UV offset printing and flexible printing combined UV light color ink, and preparation method and application thereof

A light color, flexo printing technology, applied in applications, inks, household appliances, etc., can solve the problems of ink balance fluctuation, waste products, etc., and achieve the effect of fast drying speed, low energy consumption, and good recoatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

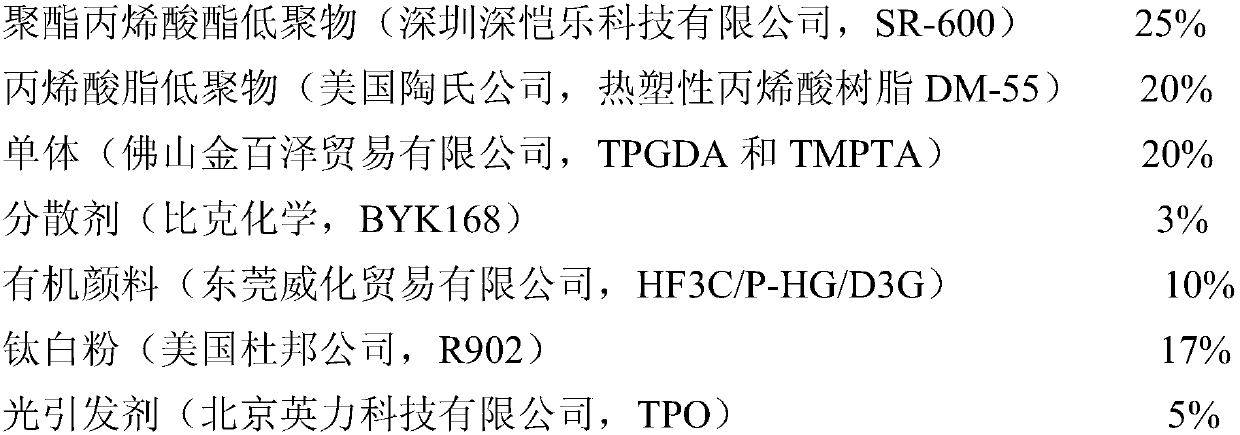

[0058] The UV offset printing combination flexo UV light color ink of the present embodiment comprises the following components according to the mass percentage:

[0059]

[0060] Preparation:

[0061] (1) Pour 25% polyester acrylate oligomer into the material tank, add 3% dispersant, 10% monomer, 10% organic pigment and 17% titanium dioxide under stirring at 800rpm, and stir evenly at 800rpm to obtain Mixture;

[0062] (2) Grinding the mixture to a particle size of ≤5 μm to obtain a color paste;

[0063] (3) Add 20% acrylate oligomer, 10% monomer and 5% photoinitiator to the color paste, stir evenly at 800rpm, and obtain the UV light color ink of combined flexo printing of UV offset printing in this embodiment.

[0064] The UV light color ink of the present embodiment is carried out viscosity, tinting strength detection, and the result is as follows:

[0065] The viscosity of the UV light color ink of this embodiment is 50s, and the tinting strength is 98%.

[0066] Th...

Embodiment 2

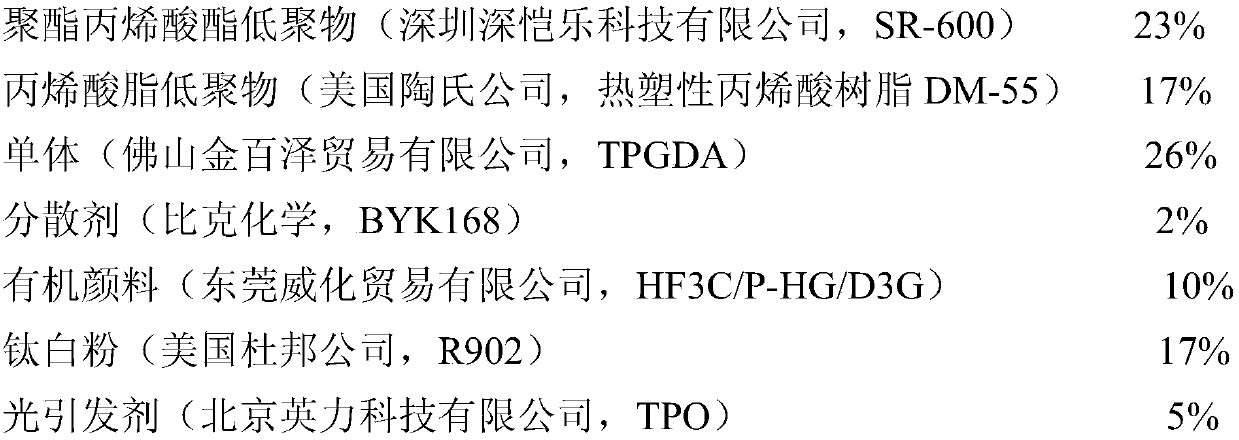

[0071] The UV offset printing combination flexo UV light color ink of the present embodiment comprises the following components according to the mass percentage:

[0072]

[0073] Preparation:

[0074] (1) Pour 20% polyester acrylate oligomer into the material tank, add 2% dispersant, 12% monomer, 10% organic pigment and 17% titanium dioxide under stirring at 800rpm, and stir evenly at 800rpm to obtain Mixture;

[0075] (2) Grinding the mixture to a particle size of ≤5 μm to obtain a color paste;

[0076] (3) Add 17% acrylate oligomer, 9% monomer and 5% photoinitiator to the color paste, and stir evenly at 800rpm to obtain the UV light-colored UV offset printing combined flexo printing ink of this embodiment.

[0077] The UV light color ink of the present embodiment is carried out viscosity, tinting strength detection, and the result is as follows:

[0078] The UV light color ink of this embodiment has a viscosity of 45s and a tinting strength of 98%.

[0079] The UV li...

Embodiment 3

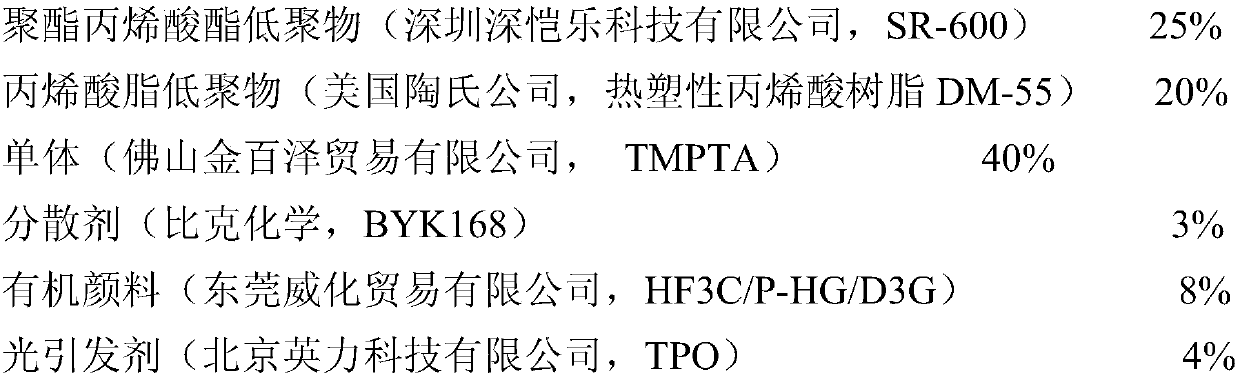

[0084] The UV offset printing combination flexo UV light color ink of the present embodiment comprises the following components according to the mass percentage:

[0085]

[0086] Preparation:

[0087] (1) Pour 25% polyester acrylate oligomer into the material tank, add 3% dispersant, 20% monomer and 8% organic pigment under stirring at 800rpm, and stir evenly at 800rpm to obtain the mixture;

[0088] (2) Grinding the mixture to a particle size of ≤5 μm to obtain a color paste;

[0089] (3) Add 20.% acrylate oligomer, 20% monomer and 4% photoinitiator to the color paste, and stir evenly at 800rpm to obtain the UV offset printing combination flexo UV light color ink of this embodiment.

[0090] The UV light color ink of the present embodiment is carried out viscosity, tinting strength detection, and the result is as follows:

[0091] The UV light color ink of this embodiment has a viscosity of 55s and a tinting strength of 98%.

[0092] The UV light-colored ink of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com