Light-emitting diode (LED) lamp

A technology of LED lights and LED light sources, applied in the field of LED lighting, can solve problems such as unsatisfactory perception, complicated assembly, incomplete light output, etc., and achieve the effect of simple structure, uniform light distribution, and large-angle uniform light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

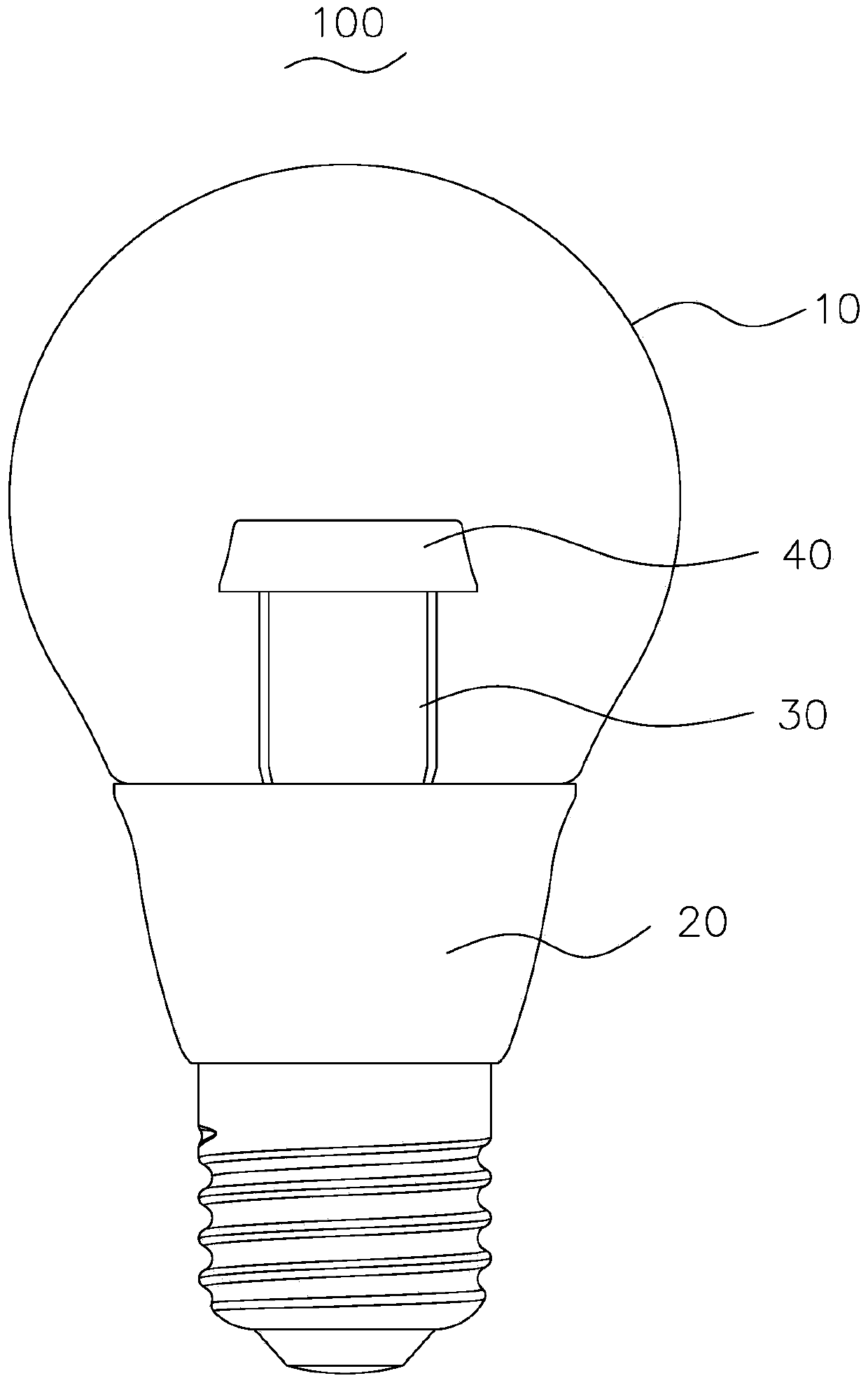

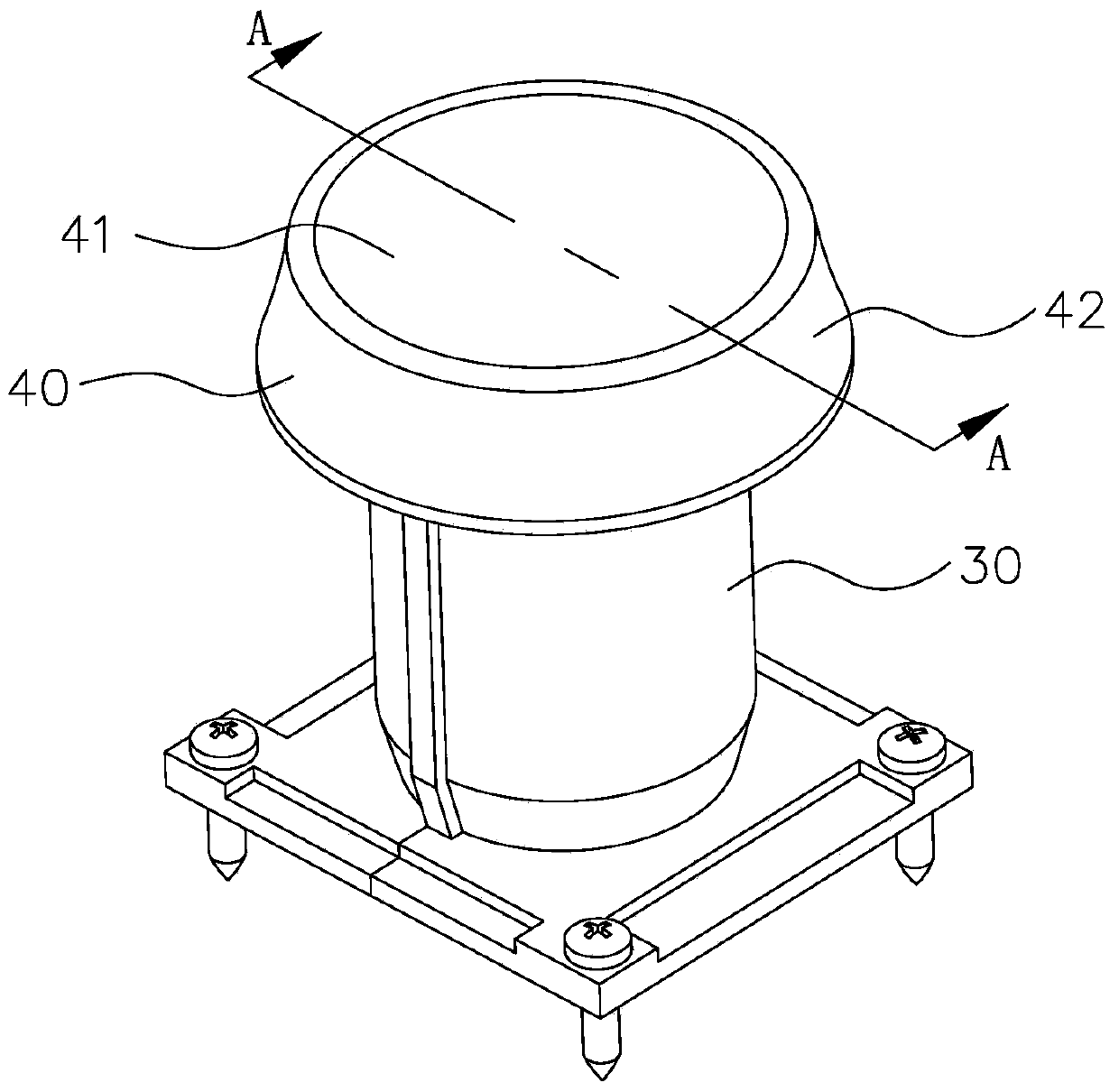

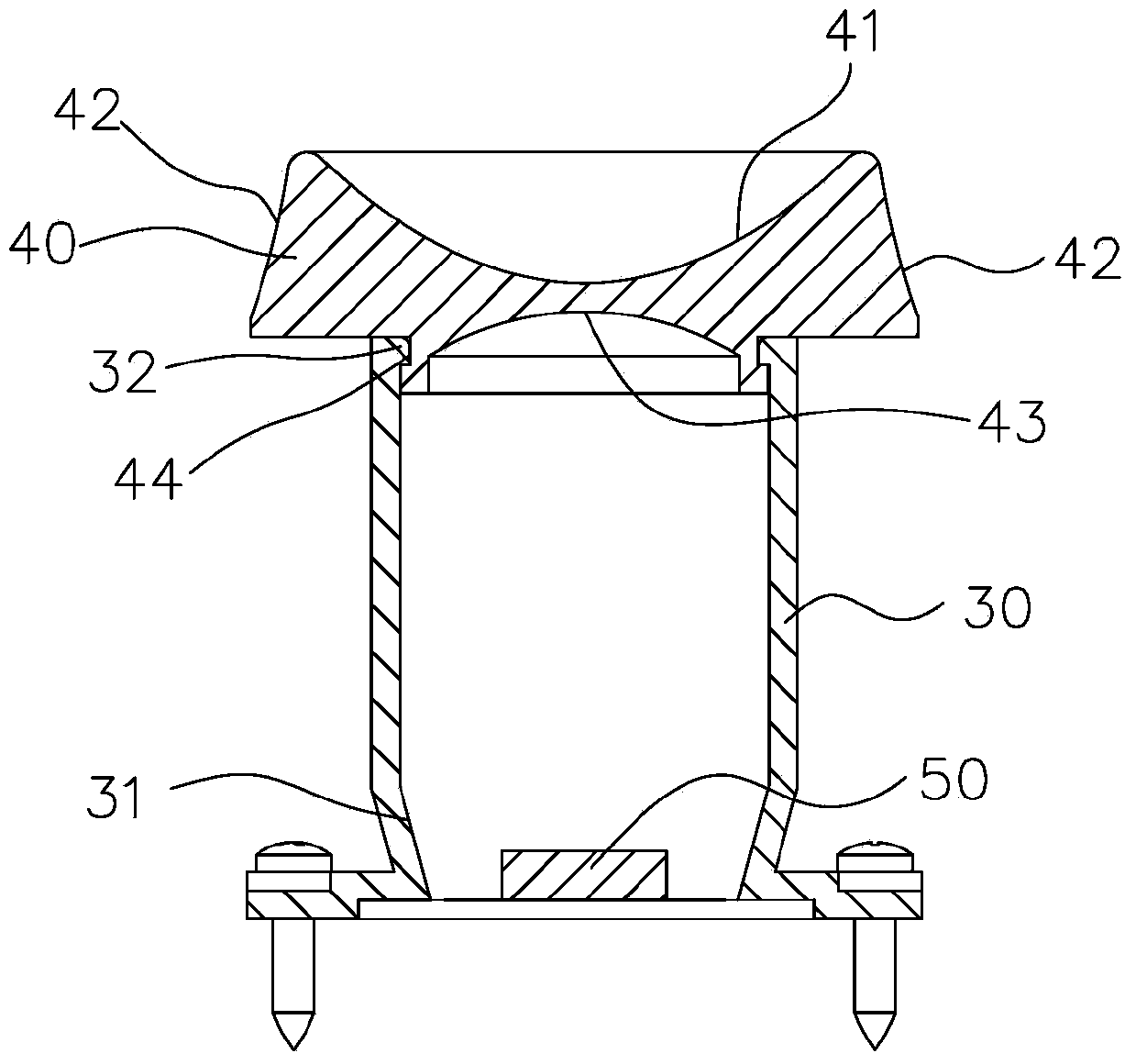

[0015] figure 1 It is an assembly diagram of the LED lamp 100 according to the first embodiment of the present invention, the LED lamp 100 includes a lamp body 20, a bulb shell 10, and an LED light source 50 (see image 3 ), the light guide column 30 and the lens 40. The bulb shell 10 is covered on the top of the lamp body 20 and accommodates the light guiding rod 30 and the lens 40 therein.

[0016] Please refer to Figure 1 to Figure 3 , the LED light source 50 is arranged on the top surface of the lamp head body 20, and the LED light source 50 is encapsulated by phosphor layers to form a surface emitting light source. The light guide column 30 is disposed above the LED light source 50 . The light guide column 30 is a hollow cylindrical structure and its inner wall is coated with a reflective layer (not shown in the figure). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com