Digital bronzing machine

A bronzing machine and digital technology, applied in the field of digital bronzing machine, can solve the problems of positioning accuracy error, increase processing cost, paper deformation, etc., and achieve the effect of reducing application, controlling scrap rate, reducing wear and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

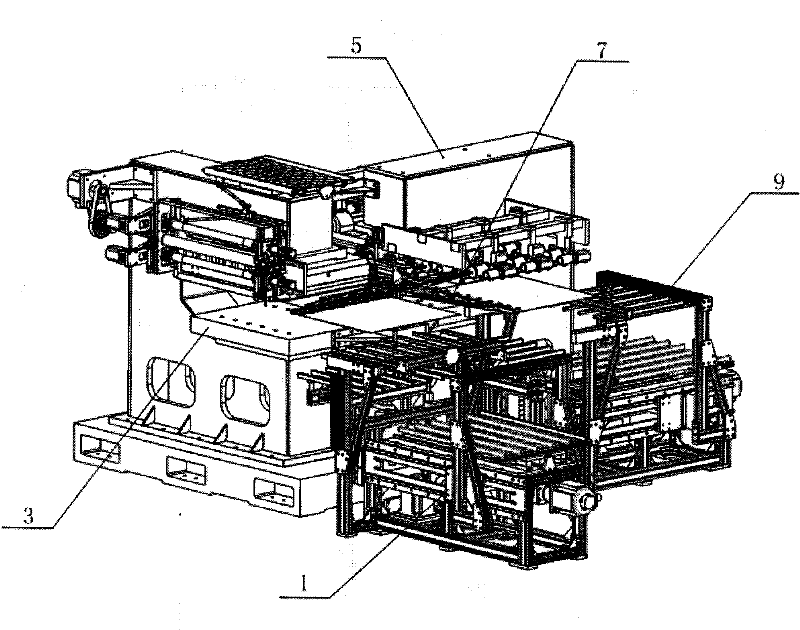

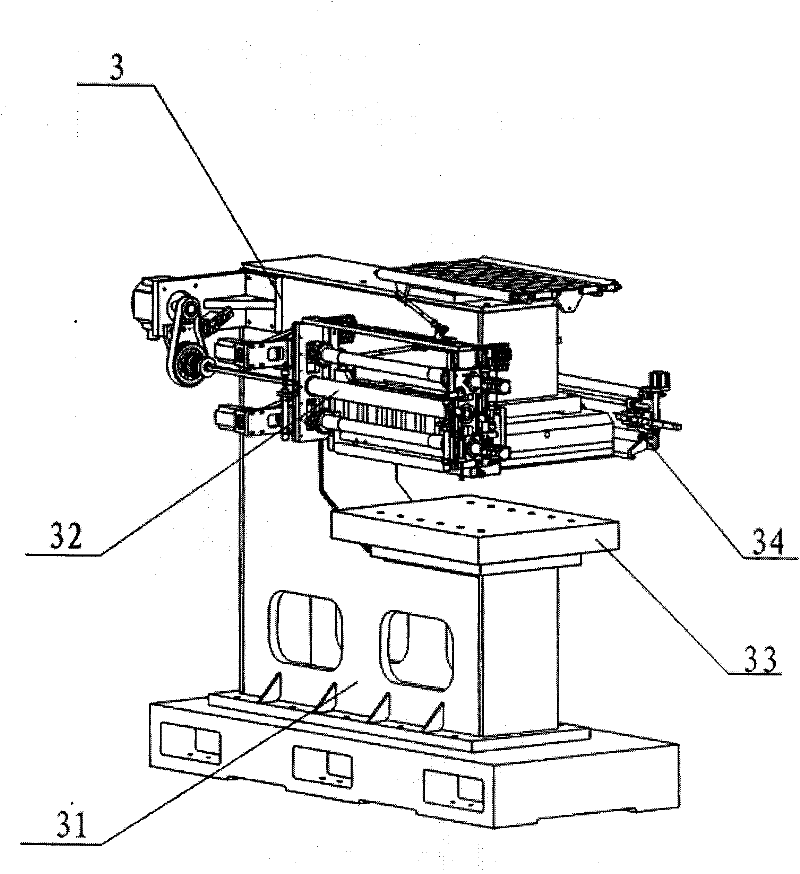

[0027] see Figure 1 to Figure 6 As shown, the present invention is a digital hot stamping machine, which includes an automatic paper feeding unit 1 , a hot stamping unit 3 , a holographic hot stamping unit 5 , a rotary paper feeding unit 7 and an automatic paper delivery unit 9 . Wherein, the automatic paper feeding unit 1, hot stamping unit 3, holographic hot stamping unit 5 and automatic paper delivery unit 9 are arranged around the rotary paper feeding unit 7; each of the above-mentioned units is an independent unit and can be assembled separately , operation and debugging.

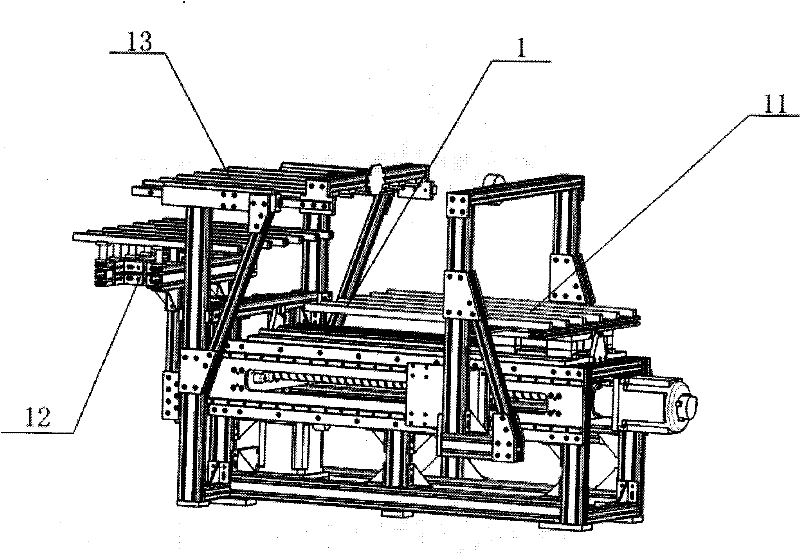

[0028] The automatic paper feeding unit 1 includes a first paper stack feeding and outputting module 11, a first paper stack lifting module 12, and an auxiliary paper feeding module 13, wherein the auxiliary paper feeding module 13 is located in the first paper stack Between the input and output module 11 and the first paper stack lifting module 12 , the rotary paper feeding unit 7 is located above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com