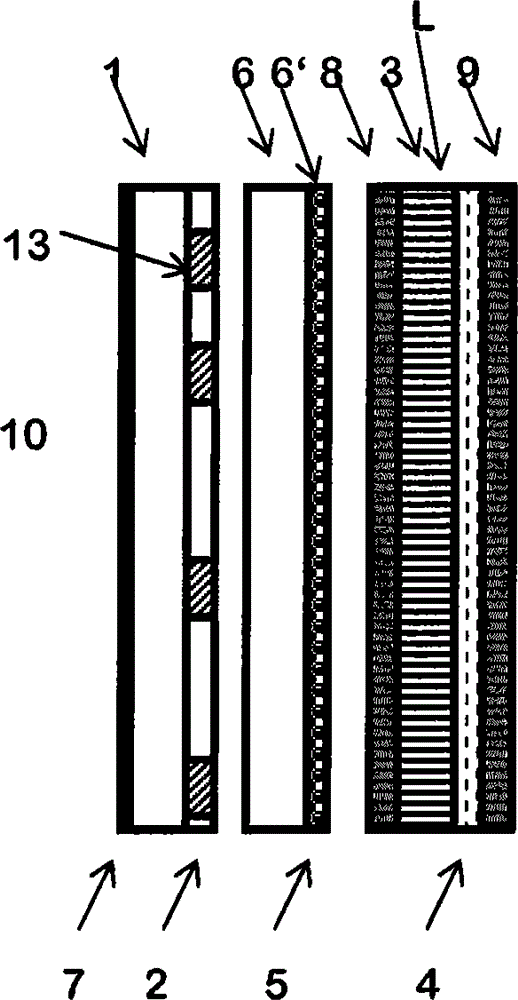

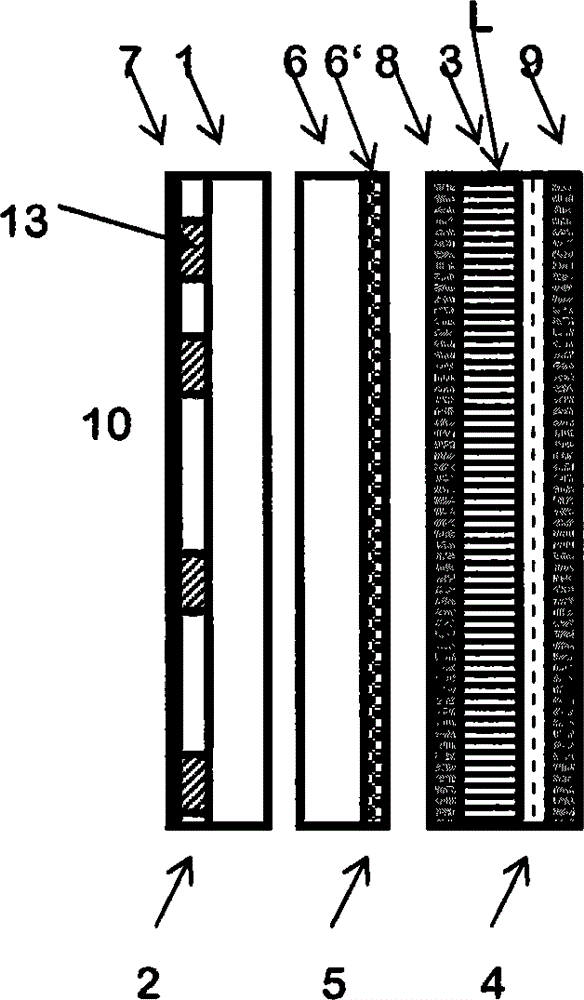

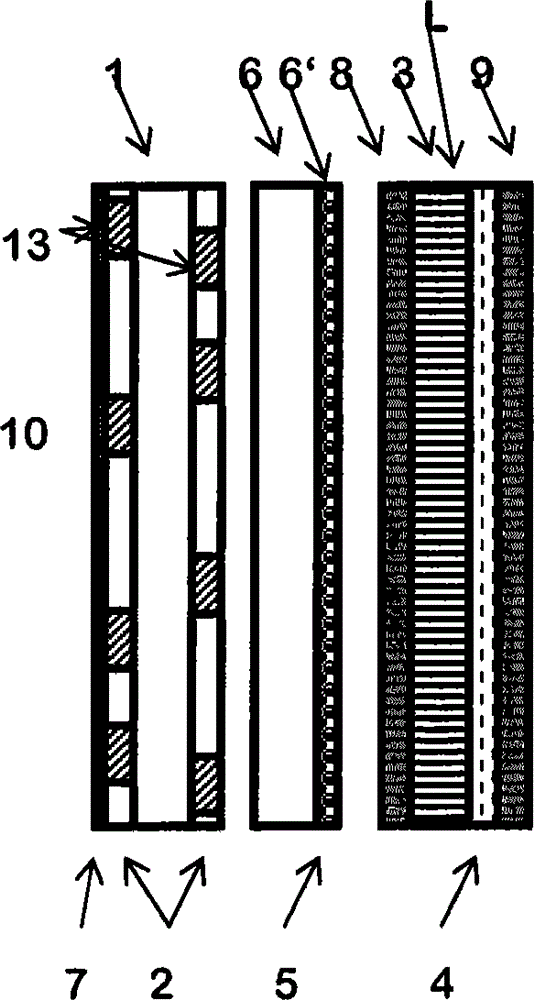

[0098] According to the first preferred embodiment, such as figure 1 Schematically shown, a display 10 according to the invention consists of a light guide plate 1 and an outcoupling device 2 comprising a holographic optical element 13 in the form of a volume grid in transmissive mode. The volume grid has an extent of, for example, 300 μm, 400 μm or even 1000 μm in at least one spatial axis running parallel to the surface of the output coupling. Therein, the light guide plate 1 and the outcoupling device 2 are in optical contact with each other. As shown, the volume grids are irregularly spaced from each other, wherein the invention is not limited to this arrangement.

[0099] The light guide plate 1 consists of a transparent plastic, preferably an essentially birefringent-free amorphous thermoplastic, particularly preferably polymethyl methacrylate or polycarbonate. Wherein, the thickness of the light guide plate is between 50 and 3000 μm, preferably between 200 and 2000 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com