Control device of direct plate making machine of nano material and control method thereof

A technology of nano-materials and control devices, applied in printing devices, printing plate preparation, printing, etc., can solve the problems of rough plate making, environmental pollution, cumbersome process, etc., and achieve the effect of improving plate making efficiency, good environmental protection, and simple plate making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

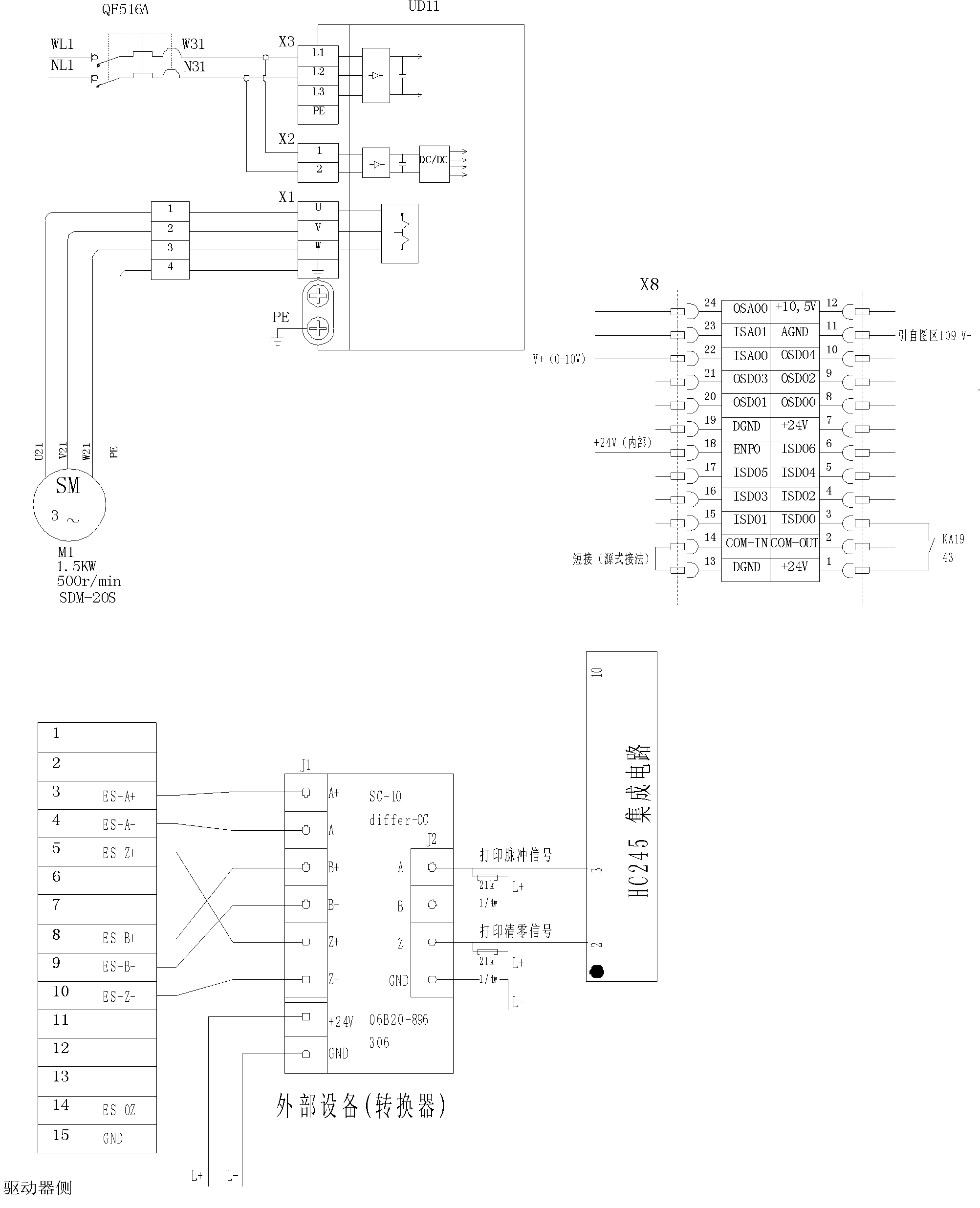

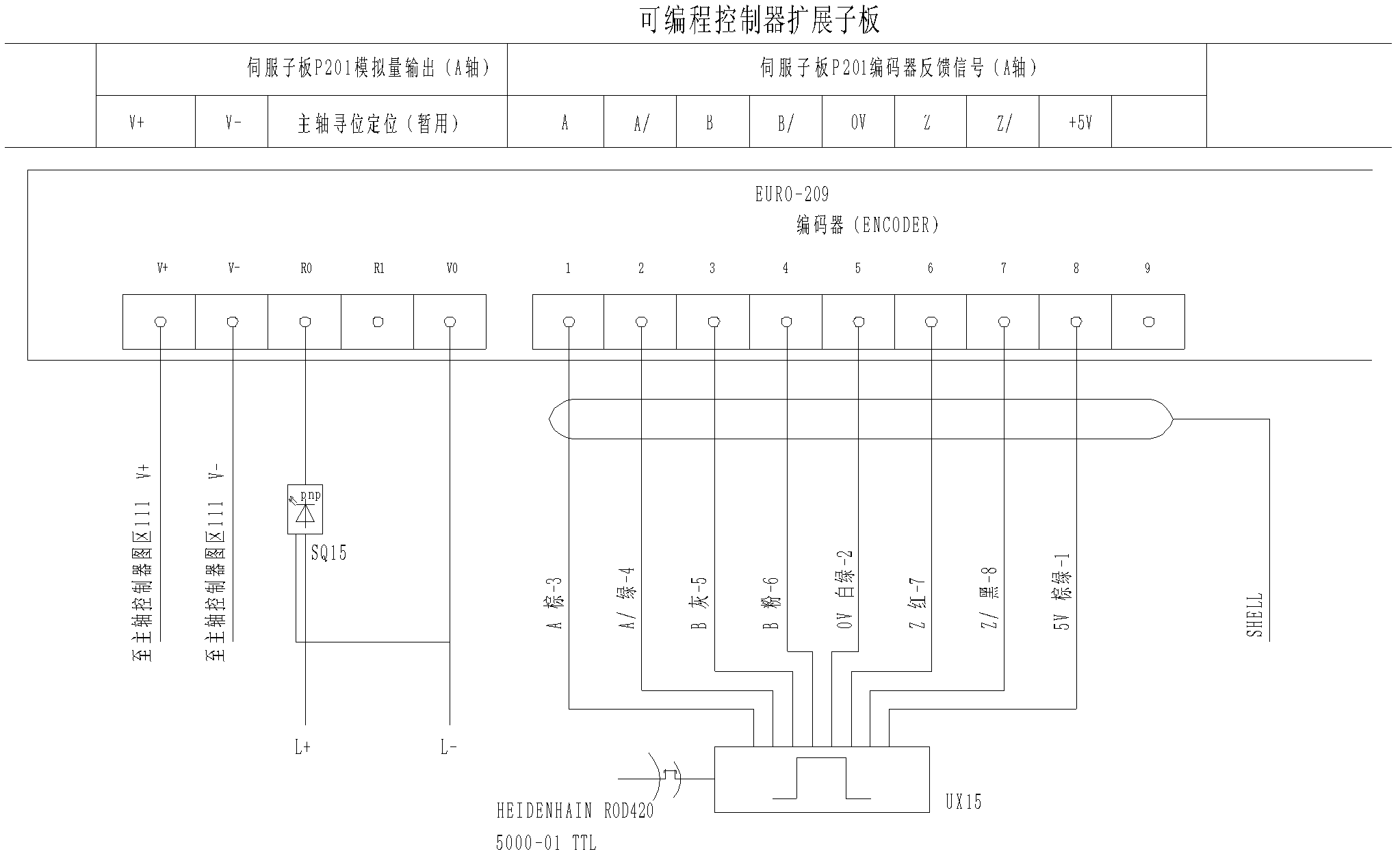

[0070] The device of the invention is a device for implementing control on a nanometer material direct plate-making machine. The nano-material direct plate-making machine is developed for inkjet using nano-materials. It abandons the traditional plate-making process and meets the requirements of high efficiency, low cost, and environmental protection. The present invention is a matching design of the equipment.

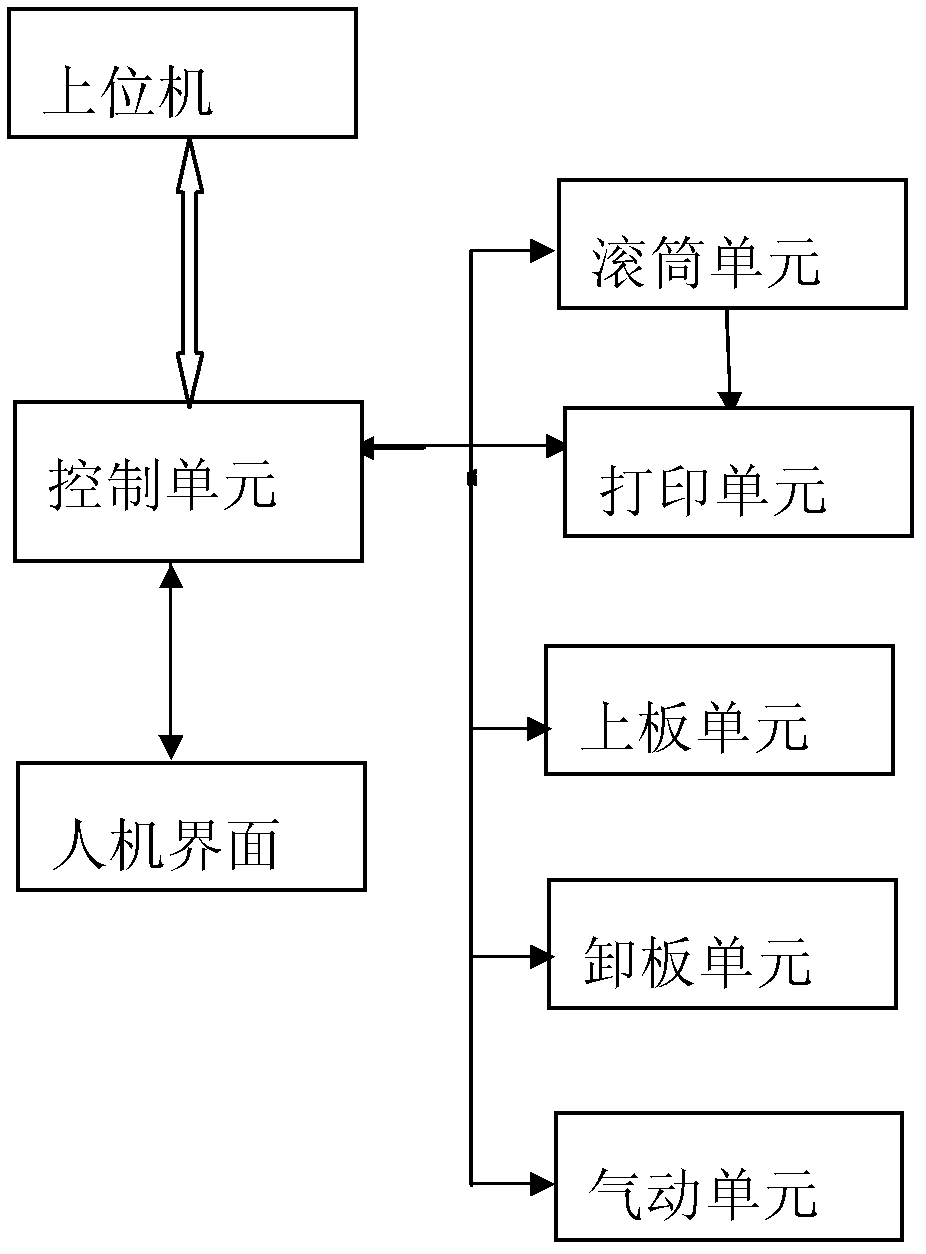

[0071] Such as figure 1 As shown, the nanomaterial direct plate-making machine control device of the present invention includes: a control unit, an upper plate unit, a roller unit, a printing unit, a pneumatic unit, and a plate unloading unit, wherein the control unit receives the upper plate unit, the printing unit, the pneumatic unit, and the roller unit Feedback position detection signal; the control output of the control unit is connected to the control circuit of the upper plate unit, the cylinder unit, the printing unit, the pneumatic unit and the plate unloadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com