Multi-position laser die pressing process and die cutting hot stamping machine

A multi-station, hot stamping machine technology, applied to printing machines, printing processes, rotary printing machines, etc., can solve the problems of products that cannot meet different sizes and die-cut shapes, and single batch production, so as to save plate-making costs , Improve production efficiency, and control the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

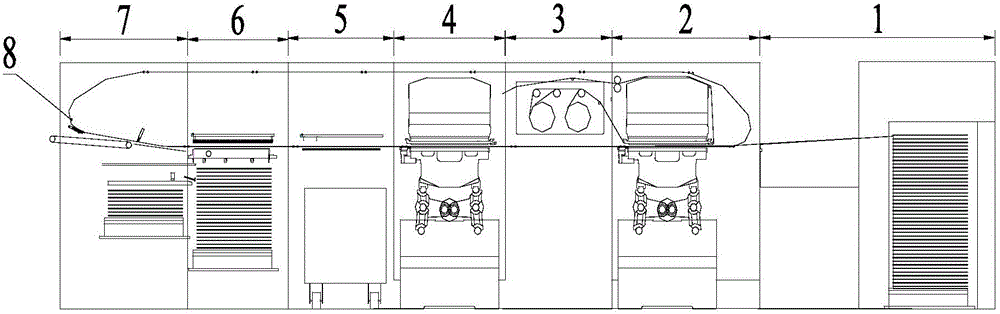

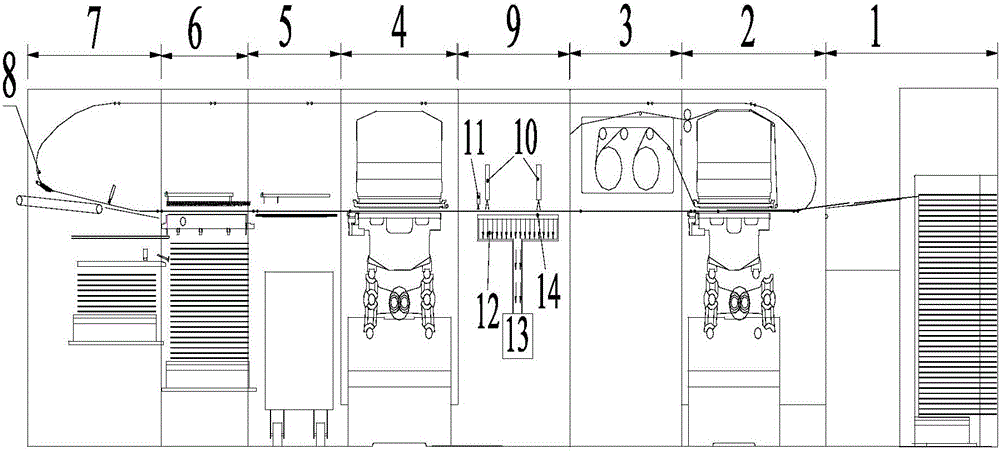

[0025] Embodiment: a kind of multi-station laser molding process is characterized in that it comprises the following steps:

[0026] (1) The sheet after being indented or stamped by the first molding unit 2 enters the laser unit 9 after passing through the aluminum foil control unit 3;

[0027] (2) The laser unit 9 die-cuts the product to save the cost of plate making and the time of stopping to replace the plate;

[0028] (3) The die-cut product enters the second molding unit 4 for creasing or hot stamping.

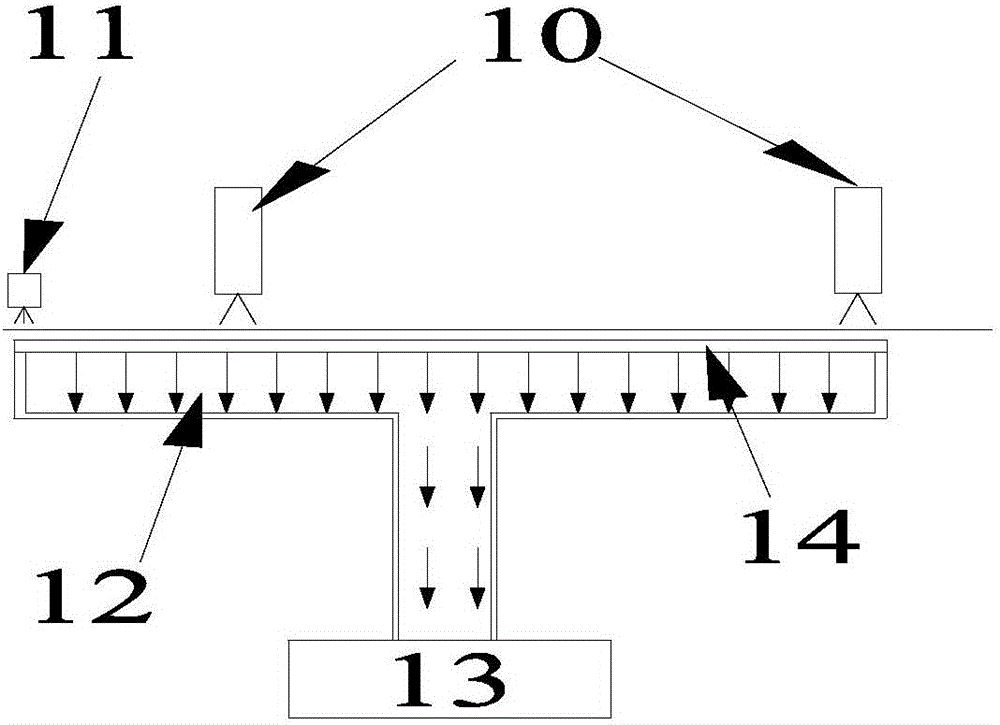

[0029] The cutting range of each laser 10 of the laser unit 9 is limited, and the number of lasers 10 varies according to the sheet format; the laser unit 9 is provided with a sensor 11 for detecting positioning marks on the sheet , the signal is transmitted to the laser 10 to precisely control the cutting position of the laser 10; the suction device 13 of the laser unit is connected to the suction device 12, and the waste after cutting is sucked away by the suction dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com