Double-motor synchronous control device and method for silicon chip conveying manipulator

A synchronous control, manipulator technology, applied in the direction of speed adjustment of multiple motors, can solve the problems of arm asynchrony, arm end tray jitter, damage to silicon wafers, etc., to improve arm synchronization, avoid silicon wafer damage, and improve synchronization. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

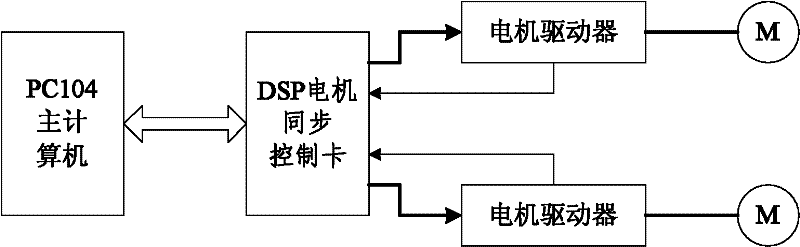

[0024] Such as figure 1 Shown, the present invention comprises main computer, DSP motor synchronous control card, motor driver and motor, wherein main computer is as host computer, and DSP motor synchronous control card is as slave, both carry out communication connection, two output ends of DSP motor synchronous control card Connect with two motor drivers respectively, the control output terminal of each motor driver is connected to the motor, and the motor speed information is sent to the DSP motor synchronous control card through the motor driver.

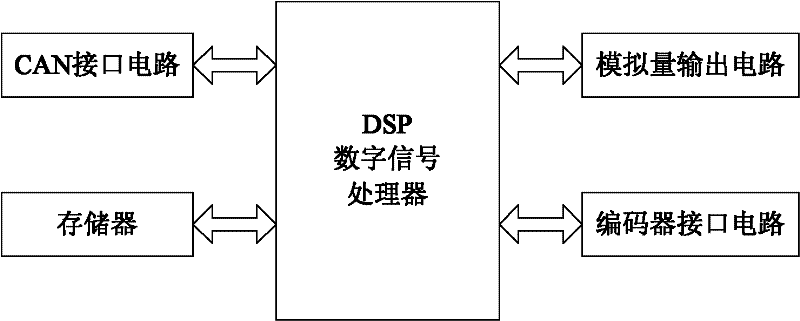

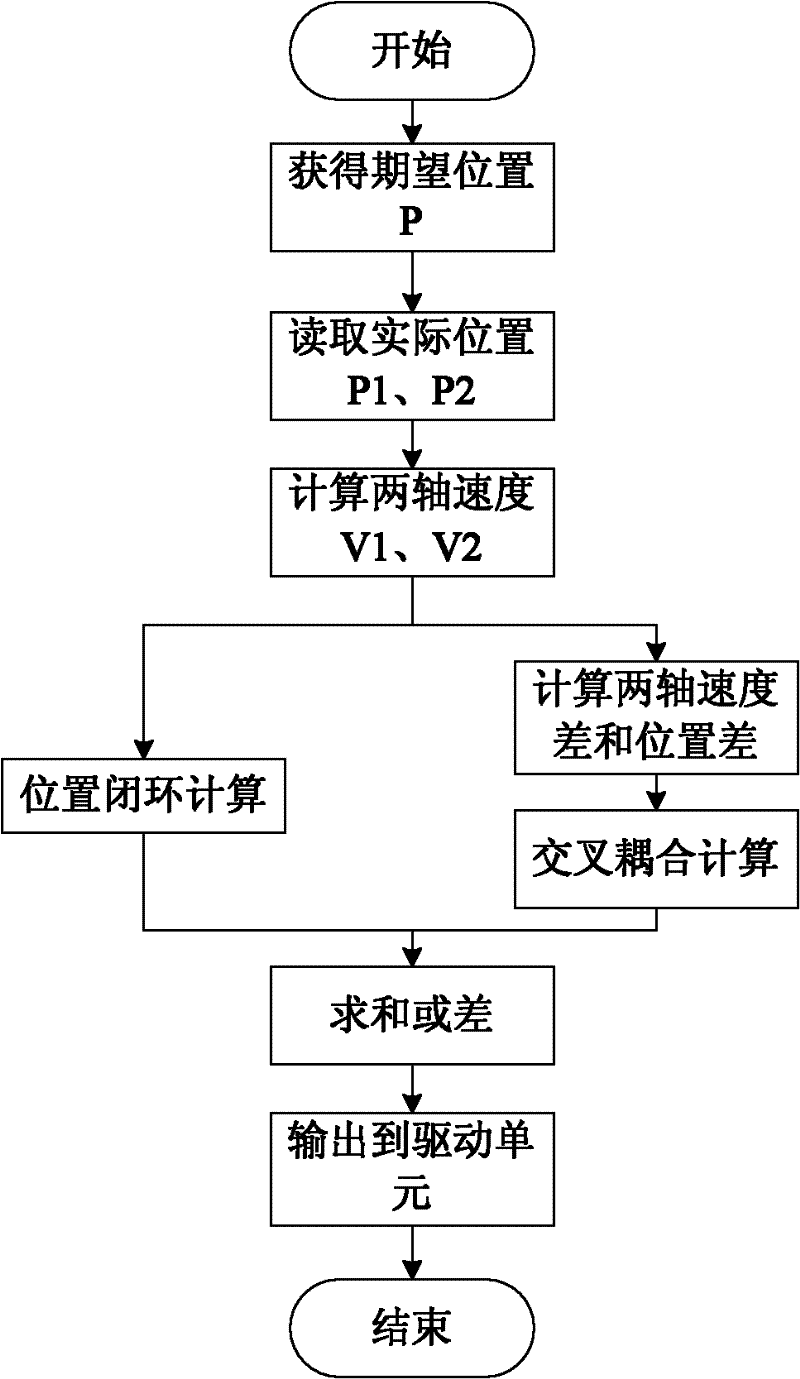

[0025] In this embodiment, the host computer adopts PC104, the host computer and the DSP motor synchronous control card communicate through the CAN bus, and the DSP motor synchronous control card acts as a slave. The host computer sends the position point of the trajectory planning to the DSP motor synchronous control card through the CAN bus every control cycle. The DSP motor synchronous control card is connected to the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com