An automatic plate making method and an automatic plate making device

A clothing and master technology, applied in the field of clothing design, can solve problems such as inability to personalize clothing, and achieve the effects of being conducive to subsequent use, convenient search, and improving plate-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

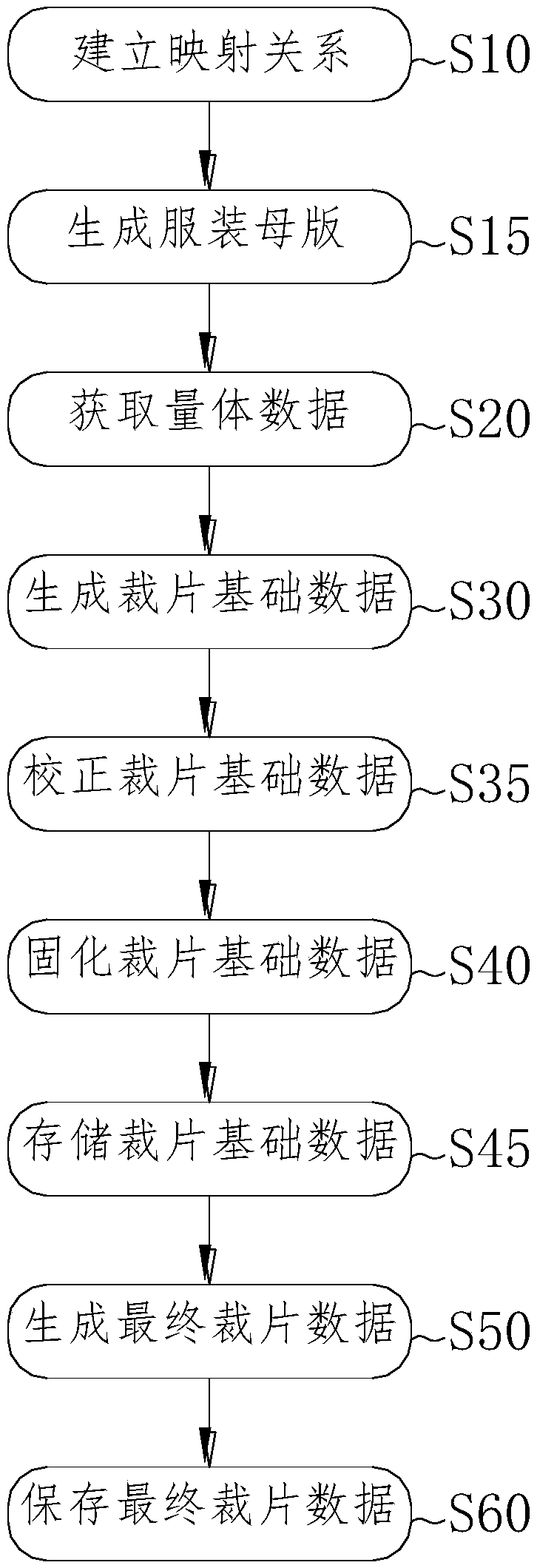

[0067] Such as figure 1 , figure 1 It is a complete flow chart of an automatic plate-making method, and some steps are unnecessary for this implementation. Therefore, some steps not mentioned in this embodiment are combined with the attached figure 1 can be omitted.

[0068] An automatic plate-making method, this scheme is based on a computer or other equipment with data processing capabilities, comprising the following steps:

[0069] S10: Establish a mapping relationship between the volume data and the basic data of the cutting piece, the mapping relationship refers to a formula or a set of data obtained by solving the relevant parameters of the cutting piece from the volume data;

[0070] S20: Obtain body measurement data, obtain human body data through measurement, and the measured human body data is body measurement data;

[0071] S30: Generate basic piece data according to the volume data and the mapping relationship between the volume data and the basic piece data, b...

Embodiment 2

[0080] This embodiment is an optimization scheme for embodiment 1 in combination with embodiment 1.

[0081] In said S10, the mapping relationship between the volumetric data and the piece basic data is established, and the volumetric data coding is compiled at the same time.

[0082] Coding volumetric data refers to expressing a certain volumetric data with a certain character.

[0083] For example, but not limited to, the code X is used to indicate the bust measurement, and X100 indicates that the bust measurement value is 100.

[0084] The compilation of codes is conducive to the classification of volume data, especially for designers with less design experience, the compilation of codes will help improve the design efficiency of designers.

[0085] For the field of fashion design, due to the large amount of data, the compilation of codes will make the data clear and clear, which is conducive to the follow-up inspection or related check by designers.

Embodiment 3

[0087] This embodiment is an optimized solution to the foregoing embodiments, and may be combined with any of the foregoing embodiments.

[0088] Optimization plan one

[0089] Such as figure 1 As shown, there is also S35 between the S30 and the S40;

[0090] S35: Correct the basic piece data generated in S30.

[0091] The S35 corrects the basic piece data generated in S30 by manual correction.

[0092] Before the basic piece data is solidified, the basic data of the piece should be corrected to avoid errors in the basic data of the piece caused by early input errors.

[0093] Since the basic data of the cutting piece is automatically generated, when correcting the basic data of the cutting piece, the method of manual checking should be used to correct it, that is, to check whether the volumetric data is wrong. The basic data of automatically generated pieces can not be checked.

[0094] Optimization scheme two

[0095] Such as figure 1 As shown, there is an S45 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com