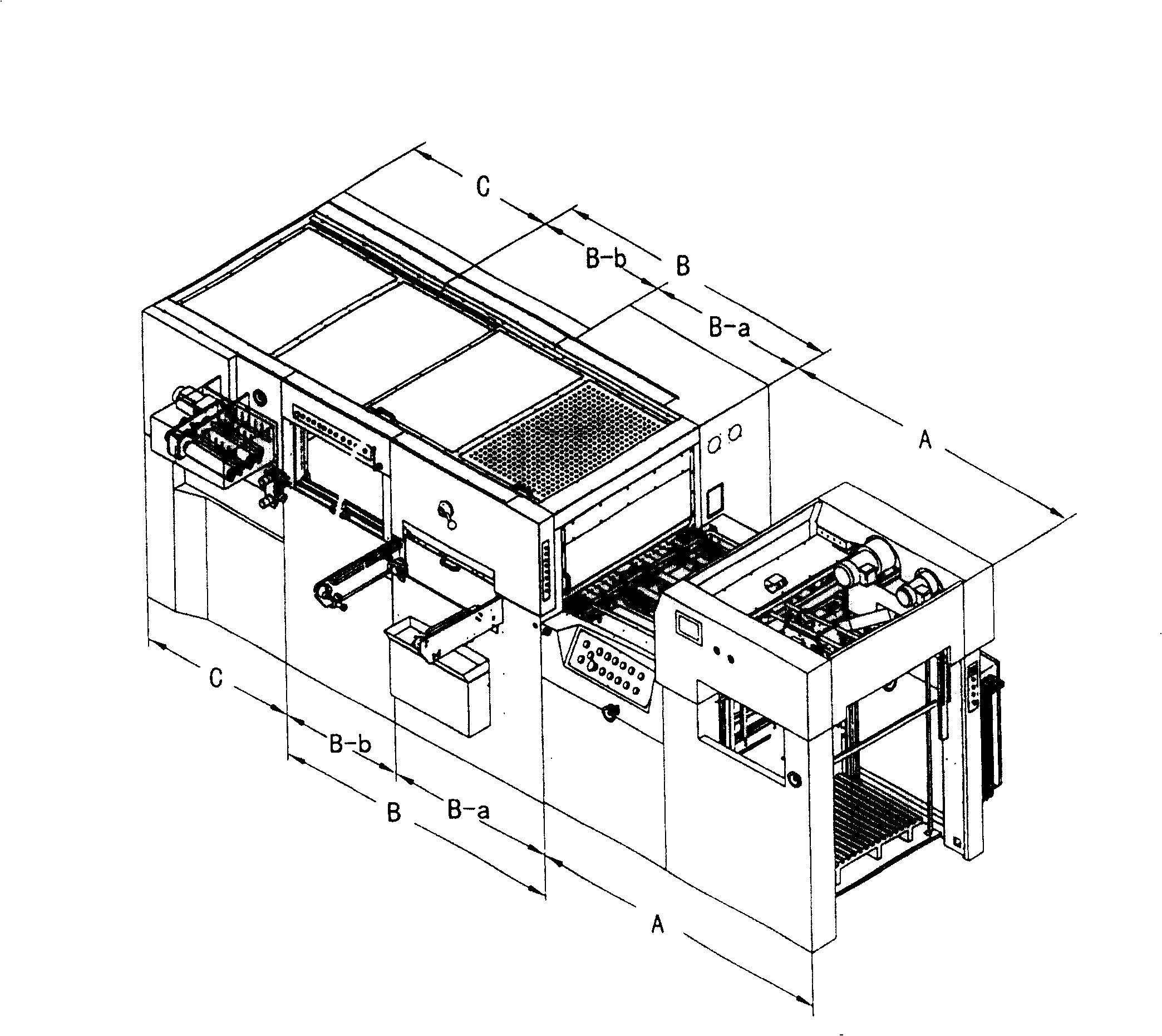

Process for multi-position mold pressing with feeding once and automatic mold cutting and stamping machine

A hot stamping machine and station technology, which is applied to flatbed printing machines, printing machines, printing, etc., can solve the problems of increasing processing costs, positioning accuracy errors, and high scrap rate, so as to improve production efficiency and control scrap rate , reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

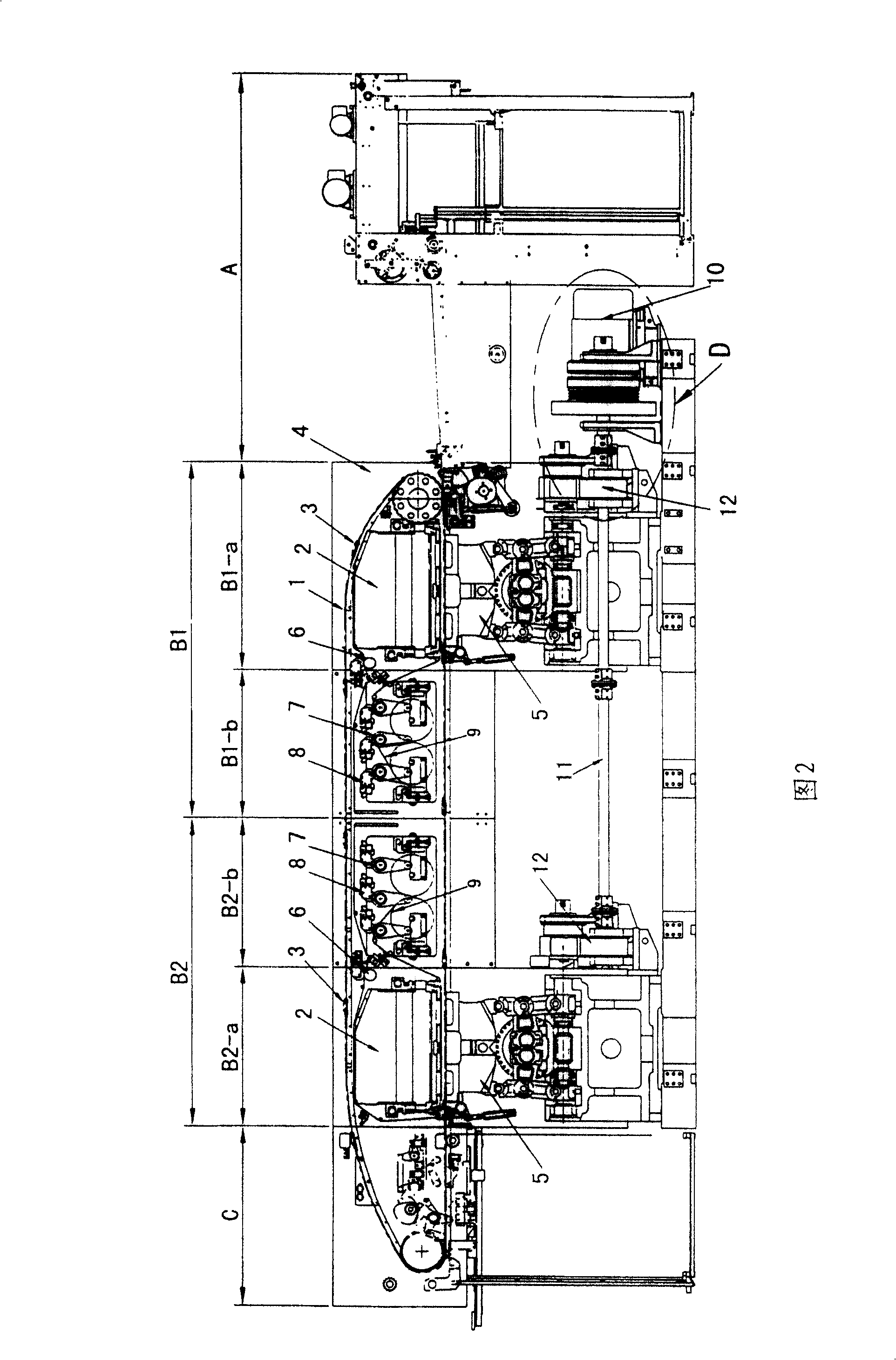

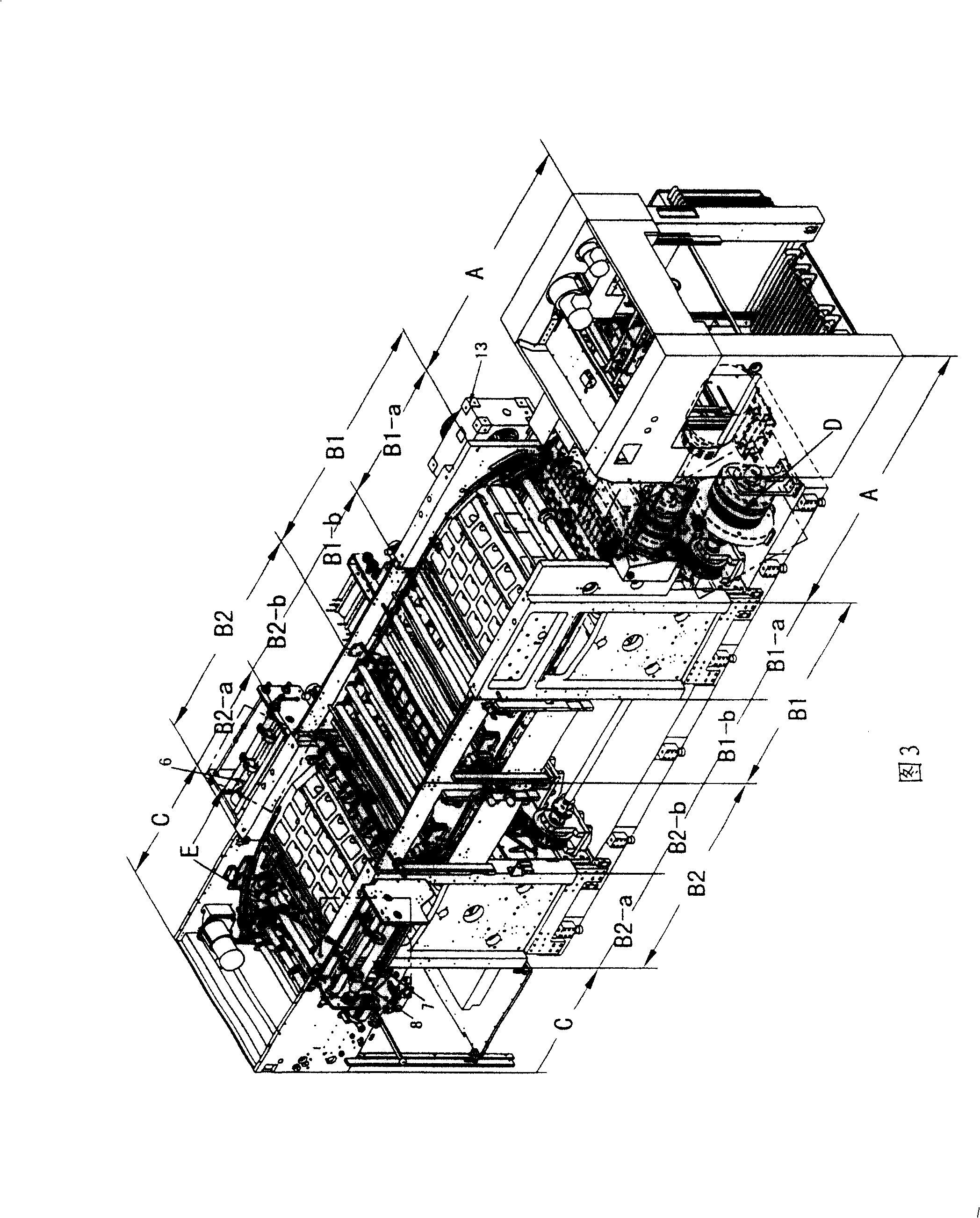

[0037] Embodiment: A molding process for feeding multiple embossing stations at one time, including a paper conveying process and a paper receiving process, characterized in that two embossing units are connected in series between the paper conveying process and the paper receiving process The embossing process, said each embossing process contains independent hot stamping, indentation, die-cutting process, and each embossing unit realizes the embossing process task of one of the above-mentioned independent three processes; The hot stamping process of the unit includes the completion of the aluminum foil conveying task, which constitutes the hot stamping process.

[0038] Each embossing process mentioned above contains independent hot stamping, creasing, and die-cutting processes. The hot stamping process can be performed twice in a row, and the creasing process and die-cutting process should not exceed one time.

[0039] The embossing method of each embossing unit mentioned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com