A direct plate-making method and application of a printing plate and plate roller integrated flexographic plate and 3D rapid prototyping printing

A technology of 3D printers and flexographic plates, applied in printing plate preparation, printing, etc., can solve problems such as unfavorable environmental protection and sustainable development, affecting production processes, and difficulty in large-scale application, so as to achieve environmental protection and sustainable development, Improve accuracy and productivity, achieve customization and personalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A direct plate-making method for 3D rapid prototyping printing of a flexible plate integrated with a printing plate and a plate roller, the steps are as follows:

[0072] Unpack→Install material pipeline→Connect USB and power supply→Adjust printing platform→Assemble printing material→Heat extruder→Observe material extrusion situation→Insert SD card→Select printing file→Automatic printing→Get printing plate and plate roller Flexible version;

[0073] details as follows:

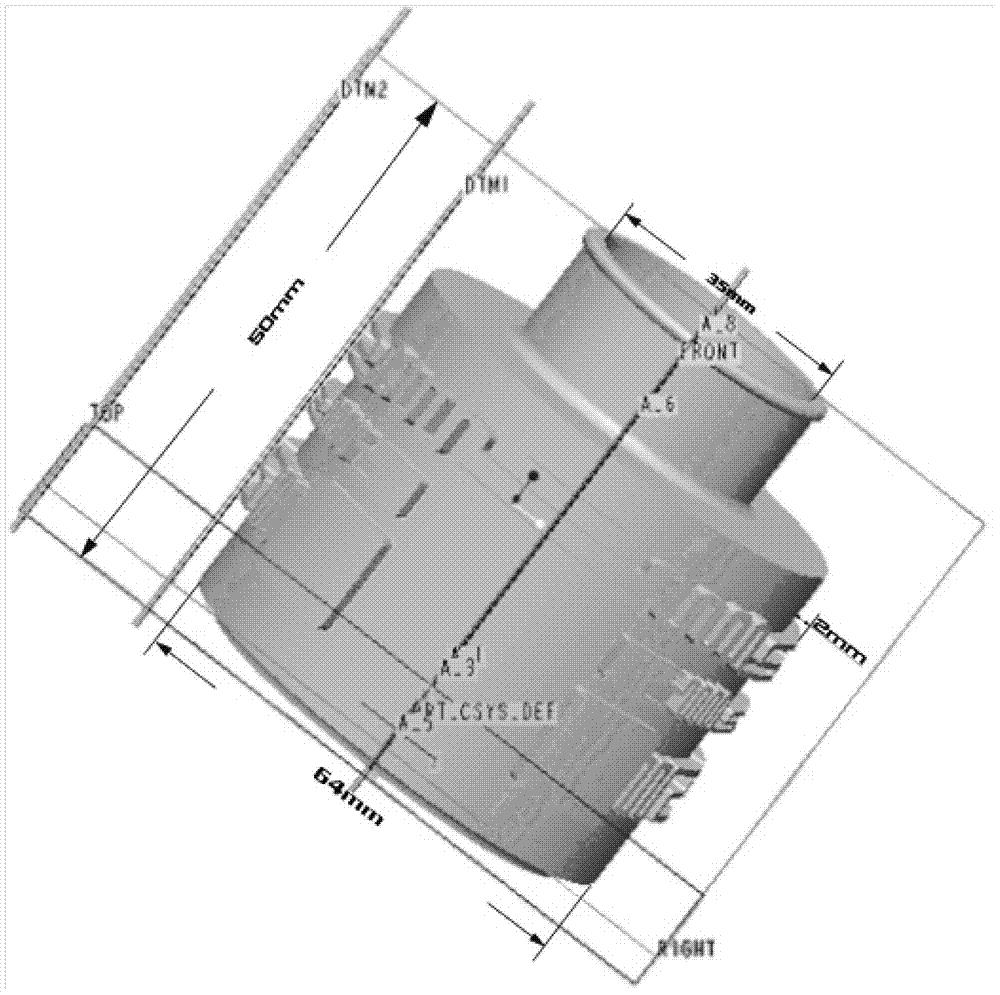

[0074] ⑴Using 3D printing for plate making method, first use three-dimensional software (such as Pro-Engineer drawing software) to design a pre-printed plate base, including the length, width, height of the base plate, and various raised or concave on the plate Graphics, set the size of the plate and the thickness of the related graphics, design the printing plate and graphics as a cylinder, wrap the graphics on the printing plate, the printing plate and the plate roller are integrated, and then store ...

Embodiment 2

[0083] A direct printing method of an ultra-high frequency RFID electronic tag antenna, the steps are as follows:

[0084] The method of plate making by 3D printing in the present invention first uses three-dimensional software to design a pre-printed plate, including the length, width, height of the plate base and various raised or concave graphics on the plate, and sets the size of the plate And the thickness of the antenna graphic, use a 3D printer to spray out the PLA polylactic acid plate, and spray the graphic on the plate. This experimental method can accurately control the height, width and length of the raised or lowered characters on the plate, reduce the waste of materials in plate making, shorten the process, save time and reduce pollution.

[0085] The printing plate roll size of the IGT-F1 AIC2-5T2000 with the antenna printing plate of the present invention design is inner diameter 35mm, outer diameter 64mm, the cylinder of high 50mm, antenna printing plate thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com