Western-style clothes sleeve cap height determination method

A certain method, the technology of sleeve mountain high, applied in the field of garment processing, can solve the problems affecting the appearance of sleeves and wearing comfort, so as to reduce blindness and improve the efficiency of plate making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

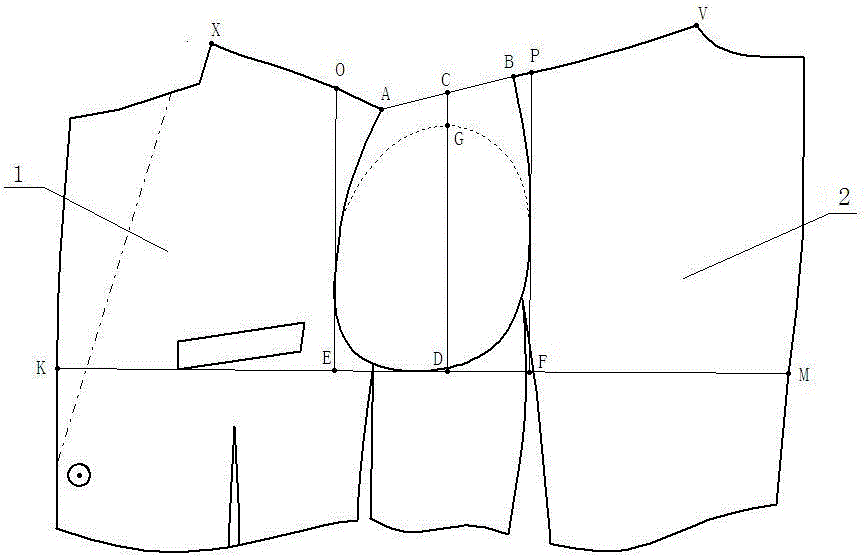

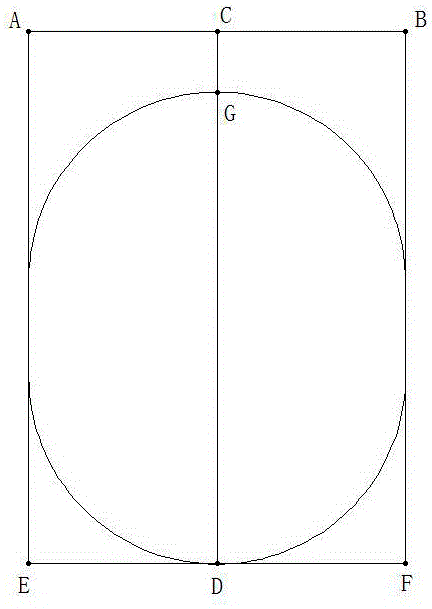

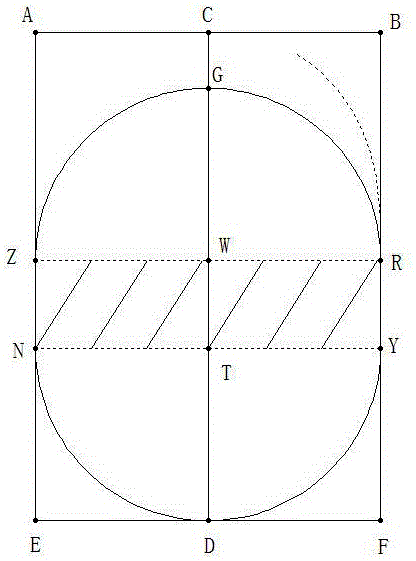

[0016] as attached Figure 1-3 As shown, the present invention includes the front panel 1 of the suit and the back panel 2 stitched with the front panel 1, and adopts the following operation steps to determine the value of the suit sleeve height:

[0017] ①. Identify points and lines:

[0018] The front shoulder line of front piece 1 is XA, then point A is the front shoulder point; the back shoulder line of back piece 2 is YB, then point B is the back shoulder point; front piece 1 and back piece 2 after sewing The bust line is KM; connect A and B, take the midpoint C of the line segment AB, and cross the bust line KM vertically from point C to point D, then the length of line segment CD is the average armhole depth, and the length value of CD is Measurement before sewing; the chest width line of the front piece 1 intersects with the front shoulder line XA at point O, and the bust line KM intersects at point E; the back width line of back panel 2 intersects with the back sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com