Circuit board and manufacturing method thereof

A production method and circuit board technology, applied in the directions of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of low plate-making efficiency of circuit boards, and achieve the effect of improving plate-making efficiency, simplifying plate-making processes, and reducing plate-making costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

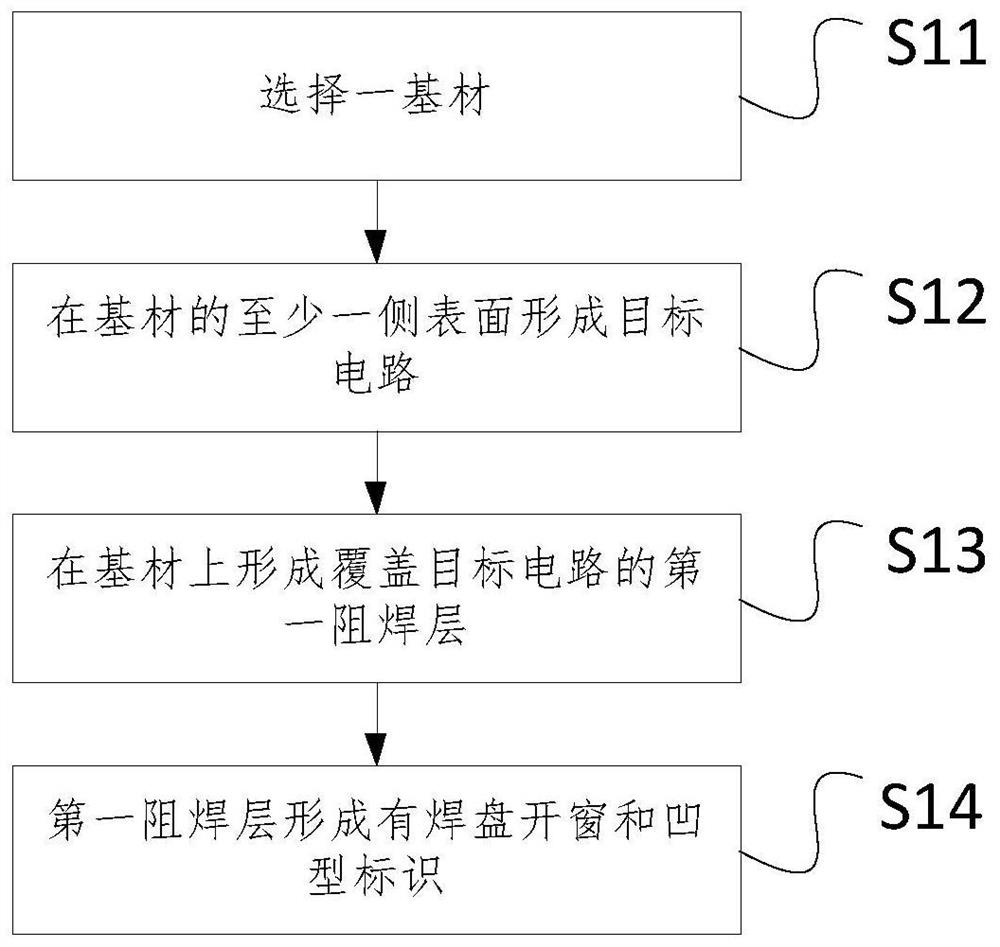

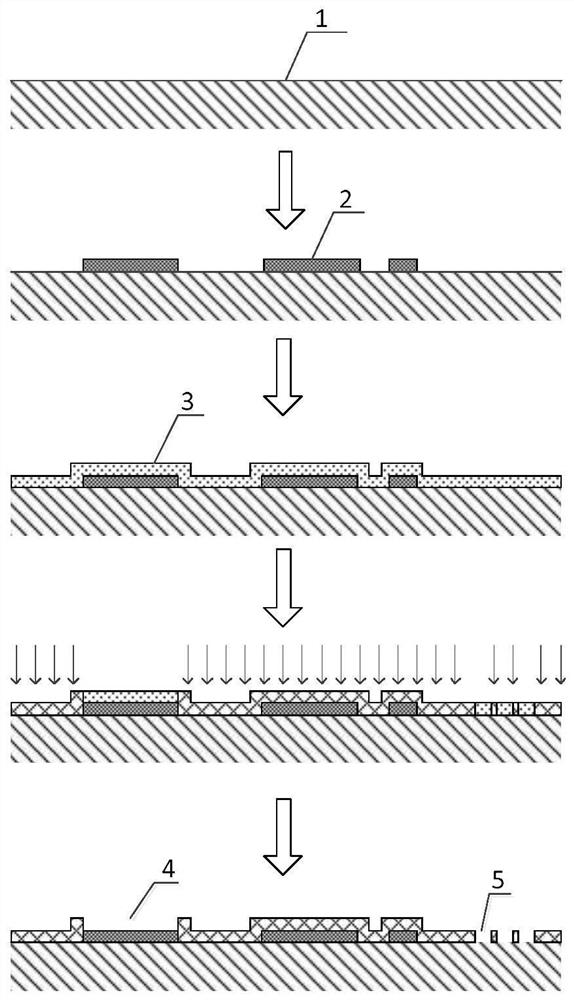

[0061] An embodiment of the present invention discloses a method for manufacturing a circuit board, comprising:

[0062] Step S21, selecting a substrate;

[0063] Step S22, using composite electronic paste to print on one side of the substrate to form a target circuit;

[0064] Step S23 , forming a first solder resist layer covering the target circuit on the side of the substrate on which the target circuit is formed;

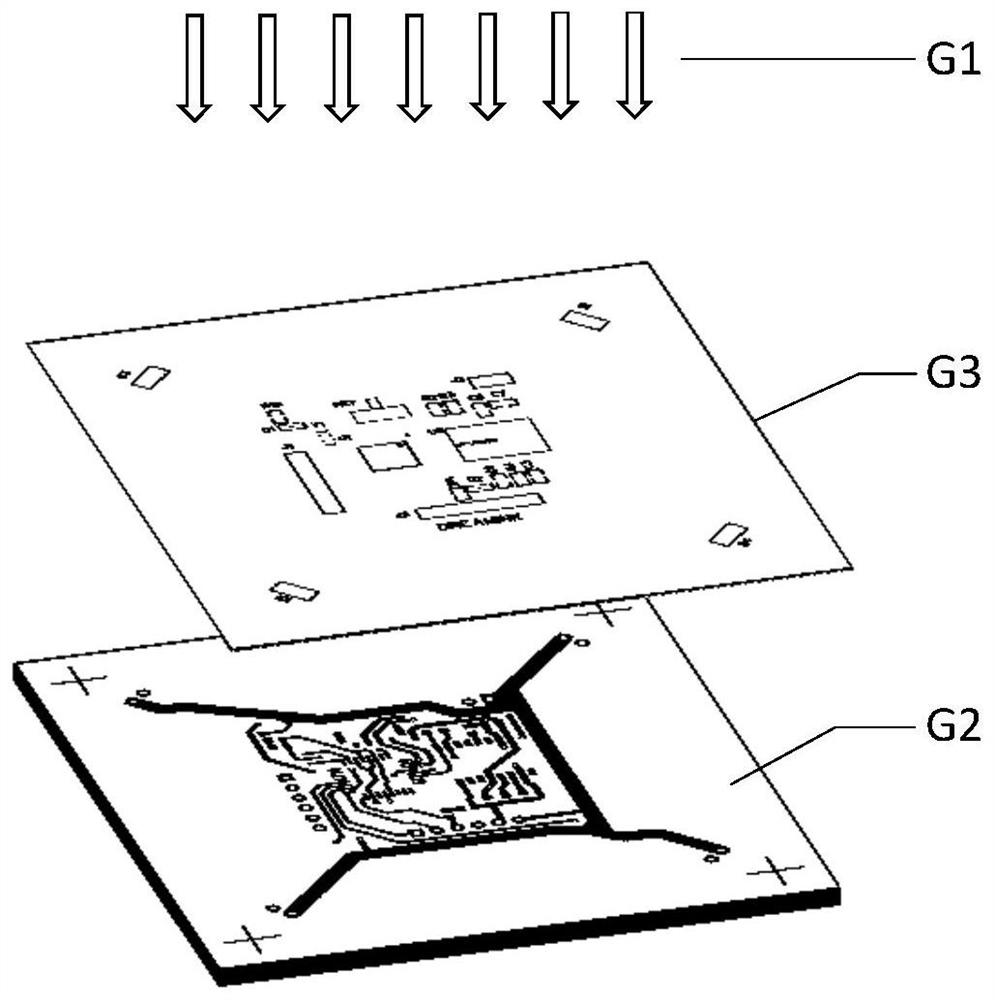

[0065] Step S24, using a digital mask to selectively expose the first solder resist layer;

[0066] Step S25 , developing the exposed first solder resist layer to obtain solder resist openings and concave marks.

[0067] This embodiment is suitable for making a single panel.

Embodiment 2

[0069] An embodiment of the present invention discloses a method for manufacturing a circuit board, comprising:

[0070] Step S31, selecting a substrate;

[0071] Step S32, forming a target circuit by using composite electronic paste printing on both sides of the substrate respectively;

[0072] Step S33, respectively forming a first solder resist layer covering the target circuit on both sides of the base material;

[0073] Step S34, using a digital mask to selectively expose the first solder resist layer;

[0074] Step S35 , developing the exposed first solder resist layer to obtain solder resist openings and concave marks.

[0075] This embodiment is suitable for making double panels.

Embodiment 3

[0077] An embodiment of the present invention discloses a method for manufacturing a circuit board, comprising:

[0078] Step S41, selecting a substrate;

[0079] Step S42, forming a second solder resist layer on a surface of the base material;

[0080] Step S43, forming a target circuit by using composite electronic paste printing on the second solder resist layer;

[0081] Step S44, forming a first solder resist layer covering the target circuit on the side of the base material on which the target circuit is formed;

[0082] Step S45, using a digital mask to selectively expose the first solder resist layer;

[0083] Step S46 , developing the exposed first solder resist layer to obtain solder resist openings and concave marks.

[0084] This embodiment is suitable for making a single panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com