Method for converting two-dimensional pattern into knitting pattern of three-dimensional full-formed garment

A knitted paper and fully formed technology, which is applied in the field of textile processing, can solve the problems of converting two-dimensional plate-making drawings into three-dimensional knitted paper patterns, and does not mention the outline design method, etc., and achieves high efficiency and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

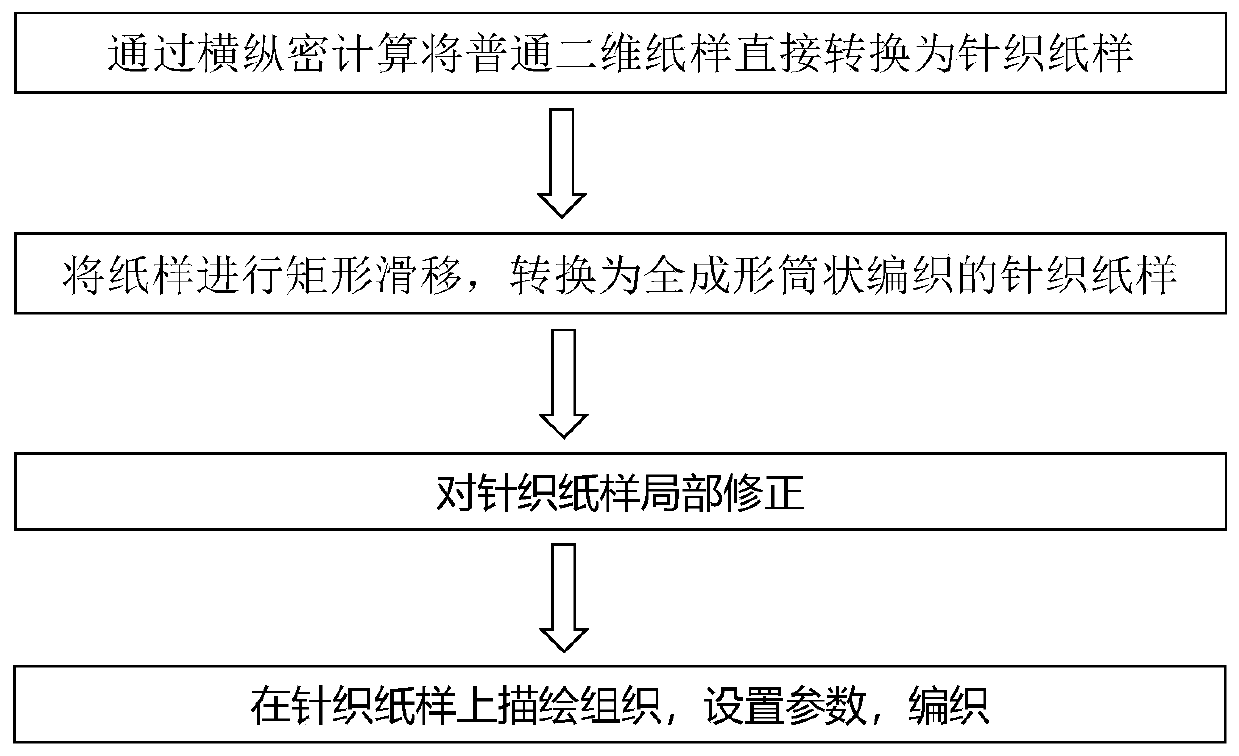

[0041] A method for converting a two-dimensional pattern into a knitted pattern for a three-dimensional fully-formed garment, which can be converted from a two-dimensional pattern for an ordinary cut-out garment to a knitted pattern suitable for weaving a fully-formed garment. Control the information and import it into the computerized flat knitting machine to weave fully formed three-dimensional knitted garments. The main steps of the method are:

[0042] (1) Directly convert ordinary two-dimensional paper patterns into knitted paper patterns through horizontal and vertical density calculations;

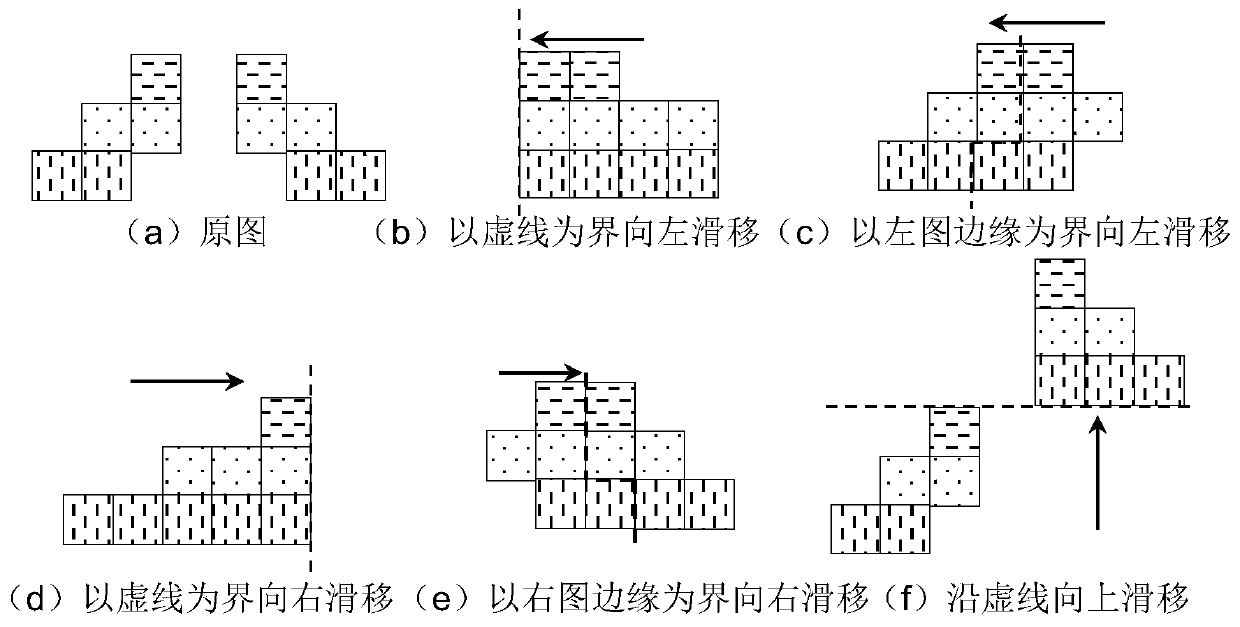

[0043] (2) According to the knitted paper pattern, combined with the principle of garment plate making and full-form weaving, rectangular sliding is carried out, and converted into a knitted paper pattern of full-form tubular weaving;

[0044] (3) According to the knitting pattern of the tubular knitting, according to the principle of retracting and retracting needles or local knitt...

Embodiment 2

[0048] Move the position of the knitting pattern corresponding to the dart of the two-dimensional pattern for garment plate-making in a rectangular horizontal direction, and transfer the width change caused by the dart stitching to the position of the retracting needle on the left and right edges of the garment or sleeve, as shown in Figure 5 It is a six-piece suit pattern, in which dart areas 1 and 2, use figure 2 Schematic diagram of the sliding principle of the middle rectangle (e), slide the left area of the dart horizontally to the right until the blank area of the dart disappears, Figure 6Shown is the knitted pattern of six-piece suit after sliding conversion;

[0049] Figure 5 The middle area 3 is that the body collar exceeds the width, and adopts figure 2 Schematic diagram of the sliding principle of the middle rectangle (c) slide the excess part to the left, Figure 6 The knitting pattern of six-piece suit is shown after sliding conversion, and there is no...

Embodiment 3

[0053] Slide the arcs on the left and right sides of the sleeve to one side, that is to ensure that one side is vertical, and the other side is retracted and retracted to form an arc. Only retracting and retracting stitches on one side can reduce knitting time, and at the same time, the traces of retracting and retracting needles are hidden inside the sleeve Can make the fabric more beautiful, such as Figure 7 It is a three-piece sleeve structure paper pattern, in order to form a fully formed tubular weave, using figure 2 Schematic diagram of the sliding principle of the middle rectangle (c) and (e) slide the small piece to the front and rear sleeve pieces until the outer contours of the front and back pieces are the same, and then use figure 2 Schematic diagram of the sliding principle of the middle rectangle (b) and (d) slide the narrowing arcs on both sides of the sleeve to one side to ensure that one side is parallel to the knitting direction, and the other side is retr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com