Plate feeding device of nanometer material computer to plate and control method for plate feeding device

A nanomaterial and plate making machine technology, applied in the direction of plate preparation, printing, etc., can solve the problems of insufficient positioning accuracy of the material plate, unable to guarantee the printing quality, unable to meet the direct printing requirements of the print head, etc., to achieve accurate positioning and improve plate making efficiency. , The effect of ensuring reliability and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

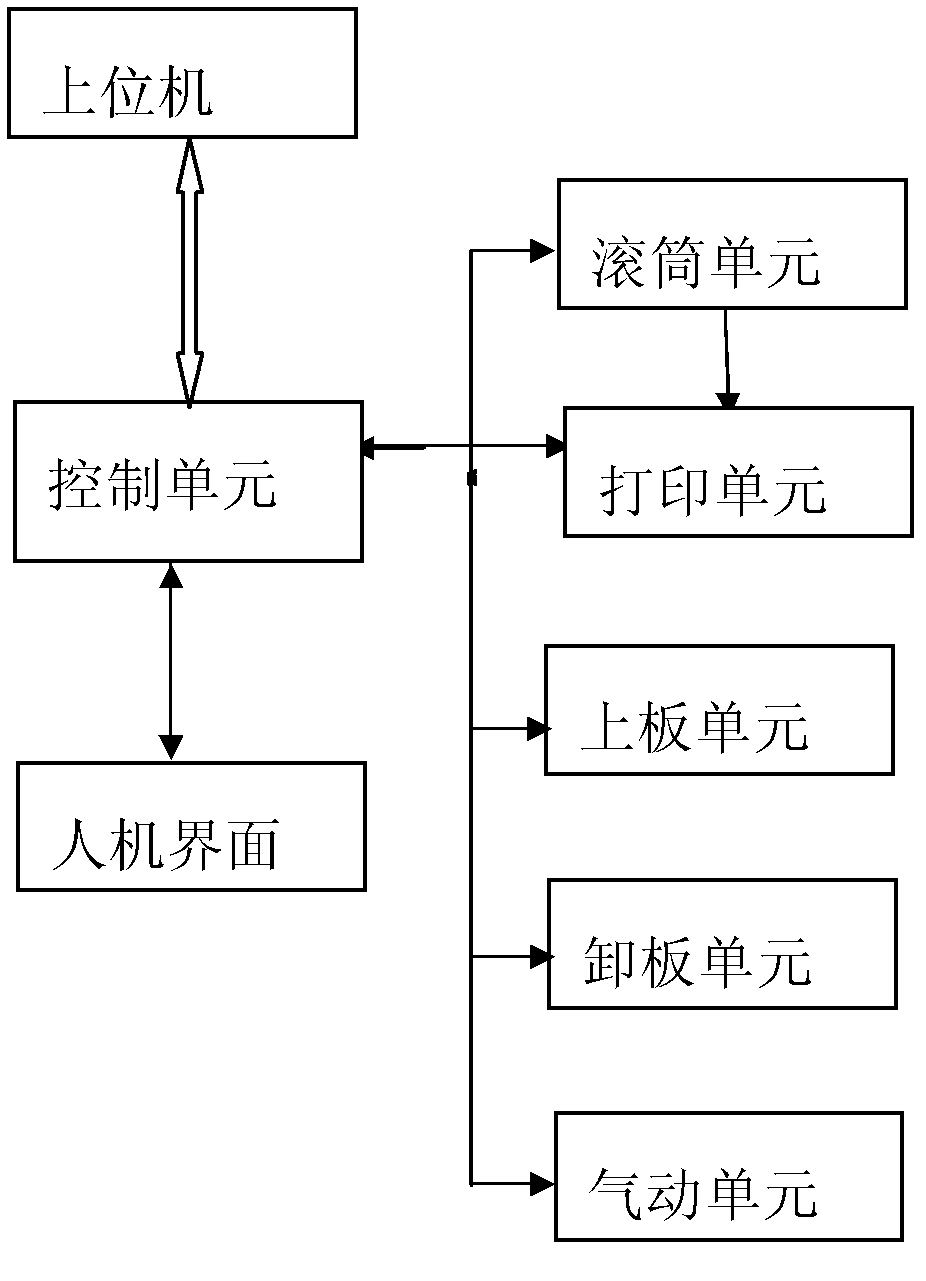

[0035] Nano-material direct plate-making technology is based on the wettability control of nano-materials. It precisely prints special transfer printing materials on super-hydrophilic plates with nano-micro-composite structures. On the printed printing plate, nano micro-regions (graphic area and non-graphic area) with opposite wettability (super lipophilic / hydrophilic) are formed, so as to realize direct plate printing, with low equipment price, consumable cost and operating cost, With the advantages of high scalability, it is a new plate-making technology that is non-photosensitive, pollution-free, low-cost, and simple in process. It abandons the current technical ideas of pre-coating of photosensitive materials and photosensitive chemical imaging, and adopts the principle of direct imaging of nano-materials, which completely solves the problems of pollution and resource waste in the printing plate making process, and will greatly accelerate the "digital, green" printing indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com