Patents

Literature

58results about How to "Improve plate making efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Garment plate making method based on human body big data

ActiveCN110264310AFast automatic plate makingAccurate automatic plate makingBuying/selling/leasing transactions3D modellingPersonalizationHuman body

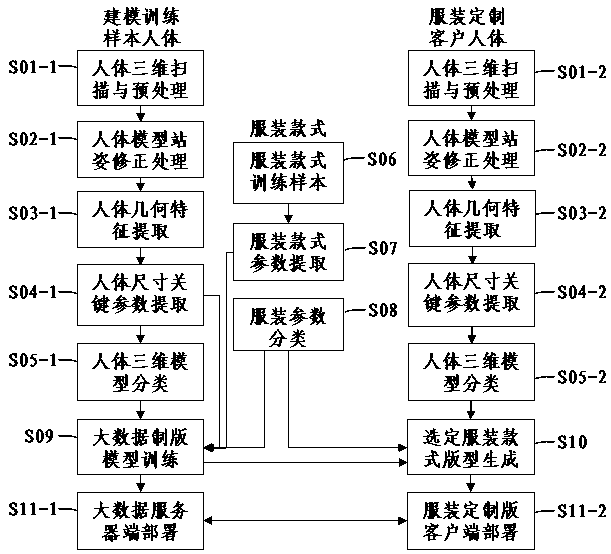

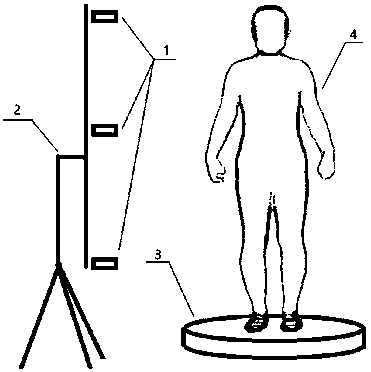

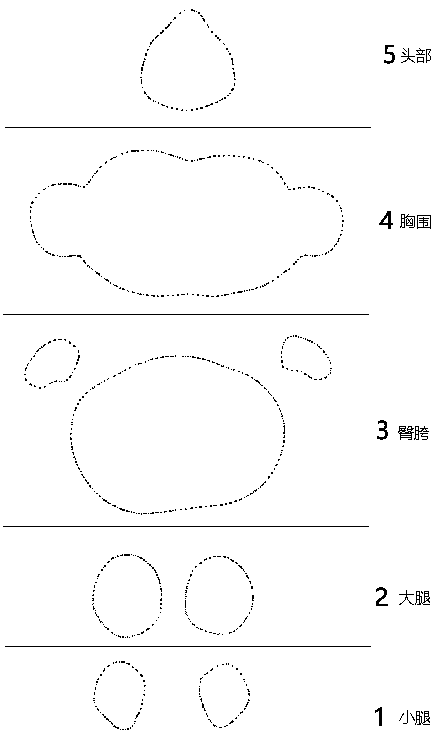

The invention provides a garment plate making method based on human body big data. The invention, and relates to the technical field of human body three-dimensional measurement and garment plate making. The problem of rapid, accurate and automatic plate making under the condition of irregularly scanning a human body model is solved. The method comprises the following steps of human body three-dimensional scanning and preprocessing, human body model standing posture correction and symmetry, human body geometric feature extraction, human body size key parameter extraction, human body three-dimensional model classification and body shape feature space construction. ; mManufacturing of the model of the garment style training sample according to the garment style; garment style parameter extraction, clothes parameter classification and clothes feature space construction; . according to the method, Tthe model of the big data platemaking neural network is trained, the pattern of the garment style is generated according to the human body model of a client, online service is deployed, rapid, accurate and automatic platemaking of the garment customization pattern based on the big data of the human body is achieved, and the big data model learns the platemaking experience of a platemaker, so that an intelligent technical solution is provided for large-scale personalized garment customization.

Owner:肖伯祥

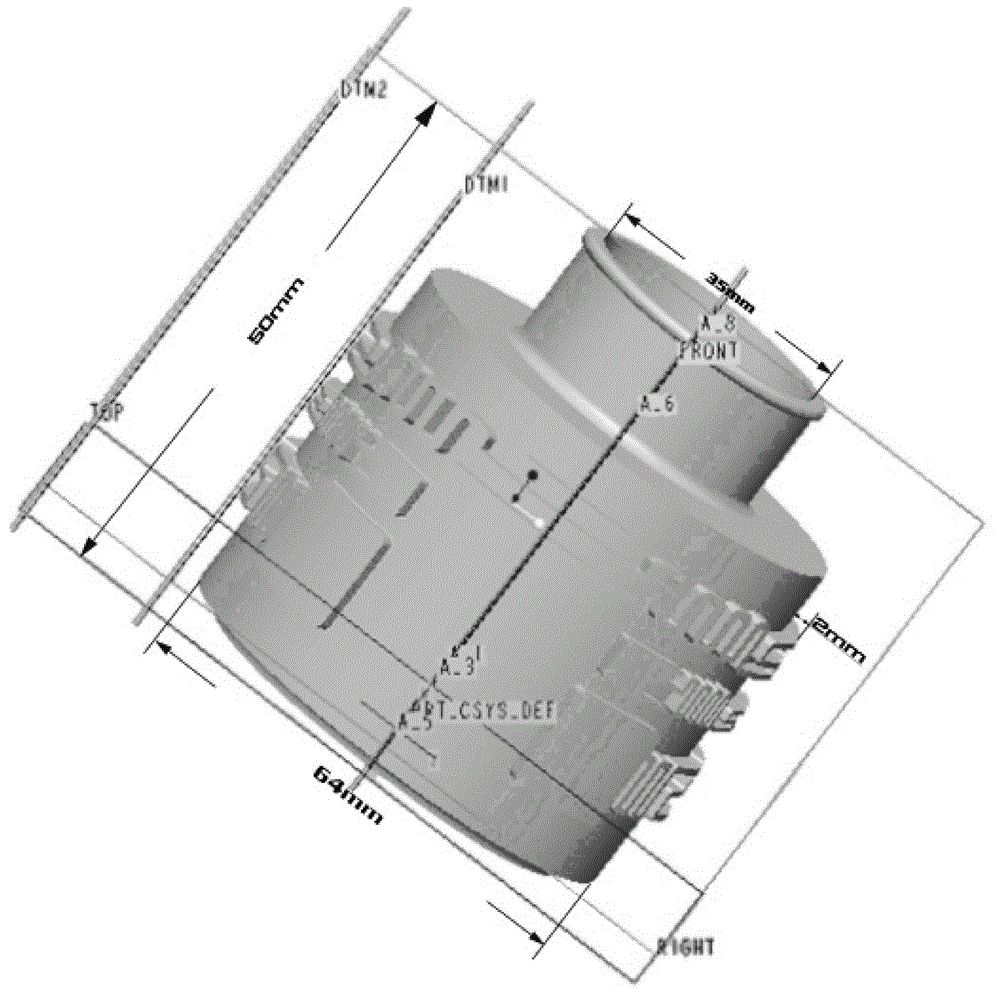

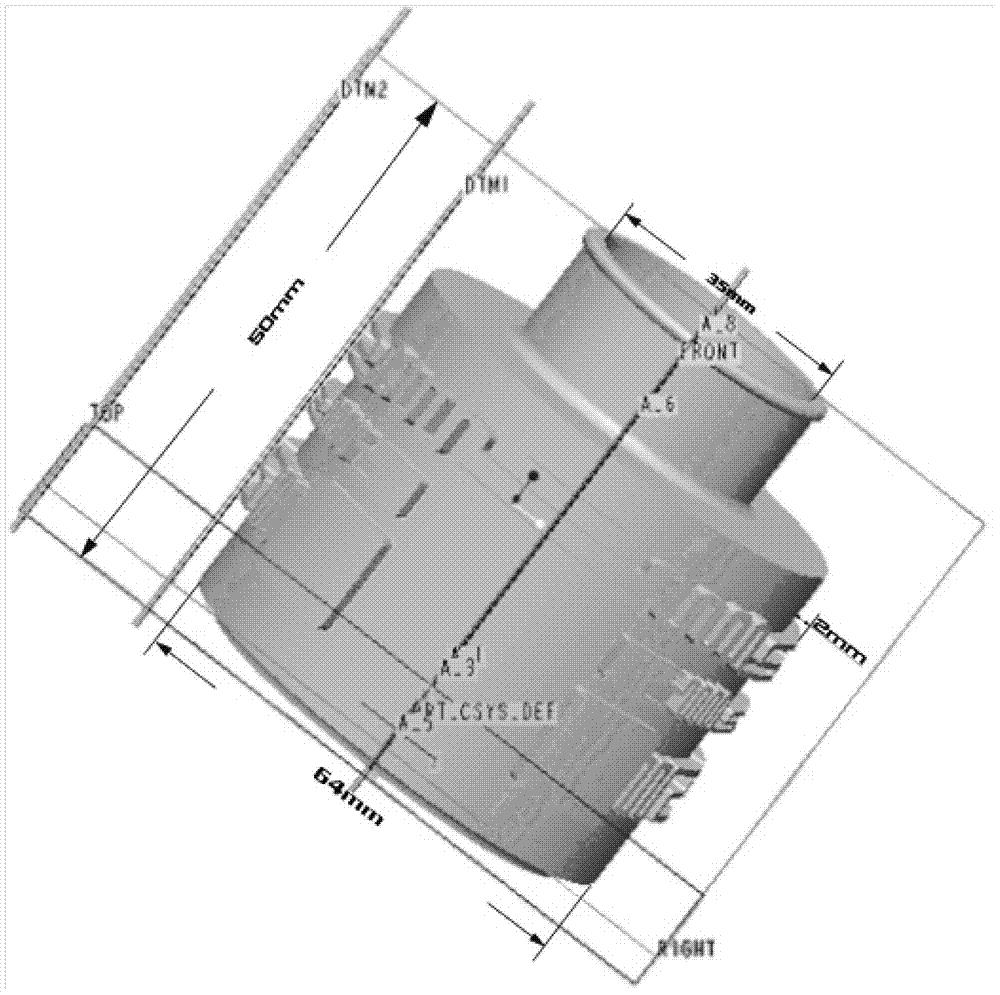

Printing plate and plate roller integrated flexible plate and 3D rapid molding printing type direct platemaking method and application

The invention provides a printing plate and plate roller integrated flexible plate and 3D rapid molding printing type direct platemaking method. The method comprises the following steps: designing a plate to be printed by utilizing a 3D printing plate making method by using three-dimensional software, and selecting a printing material; and spraying to obtain a printing plate material and images and texts on the printing plate material by using a 3D printing machine to obtain a printing plate and plate roller integrated flexible plate. According to the method, a printing plate and the images and texts in a 3D design image are designed into cylindrical shapes; mounting steps are omitted and troubles and labor are not wasted; the operability and the safety are improved; the bending deformation caused by installation does not occur, and the accuracy and the working efficiency are improved; meanwhile, a compensation step of pre-printing deformation amount is omitted; the antenna images and texts cover the printing plate so that the images and texts, and the printing plate are integrated, and the printing plate and a roller are integrated; the content of the images and texts on the printing plate is determined, and the image and text copying accuracy is improved; and the method can be used for creating a new chapter of a printing plate and plate roller integrated flexible plate platemaking technology, and fills up the national blank.

Owner:TIANJIN HAISHUN PRINTING & PACKAGING

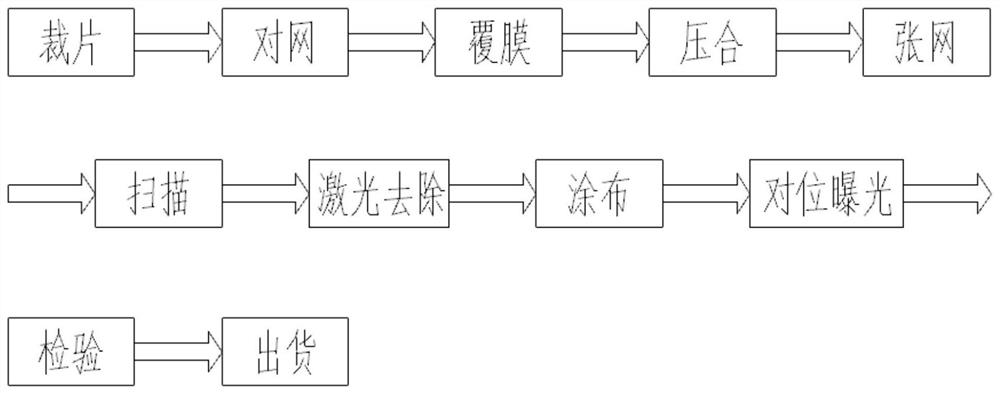

Manufacturing method of high-opening SE net-knot-free screen printing plate

The invention discloses a manufacturing method of a high-opening SE net-knot-free screen printing plate. The manufacturing method comprises the following steps of piece cutting, net aligning, film laminating, pressing, net opening, scanning, laser removing, coating, film layer laser removing, alignment exposure, inspection and shipment. According to the method, the gauze in an effective area of apattern is removed at a fixed point by using laser, so that the film raw material cost is greatly saved, the overall platemaking time is saved, and the platemaking efficiency is improved; meanwhile, the gauze in the corresponding area is removed through lasers, poor screen printing plates and raw material scrapping caused by the screen stretching process are reduced, the production cost of a company is reduced, meanwhile, a scanning program and a laser removing program run synchronously, and the existing platemaking working hours are reduced; and the gauze in the area corresponding to the pattern is removed by laser without changing the pattern of a client, so that a net-knot-free screen printing plate required by SE technology printing can be manufactured.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

Ultraviolet offset printing continuous machine white ink and preparation method thereof

ActiveCN105542560AIncreased flexibility and weather resistanceIncrease drying speed and fullnessInksPolyesterPhotoinitiator

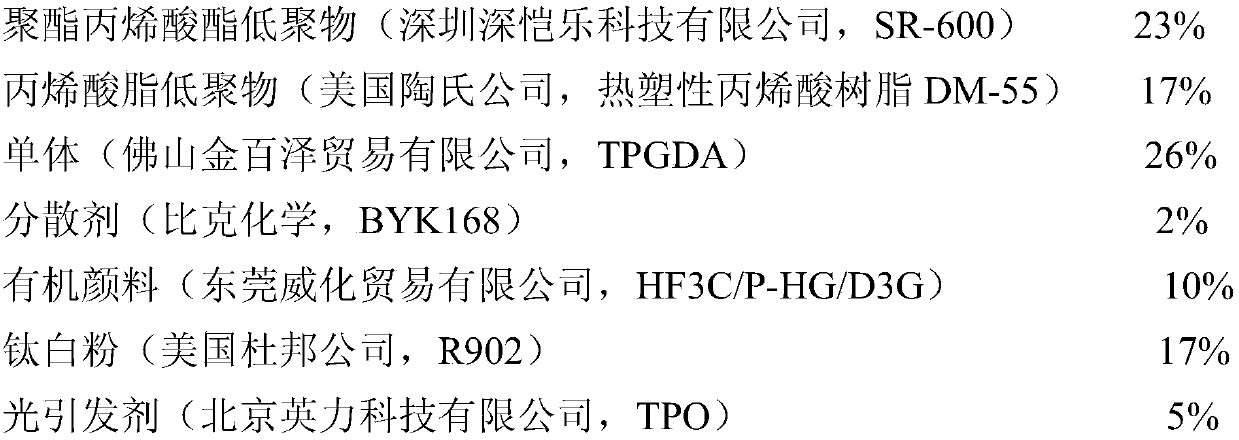

The invention relates to the technical field of printing, and particularly discloses ultraviolet offset printing continuous machine white ink and a preparation method thereof. The ultraviolet offset printing continuous machine white ink is prepared from, by mass, 15.0%-25.0% of polyester acrylate oligomer, 10.0%-20.0% of thermoplastic acrylic resin, 40.0%-50.0% of titanium dioxide, 2.0%-3.0% of a dispersing agent, 3.0%-5.0% of a photoinitiator and 10.0%-20.0% of monomers. According to the ultraviolet offset printing continuous machine white ink, the covering power of traditional ultraviolet screen printing ink is compatible with the high-speed printing characteristics of ultraviolet offset printing ink, not only is the covering effect of the UV screen printing ink achieved, but also the high-speed cooperating requirement of the UV offset printing ink is achieved.

Owner:山东布瑞特油墨有限公司

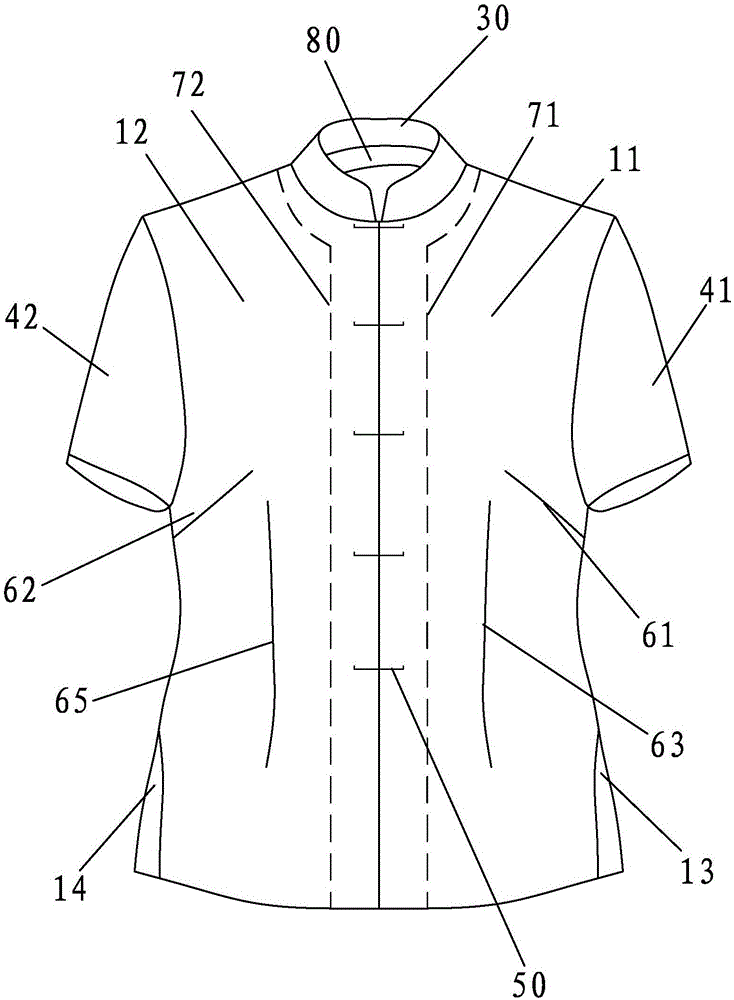

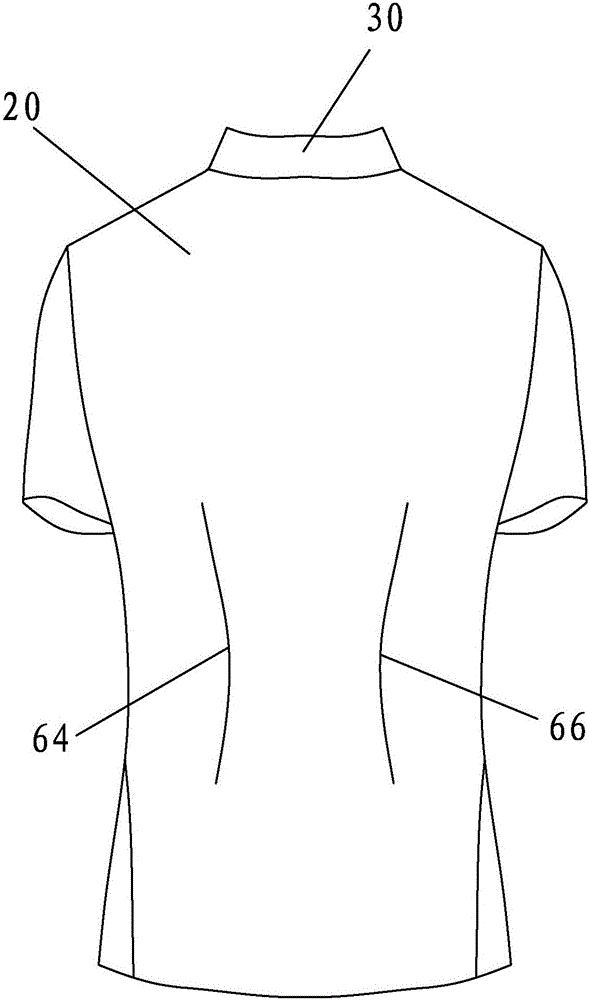

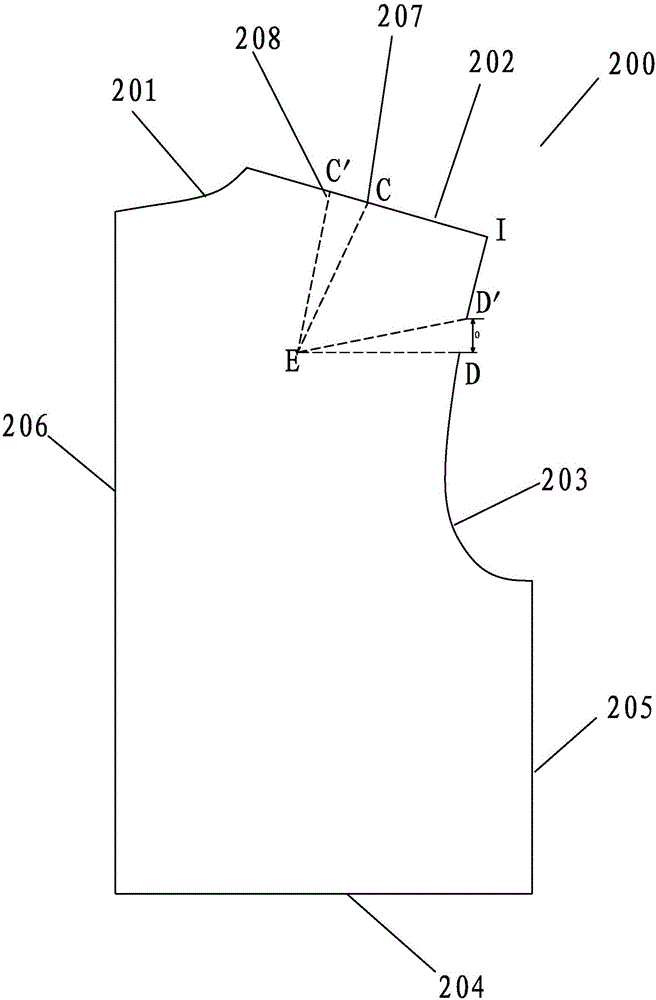

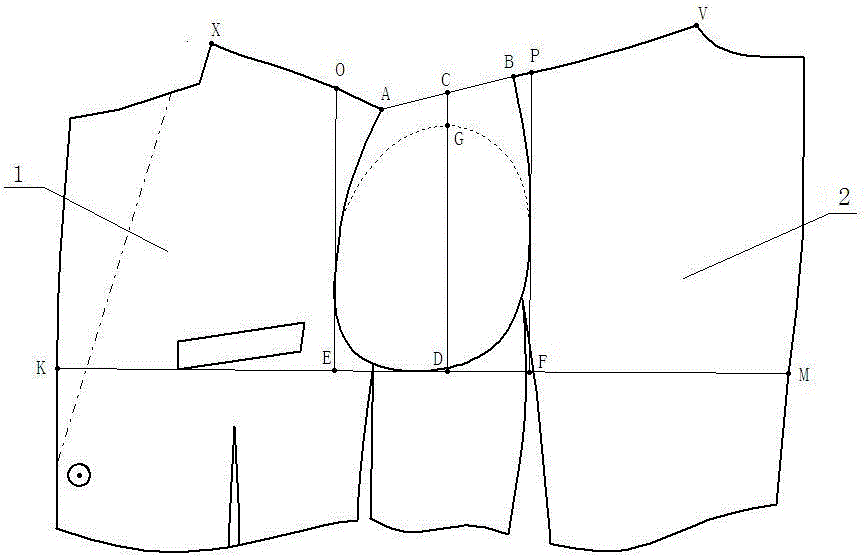

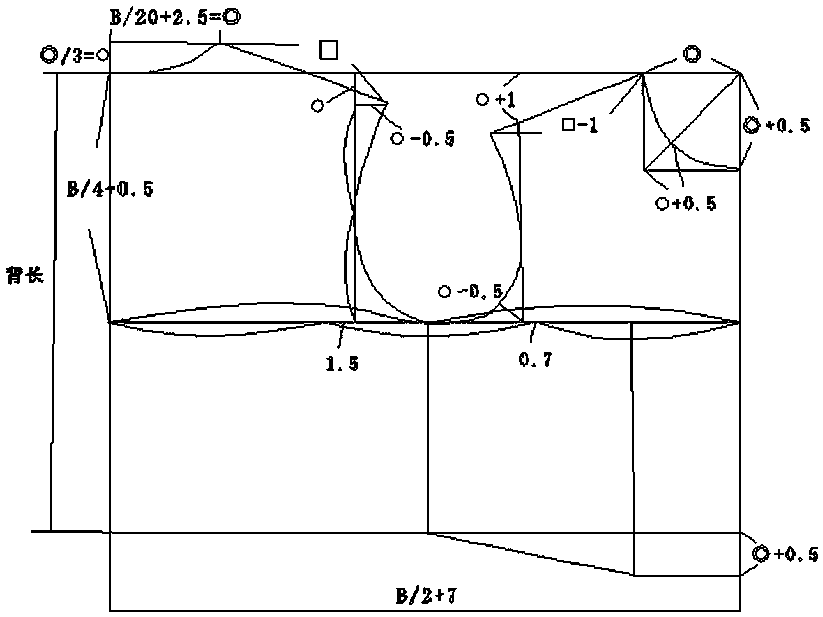

Tang style blouse and method for making Tang style blouse

The invention relates to a Tang style blouse. The Tang style blouse includes a front clothes body, a back clothes body, a collar connected with a neckline and sleeves connected with armholes. A first folding-shrinkage portion is formed on the left front clothes body by folding and sewing a first fold line, a first looseness portion corresponding to the first folding-shrinkage portion is formed on the left armhole, a second folding-shrinkage portion is formed on the right front clothes body by folding and sewing a second fold line, and a second looseness portion corresponding to the second folding-shrinkage portion is formed on the right armhole. According to the Tang style blouse, the folding-shrinkage amount of the first folding-shrinkage portion is transferred into the first looseness portion of the left armhole, and the folding-shrinkage amount of the second folding-shrinkage portion is transferred into the second looseness portion of the right armhole, so as to provide the looseness of activities for the movement of arms, and the wearing comfort and sporting functionality of the sleeves are thus enhanced. The invention further provides a method for making the Tang style blouse, in the method, the front clothes body and the back clothes body are cut based on a prototype template, and the production efficiency of the clothes body is thus improved.

Owner:河南赛琪实业有限公司

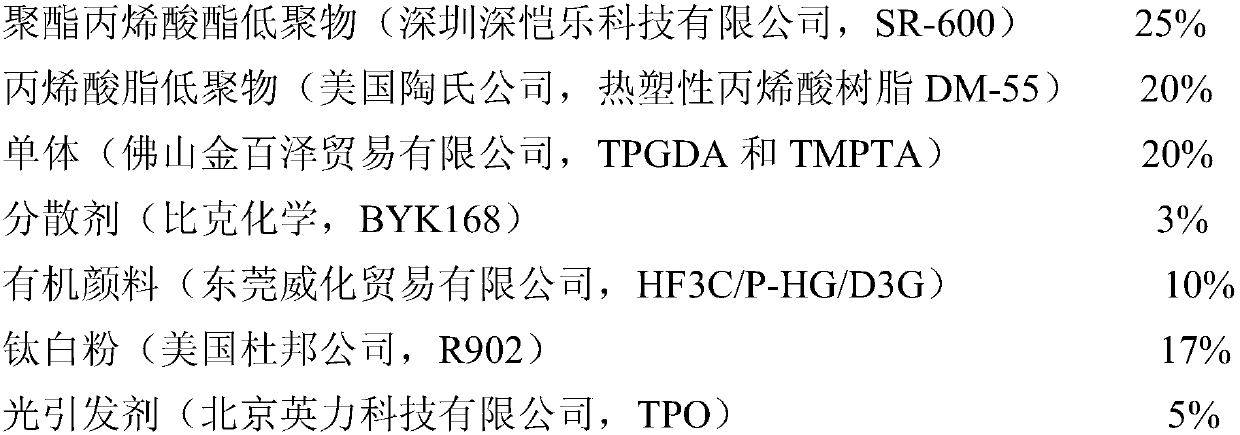

UV offset printing and flexible printing combined UV light color ink, and preparation method and application thereof

The invention provides UV offset printing and flexible printing combined UV light color ink, and a preparation method and application thereof. The UV light color ink comprises the following componentsin percentage by mass: 15 to 25 percent of polyester acrylate oligomer, 10 to 20 percent of acrylic ester oligomer, 20 to 40 percent of monomers, 2 to 3 percent of a dispersing agent, 3 to 5 percentof a photoinitiator, 5 to 10 percent of an organic pigment and 0 to 20 percent of a titanium dioxide powder. Solvent-free UV resin is adopted, the organic pigment and the titanium dioxide powder are added, an organic solvent does not exist in the whole process, VOCs are close to zero emission, the environment can be protected effectively, and the performance requirement and the integrated effect after printing are met by blending different UV resin.

Owner:山东布瑞特油墨有限公司

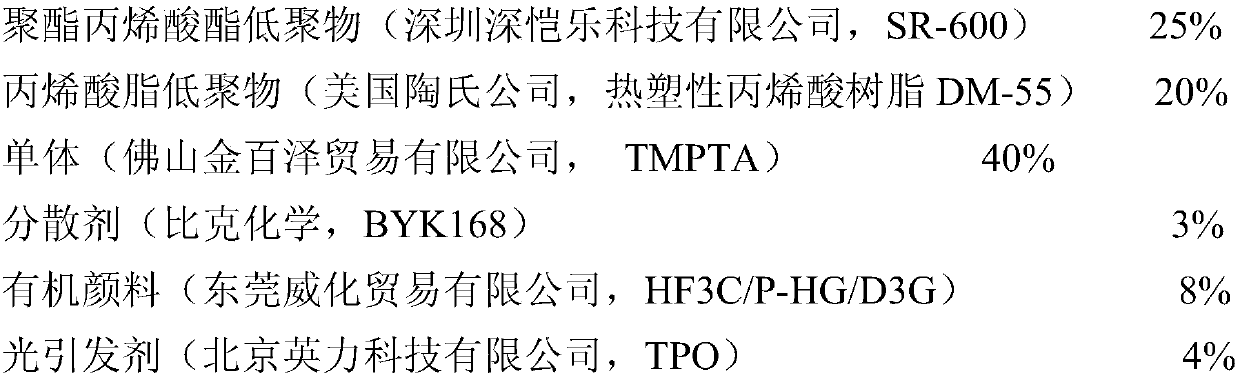

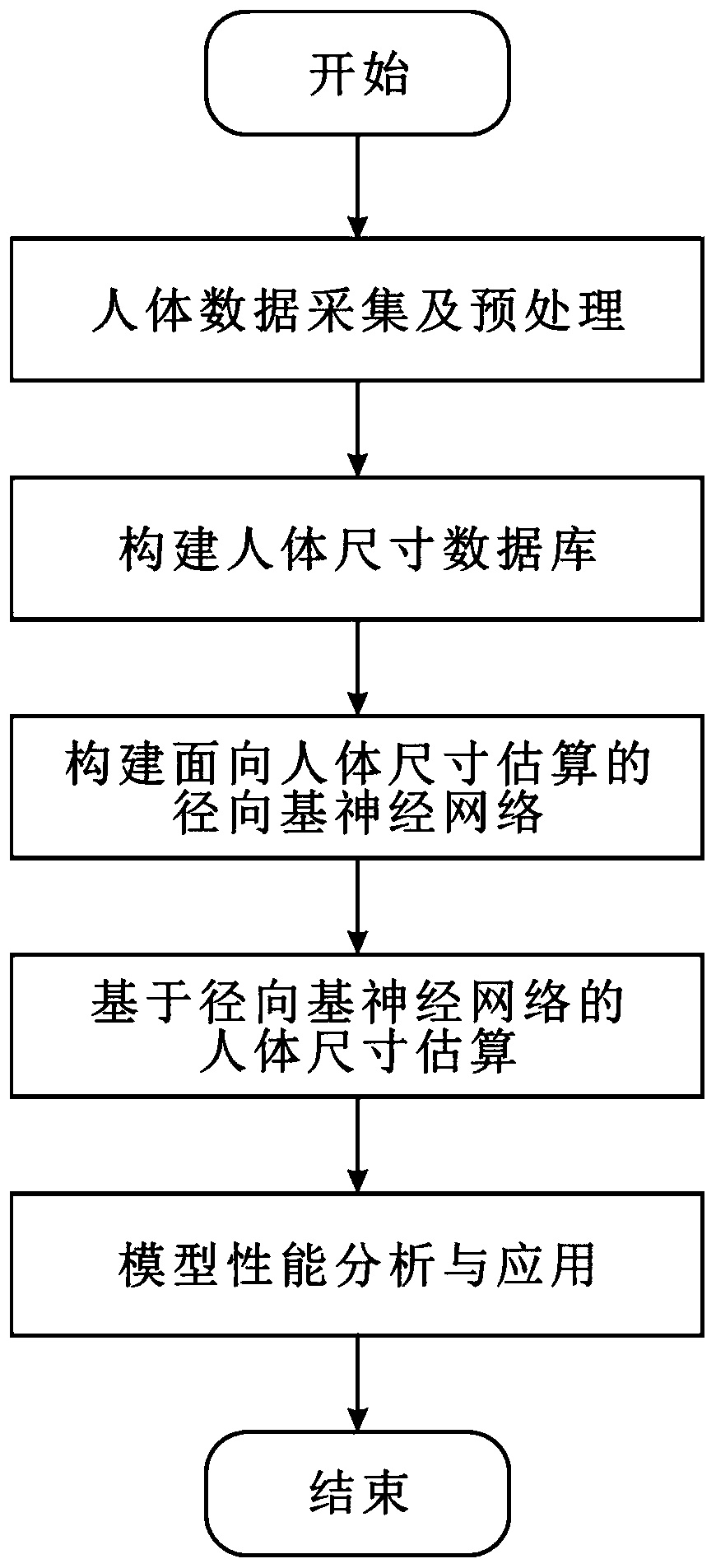

Human body size estimation method based on a radial basis function neural network

PendingCN109801328ASmart estimateAccurate estimateImage analysisCharacter and pattern recognitionHuman bodyAlgorithm

The invention relates to a human body size estimation method based on a radial basis function neural network. The human body size estimation method comprises the following steps: collecting static human body net body data; preprocessing the collected human body net body data, and constructing a human body database; constructing a radial basis function neural network model of human body size estimation, an input layer of the radial basis function neural network model being a key part size which is easy to measure, and an output layer being a detail size which is not easy to measure; dividing the data in the human body database into a training sample set and a test sample set, training the radial basis function neural network by using the training sample set, randomly selecting a plurality of samples from the test sample set for simulation test after the training is completed, and estimating the detail size which is not easy to measure by the human body. The method can quickly and effectively calculate the size of the human body required by the garment making plate.

Owner:DONGHUA UNIV

Garment pattern automatic generation method, system and device and medium

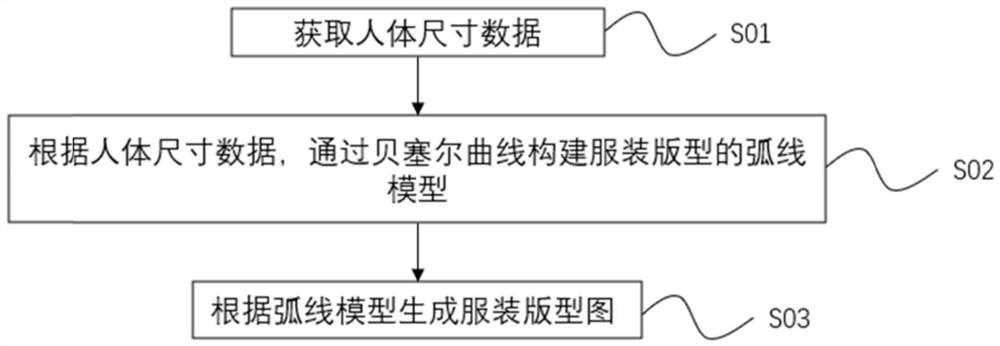

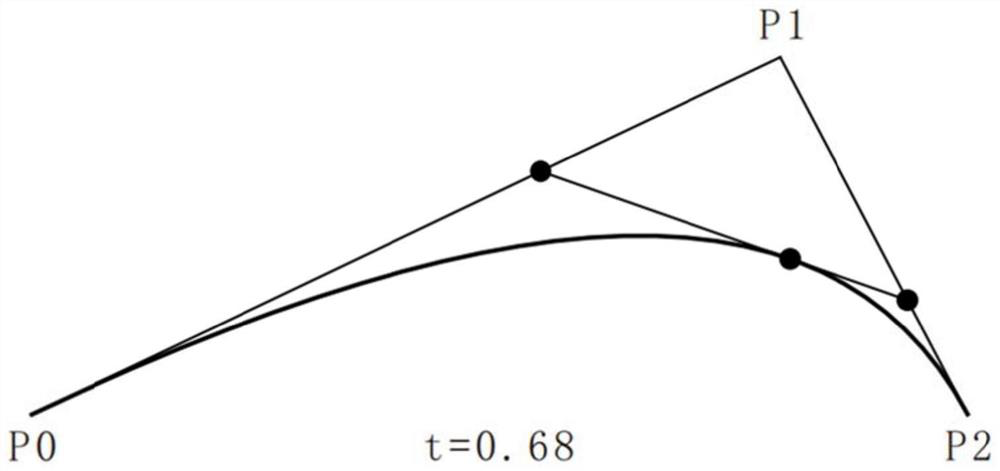

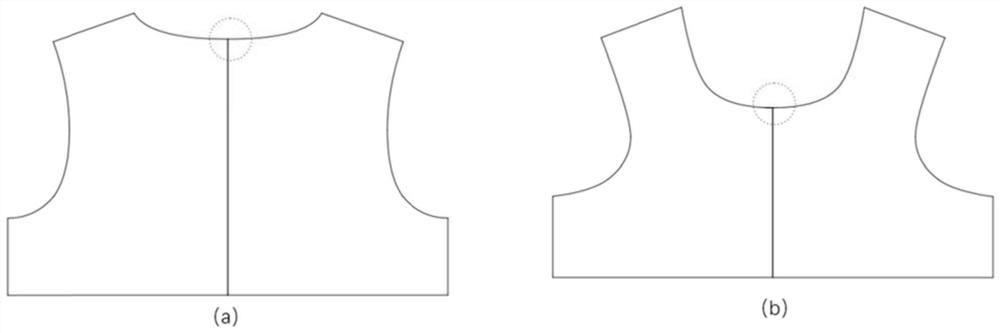

PendingCN111881491AContour lines are precise and smoothImprove plate making efficiencyGeometric CADClothes making applicancesHuman bodyAlgorithm

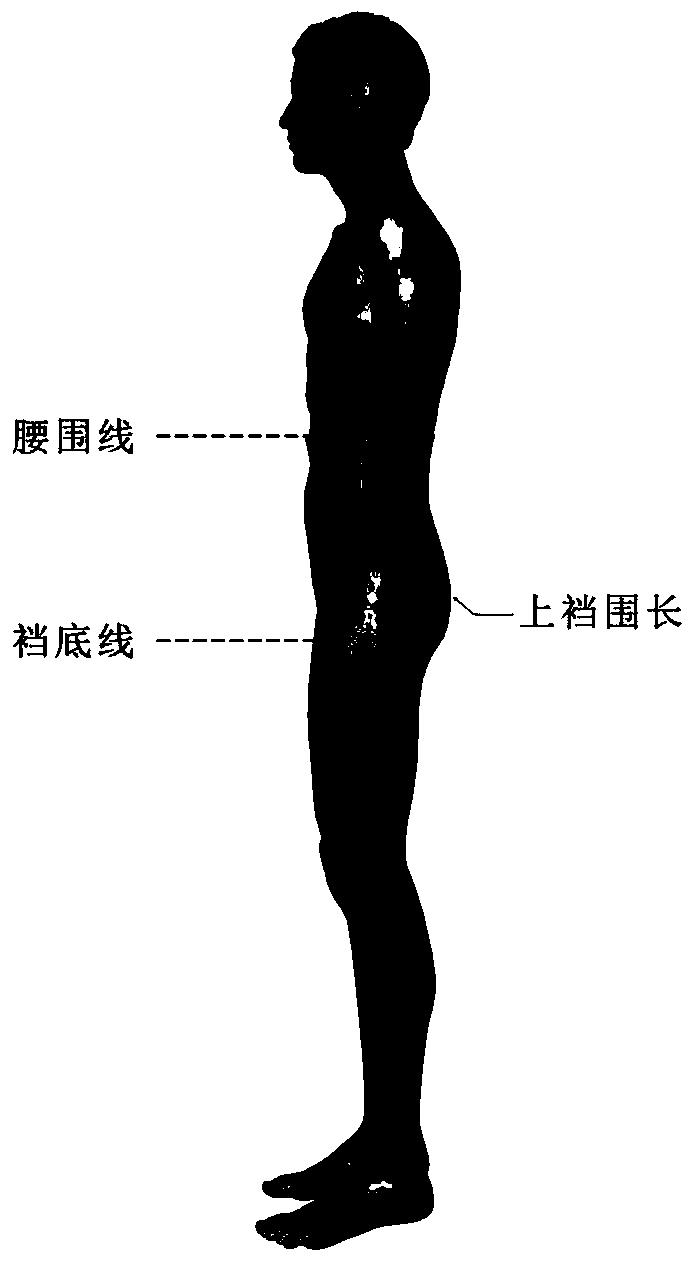

The invention discloses a method for automatically generating a clothing pattern. The method comprises the following steps: acquiring human body size data; according to the human body size data, constructing an arc model of the garment model through a Bezier curve, and the arc model is a second-order Bezier function; and generating a clothing pattern graph according to the arc model. According tothe technical scheme, human body size data are directly obtained, and then the pattern graph of the garment is automatically generated according to the mathematical model based on the second-order Bessel function, so that manual repeated parameter setting and adjustment and modification are not needed; mathematical expression of a relation structure is carried out through a mathematical model of an order Bessel function, a drawn clothing layout is more standard, contour lines are more accurate and smooth, meanwhile, unified drawing specifications and standards can be provided, and the plate making efficiency is greatly improved. The method can be widely applied to the technical field of clothing pattern making.

Owner:岳昕

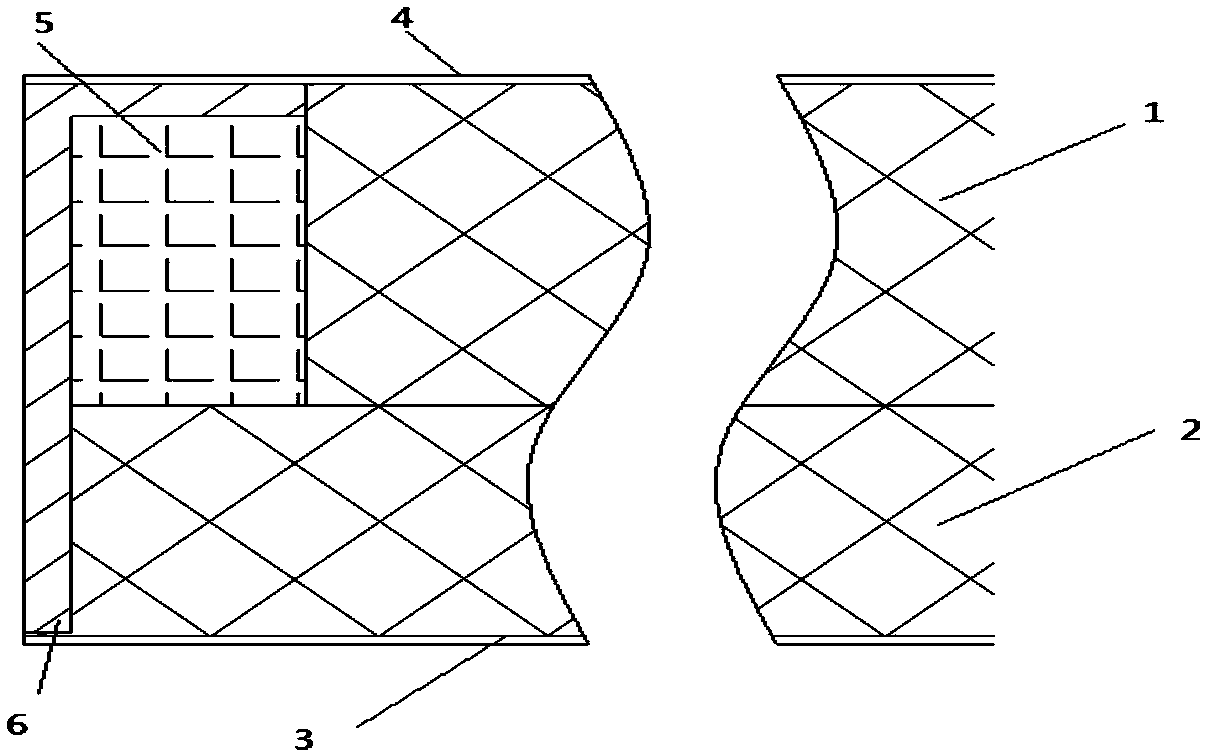

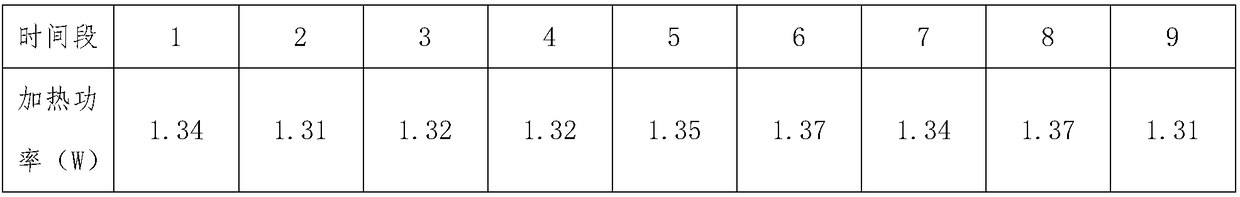

Refrigeration compartment board and preparation method thereof

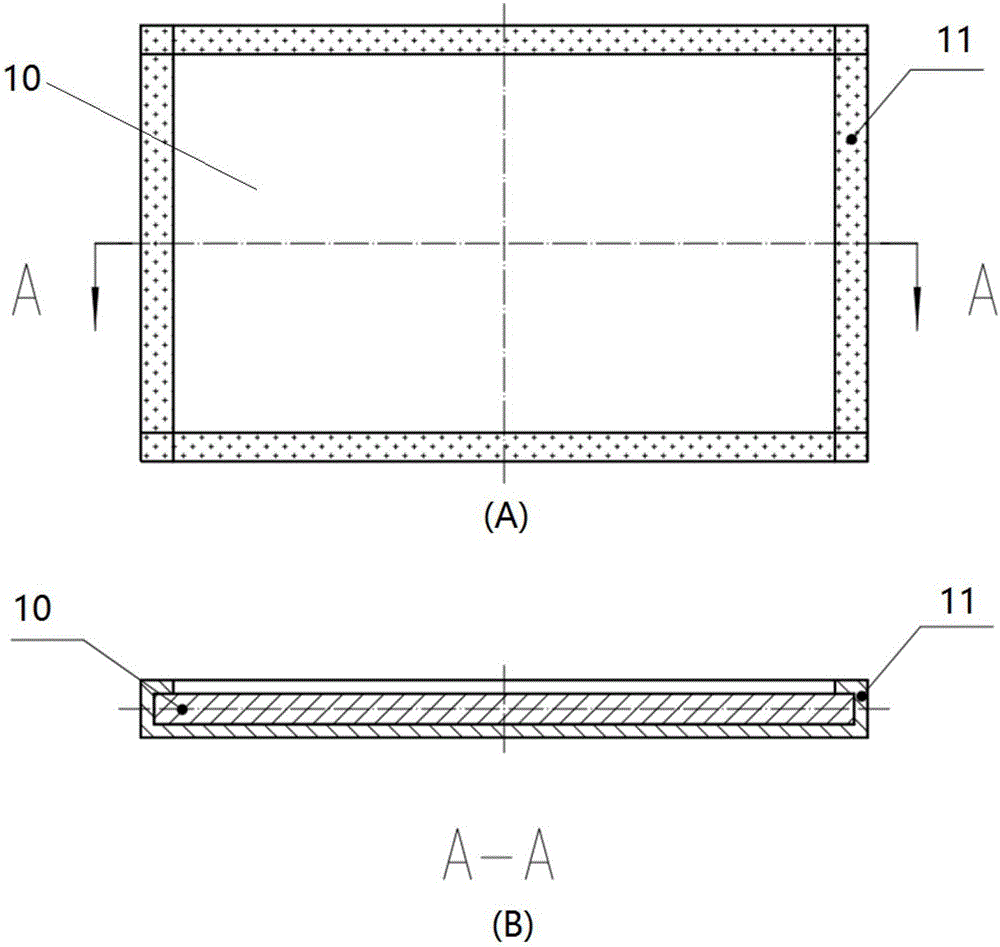

ActiveCN108545010AImprove construction conditionsImprove surface strengthRefrigerated goods vehicleSynthetic resin layered productsHeat transmissionSandwich board

The invention discloses a refrigeration compartment board and a preparation method thereof. The refrigeration compartment board comprises a frame composite structure and skins pasted to the upper surface and the lower surface of the frame composite structure through hot melt adhesive. The frame composite structure comprises a layer A and a layer B, wherein the layer A comprises a frame and a skinning polyurethane foam board filled in the frame; the layer B is a skinning polyurethane foam board, and the layer A and the layer B are pasted through the hot melt adhesive; and the frame is made frommultiple waterproof battens, a waterproof agent is injected into common wood under the high pressure to form waterproof wood, and the waterproof wood is machined into the waterproof battens. The refrigeration compartment board is good in waterproof performance and good in heat preservation effect, a double-layer seam elimination composite structure is adopted, certain rigidity of sandwich boardscan be guaranteed, heat conduction generated by foam seams can be effectively eliminated, heat transmission is stopped, and a heat preservation effect is remarkable. The board manufacturing efficiencyis high, a quick-forming board manufacturing process is adopted, a component is quickly located, each sandwich board is compositely formed only within 10 min to 15 min, and the board manufacturing efficiency is high.

Owner:SYST EQUIP CO LTD OF THE 28TH RES INST LI YANG

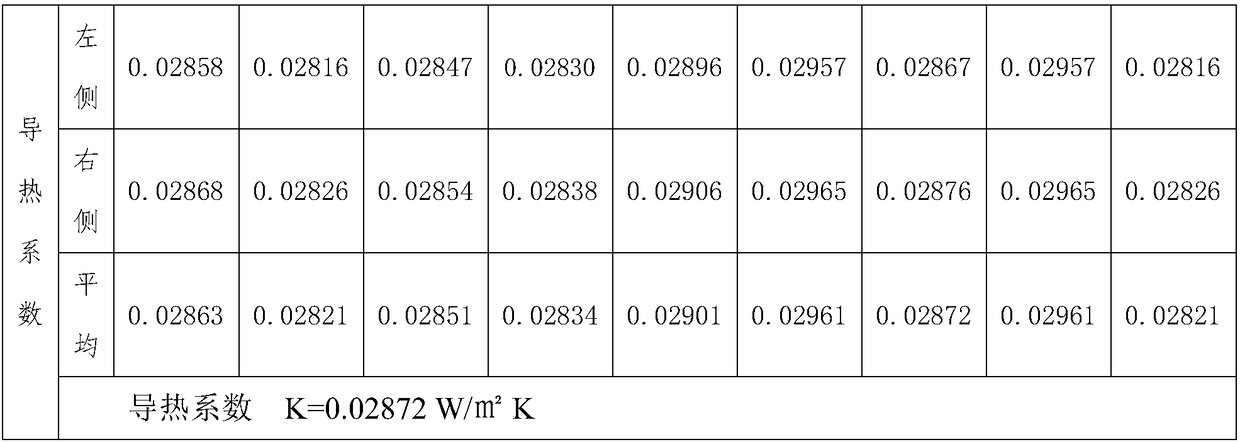

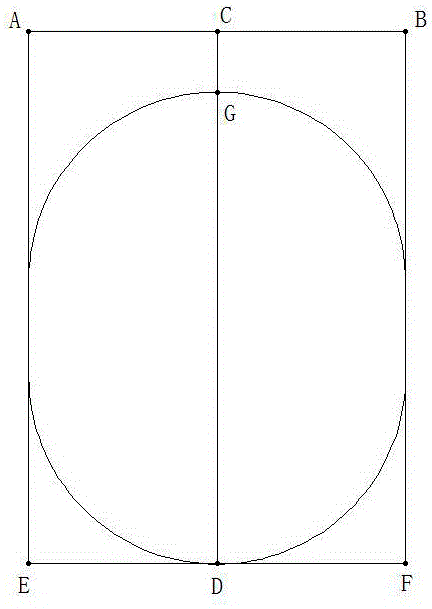

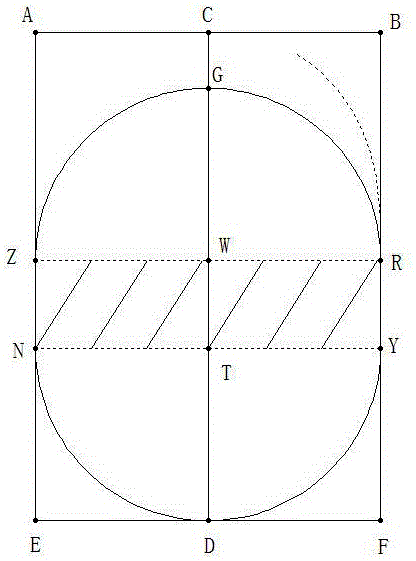

Western-style clothes sleeve cap height determination method

ActiveCN106174831AReduce blindnessReasonable methodGarmentsClothes making applicancesHigh volume manufacturingAgricultural engineering

The invention relates to a western-style clothes sleeve cap height determination method which comprises a front cut part and a rear cut part of western-style clothes. The determination method comprises the following operation steps of determining all points and connection lines, determining a sleeve cap height line and determining a sleeve cap height value. The method can determine the sleeve height value of a sleeve matched with the cut parts according to the front cut part and the rear cut part and can determine the height of an armhole circle formed after the front cut part and the rear cut part are sewed before the front cut part and the rear cut part are sewed, and the height of the armhole circle is the sleeve cap height of the sleeve matched with the clothes. Compared with a traditional sleeve cap height determination method, the determination method is more reasonable, reduces the blindness in sewing sleeves of the western-style clothes, improves pattern making efficiency and is suitable for being popularized and applied to large-scale clothes production.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

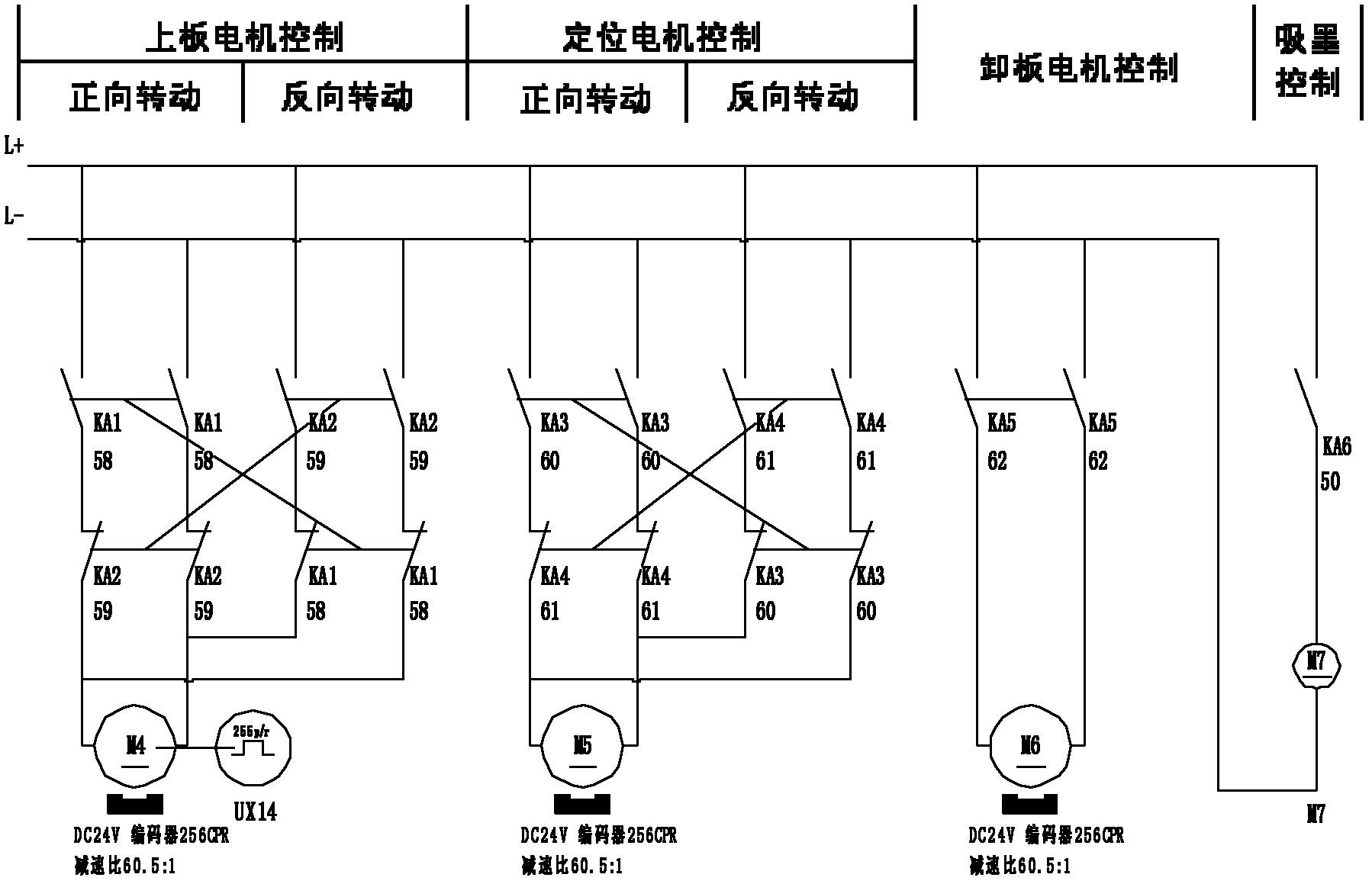

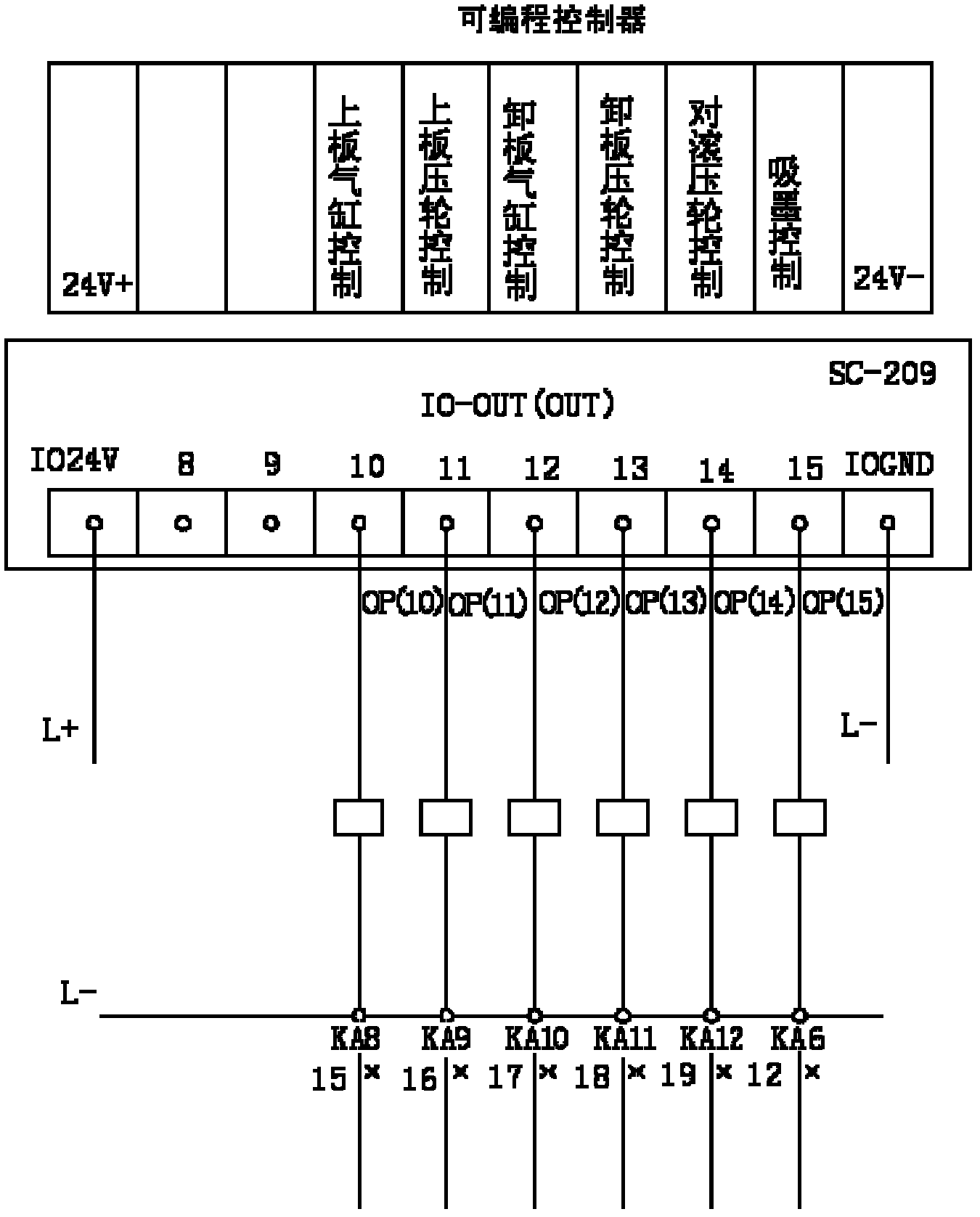

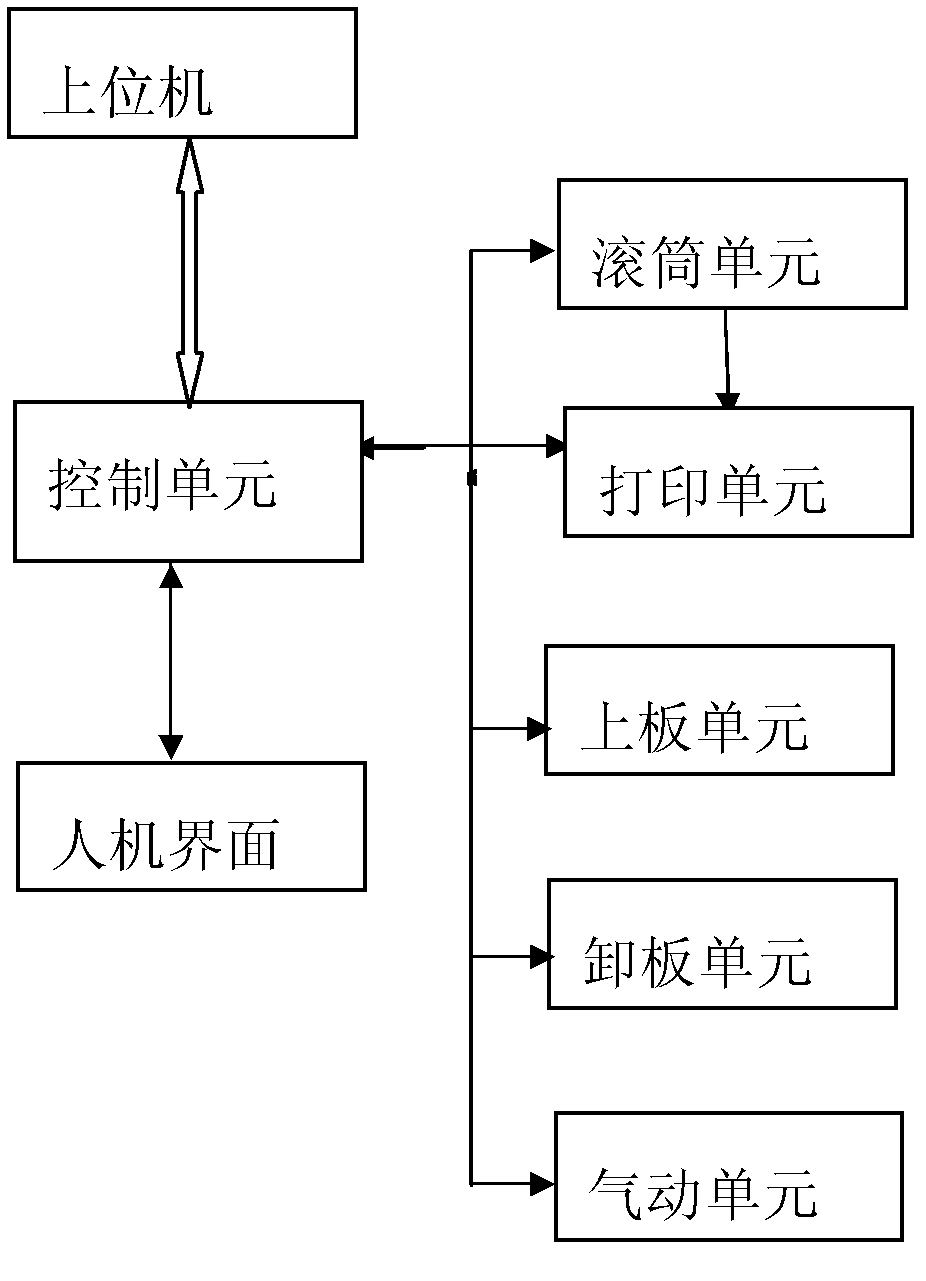

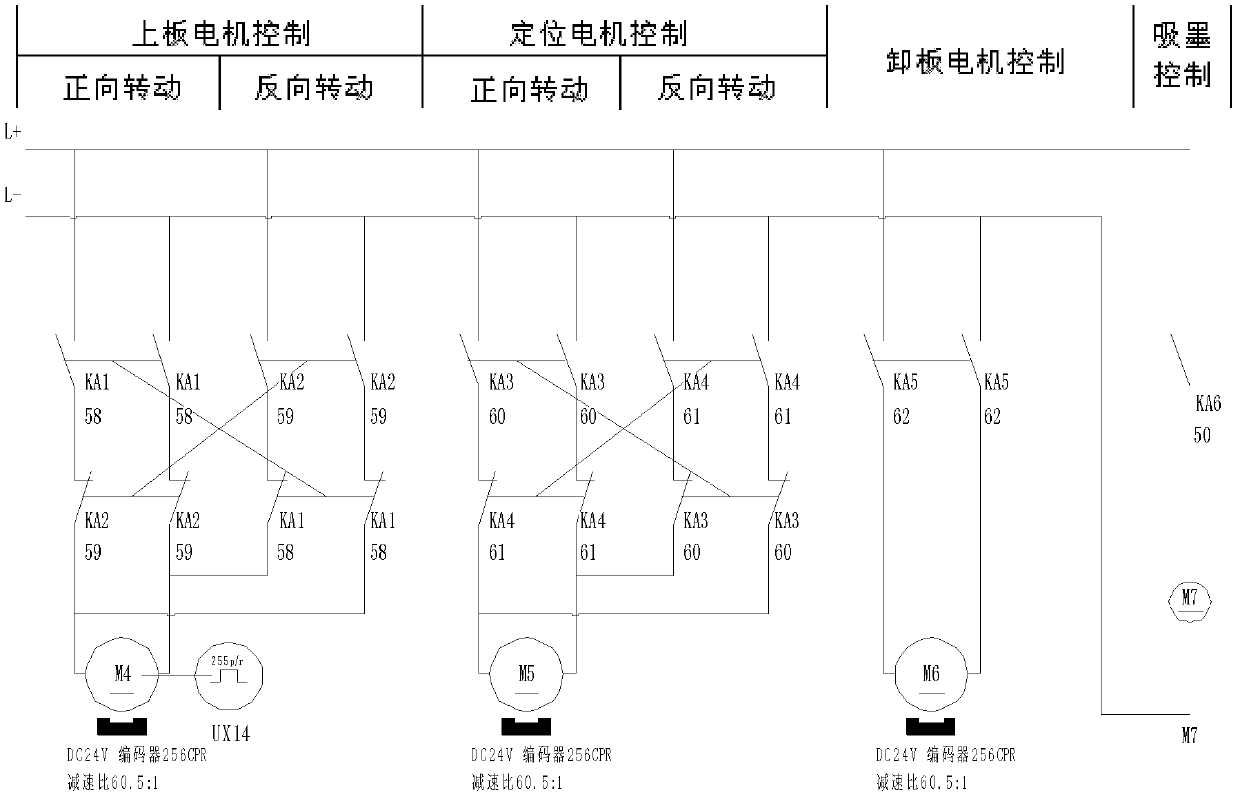

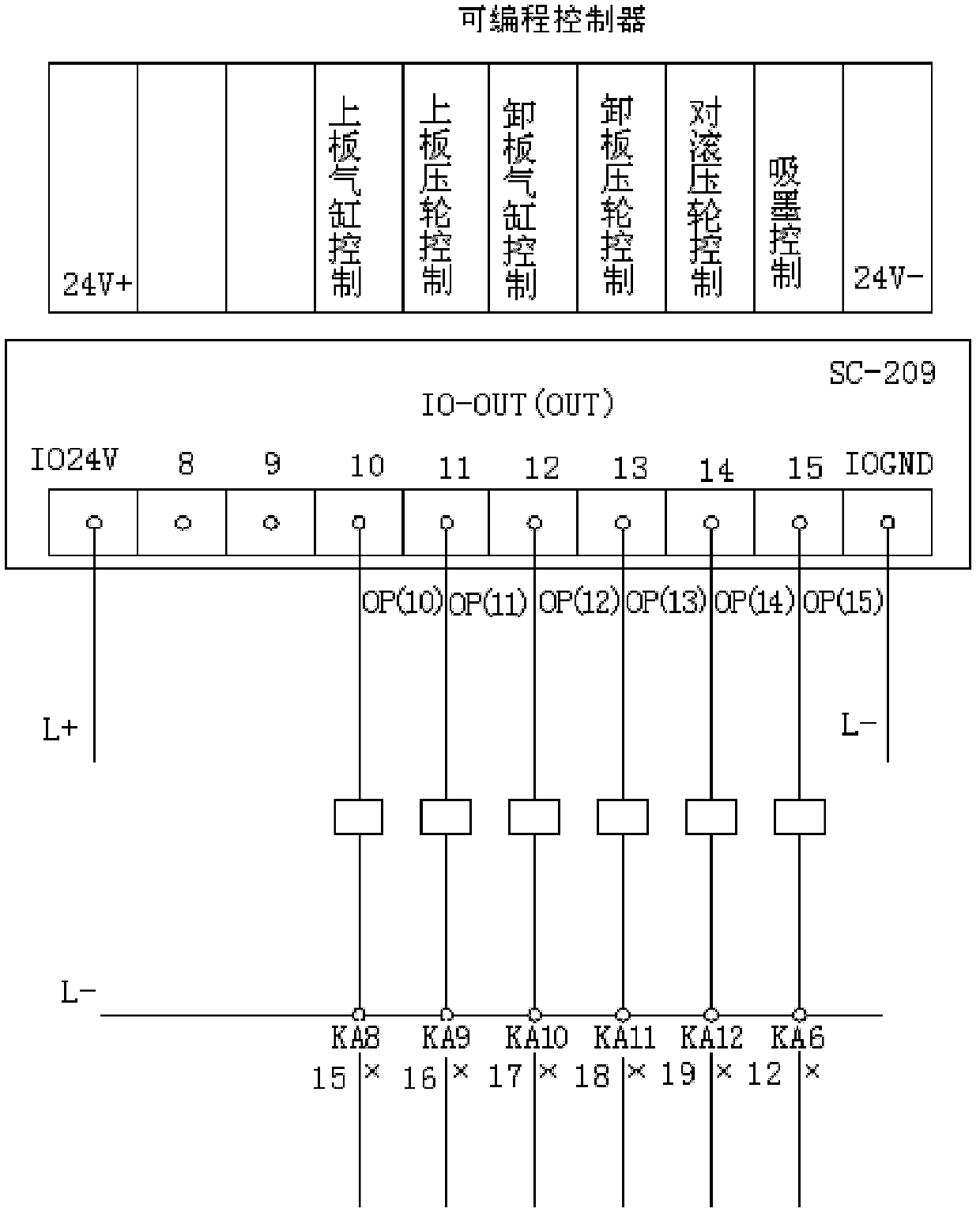

Plate feeding device of nanometer material computer to plate and control method for plate feeding device

ActiveCN102582216APrecise positioningPlay a preliminary roleForme preparationControl signalComputer to plate

The invention relates to a plate feeding device of a nanometer material computer to plate and a control method for the plate feeding device. A driving motor of a first roller in the device is used for receiving a control signal to drive a material plate to enter the plate feeding device; a positioning device is used for positioning the material plate in the axial direction of a drum; a control unit is used for receiving a position feedback signal of the driving motor of the first roller and outputting the control signal to a control loop of a head clip cylinder; and the control unit is used for outputting the control signal to a control loop of a tail clip cylinder according to a position signal fed back by a printing unit. The method comprises the following steps of: starting the drum to rotate to an original point and starting a pneumatic unit; starting the first roller to roll the material plate and positioning the material plate at a first detection position; when the material plate reaches a second detection position, sending a rotation position signal of the first roller to the control unit; when the material plate reaches a head clip position, turning off a head clip; and when the material plate reaches a tail clip position, turning off a tail clip to end a plate feeding process. According to the plate feeding device of the nanometer material computer to plate, the material plate can be totally rolled onto the drum, so that a printing face is solid and smooth, positioning is accurate, and the operating accuracy and the control precision of the whole nanometer material computer to plate are ensured.

Owner:辽宁中科洪笙纳米装备技术有限公司

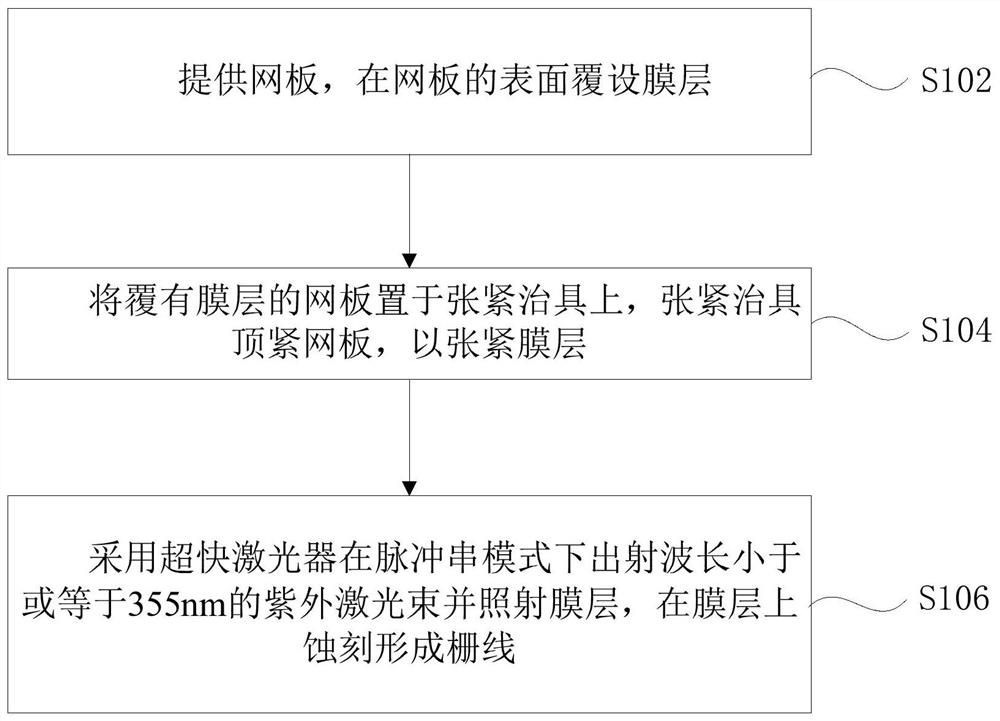

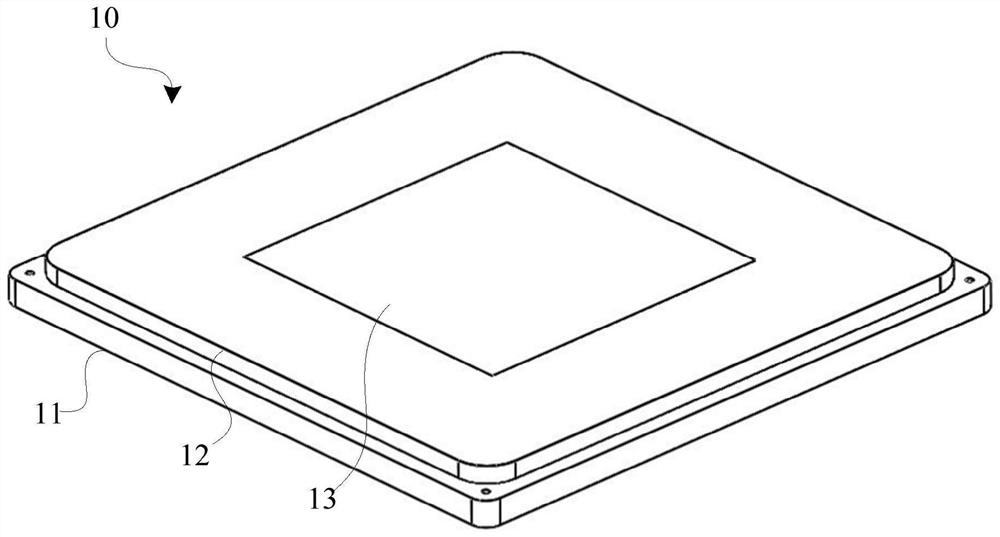

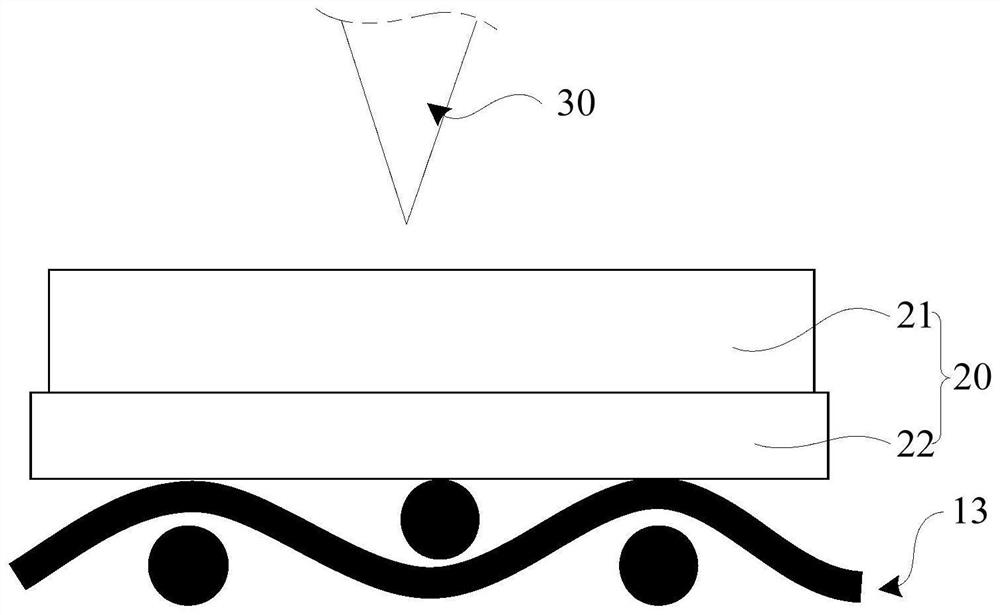

Plate making method of silk-screen printing plate

PendingCN113075863AAvoid damageExtended service lifePhotomechanical exposure apparatusMicrolithography exposure apparatusScreen printingUltraviolet

The invention relates to a plate making method of a silk screen plate, and the method comprises the following steps: providing a screen plate, and covering a film layer on the surface of the screen plate; placing the screen plate covered with the film layer on a tensioning jig, and enabling the tensioning jig to abut against the screen plate so as to tension the film layer; adopting an ultrafast laser to emit ultraviolet laser beams with the wavelength smaller than or equal to 355 nm in a pulse string mode, irradiating the film layer, and forming grid lines on the film layer in an etching mode. According to the plate making method of the silk-screen printing plate, an ultrafast laser device is adopted to emit ultraviolet laser beams with the wavelength smaller than or equal to 355 nm in a pulse string mode and irradiate a film layer, and grid lines are formed on the film layer in an etching mode. According to the method, the negative film does not need to be replaced, the plate making process is simplified, the plate making efficiency is improved, meanwhile, damage to the metal wire mesh can be reduced as much as possible through the machining mode that the ultrafast laser emits the laser beams in the pulse string mode, and therefore the service life of the metal wire mesh is prolonged, and cost is reduced.

Owner:HANS LASER TECH IND GRP CO LTD

Epoxy resin casting body plate preparation method and device

The invention relates to an epoxy resin casting body plate preparation method and device. A mold of which the periphery is opened is built through two glass plates, and both mold assembly operation and resin casting-in operation are simple and convenient. The thickness of the mold is controlled through cushion blocks, adjustment is convenient, and the mold can be used for preparing resin casting body plates of which the thicknesses are different. As the mold building mode is simple, adjustment is convenient in the operation process, and the probability of occurrence of defective goods can be decreased. Transparent adhesive tapes are stuck to one side and the periphery of each glass plate, and as the transparent adhesive tapes are made of a hydrophobic material, separation from resins is easy after resin curing and cleaning is convenient. The preparation method of the casting body plates is protected, the most important characteristic lies in that the mold is formed by assembling the two glass plates and the thickness controlling cushion blocks in a simple mode, and adjustment is convenient.

Owner:保定华翼风电叶片研究开发有限公司

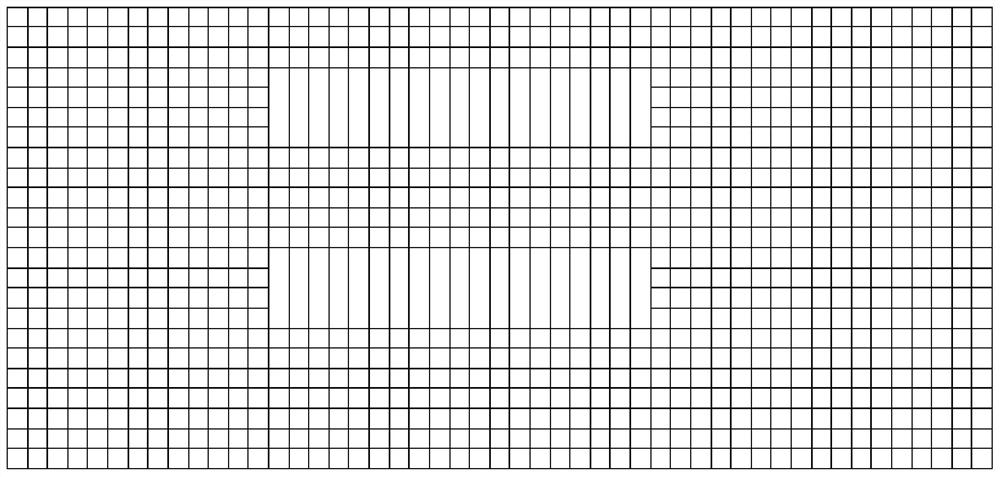

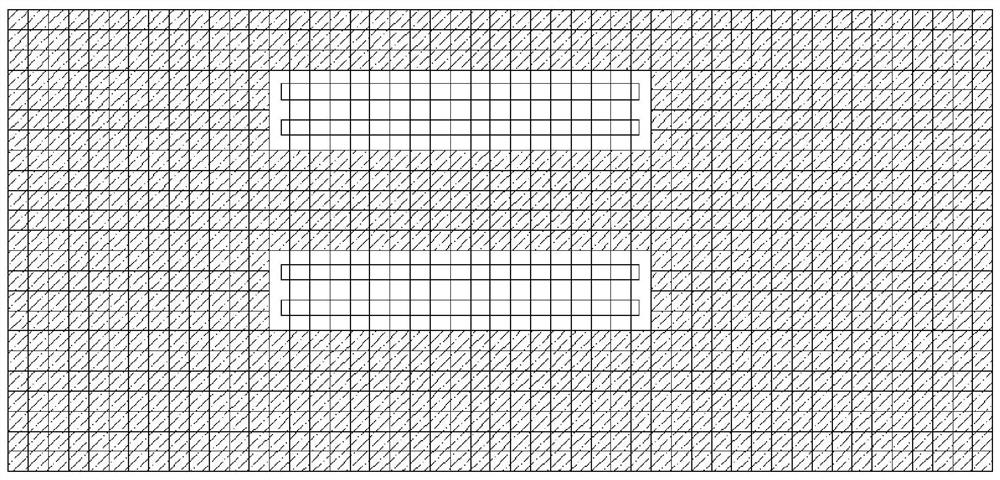

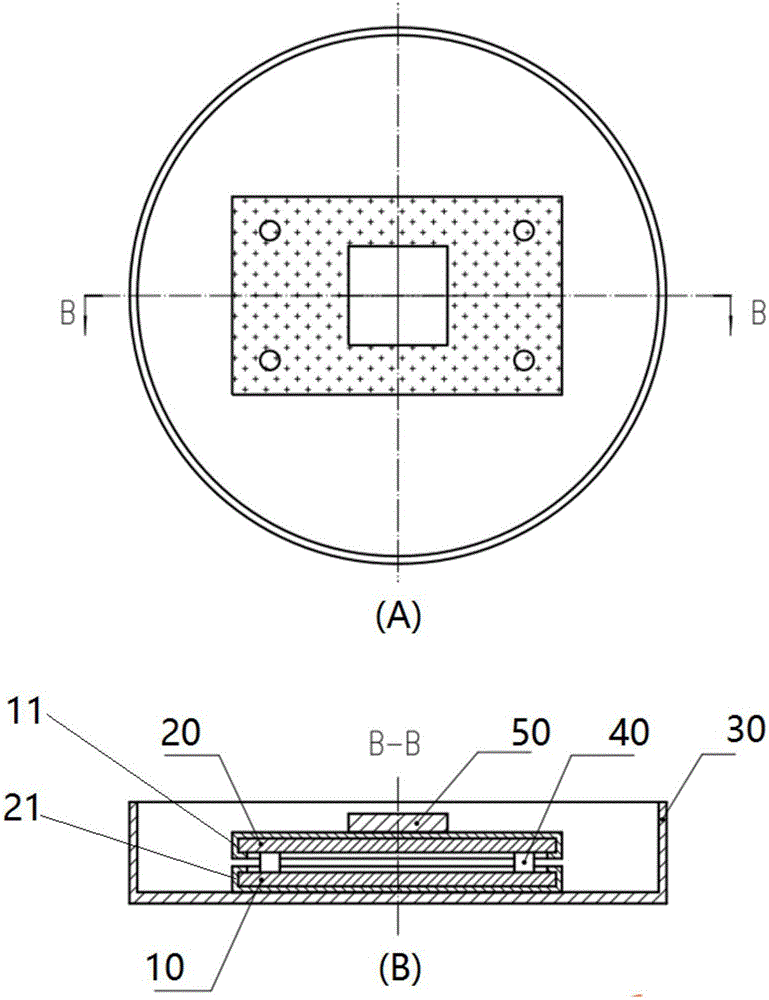

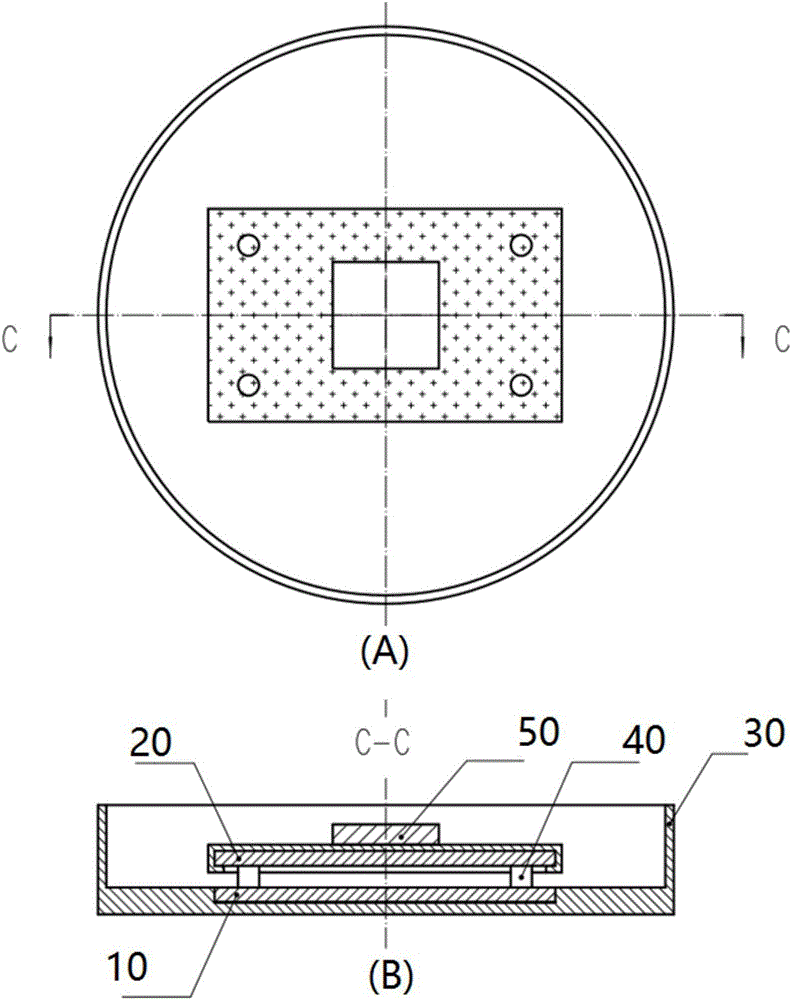

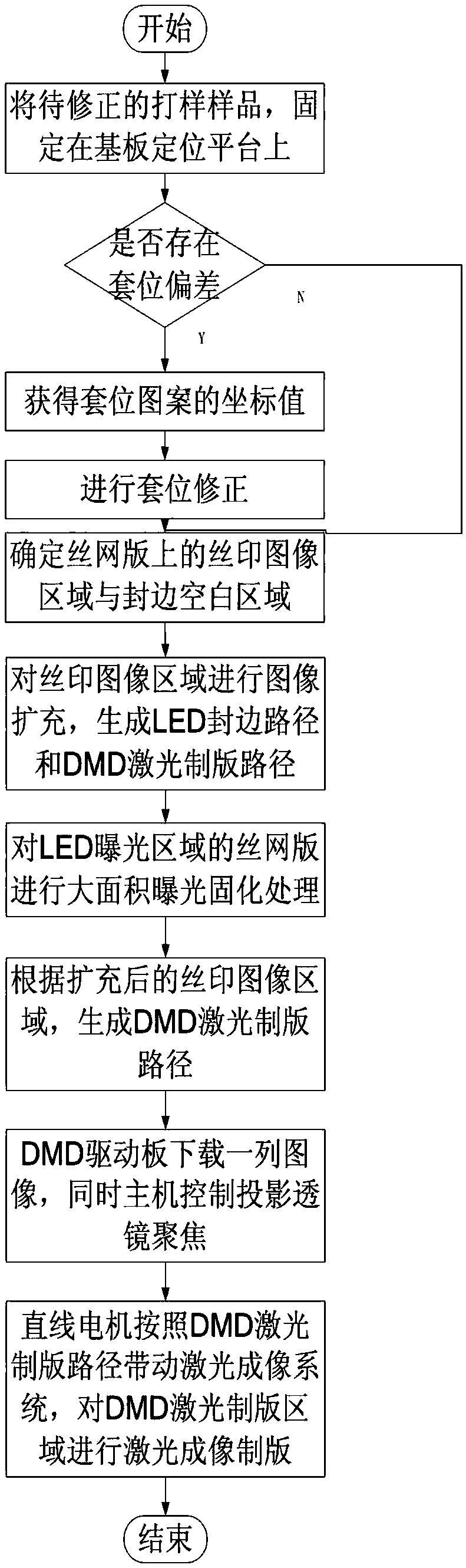

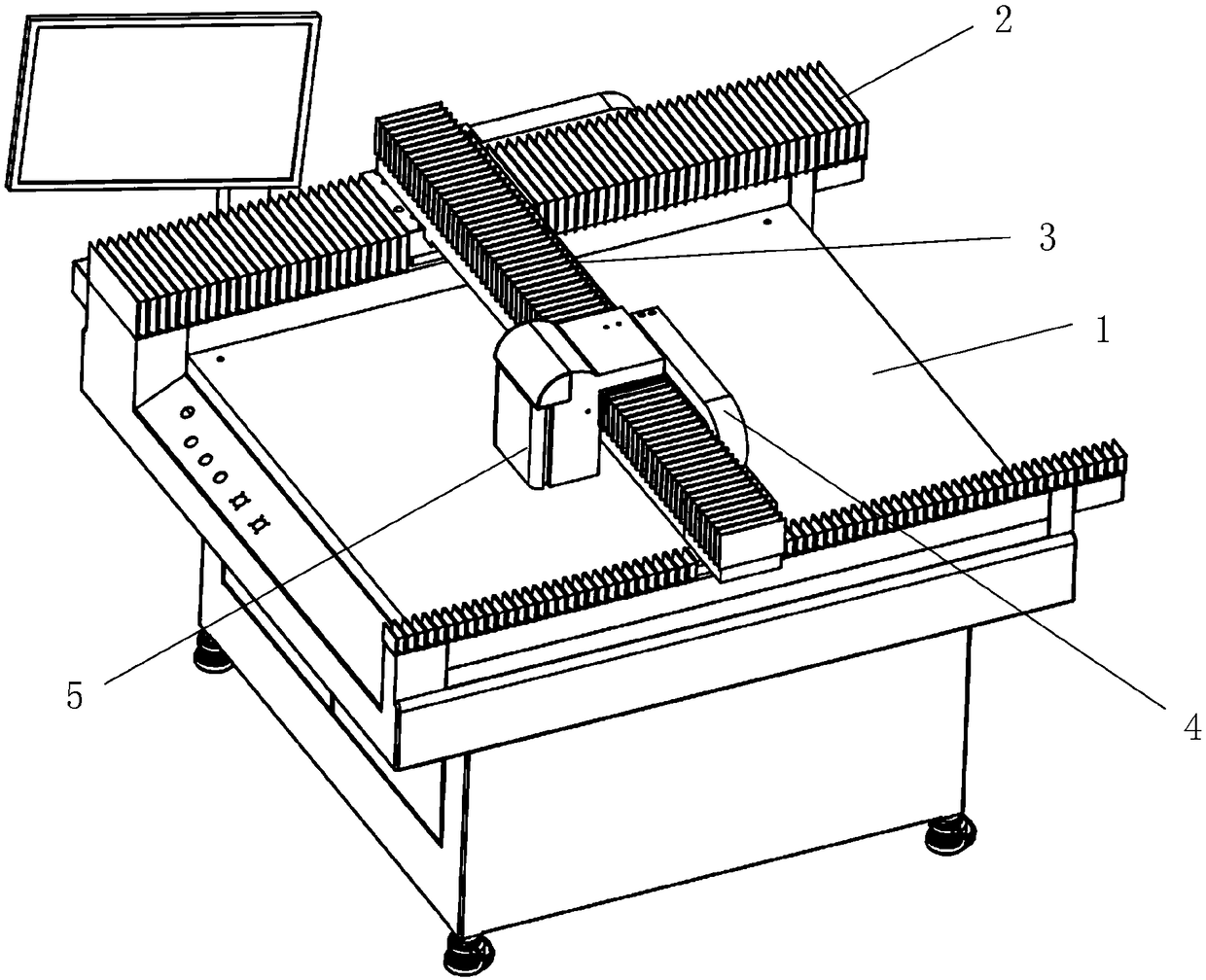

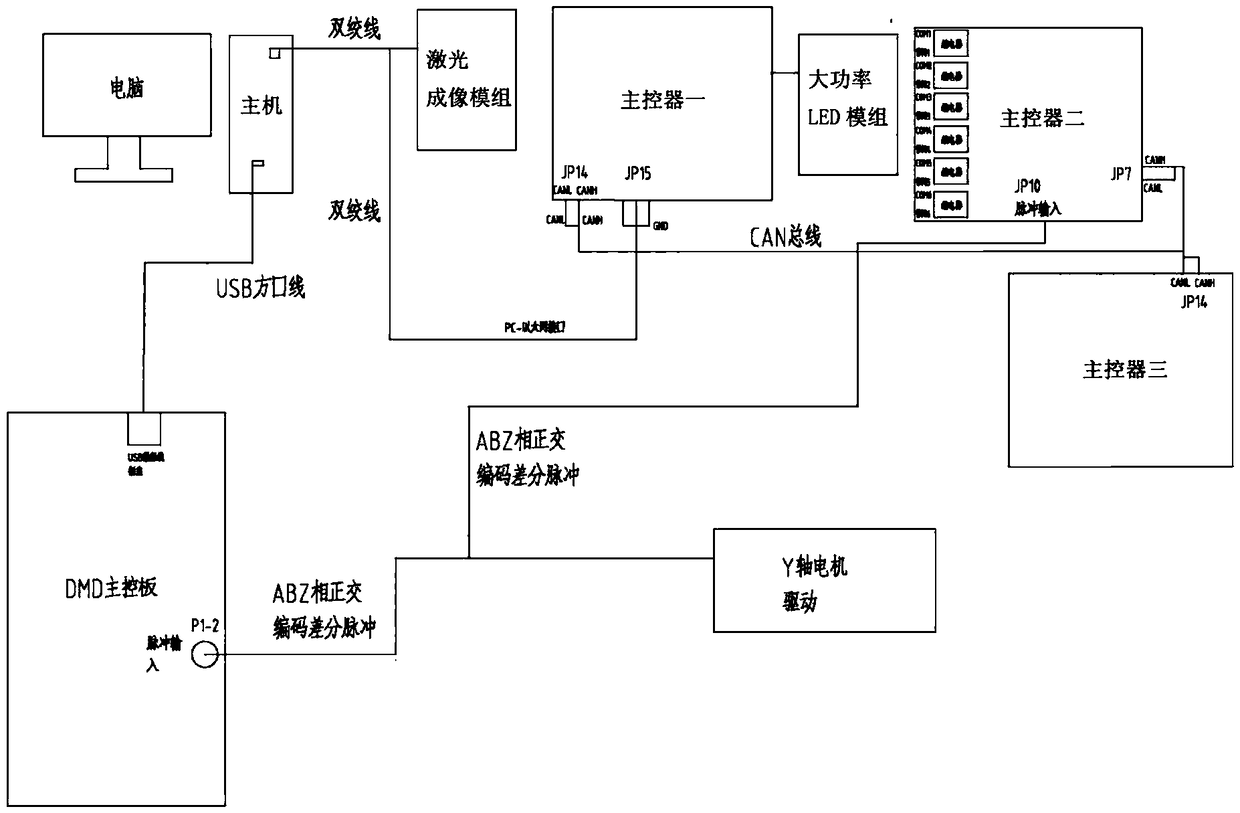

Intelligent silk screen nesting board-making technology

ActiveCN108646518AIncrease freedomReduce loadPhotomechanical exposure apparatusMicrolithography exposure apparatusHuman powerMaterial resources

The invention discloses an intelligent silk screen nesting board-making technology. By virtue of the technology, high correction precision is achieved, waste of manpower and material resources is highly lowered, and working efficiency is further improved. Two kinds of correction modes are adopted: 1, a coordinate value of an offset printing pattern is obtained and corrected, the corrected value istransmitted to a host, and a corrected coordinate value is worked out by calculation of the host; 2, the nesting correction information is recorded automatically, and all nesting correction information generates a nesting correction data table; manual correction is performed according to the nesting correction data table, and then board making is performed; and through a board making mode of a combination of DMD laser direct board making and large-area explosion of an LED module, quick edge sealing can be realized through the LED module, so that the board making effect of the silk printed effect is not influenced, the load of the laser imaging system is lowered, and service life of a DMD optical micro-mirror array is also prolonged.

Owner:北京弘浩千瑞科技有限公司 +1

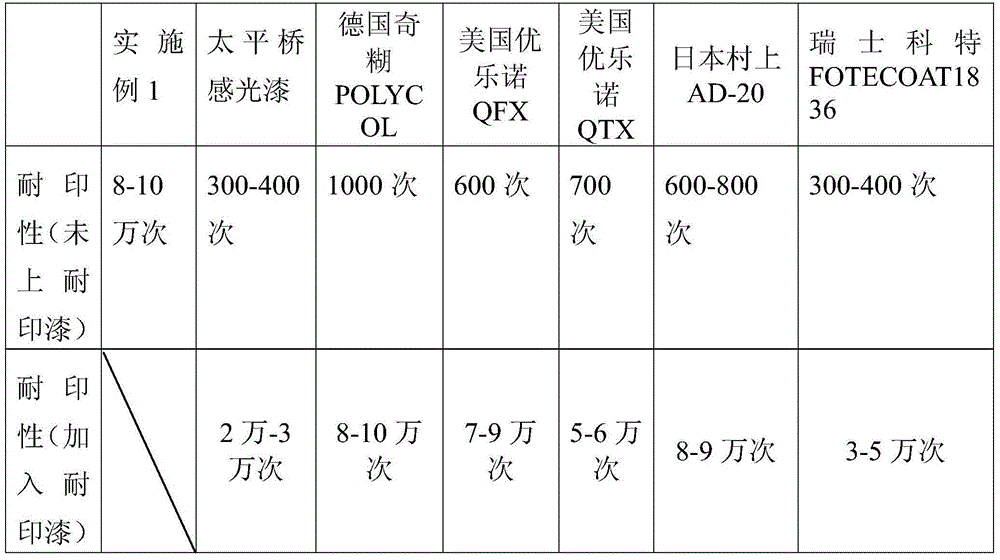

Long-pressrun photosensitiser for printing of blanket and towel

ActiveCN104911926AExcellent printing resistanceReduce usageDyeing processPhotosensitive materials for photomechanical apparatusOrganic solventEmulsion

The invention brings forward a long-pressrun photosensitiser for printing of blanket and towel. The long-pressrun photosensitiser is prepared by mainly using a modified polyvinylalcohol aqueous solution, modified vinyl acetate, acrylate, an organosilicone monomer copolymer emulsion and modified photosensitive urethane acrylate. The photosensitiser provided by the invention has good long-pressrun performance. Without a long-pressrun paint, pressrun number can meet actual use requirements, platemaking process is minimized, and platemaking efficiency is raised. During production, use of the long-pressrun paint is reduced, and the damage of an organic solvent in the long-pressrun paint to workers and the environment is avoided.

Owner:JIASHAN MINGXIAN NEW MATERIAL TECH

Waterborne flexographic printing scraping white ink and preparation method and application thereof

The invention discloses a waterborne flexographic printing scraping white ink and a preparation method and the application thereof, and belongs to the technical field of printing. The waterborne flexographic printing scraping white ink is composed of, by mass percent, the following components of 15.0-25.0% of waterborne polyurethane A, 20.0-30.0% of waterborne polyurethane B, 40.0-50.0% of titanium dioxide, 2.0-3.0% of dispersing agents, 0.1-0.3% of defoaming agent and 10.0-20.0% of water. According to the waterborne flexographic printing scraping white ink and the preparation method and the application thereof, the solvent-free waterborne polyurethane is adopted, the titanium dioxide is added, no organic solvent exists in the full process, VOC emission is nearly zero, the environment can be effectively protected, and mixing of the different waterborne polyurethane is adopted to achieve the overall effect after printing is performed; materials which harm a human body are not contained, a workshop is free of odor and poisonous gas, and the worker health is guaranteed; even if an end consumer makes contact with scraped ink powder when the end consumer scrapes the ink, health hazards are not generated.

Owner:SHENZHEN BRIGHT INK & COATING CO LTD

Circuit board and manufacturing method thereof

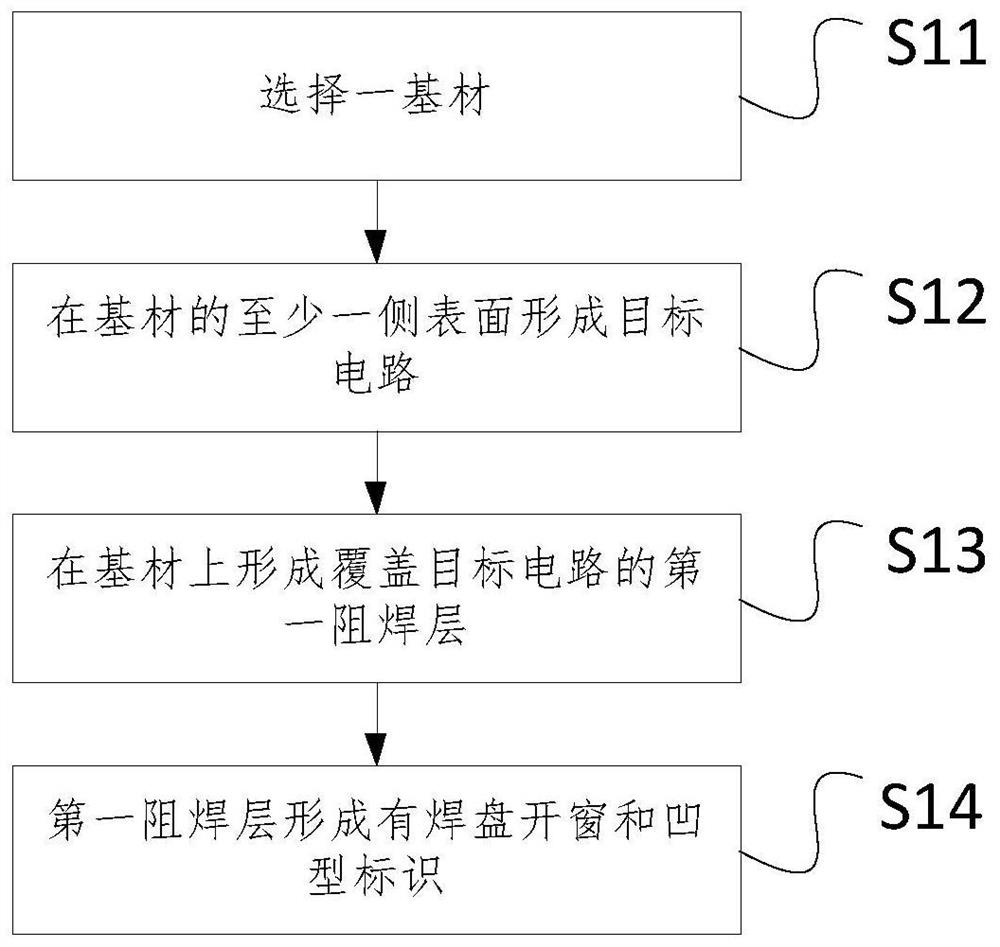

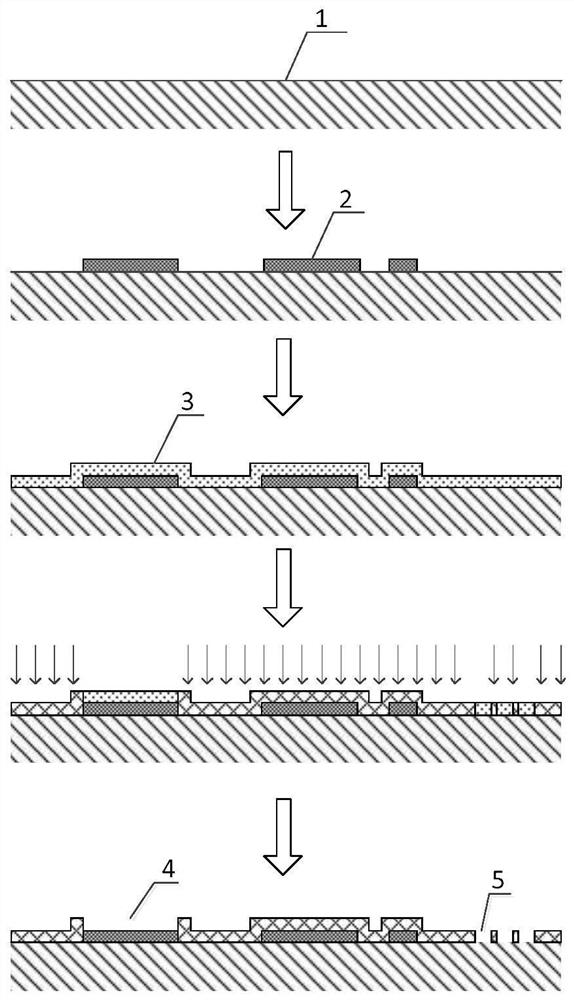

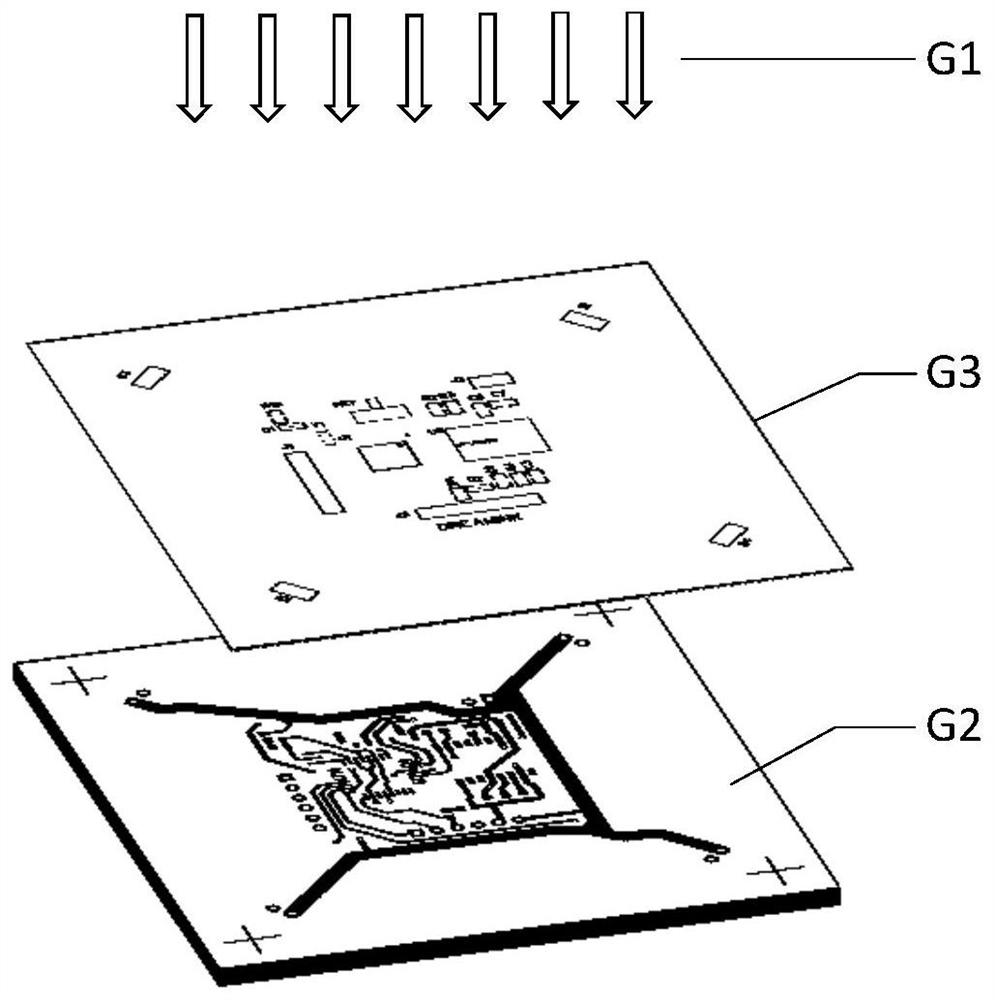

PendingCN114666994AImprove plate making efficiencySimplify the plate making processInspection/indentification of circuitsNon-metallic protective coating applicationSolder maskHemt circuits

The invention discloses a circuit board and a manufacturing method thereof, and relates to the technical field of electronic circuit manufacturing. The manufacturing process of the circuit board comprises the following steps: selecting a base material; forming a target circuit on at least one surface of the substrate; forming a first solder mask layer covering the target circuit on the substrate; and selectively exposing a partial region of the first solder mask layer, and forming a pad window for exposing the target circuit pad and a concave identifier for indicating the target circuit information on the first solder mask layer after development. According to the embodiment of the invention, the silk-screen mark and the solder resist windowing are integrally formed in a concave mark mode, so that the plate-making process is simplified, the plate-making efficiency of the circuit board is improved, and the plate-making cost is reduced.

Owner:BEIJING DREAM INK TECH CO LTD

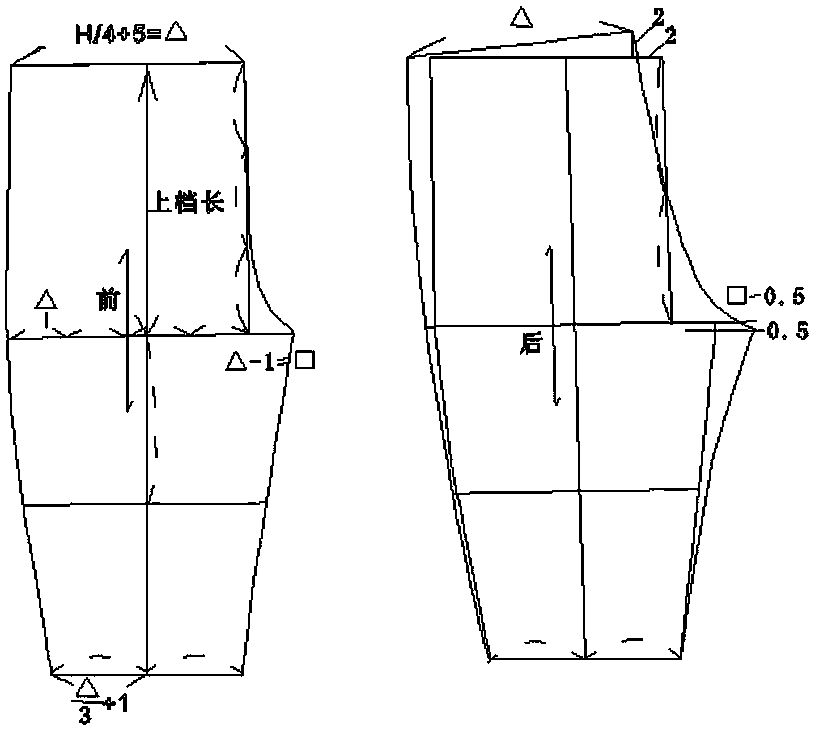

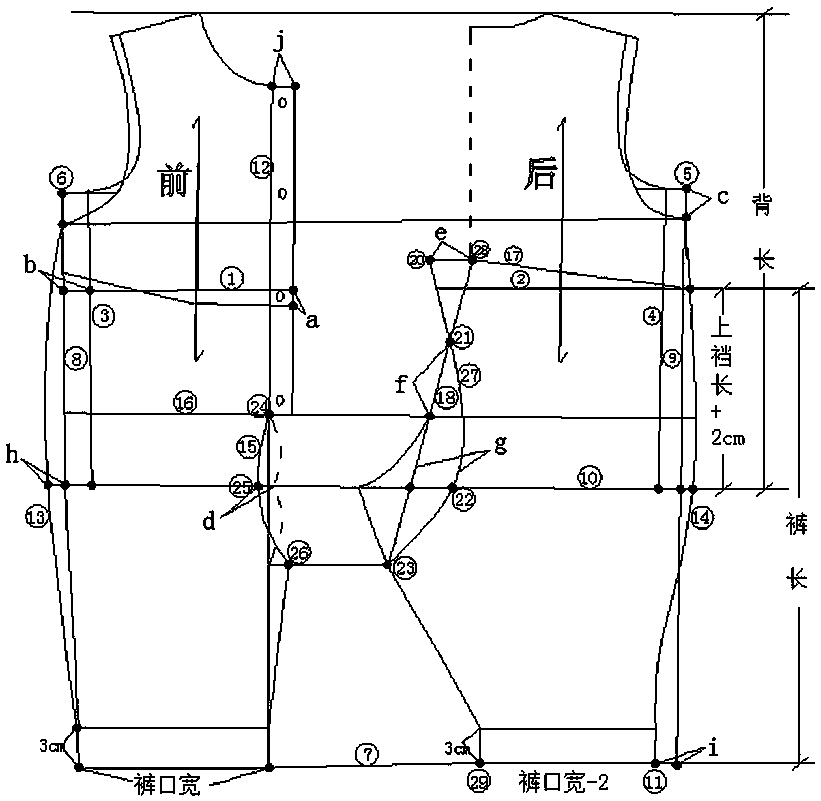

Infant onesie card board production method

ActiveCN110584252APlate making steps are simpleThe plate making process is clearClothes making applicancesEngineeringMechanical engineering

The invention relates to an infant onesie card board production method. According to the card board production method, a Japanese cultural child top prototype and child trouser prototype are used forstructure production. The method comprises the step of structure production of a front piece and a rear piece, including structure production of upper body pieces, structure production of trouser pieces, overall structure production of a onesie and structure production of a crotch, wherein the structure production of the crotch comprises the steps that 2.1, a front piece crotch cutting structure is made, wherein concave design is performed on the crotch opening position of the front piece, the vertex of the original crotch opening position, the vertex of the concave position and front piece crotch points at the original front piece crotch opening position are connected through arc lines to form a front piece crotch cutting position; and 2.2, a rear piece crotch cutting structure is made, wherein back-upwarp design is performed on a waist line of the rear piece, concave design is performed on the crotch opening position of the rear piece, and the back-upwarped waist line of the rear piece and the concave design are combined to form a rear piece crotch cutting position. According to the infant onesie card board production method, the Japanese cultural child top prototype and child trouser prototype are used for structure production of the front piece, the rear piece and the crotch; and the method has the advantages that board production steps are simple, gradually change and areeasy to learn, board production efficiency is high, a produced finished product is attractive in appearance, and the crotch has good comfort.

Owner:HUIZHOU UNIV

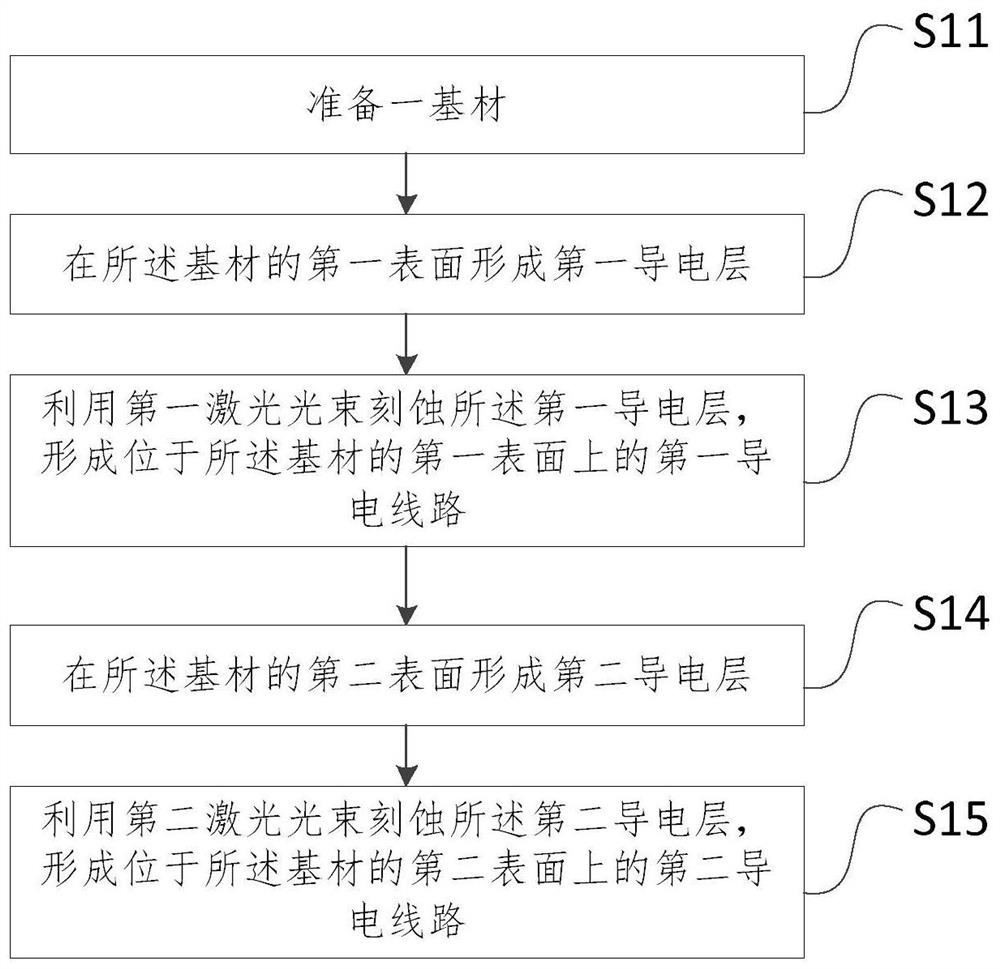

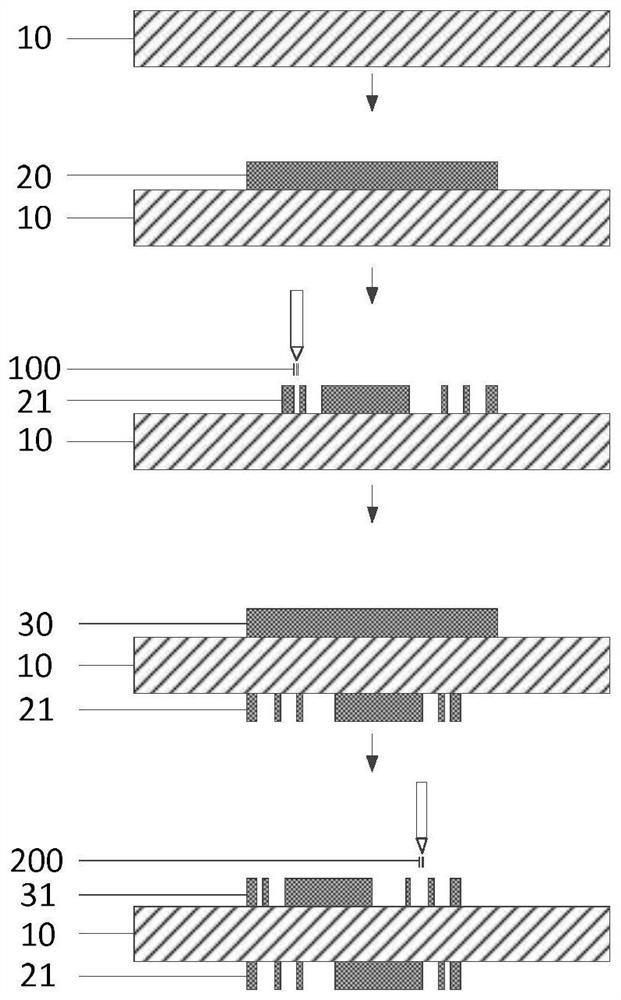

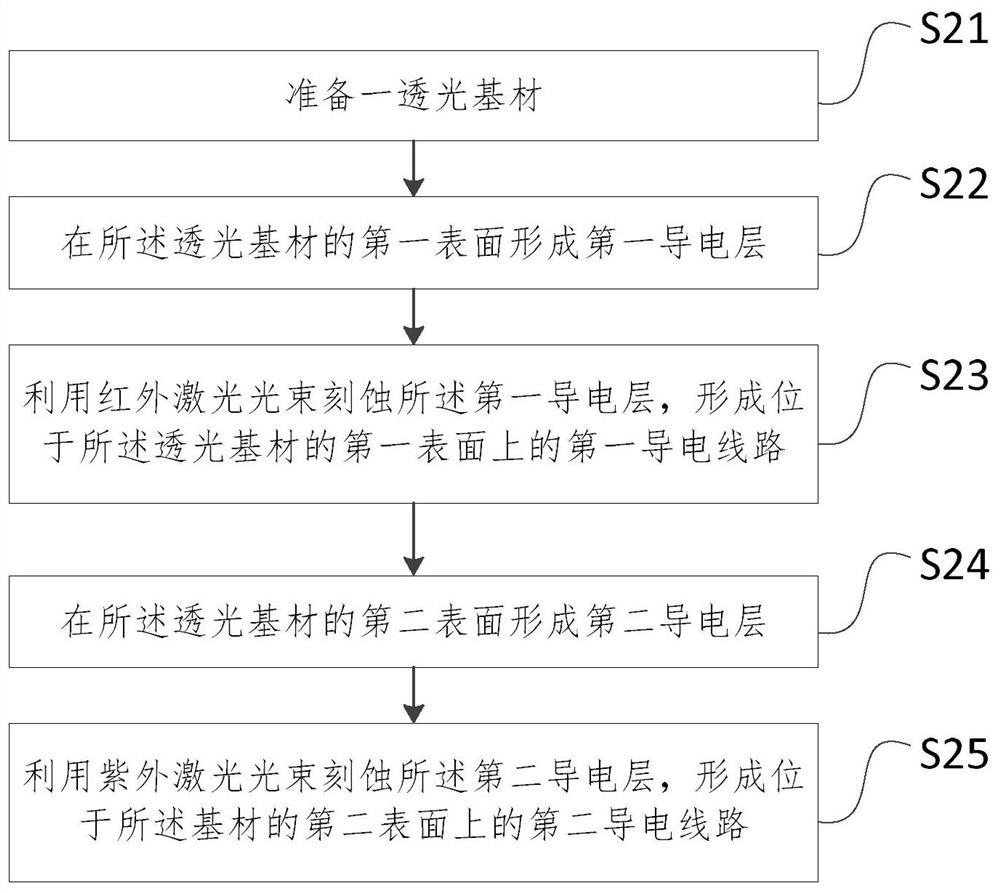

Double-sided circuit board and manufacturing method thereof

ActiveCN113068310AImprove plate making efficiencySimple processElectrical connection printed elementsConductive material removal by irradiationLaser etchingMechanical engineering

The invention discloses a double-sided circuit board and a manufacturing method thereof, and relates to the technical field of electronic circuit preparation. The manufacturing method of the double-sided circuit board comprises the following steps: preparing a base material; forming a first conductive layer on the first surface of the base material; etching the first conductive layer by using a first laser beam to form a first conductive circuit located on the first surface of the base material; forming a second conductive layer on the second surface of the base material; and etching the second conductive layer by using a second laser beam to form a second conductive circuit on the second surface of the base material. According to the embodiment of the invention, the conductive layer is processed and formed on the substrate through the laser etching process, the high-precision circuit board can be manufactured by means of the high-precision performance of the laser beams, and the process is simple, high in plate making efficiency and capable of meeting the industrial plate making requirement.

Owner:BEIJING DREAM INK TECH CO LTD

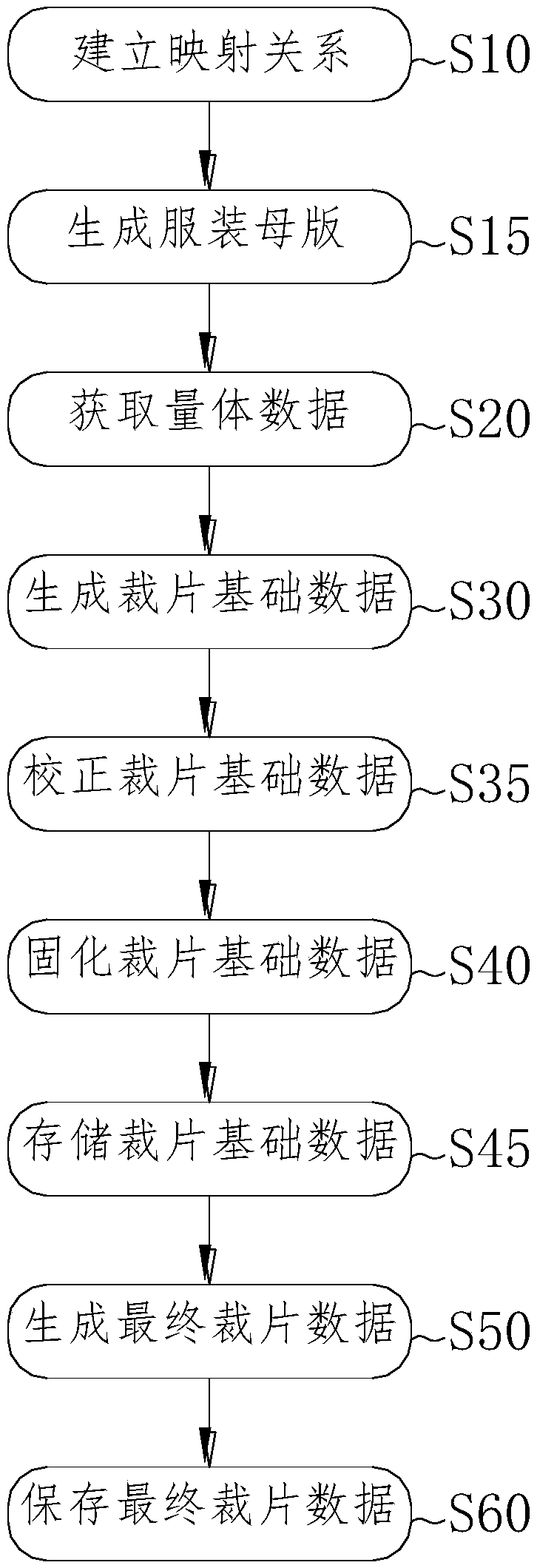

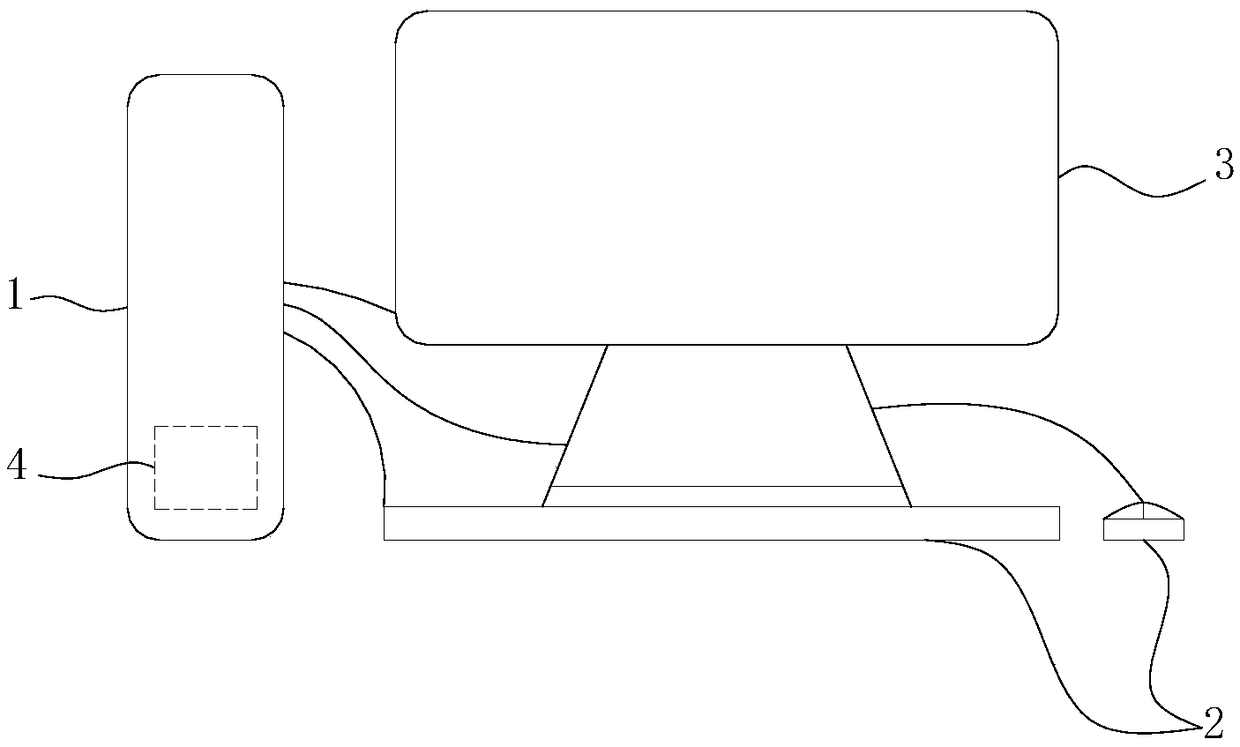

An automatic plate making method and an automatic plate making device

PendingCN109299527AWon't make a big differenceNo changeSpecial data processing applicationsPersonalizationData science

The invention relates to a garment plate making method. The invention provides an automatic plate making method, which is used for solving the technical problem that the garment can not be individually decorated when a computer is used for plate making in the prior art. The invention relates to an automatic plate making method, The mapping relationship between volume data and basic cutting data isestablished. After volume data is obtained, basic cutting data is generated automatically according to volume data and mapping relationship between volume data and basic cutting data, which realizesautomatic plate making, reduces labor intensity of operators and improves cutting precision. The data is cured after the basic data of cutting is generated, Then, the basic data of cutting is modifiedto meet the needs of personalized plate-making. As the basic data of cutting is solidified, the modification will not cause significant changes in the basic data of cutting, and furthermore, the comfort of clothing will not be affected while meeting the needs of personalized clothing.

Owner:东蒙集团有限公司

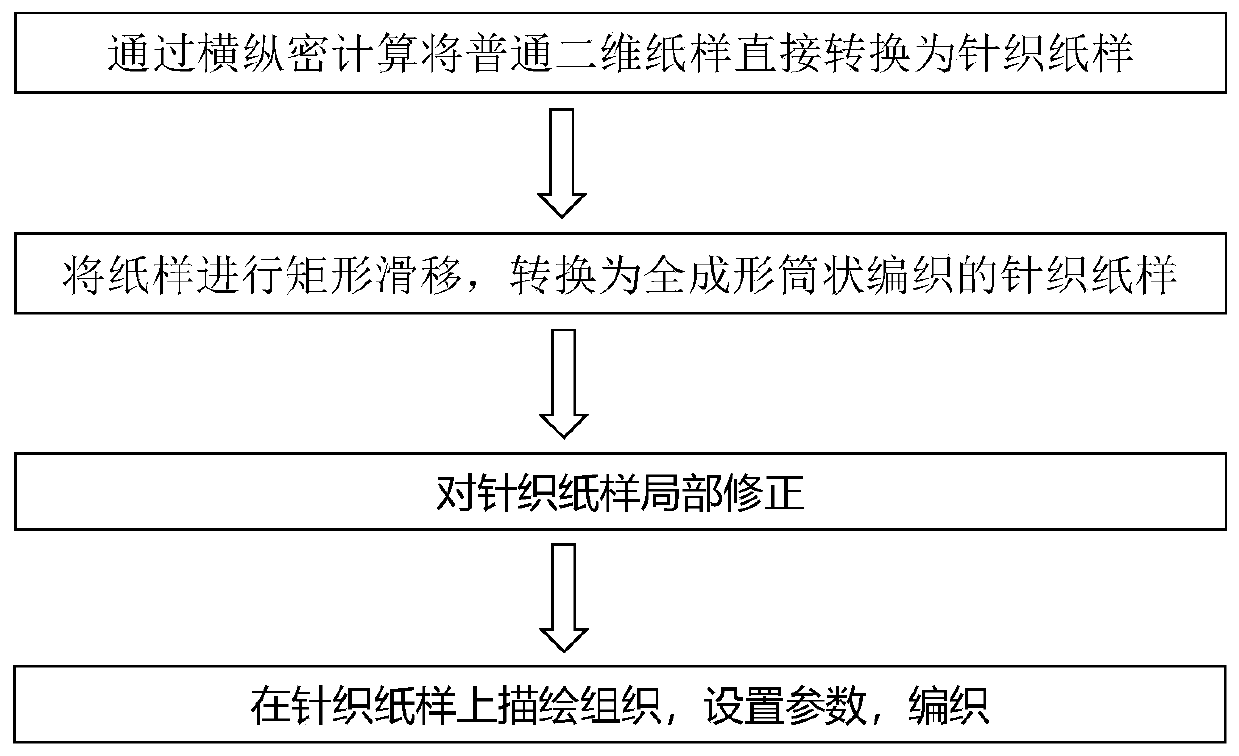

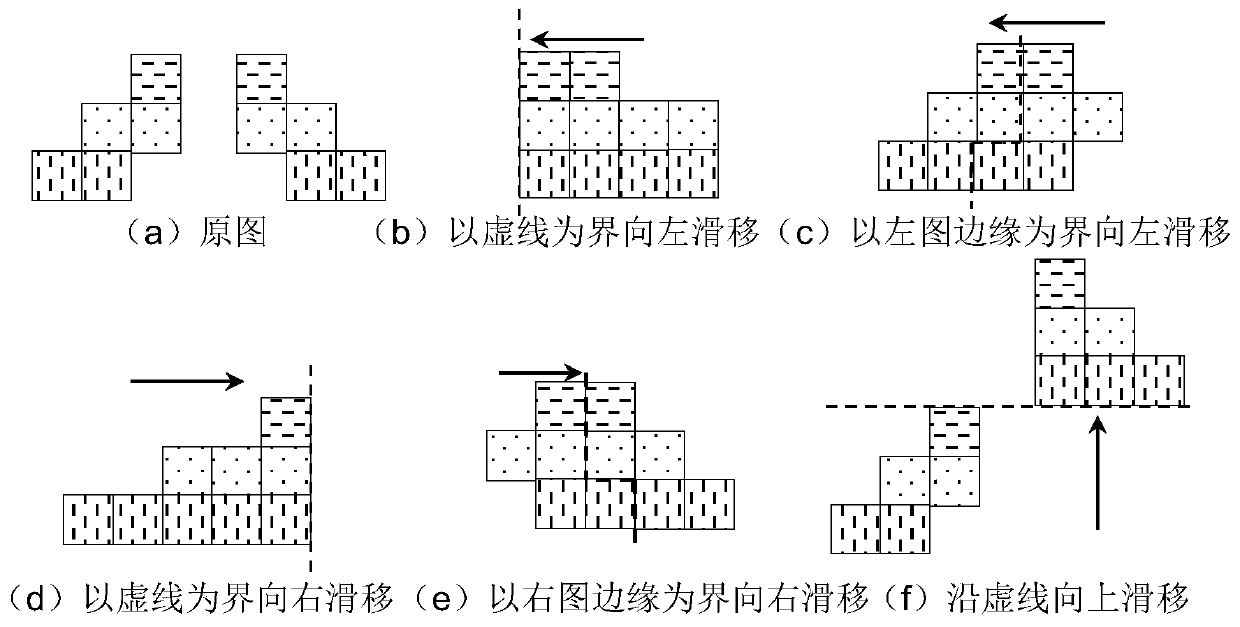

Method for converting two-dimensional pattern into knitting pattern of three-dimensional full-formed garment

ActiveCN110485042AImprove plate making efficiencyQuality improvementWeft knittingClothes making applicancesEngineeringVolumetric Mass Density

The invention discloses a method for converting a two-dimensional pattern into a knitting pattern of a three-dimensional fully-formed garment. A common two-dimensional paper pattern is directly converted into a knitting pattern through transverse and longitudinal density calculation; according to the knitting pattern, rectangular slippage is carried out to convert the knitting pattern into a fully-formed tubular knitting pattern for knitting. The full-formed garment is high in pattern-making efficiency and quality, and the method is also suitable for forming knitting of a double-needle bed.

Owner:JIANGNAN UNIV

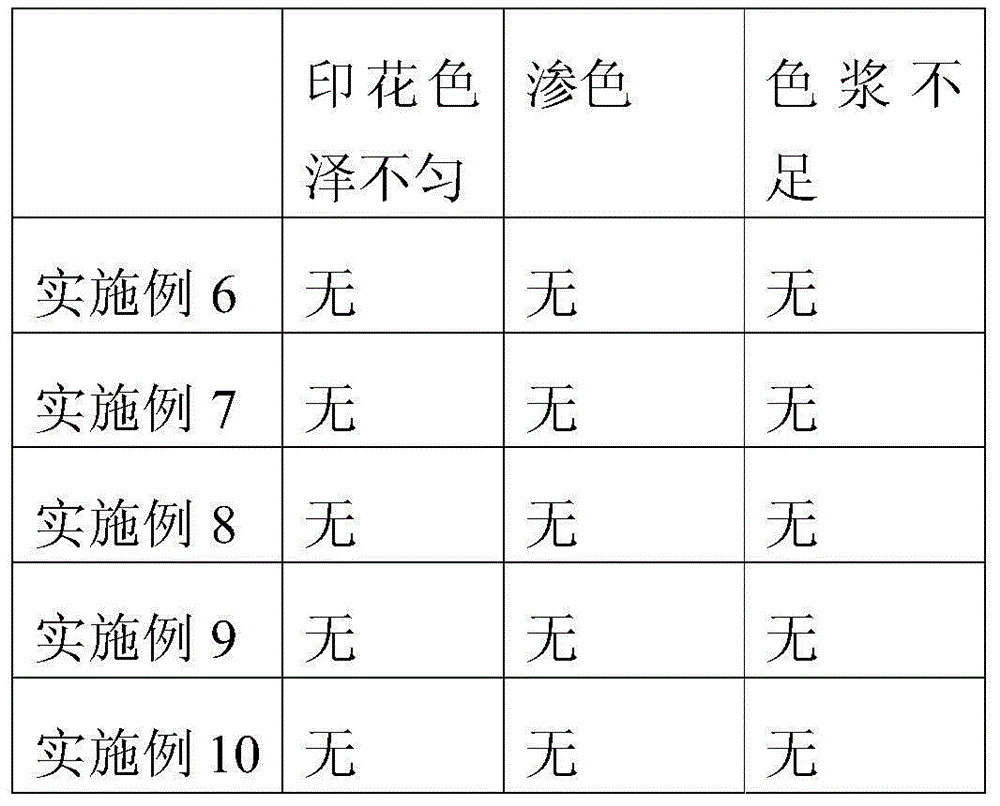

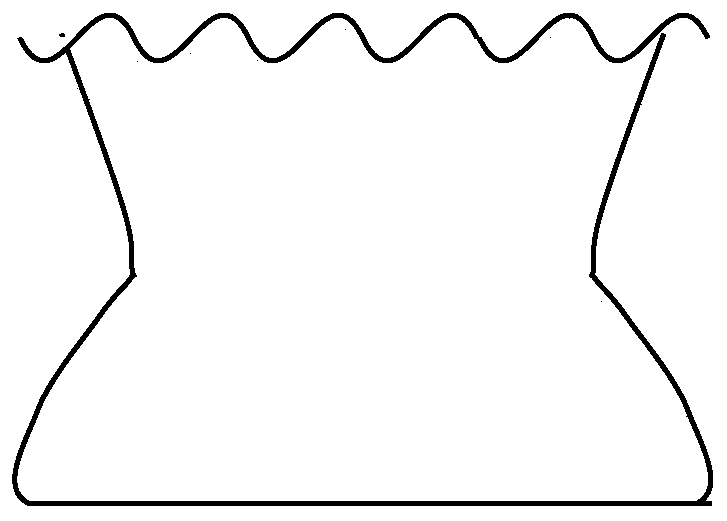

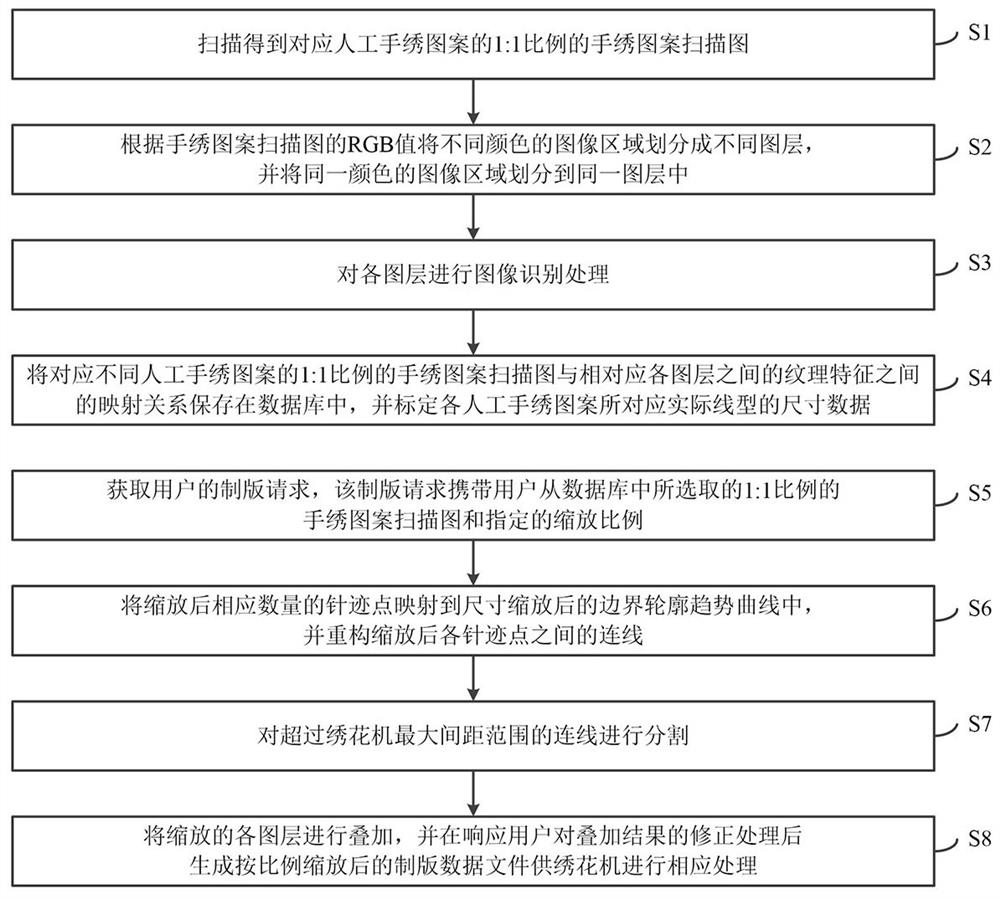

Image data processing method and system in Hunan embroidery plate-making process

ActiveCN113298081BImprove reuse rateImprove plate making efficiencyCharacter and pattern recognitionBoundary contourImaging processing

The invention relates to the technical field of image processing, and discloses an image data processing method and system in the plate making process of Hunan embroidery, so as to improve the plate making efficiency and the reuse rate of resources. The method includes: scanning to obtain a hand-embroidered pattern scan in a ratio of 1:1 corresponding to the artificial hand-embroidery pattern, dividing image areas of different colors into different layers according to the RGB values of the hand-embroidery pattern scan, and dividing the same color image area into different layers. The image area is divided into the same layer; image recognition processing is performed on each layer, and during the recognition process of any layer, the stitches, connecting lines and texture features of the layer are recognized; The stitch points are mapped to the trend curve of the boundary contour after size scaling, and the connection lines between the stitch points after scaling are reconstructed; then the connection lines that exceed the maximum spacing range of the embroidery machine are divided; finally, the scaled layers are divided Superimpose to obtain the plate-making data file for the embroidery machine.

Owner:HUNAN NORMAL UNIVERSITY

Method for simulating plate making by computer instead of band engraving

InactiveCN1415492ALow costShorten the plate making periodStampsDecorative surface effectsEngravingComputer graphics (images)

A method fo r preparing woodcut by computer to simulate manual carving features that a group of vector lines with different widthes is used to map the gray scales of traditional woodcut. Its advantage is high productivity.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

A direct plate-making method and application of a printing plate and plate roller integrated flexographic plate and 3D rapid prototyping printing

The invention provides a direct plate-making method of 3D rapid prototyping printing of a flexible plate integrated with a printing plate and a plate roller. The steps are as follows: using 3D printing to make a plate, first use three-dimensional software to design a pre-printed plate, and then select the printing material , use a 3D printer to print out the printed material and the graphics on the printed page, and then get a flexographic plate with an integrated printing plate and plate roller. The method of the present invention designs the printing plate and graphics into a cylindrical shape directly in the 3D design drawing, saves installation steps, does not require labor and labor, improves operability and safety, does not cause bending deformation caused by installation, and improves accuracy. At the same time, this method saves the compensation step of the pre-press deformation, wraps the antenna graphic on the printing plate, integrates the graphic and printing plate, and the printing plate and the cylinder. The content of the graphic and text is fixed, and the accuracy of graphic and text duplication is improved. The method of the present invention will create a new chapter in the flexographic plate making technology of the integration of the printing plate and the plate roller, and fill the domestic blank.

Owner:TIANJIN HAISHUN PRINTING & PACKAGING

Plate feeding device of nanometer material computer to plate and control method for plate feeding device

ActiveCN102582216BPrecise positioningPlay a preliminary roleForme preparationLoop controlComputer to plate

The invention relates to a plate feeding device of a nanometer material computer to plate and a control method for the plate feeding device. A driving motor of a first roller in the device is used for receiving a control signal to drive a material plate to enter the plate feeding device; a positioning device is used for positioning the material plate in the axial direction of a drum; a control unit is used for receiving a position feedback signal of the driving motor of the first roller and outputting the control signal to a control loop of a head clip cylinder; and the control unit is used for outputting the control signal to a control loop of a tail clip cylinder according to a position signal fed back by a printing unit. The method comprises the following steps of: starting the drum to rotate to an original point and starting a pneumatic unit; starting the first roller to roll the material plate and positioning the material plate at a first detection position; when the material plate reaches a second detection position, sending a rotation position signal of the first roller to the control unit; when the material plate reaches a head clip position, turning off a head clip; and when the material plate reaches a tail clip position, turning off a tail clip to end a plate feeding process. According to the plate feeding device of the nanometer material computer to plate, the material plate can be totally rolled onto the drum, so that a printing face is solid and smooth, positioning is accurate, and the operating accuracy and the control precision of the whole nanometer material computer to plate are ensured.

Owner:辽宁中科洪笙纳米装备技术有限公司

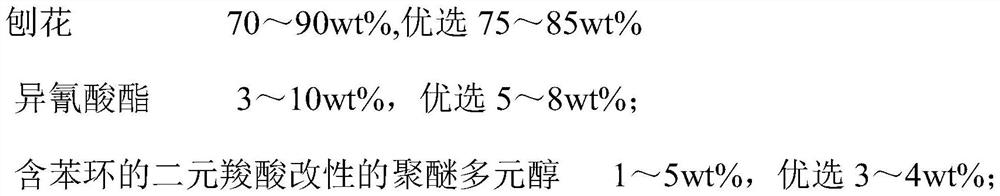

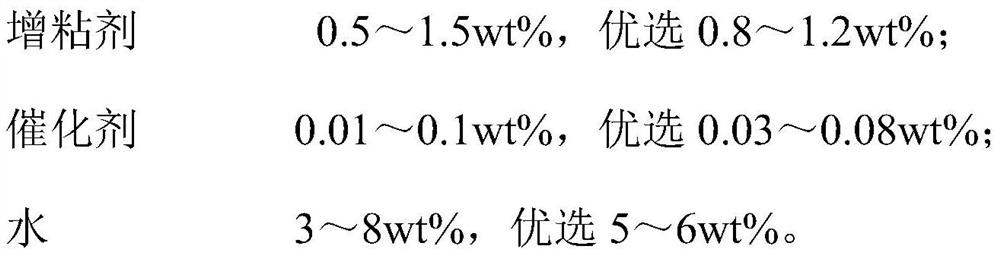

A kind of aldehyde-free light particle board and preparation method thereof

ActiveCN112388794BMeet performance index requirementsLow densitySolid waste managementFlat articlesPtru catalystPolyol

The invention discloses an aldehyde-free light particle board and a preparation method thereof. The density ranges from 0.4 to 0.6 g / cm. 3 . The raw materials used mainly include: shavings, isocyanate, benzene ring-containing dicarboxylic acid-modified polyether polyol, tackifier, catalyst, and water. The light-weight particleboard prepared by the invention has low density and excellent performance, can meet the requirements of various performance indicators for particleboard in the national standard GB / T 4897‑2015, has excellent dimensional stability and water resistance, and can be widely used in various indoor Decoration, and the board material is light, easy to move indoors, and strong practicability.

Owner:WANHUA CHEM GRP CO LTD

Method for simulating plate making by computer instead of band engraving

InactiveCN1175973CLow costShorten the plate making periodStampsDecorative surface effectsEngravingComputer graphics (images)

A method fo r preparing woodcut by computer to simulate manual carving features that a group of vector lines with different widthes is used to map the gray scales of traditional woodcut. Its advantage is high productivity.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

A kind of ultraviolet offset printing inline white ink and preparation method thereof

The invention relates to the technical field of printing, and particularly discloses ultraviolet offset printing continuous machine white ink and a preparation method thereof. The ultraviolet offset printing continuous machine white ink is prepared from, by mass, 15.0%-25.0% of polyester acrylate oligomer, 10.0%-20.0% of thermoplastic acrylic resin, 40.0%-50.0% of titanium dioxide, 2.0%-3.0% of a dispersing agent, 3.0%-5.0% of a photoinitiator and 10.0%-20.0% of monomers. According to the ultraviolet offset printing continuous machine white ink, the covering power of traditional ultraviolet screen printing ink is compatible with the high-speed printing characteristics of ultraviolet offset printing ink, not only is the covering effect of the UV screen printing ink achieved, but also the high-speed cooperating requirement of the UV offset printing ink is achieved.

Owner:山东布瑞特油墨有限公司

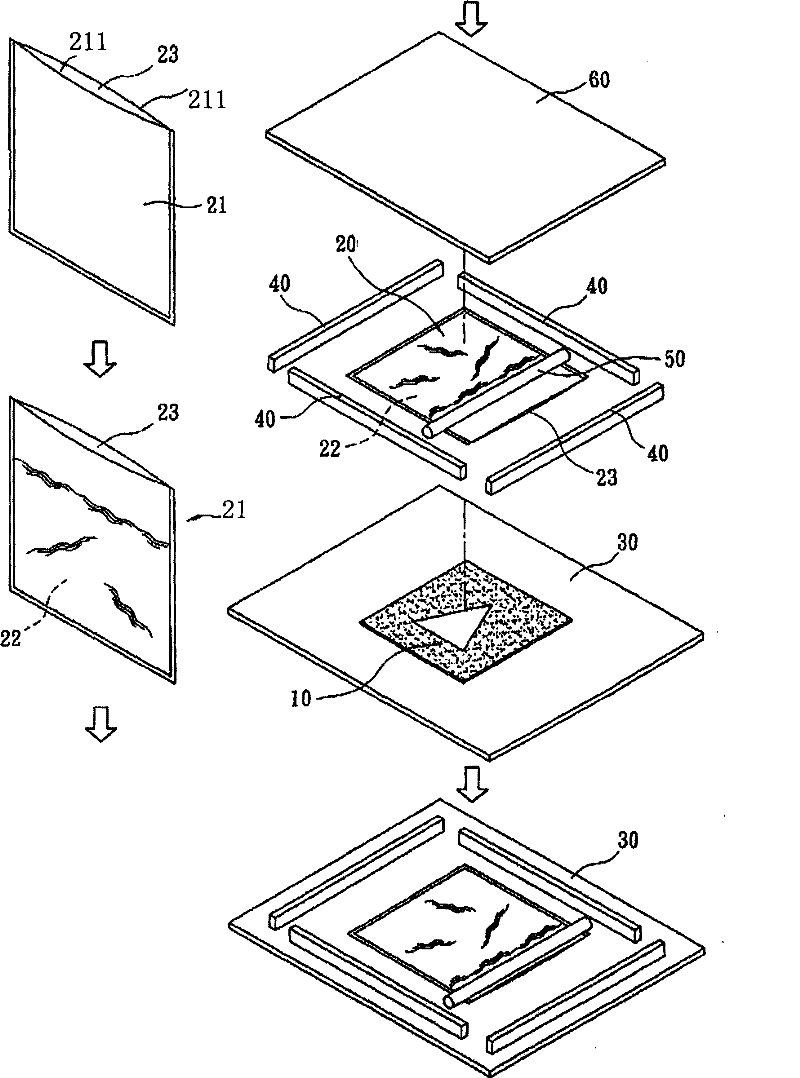

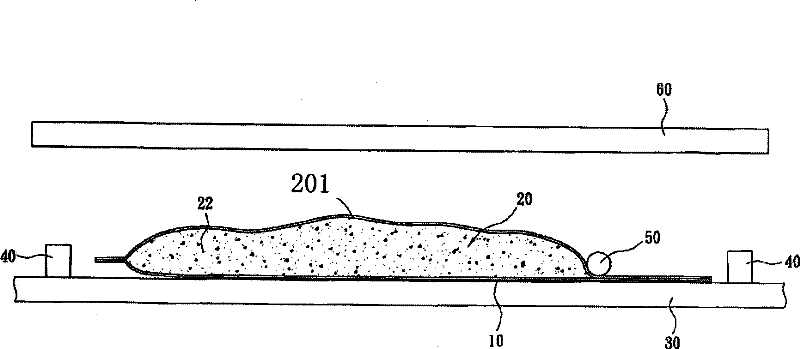

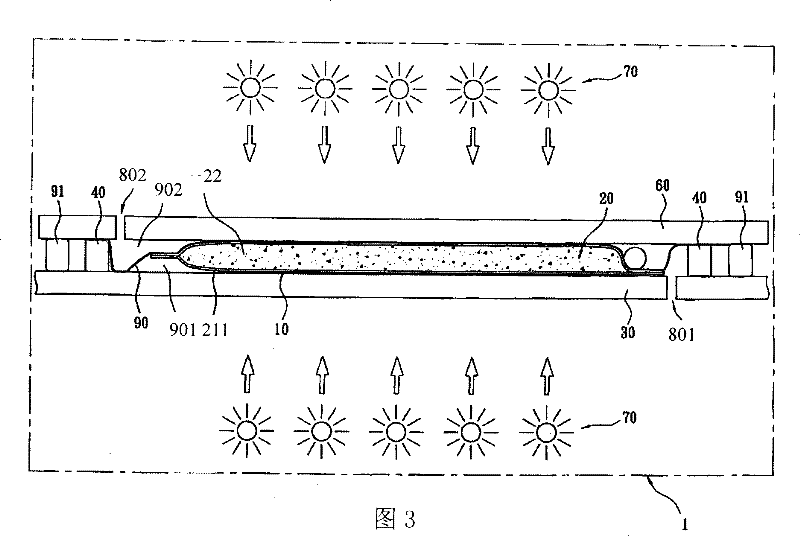

Printing plate producing method applying liquid photosensitive resin bag, and apparatus thereof

InactiveCN101592865BAvoid wastingEasy to manufacturePhotomechanical apparatusPolymer scienceEngineering

The invention relates to a printing plate producing method of a liquid photosensitive resin bag capable of free packaging and free batching, and an apparatus thereof. A transparent bag body is selected according to the formation specification of a printing plate and is provided with at least one open lateral edge. Liquid photosensitive resin with proper amount is filled in the transparent bag body and obstructed from flowing towards the unsealed lateral edge by using a thrust rod capable of free rolling or sliding. In the process of planishing the liquid photosensitive resin, the liquid photosensitive resin can freely flow towards the unsealed lateral edge and simultaneously push the thrust rod to move outwards till the flowing is naturally stopped. The apparatus for realizing the printing plate producing method consists of the transparent bag body, a lower transparent clamping plate, a thickness gauge, an upper transparent clamping plate, a light source and the thrust rod. The apparatus can avoid the problem that in the prior art the thoroughly-sealed and quantificational liquid photosensitive resin cannot correctly match with the specification of the printing plate and leads to waste; and the apparatus can simplify the production process of the printing plate and a printing plate producing apparatus and is beneficial to improving the printing plate production efficiency.

Owner:黄秀臣

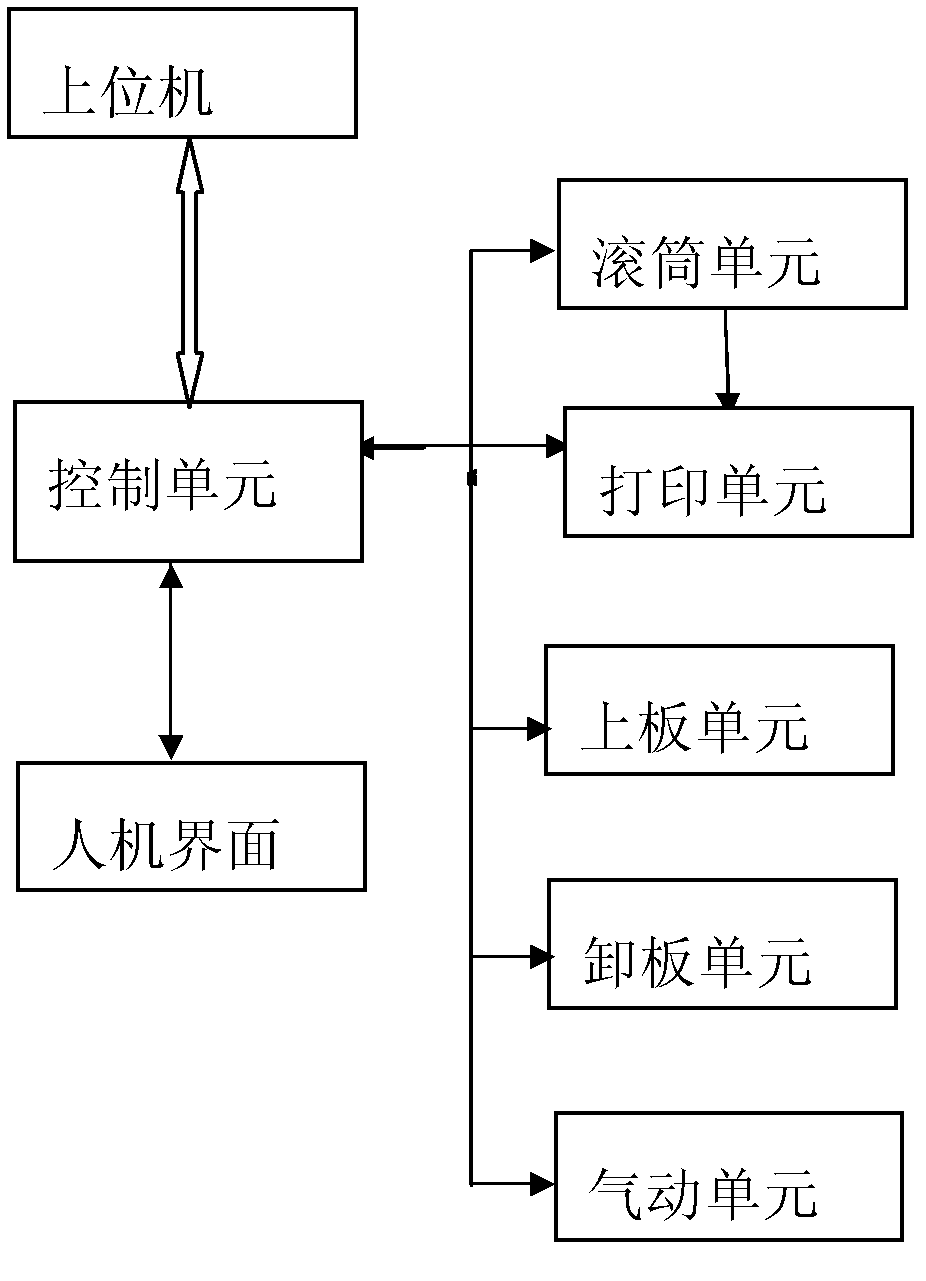

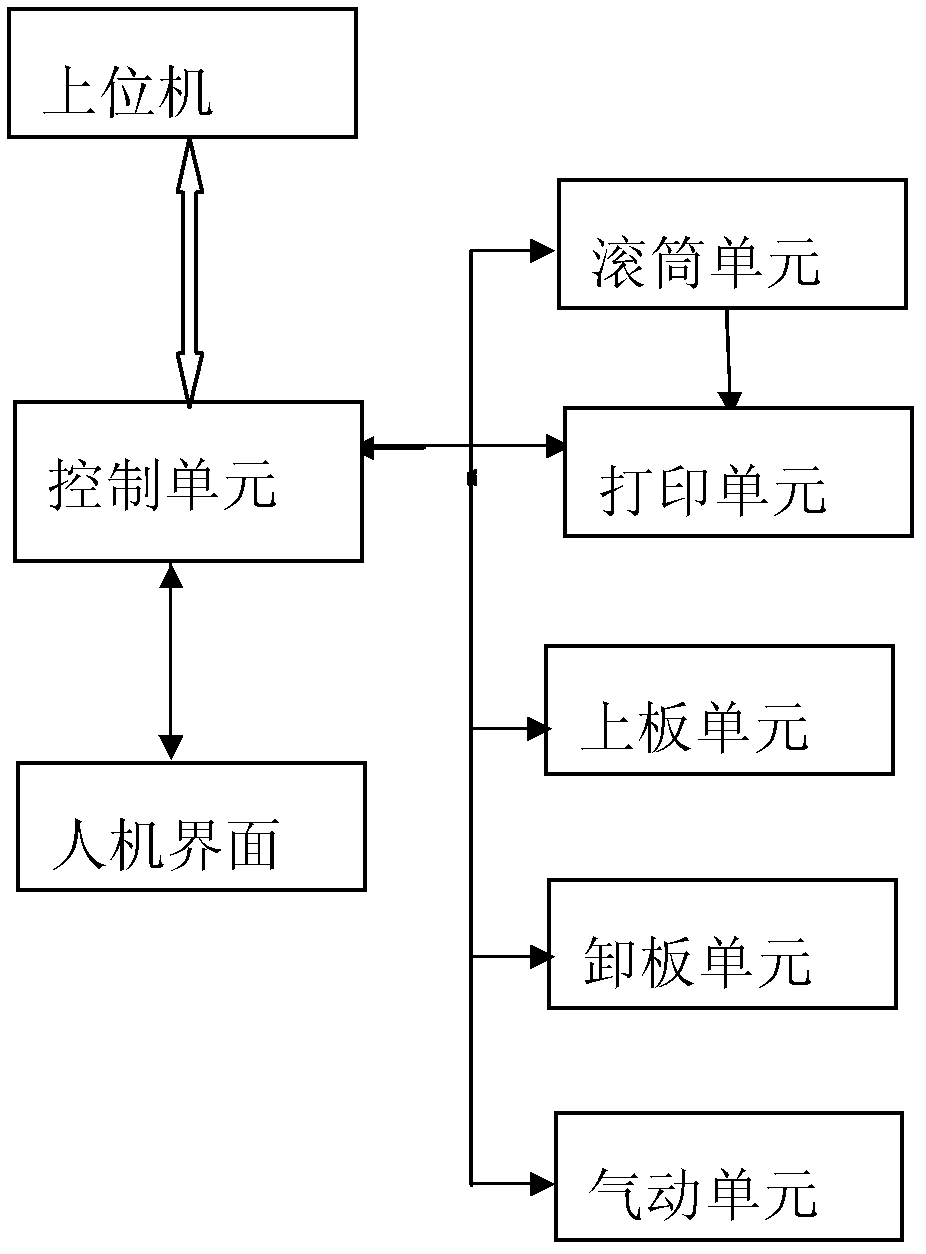

Control device of direct plate making machine of nano material and control method thereof

ActiveCN102602125BReduce pollutionPromote environmental protectionOther printing apparatusForme preparationComputer to plateTwo-way communication

The invention relates to a control device of a direct plate making machine of a nano material and a control method thereof. The device has the following structure that: position detection signals which are fed back by an upper plate unit, a printing unit, a pneumatic unit and a roller unit are received by a control unit; the control output end of the control unit is connected to the control loops of the upper plate unit, the roller unit, the printing unit, the pneumatic unit and a plate discharging unit; a position feedback signal of the roller unit is received by the printing unit; and the control unit is connected with an upper computer in a two-way communication way. The method comprises the following steps of: initializing each unit; carrying out ink-sucking protection on a printing head; starting the upper plate unit and the pneumatic unit and carrying out upper plate operation under the matching of the roller unit; starting the printing unit and realizing printing operation on a material plate; and after finishing the printing operation completely, starting the plate discharging unit and the pneumatic unit for plate discharge and output so as to finish the one-step plate making process. According to the control device of the direct plate making machine of the nano material and the control method thereof, a physical plate making mode is successfully realized, the environmental pollution is greatly reduced, the working procedure of plate making is simplified, and the running reliability and the control accuracy of equipment are ensured.

Owner:辽宁中科洪笙纳米装备技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com