Printing plate producing method applying liquid photosensitive resin bag, and apparatus thereof

A technology of photosensitive resin and manufacturing method, applied in the field of printing plate making, can solve problems such as inability to accurately match printing plate specifications, waste, etc., and achieve the effect of improving plate-making work efficiency, simplifying the production process, and simplifying plate-making machinery and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

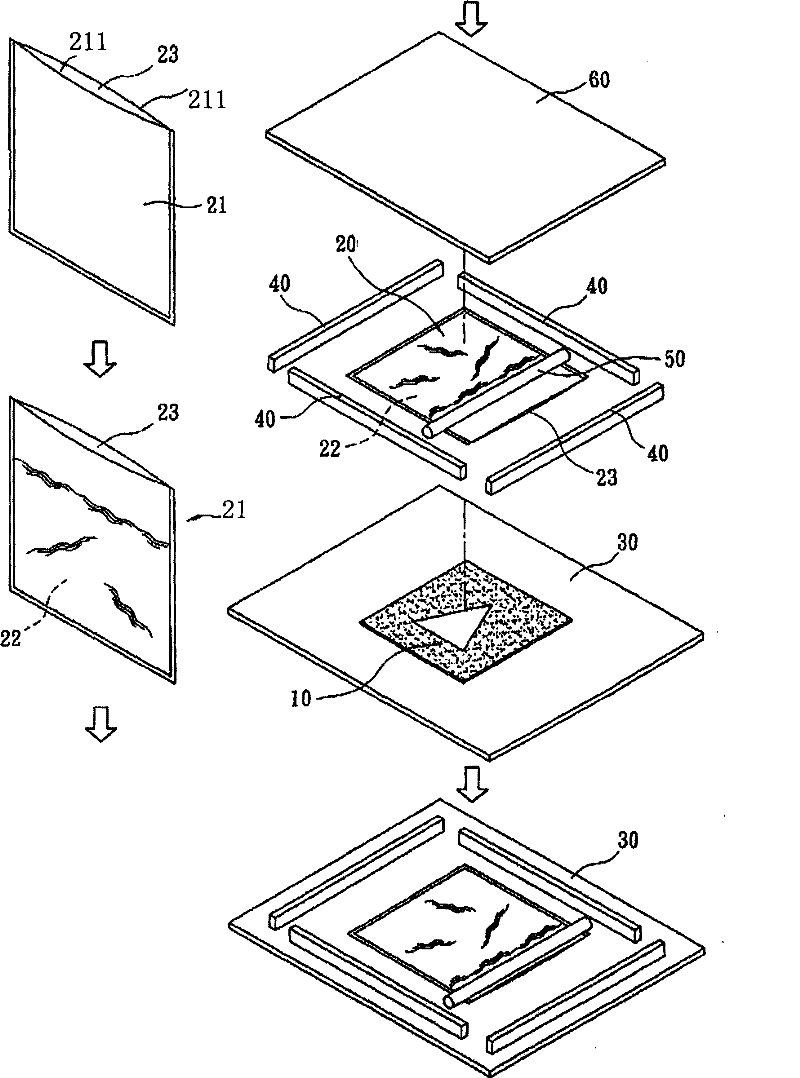

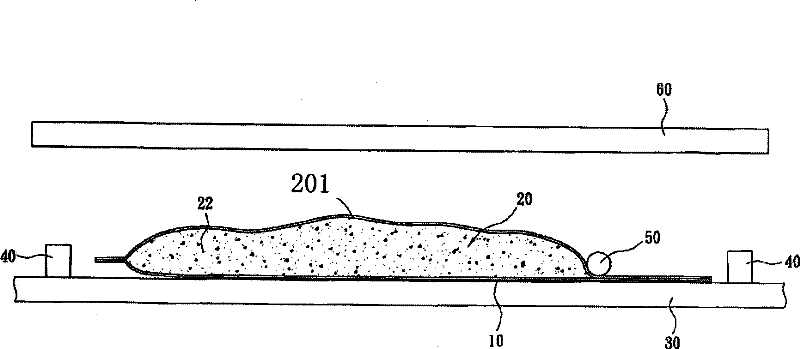

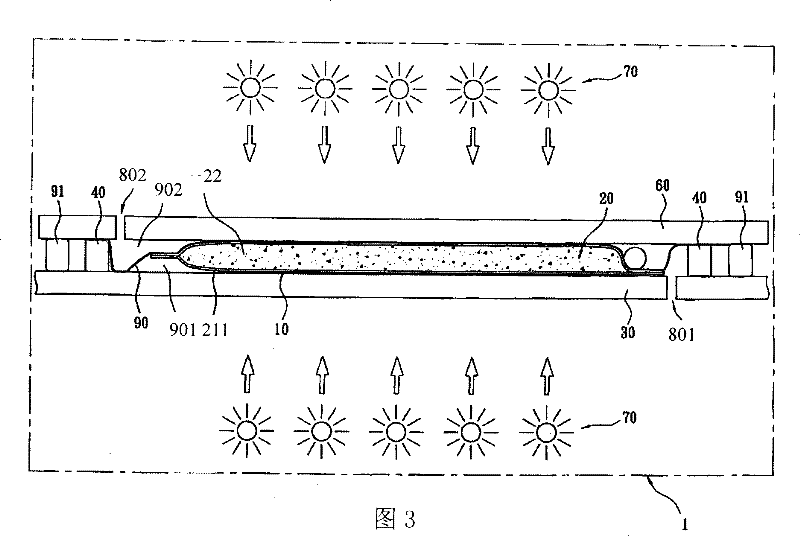

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the printing plate manufacturing method of the liquid photosensitive resin bag that can be freely encapsulated and quantified freely of the present invention includes a process of utilizing an exposure machine to expose and harden the liquid photosensitive resin 22. 22. During the process of exposing and hardening, a transparent bag body 21 is used to accommodate the liquid photosensitive resin 22, and an upper transparent clamping plate 60 and a lower transparent clamping plate 30 are used to remove from both sides of the transparent bag body 21. Flatten the liquid photosensitive resin 22 in the transparent bag body 21 side by side, place the negative film 10 between the transparent bag body 21 and the light source 70 of the exposure machine, and turn on the light source 70 of the exposure machine for exposure hardening, wherein the transparent bag body 21 has at least one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com