Patents

Literature

35results about How to "Expand the scope of manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

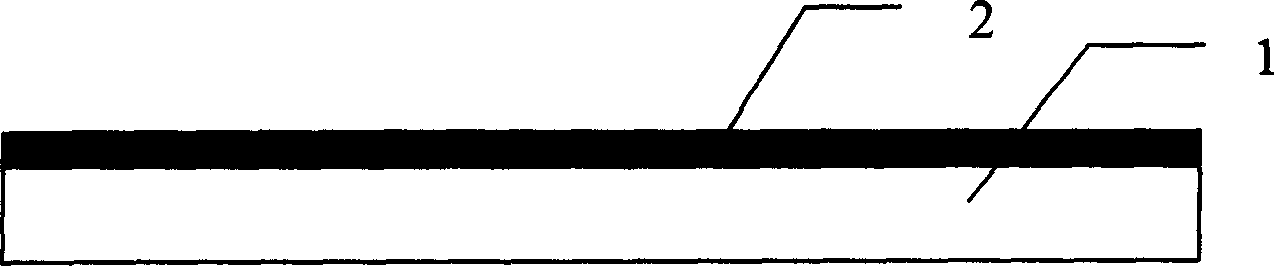

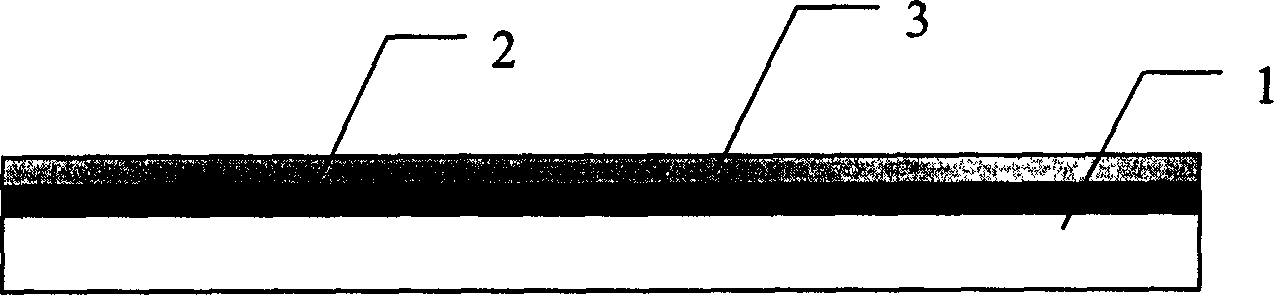

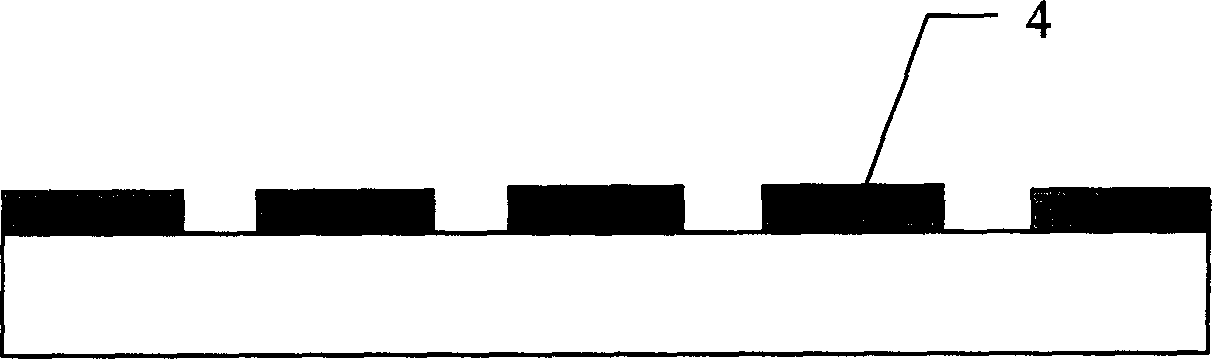

Preparation method of three-dimensional self-supporting micro-nano functional structure based on thin film material

ActiveCN103043600ARich varietyUnique functionDecorative surface effectsChemical vapor deposition coatingMaterial typeControllability

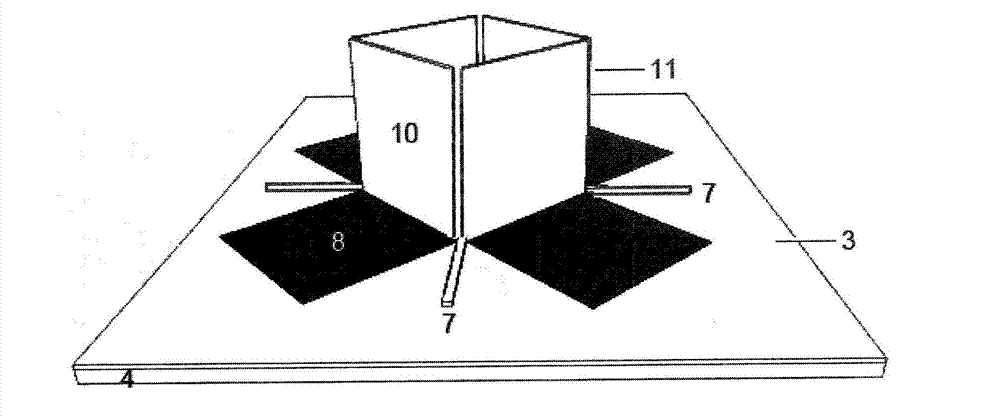

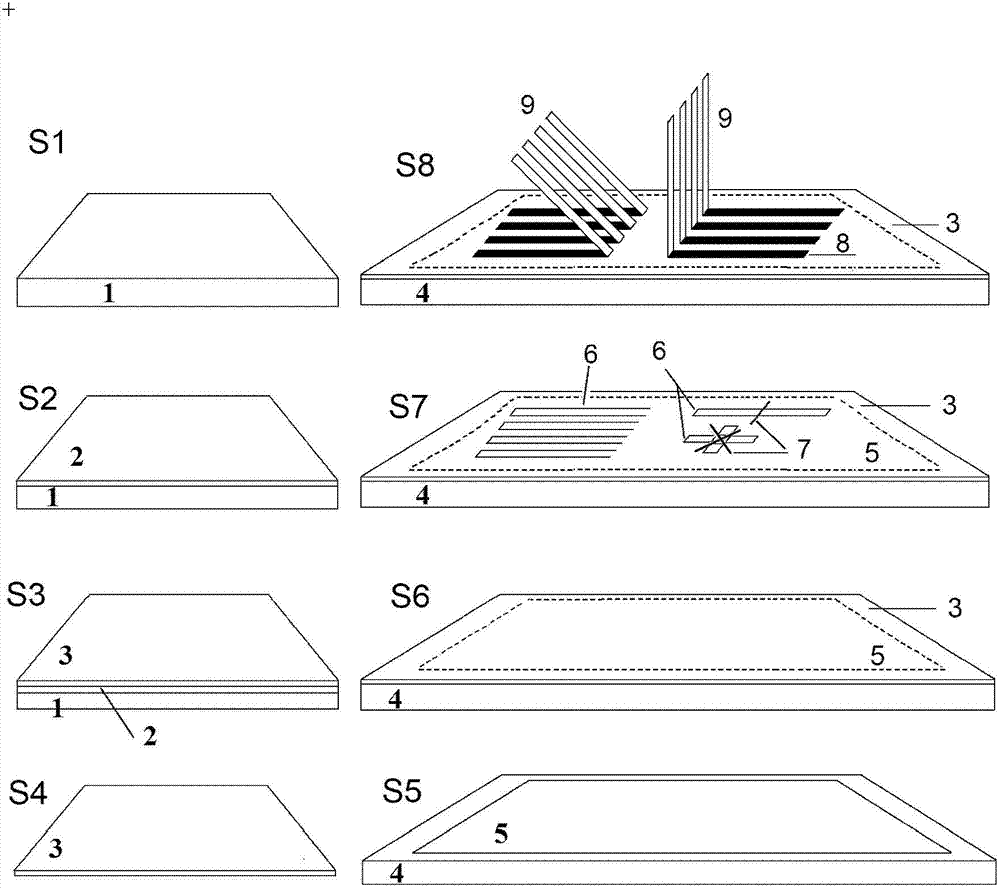

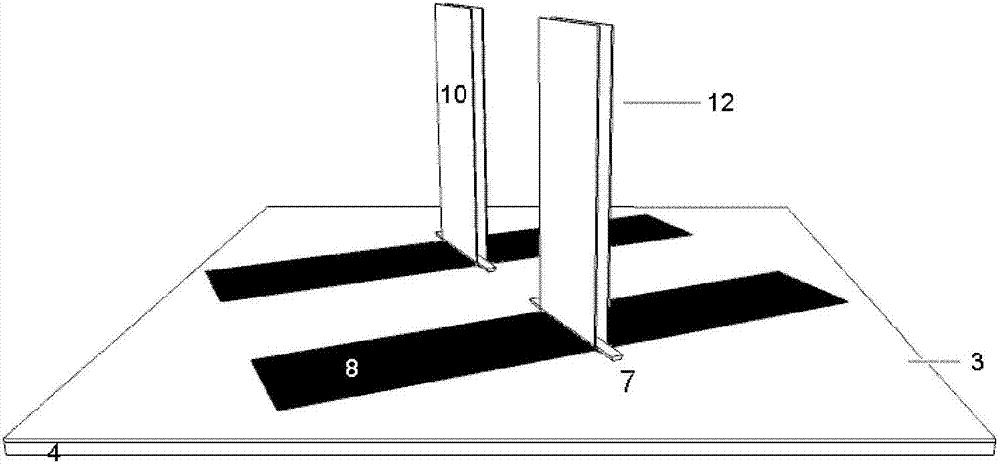

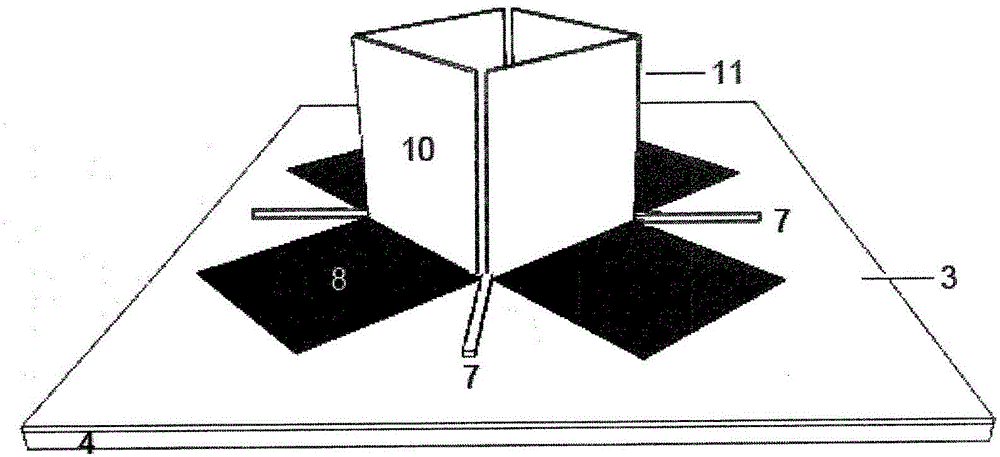

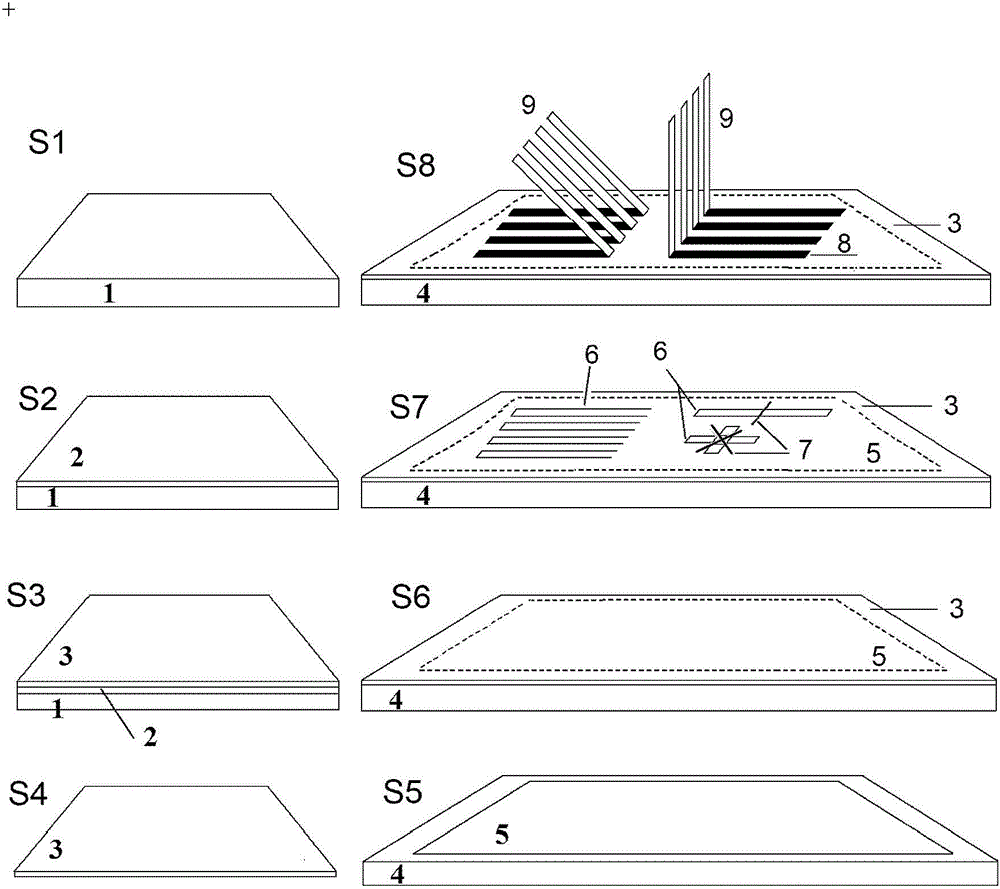

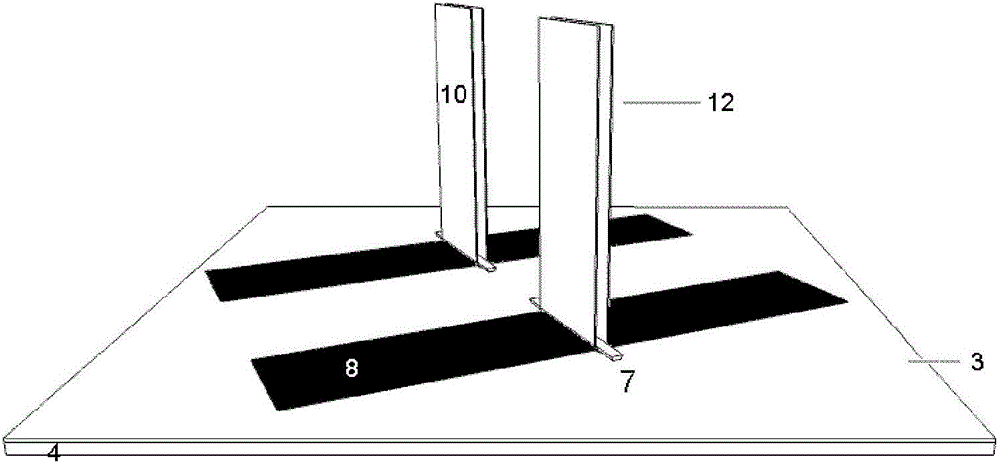

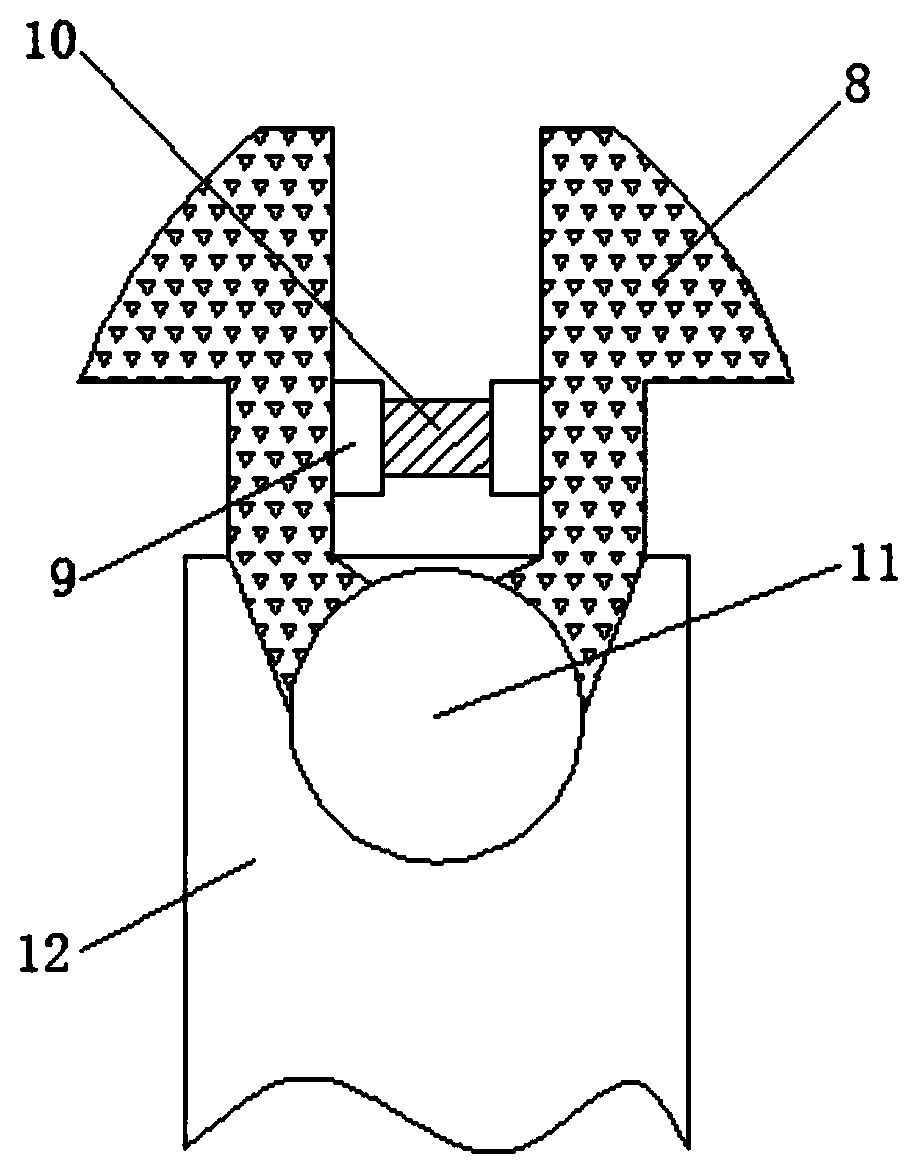

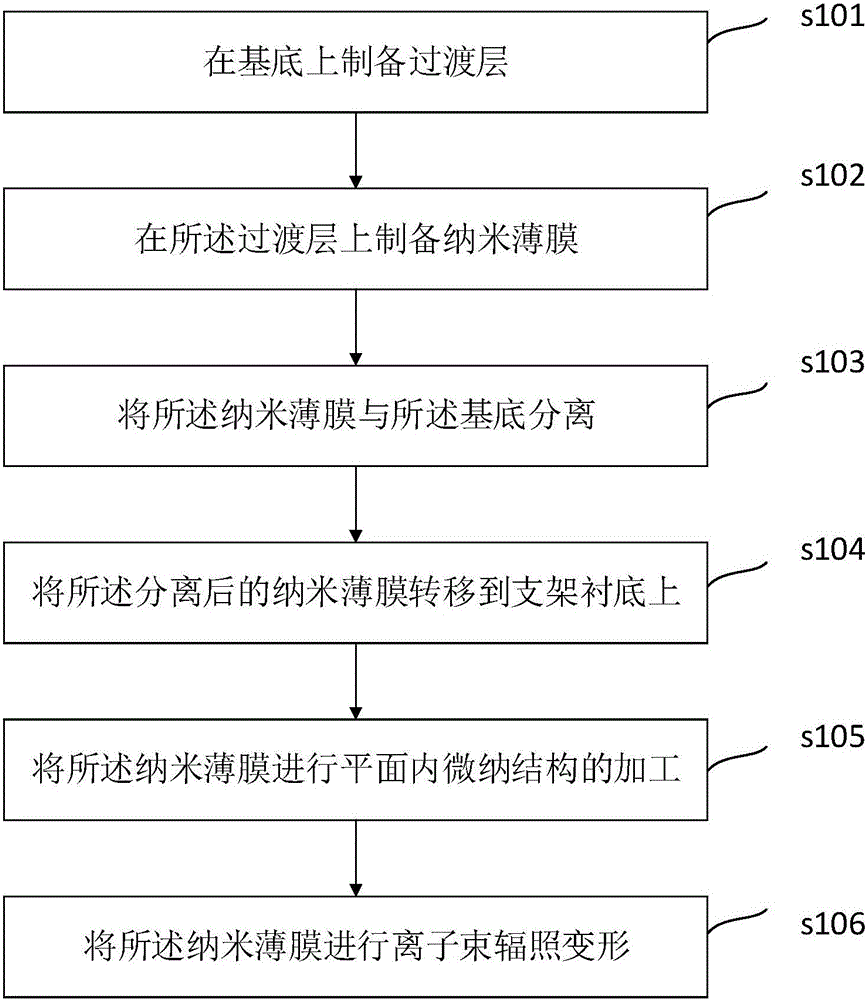

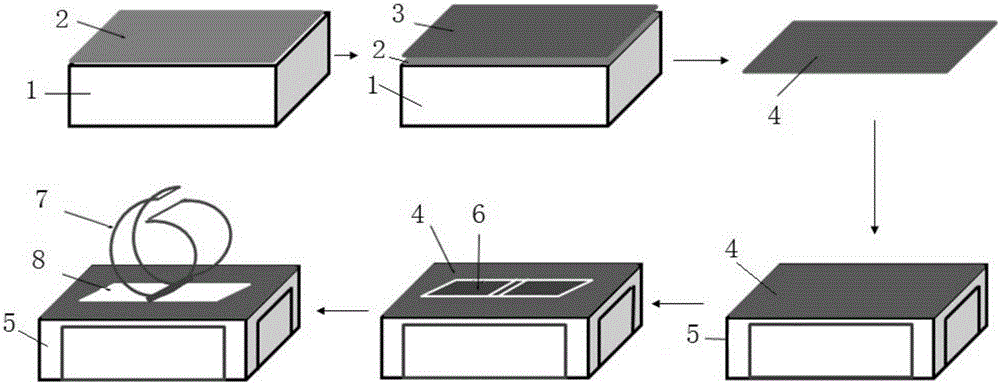

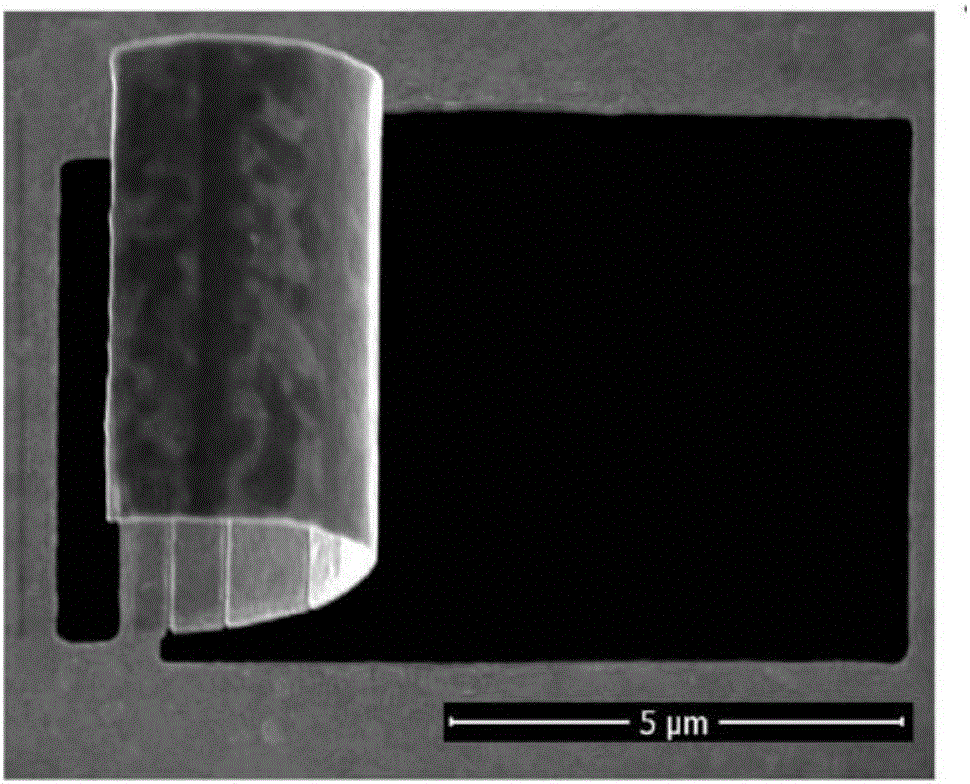

The present invention relates to a preparation method of a three-dimensional self-supporting micro-nano functional structure based on a thin film material, comprising the steps of: preparing a transition layer on a clean smooth substrate; preparing nano thin film and peeling nano thin film from a smooth substrate; preparing a supporting substrate with a pore structure; transferring the nano thin film to the supporting substrate with the pore structure; preparing a micro-nano graph on the nano thin film; and inducing the micro-nano graph on the nano thin film by ion beam irradiation to deform and form a finished product with the three-dimensional self-supporting micro-nano structure. The present invention is a novel method for preparing the self-supporting three-dimensional micro-nano functional structure based on the combination of the preparation of micro-nano structure on the nano thin film and ion beam irradiation-induced three-dimensional deformation, and has the characteristics of flexible technology, high efficiency, good controllability, low cost and large-scale preparation. The prepared micro-nano graph is designable in structure, morphology, size, and cycle, is various in material types, and has the characteristics of novel functions and physical properties.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Non-oriented electrical steel plate and production method thereof

InactiveCN103572158AImprove thermal conductivityReduce carbon increaseMetal rolling arrangementsProduction lineElectrical steel

The invention relates to a non-oriented electrical steel plate Which comprises the following components in percentage by mass: less than or equal to 0.0060 percent of C, 0.60 to 0.80 percent of Si, 0.20 to 0.40 percent of Mn, less than or equal to 0.10 percent of P, less than or equal to 0.0080 percent of S, 0.015 to 0.025 percent of Als, 0.001 to 0.002 percent of B, and the balance of Fe and unavoidable impurity elements. The production method comprises the following steps of smelting in a converter, argon blowing to steel ladle, RH vacuum treatment, refining of an LF furnace, continuous casting of a sheet billet, heat equalizing through a tunnel, fine rolling, cooling, coiling, acid pickling, cold rolling and continuous annealing. Compared with the prior art, the method is high in magnetic induction and low in iron loss. A manufacturing process for producing the non-oriented electrical steel plate by continuously casting and continuously rolling the sheet billet is provided for the first time, and the technical support is provided for production of a novel non-oriented electrical steel hot-rolling raw material with excellent environmental-protection performance by utilizing a sheet billet continuous-casting and continuous rolling production line.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Aerogel vacuum insulation panel, core material thereof and preparation methods thereof

InactiveCN109210319APromote the industrialization process of comprehensive utilizationReduce manufacturing costThermal insulationLaminationSilanesDissolution reaction

The invention provides preparation methods for a vacuum insulation panel and a core material thereof. In the preparation methods, waste solid coal ash and straw ash discharged from a thermal power plant in China are used as a silicon source, thermokalite dissolution reaction is performed at a high temperature and a high pressure, an innovative inorganic dispersion sol-gel method and an epoxide method preparation process are adopted, a coagulation method for preparing organic aerogel, a co-polymerization method for preparing hydrophobic aerogel, and a doped modified aerogel in-situ method are combined, an in-situ co-precursor modification method is adopted, at the same time, a silane with a hydrophobic group is introduced and mixed with the silicon source for a sol-gel process, secondary hydrophobic modification of gel and organic matter toughening and strengthening are adopted, an inorganic / organic hybrid composite bulk aerogel vacuum insulation panel core material is prepared under normal pressure, and a vacuum insulation panel is prepared by using the core material. The vacuum insulation panel core material of the invention can be separately applied to the building thermal insulation engineering, has good anti-NIR performance, high strength and good toughness, does not crush under extrusion and is low in cost. The aerogel vacuum insulation panel of the invention does not produce a cold and heat bridge phenomenon, with the vacuum degree being maintained for a long time, is not prone to bulging and scratching, and can be made into a bulk.

Owner:王贵然 +1

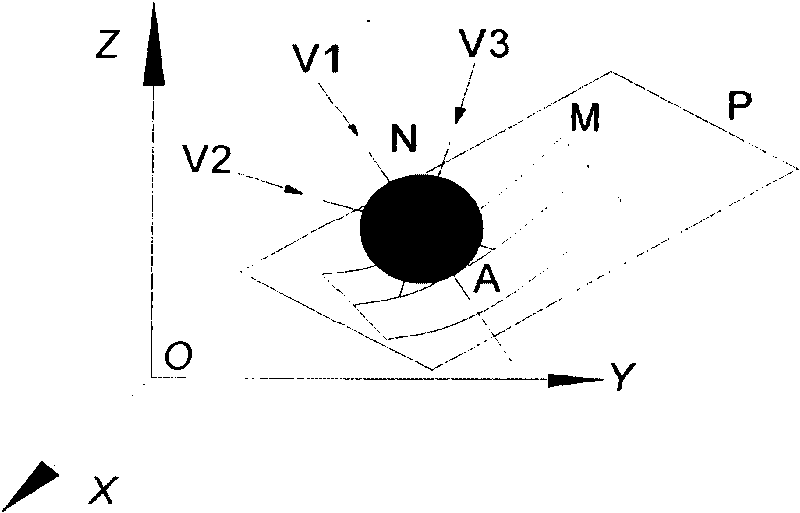

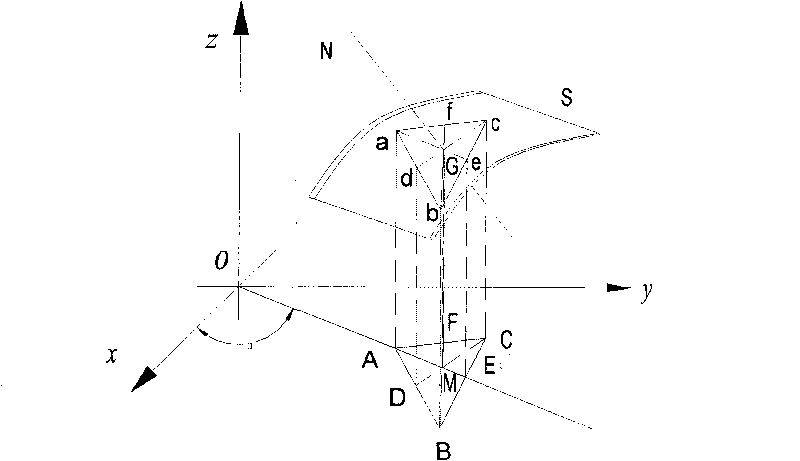

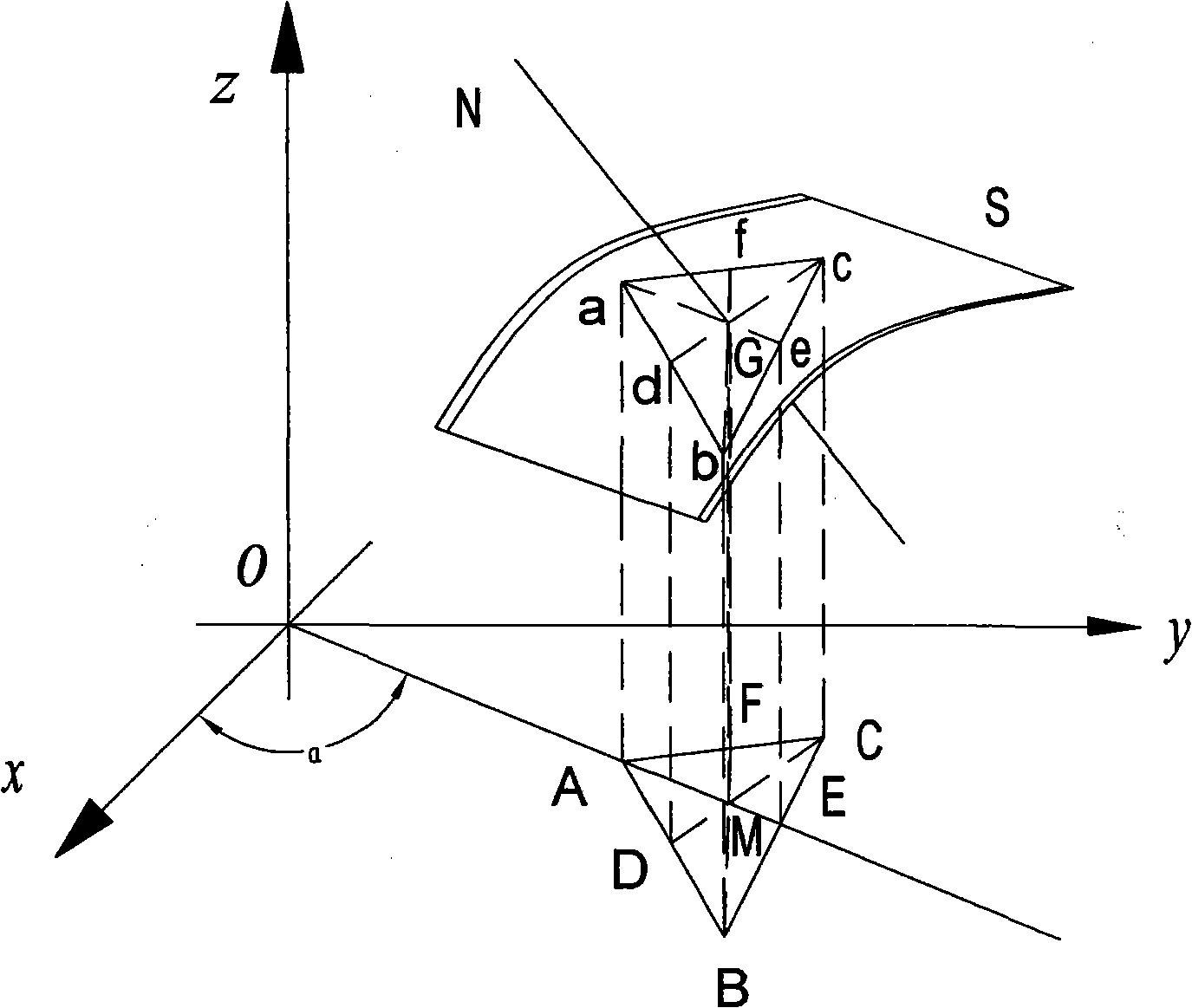

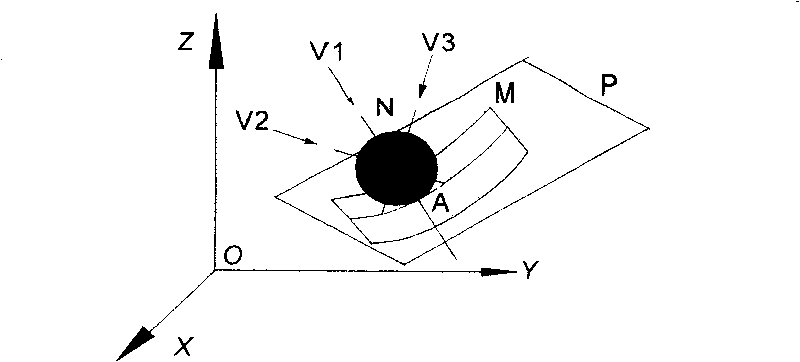

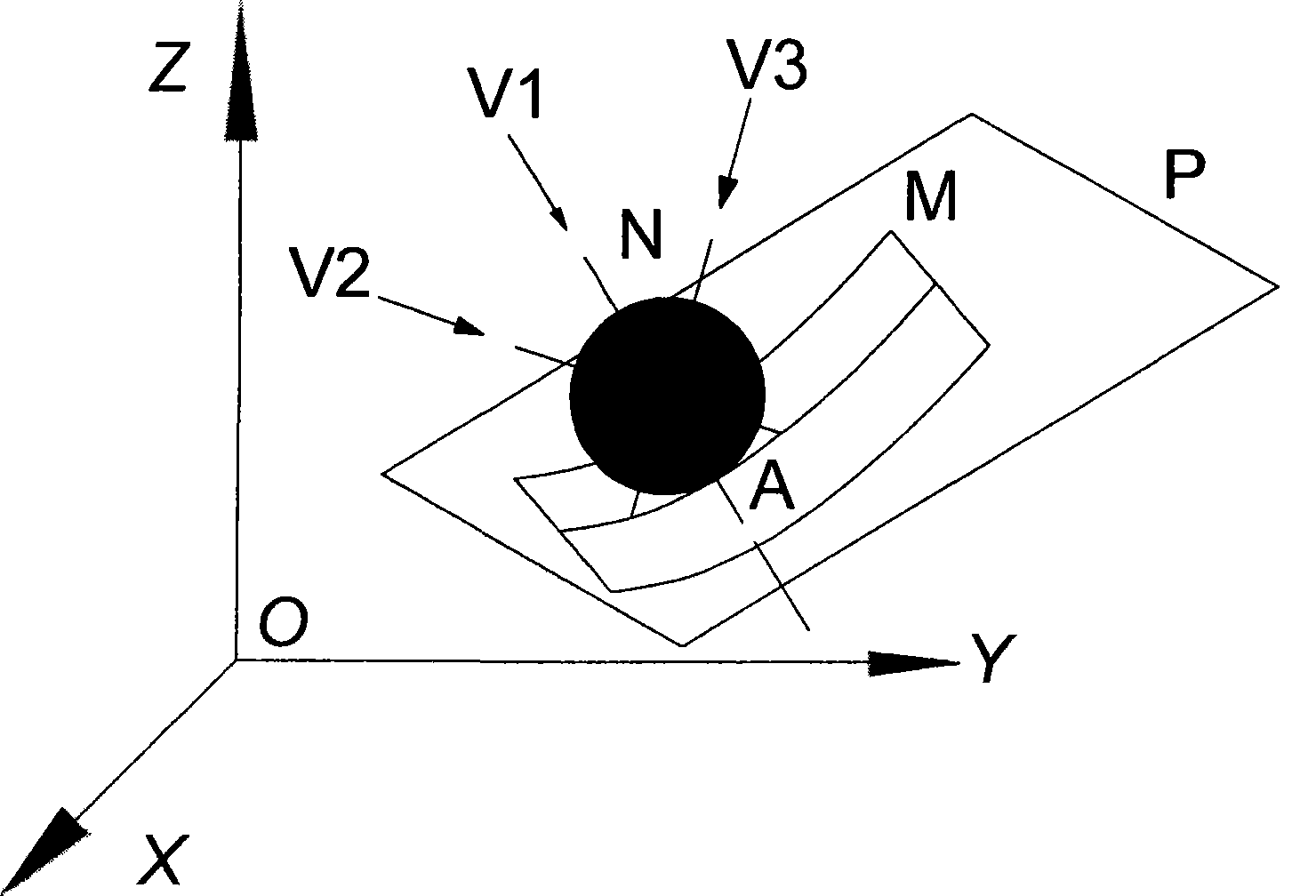

Method for precisely measuring 3D profile by using measuring needle central coordinate and vector compensation technology

InactiveCN101750044AExpand the scope of manufacturingEasy to useMeasurement devicesMeasurement pointProjection plane

The invention discloses a method for precisely measuring a 3D profile by using the measuring needle central coordinate and vector compensation technology, which comprise: establishing a spatial measurement coordinate system according to the 3D profile; setting the measurement range which covers the 3D profile; closing measuring needle radius compensation to allow a measuring needle to measure along the vector direction vertical to the projection plane of the profile; collecting four measuring points in the curved surface of the space, so that three measuring points form a micro triangle, the three vertexes of the triangle form an equilateral triangle in the projection plane of the measurement coordinate system, and the projection point of the other measuring point P is of the center M of the equilateral triangle; calculating the normal vector V1 of the plane of the micro triangle formed by the three measuring points; starting measuring needle radius compensation, taking the P point as a measuring target point, taking the V1 as the measuring needle approach and compensation direction to measure the 3D profile; and so forth, completing the measurement of the 3D profile. The invention can be used for the measurement of the 3D profile with large range and complex profile, and has the advantages of high accuracy and measuring efficiency.

Owner:HONGTA TOBACCO GRP

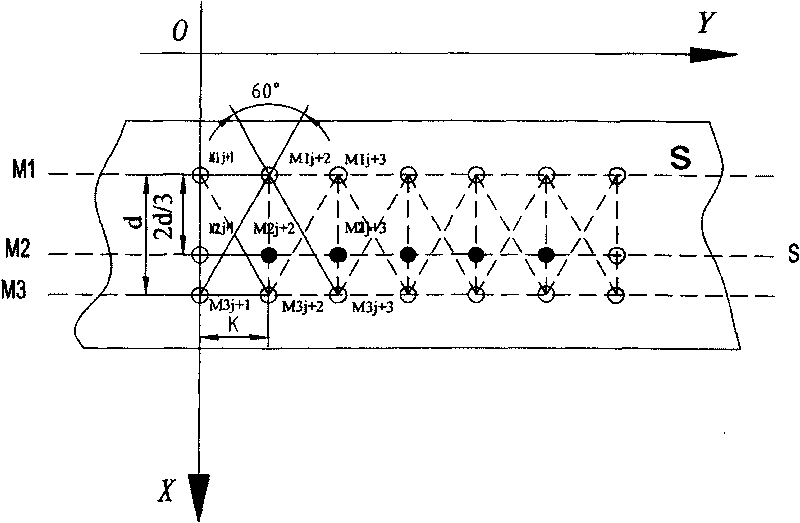

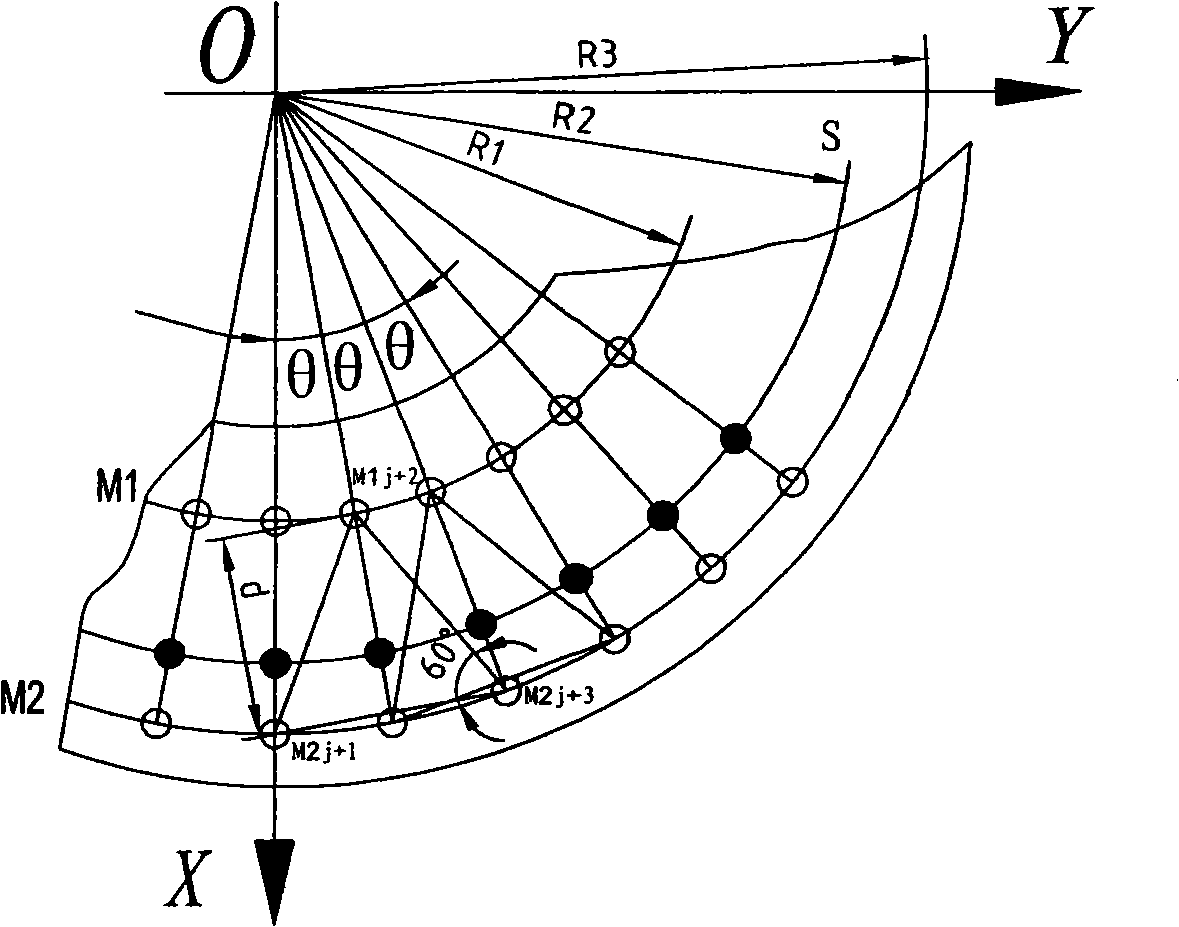

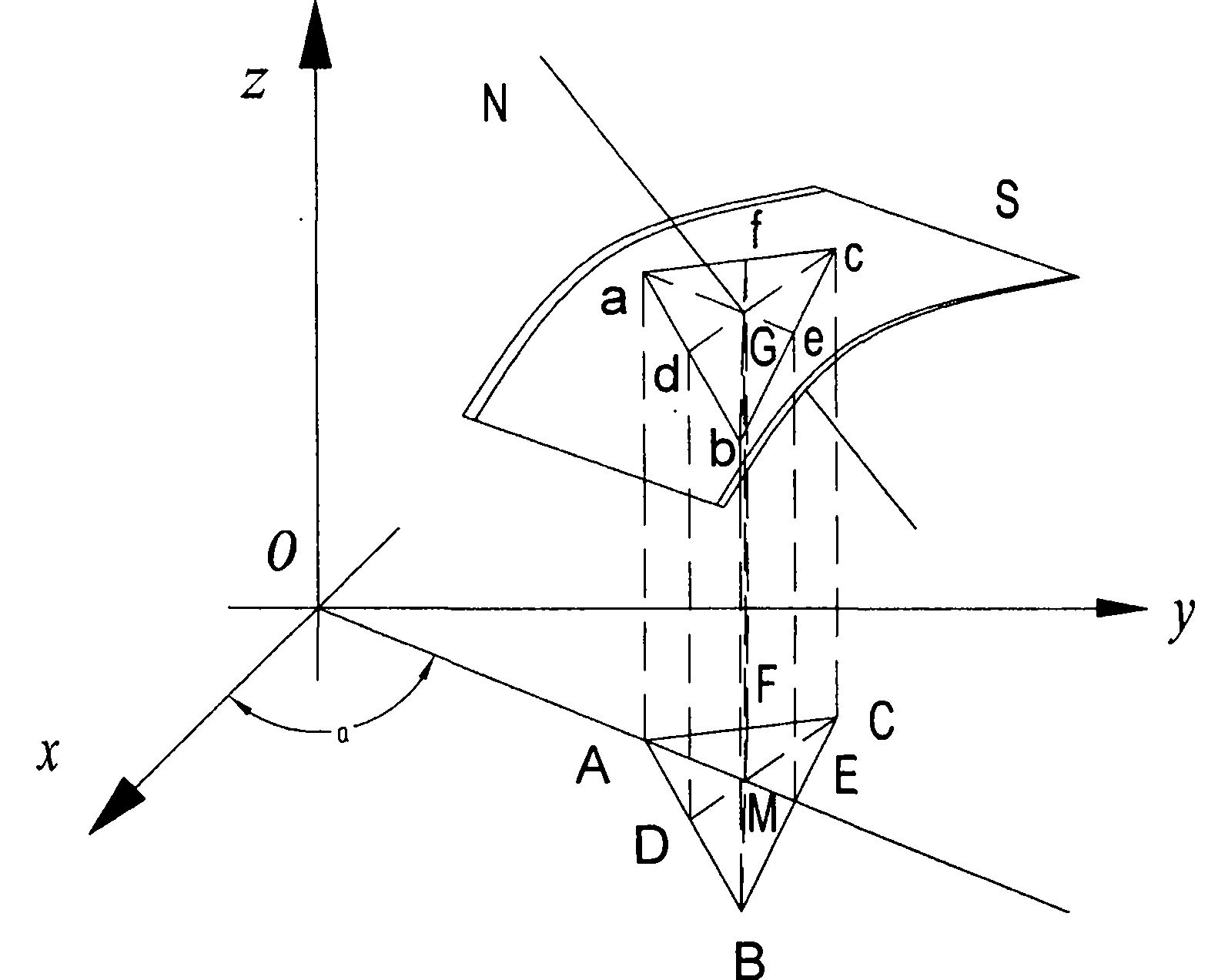

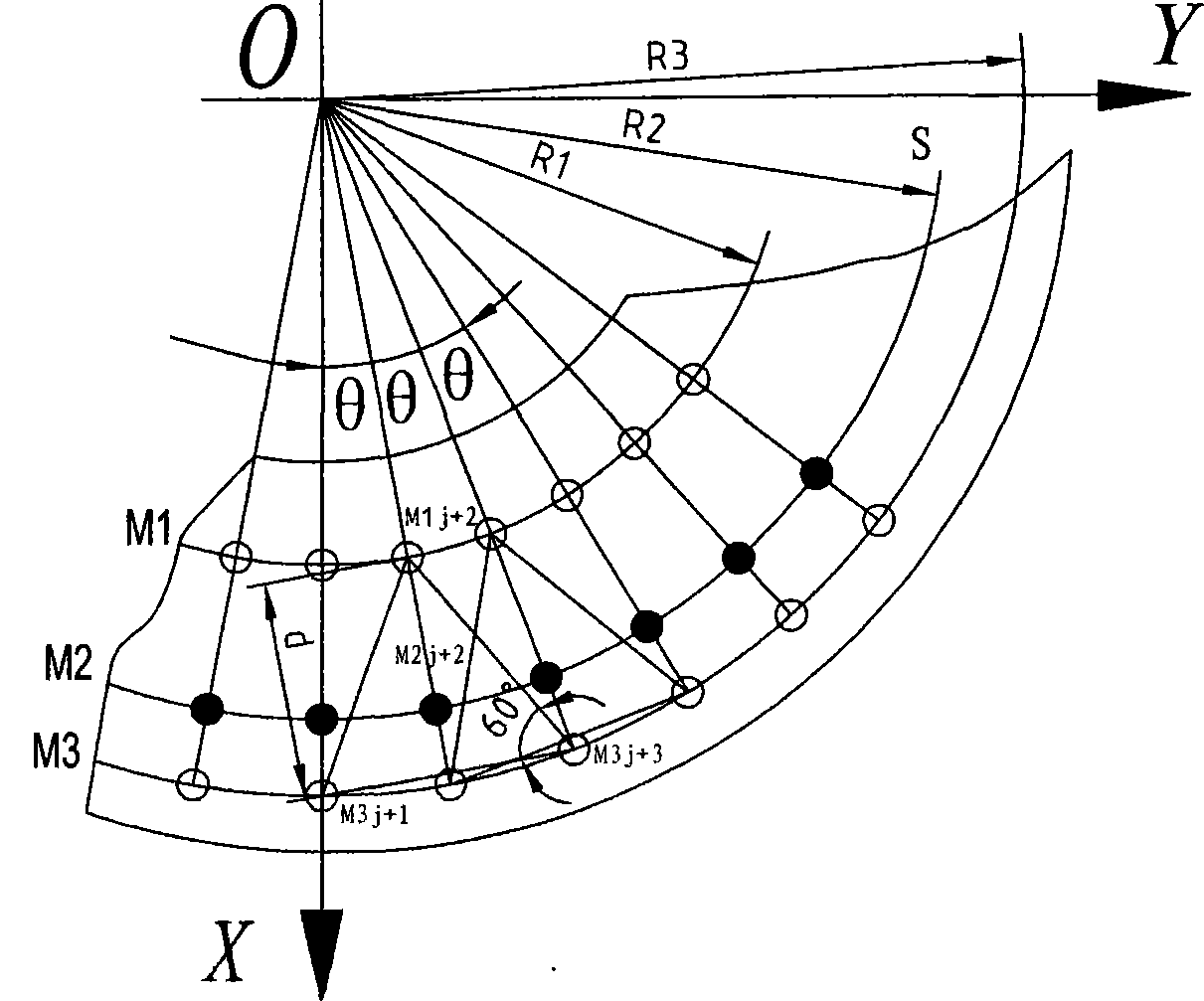

Method for measuring space rotating curved surface with microdelta barycentric coordinates as objective point

InactiveCN101403611AExpand the scope of manufacturingFast reverse analysisMeasurement devicesObject pointData file

The invention discloses a space rotation surface measurement method by using a micro triangle gravity coordinate as an object point. The method comprises the steps of: constructing a coordinate system according to the space rotation surface; determining the measurement range of the space rotation surface; and selecting a plurality of polar radii Rs in the range; aiming at each polar radius R, constructing a plurality of micro triangles to calculate the plane normal vector, and calculating the gravity coordinates, and the gravity is regarded as an object point, using sub-degree method to measure each curve in the space rotation surface; generating datum file consistent with the professional software to read; and analyzing the value range of the equilateral triangle height d through the standard ball experiment. Adopting the method that the gravity coordinates are regarded as the object point can measure the space rotation surface, and the measuring precision is high.

Owner:HONGTA TOBACCO GRP

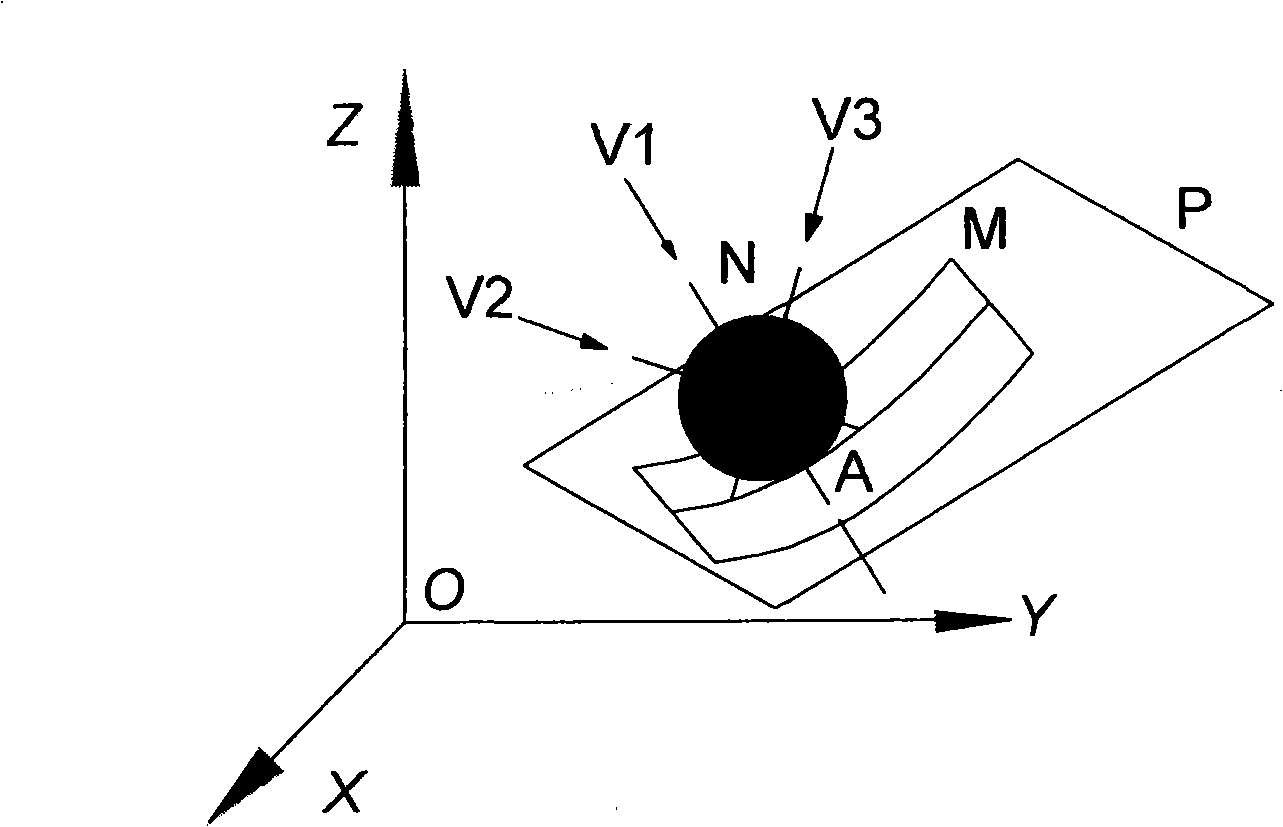

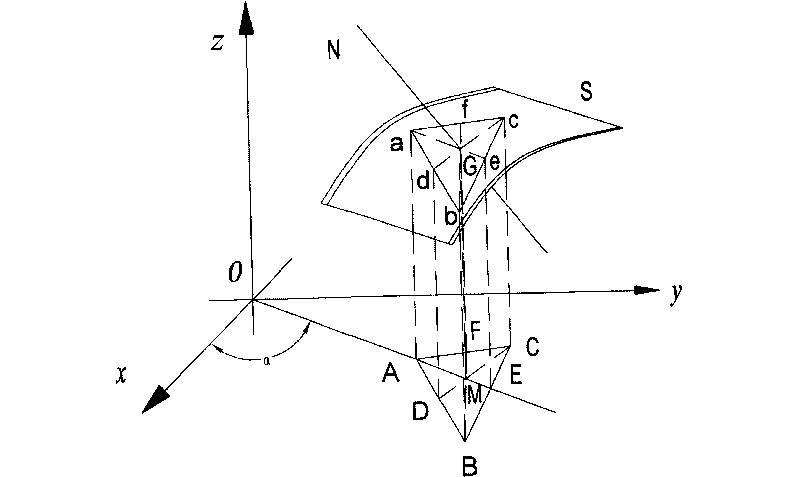

Method for measuring 3D profile surface by trigger measuring head on measuring machine

InactiveCN101750043AExpand the scope of manufacturingImprove measurement efficiencyMeasurement devicesMeasurement pointMeasurement precision

The invention discloses a method for measuring a 3D profile surface by a trigger measuring head on a measuring machine, comprising the following steps: establishing a spatial measurement coordinate system according to the 3D profile surface; setting a measuring range covering the 3D profile surface; closing measuring needle radius compensation to cause a measuring needle to measure along a vector direction perpendicular to a profile projective surface; collecting measurement points on the 3D profile surface to cause three of the measurement points to form an equilateral triangle in the projective surface of the measurement coordinate system; calculating the center of gravity coordinate G of a micro-triangle plane formed by the three measuring points; calculating the normal vector V1 of the micro-triangle plane formed by the three measuring points by a vectormeter, starting the measuring needle radius compensation, taking the center of gravity coordinate G as a measurement target point, taking the normal vector V1 as a measuring needle reaching direction to measure the coordinate figure of the center of gravity coordinate G, and the like completing the measurement of the 3D profile surface. The method can be used for the measurement of the 3D profile surface of a large-scale complex profile and has the advantages of high measurement accuracy and high measurement efficiency.

Owner:HONGTA TOBACCO GRP

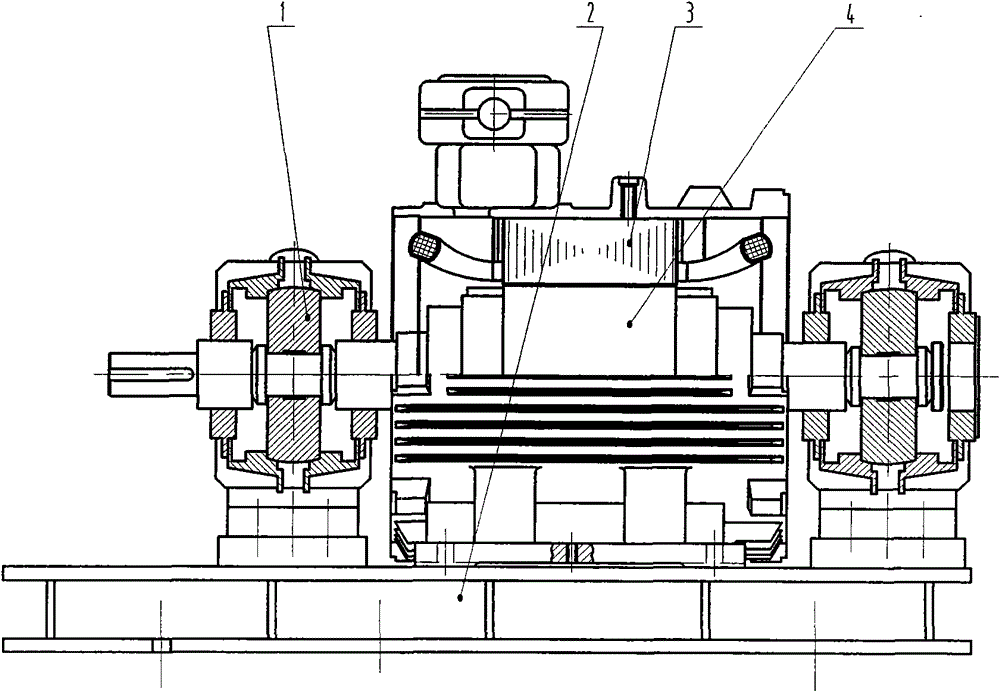

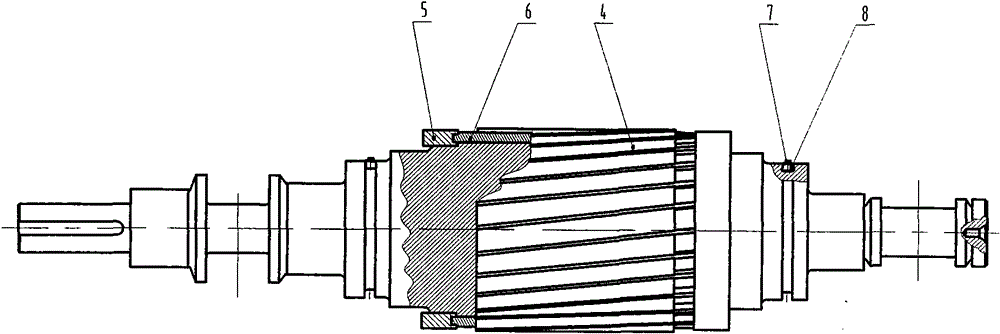

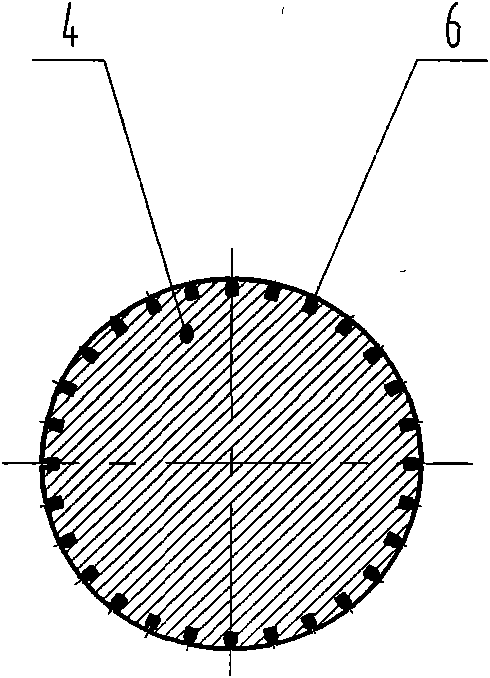

High-speed motor with solid rotor

InactiveCN102801267AIncrease the critical speedIncrease deflectionAsynchronous induction motorsMechanical energy handlingPunchingElectric machine

The invention discloses a high-speed motor with a solid rotor. A laminated structure for punching of the iron core of the conventional motor rotor is changed; the iron core of the rotor is manufactured through a solid rotating shaft; the diameter of the rotating shaft is increased to an extreme size, so that the extreme rotating speed of the motor is increased; and a slot is formed in the surface of the rotating shaft, and a copper conductive strip is embedded into the slot and welded with copper end rings at two ends, so that the high-speed motor which has the power of below 400 KW and is used for starting and running a mouse cage is formed. By the structure, the high-speed motor can run in a speed range of 0 to 20,000 r / min.

Owner:SHANGHAI PINXING EXPLOSION PROOF MOTOR

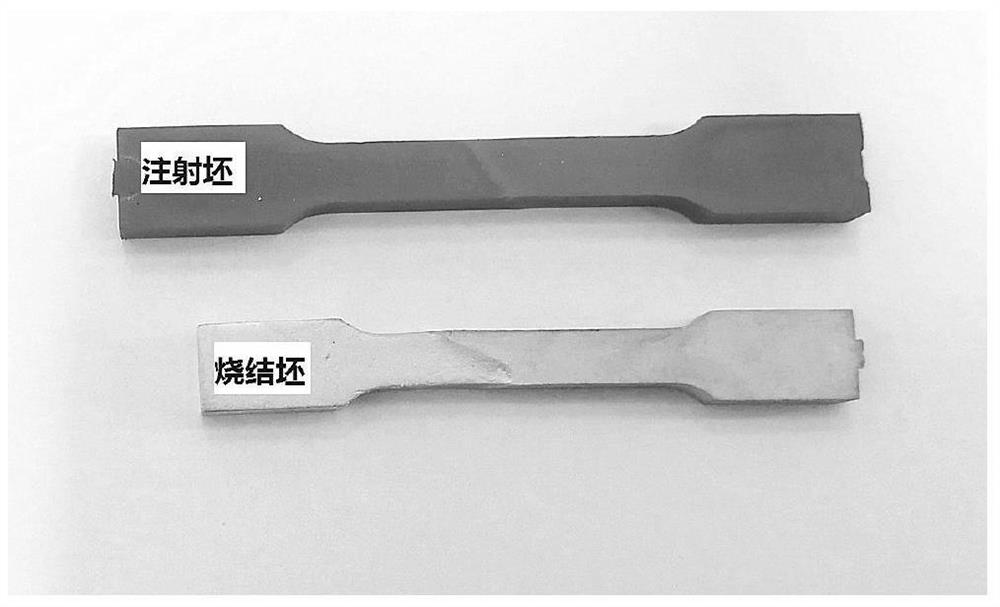

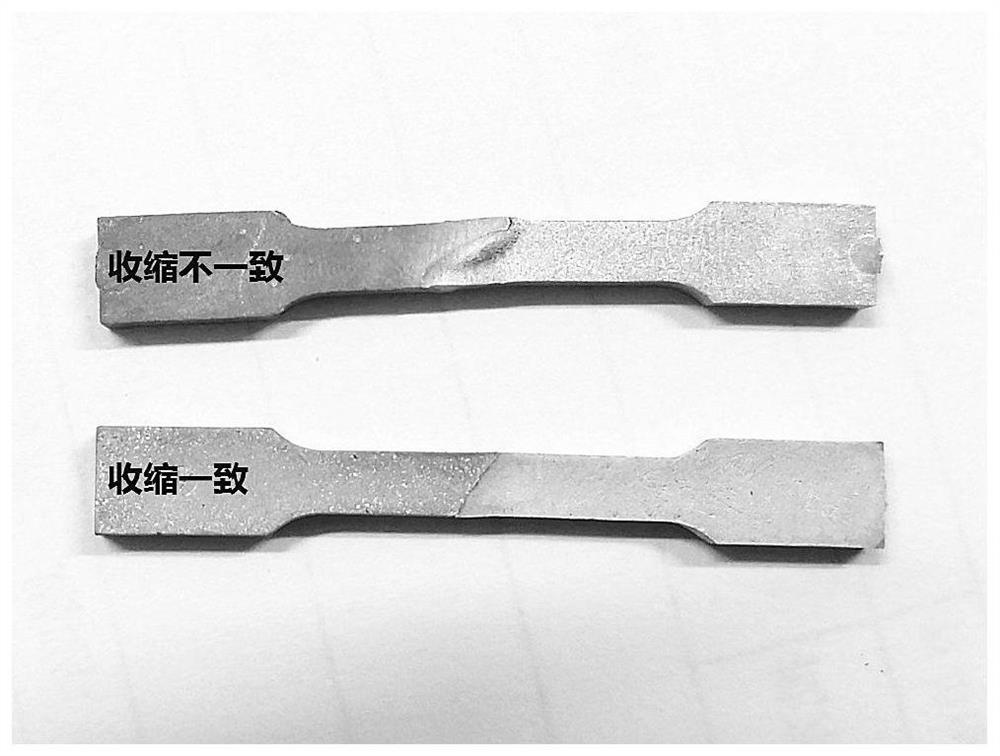

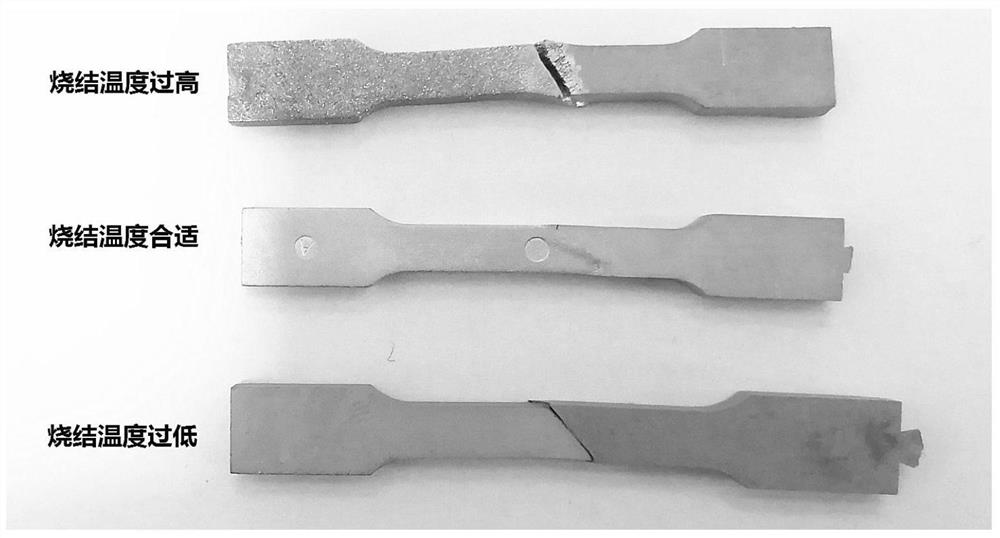

Powder metallurgy preparation method for step-by-step formed cemented carbide hard alloy/steel double-layer structure composite material

The invention relates to a powder metallurgy preparation method of a step-by-step formed cemented carbide hard alloy / steel double-layer structure composite material, belongs to the technical field of composite material preparation. The method includes the steps that firstly, a steel powder material and carbide hard alloy powder are mixed and granulated with a binder to obtain a steel powder material feed and a carbide hard alloy material feed, and then the steel powder material feed and the carbide hard alloy material feed are sequentially injected into a mold cavity step by step through an injection molding technology to obtain a product green body; and part of the binder in the green body is removed through catalytic degreasing, and finally the carbide hard alloy / steel double-layer structure composite material is obtained through co-sintering densification. The powder metallurgy preparation method of the step-by-step formed cemented carbide hard alloy / steel double-layer structure composite material is simple and controllable, an obtained product is excellent in performance, and large-scale industrial application is facilitated.

Owner:湖南英捷高科技有限责任公司

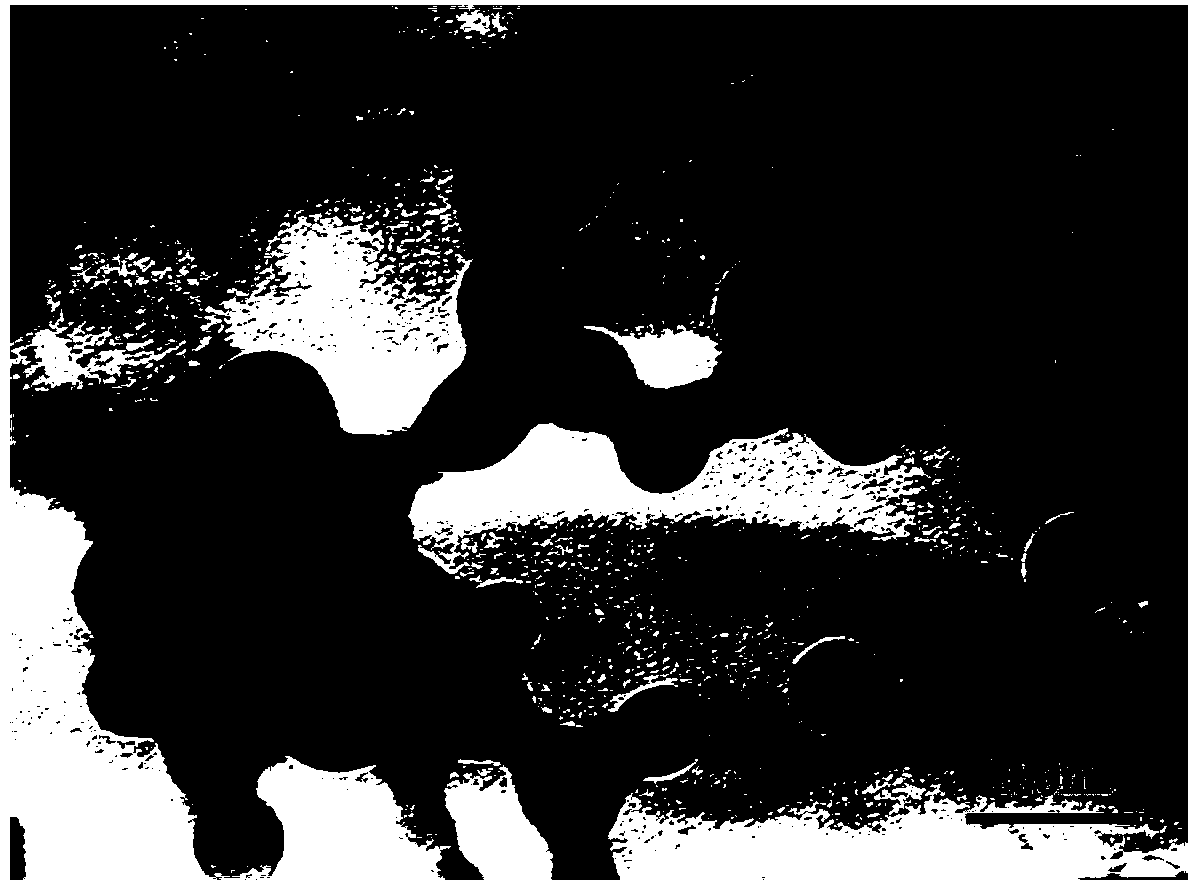

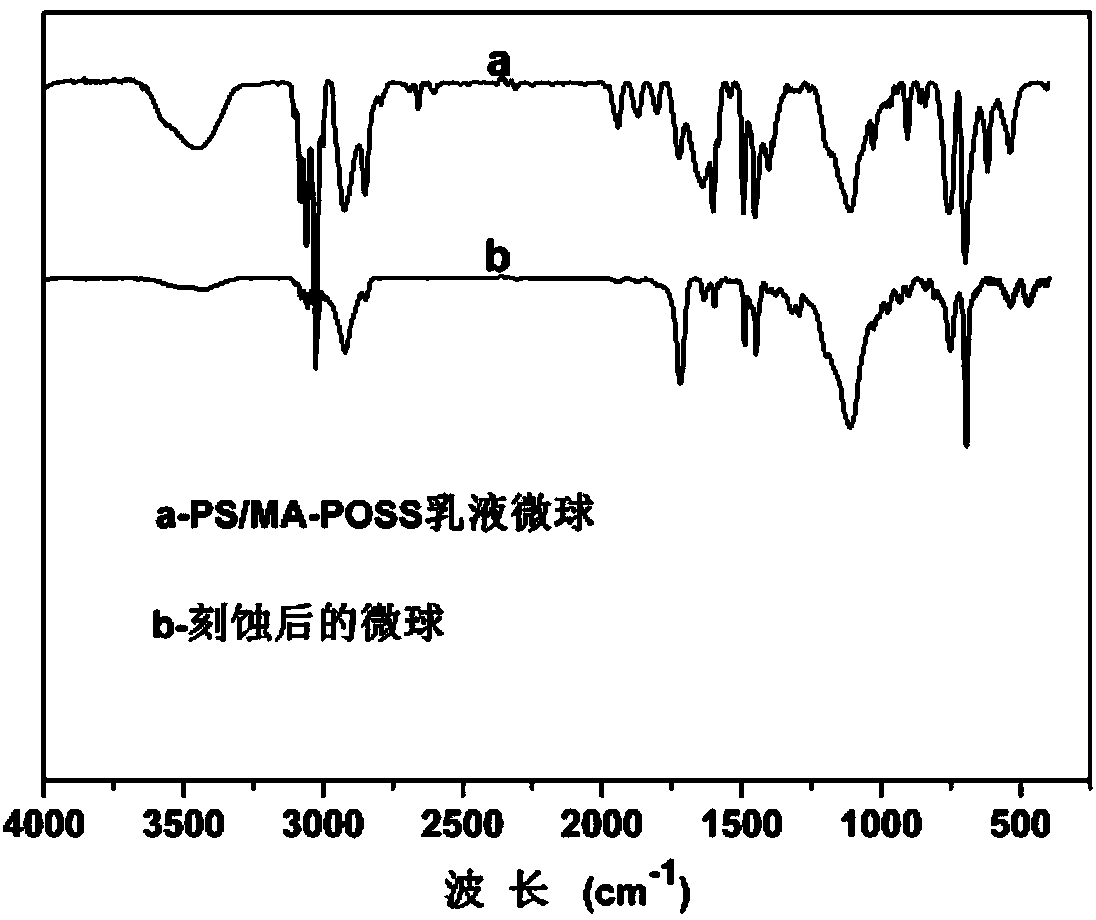

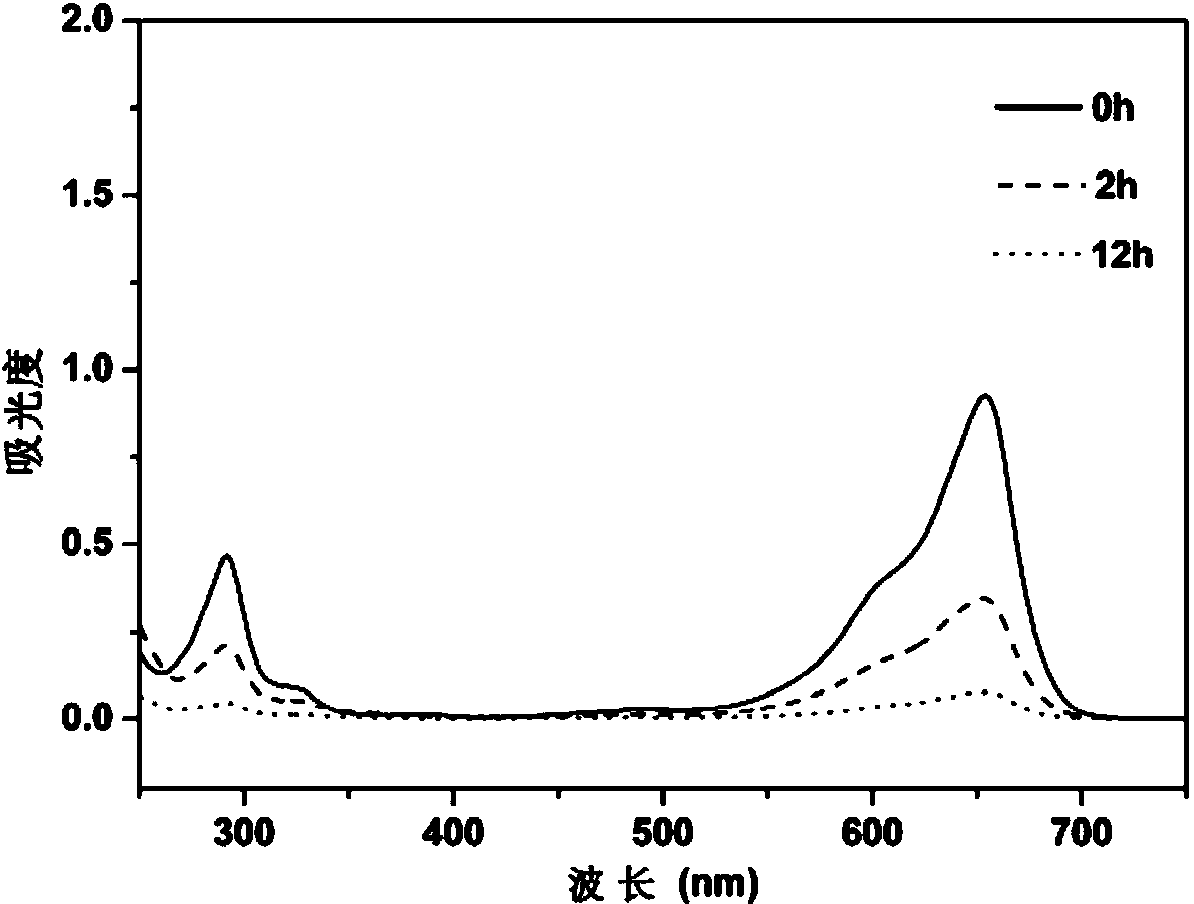

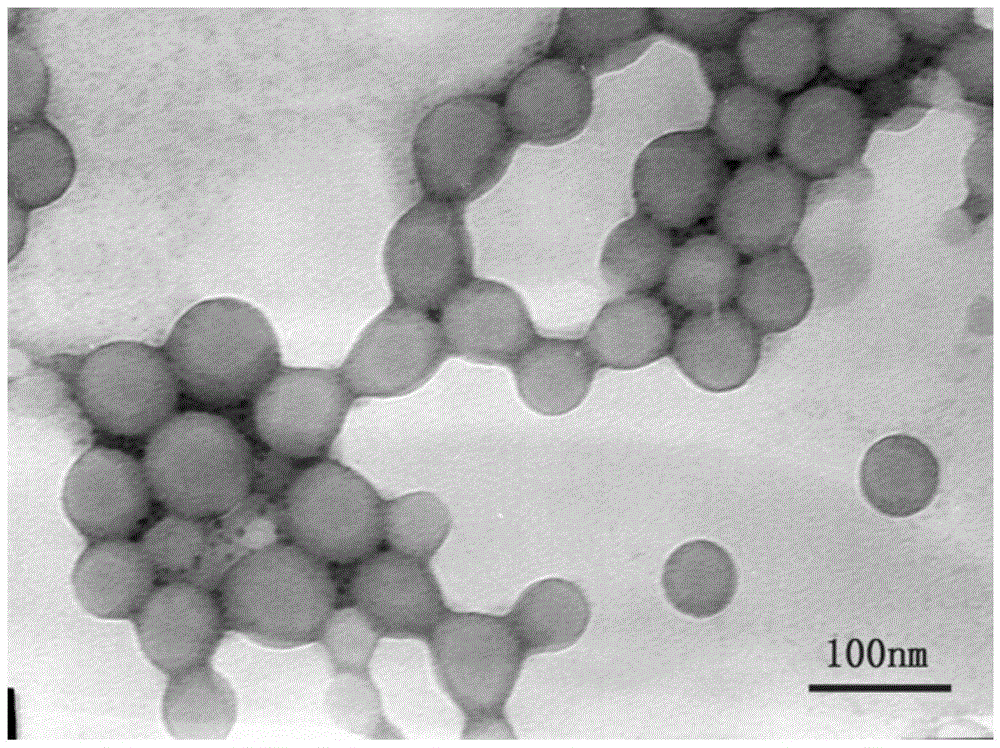

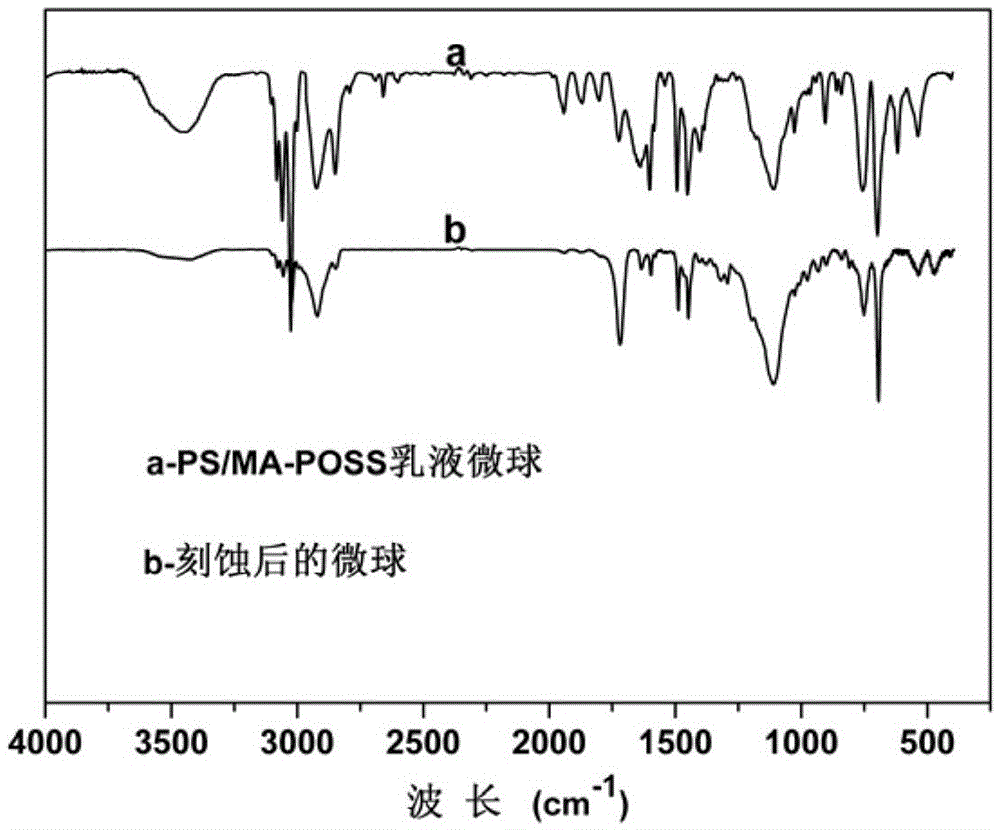

Hollow microsphere based on methacrylic acyloxy cage-like silsesquioxane and preparation method and application thereof

ActiveCN104226275AReduce usageReduce manufacturing costOther chemical processesAlkali metal oxides/hydroxidesMicrospherePolystyrene

The invention belongs to the technical field of organic and inorganic nano hybrid materials, and discloses a hollow microsphere based on methacrylic acyloxy cage-like silsesquioxane as well as a preparation method and an application thereof. The method comprises the following steps: preparing emulsion with stable methacrylic acyloxy cage-like silsesquioxane and Pickering effect, and drying the emulsion; soaking the dried emulsion by adopting a mixed solution which contains acetone and cyclohexane and serves as an etching agent so as to remove polystyrene nuclear to obtain a product. The product is extremely good in adsorption performance and can be applied to the field of sewage treatment. The operation technology is relatively simple, and experiment conditions are mild; the selected raw materials and reagents are easily obtained, and the yield of reaction is high.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Biscuit producing and shaping mold convenient to carry and store

Owner:安徽品滋味食品股份有限公司

Preparation method of three-dimensional self-supporting micro-nano functional structure based on thin film material

ActiveCN103043600BRich varietyUnique functionDecorative surface effectsChemical vapor deposition coatingMaterial typeControllability

The present invention relates to a preparation method of a three-dimensional self-supporting micro-nano functional structure based on a thin film material, comprising the steps of: preparing a transition layer on a clean smooth substrate; preparing nano thin film and peeling nano thin film from a smooth substrate; preparing a supporting substrate with a pore structure; transferring the nano thin film to the supporting substrate with the pore structure; preparing a micro-nano graph on the nano thin film; and inducing the micro-nano graph on the nano thin film by ion beam irradiation to deform and form a finished product with the three-dimensional self-supporting micro-nano structure. The present invention is a novel method for preparing the self-supporting three-dimensional micro-nano functional structure based on the combination of the preparation of micro-nano structure on the nano thin film and ion beam irradiation-induced three-dimensional deformation, and has the characteristics of flexible technology, high efficiency, good controllability, low cost and large-scale preparation. The prepared micro-nano graph is designable in structure, morphology, size, and cycle, is various in material types, and has the characteristics of novel functions and physical properties.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

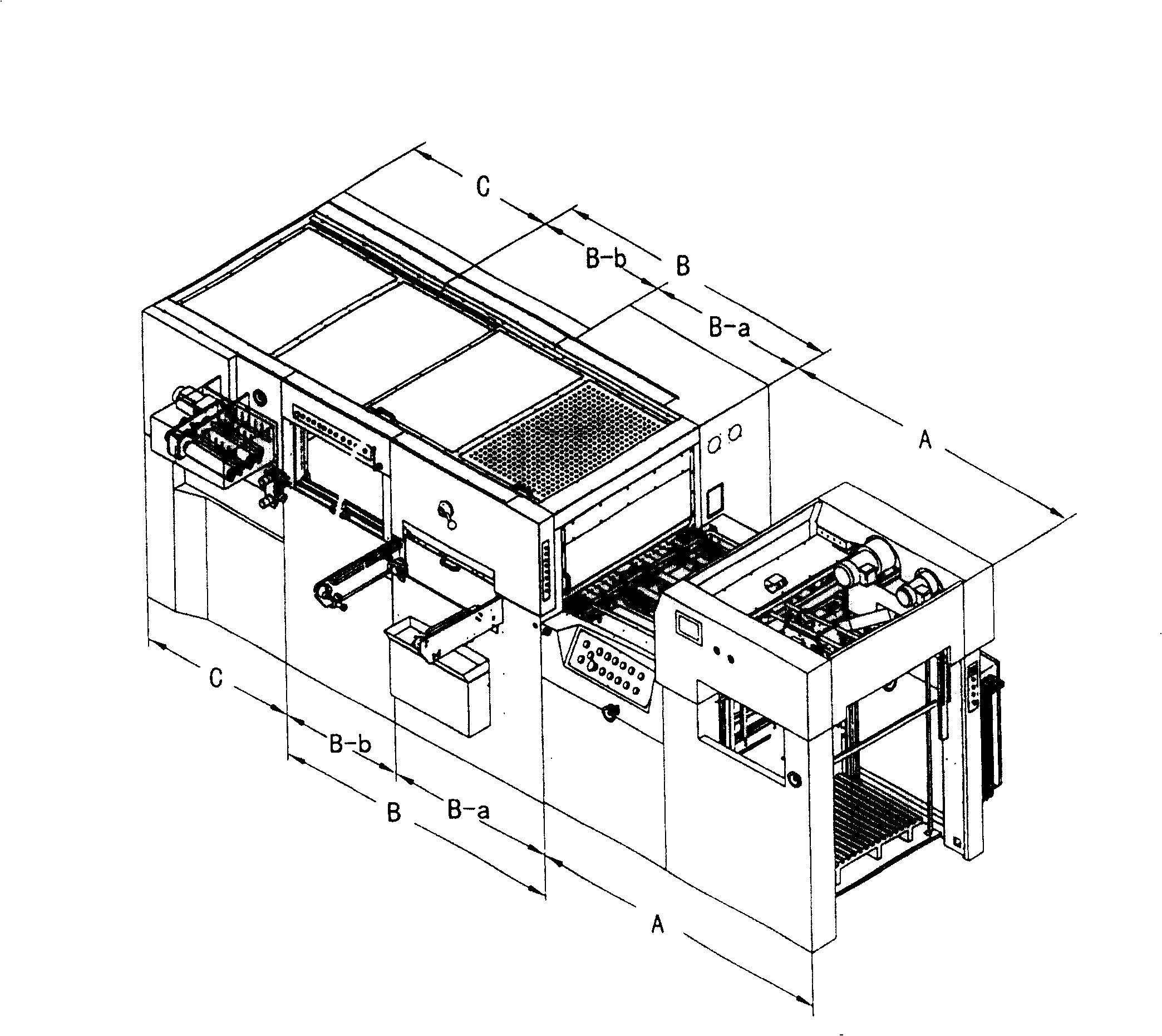

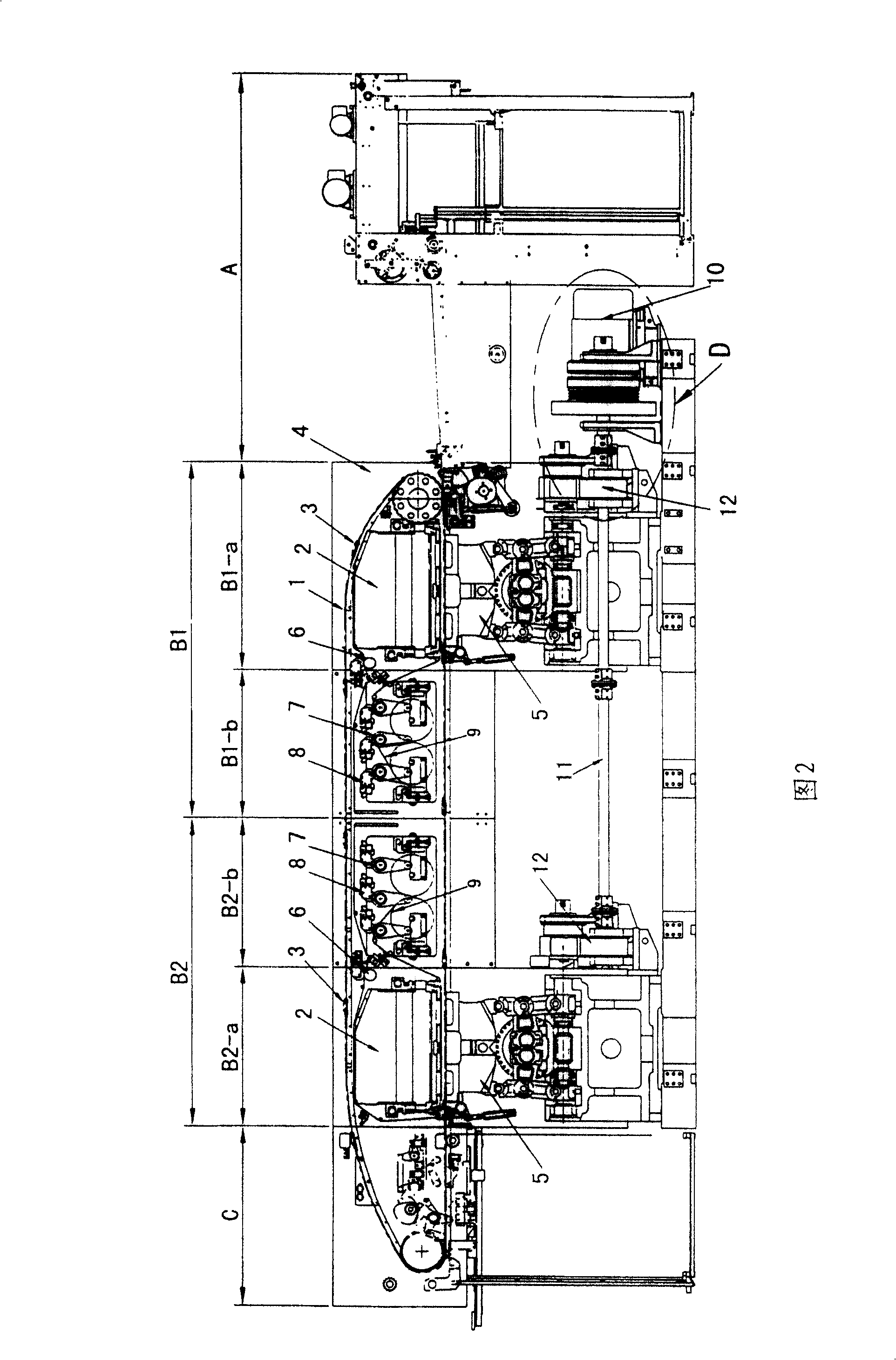

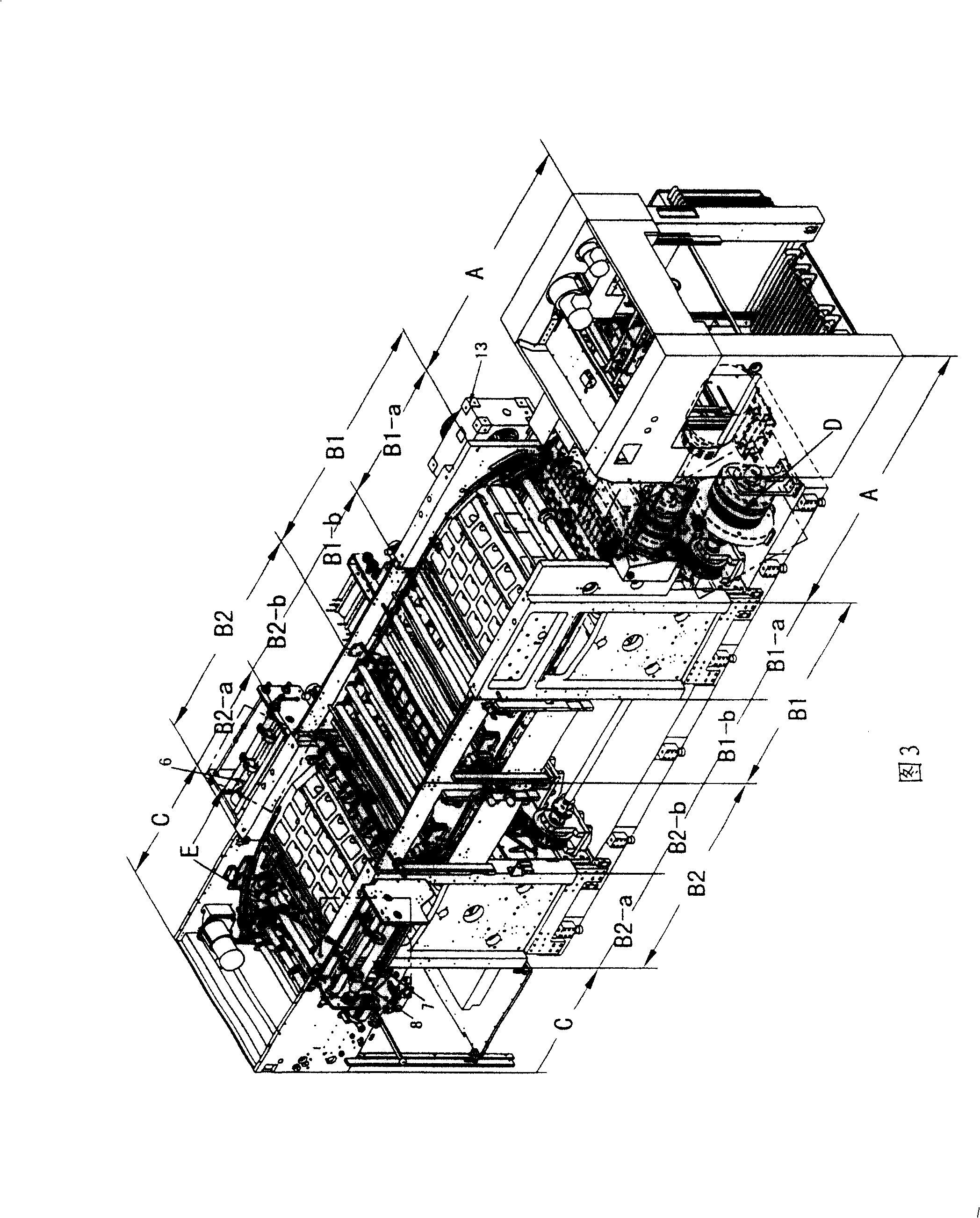

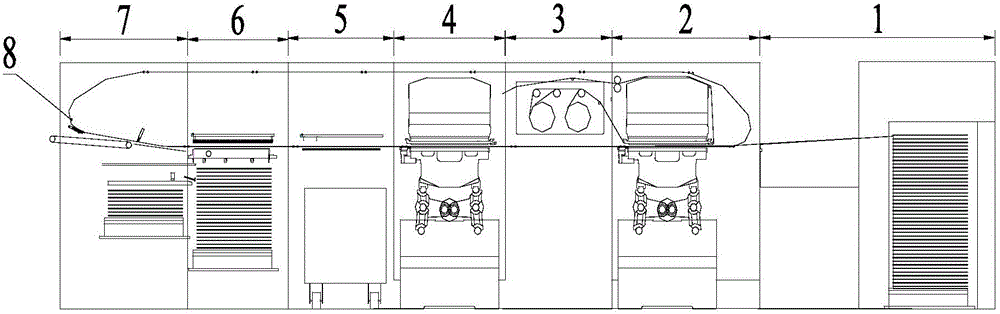

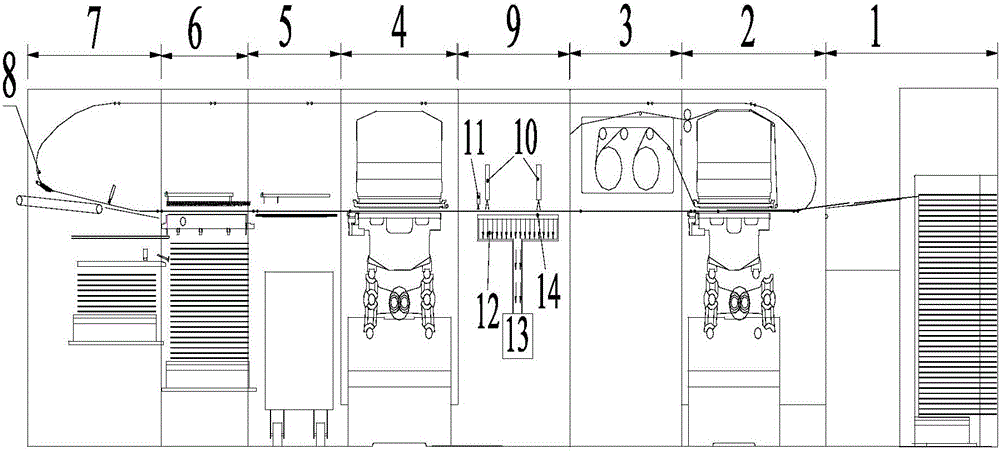

Process for multi-position mold pressing with feeding once and automatic mold cutting and stamping machine

ActiveCN100445103CReduce the number of paper passesReduce distortionPlaten pressesThermographyPulp and paper industryPaper sheet

An embossing technology featuring that after the paper is fed once, the embossings can be conducted at more working positions includes such steps as delivering paper, embossing at multiple positions by multiple embossing unit, and receiving paper. An automatic cutting-thermopminting machine is composed of a paper delivering unit, an embossing unit with move than two mechanics for performing the thermoprinting, stamping, and cutting, and a paper receiving unit.

Owner:MASTERWORK GROUP CO LTD

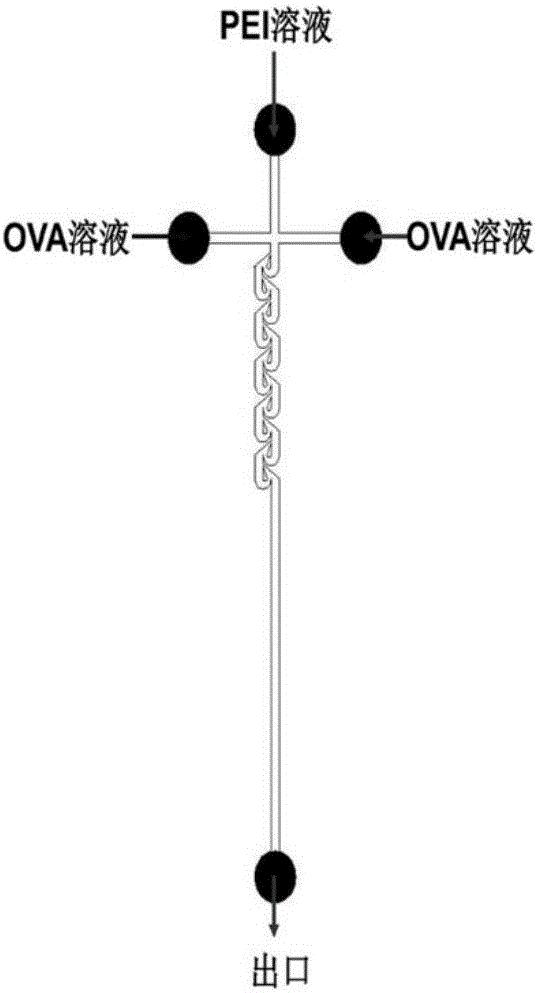

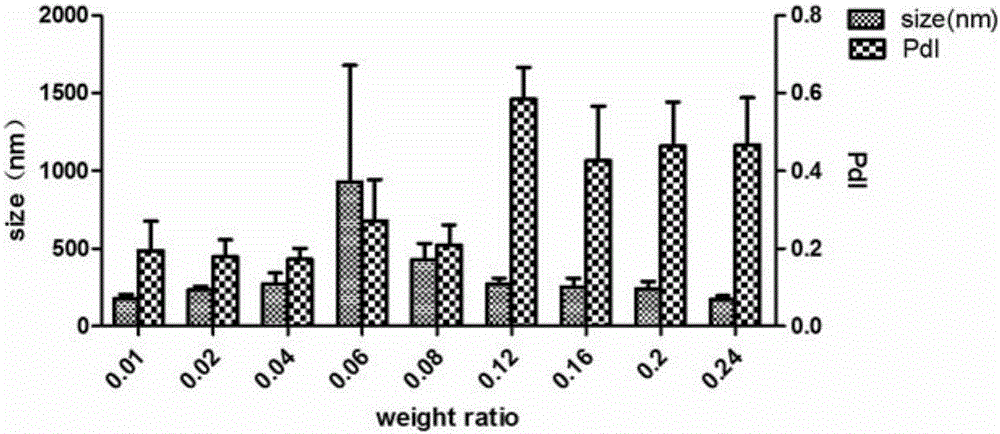

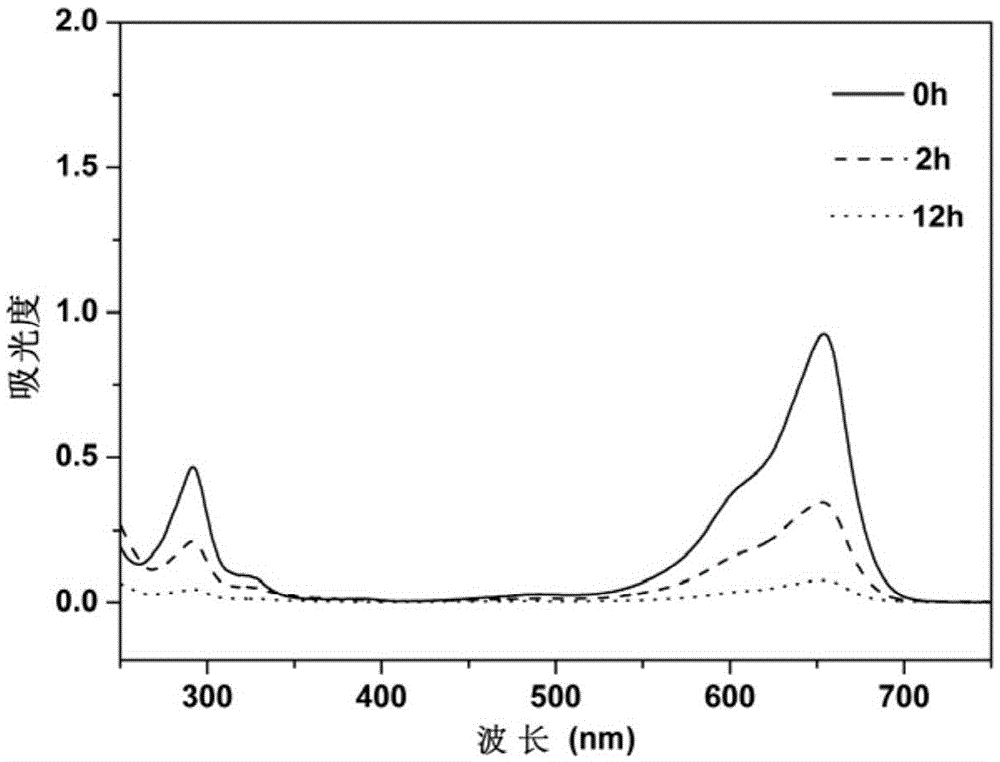

Microfluid preparation method for tumor therapeutic vaccine nanocarriers

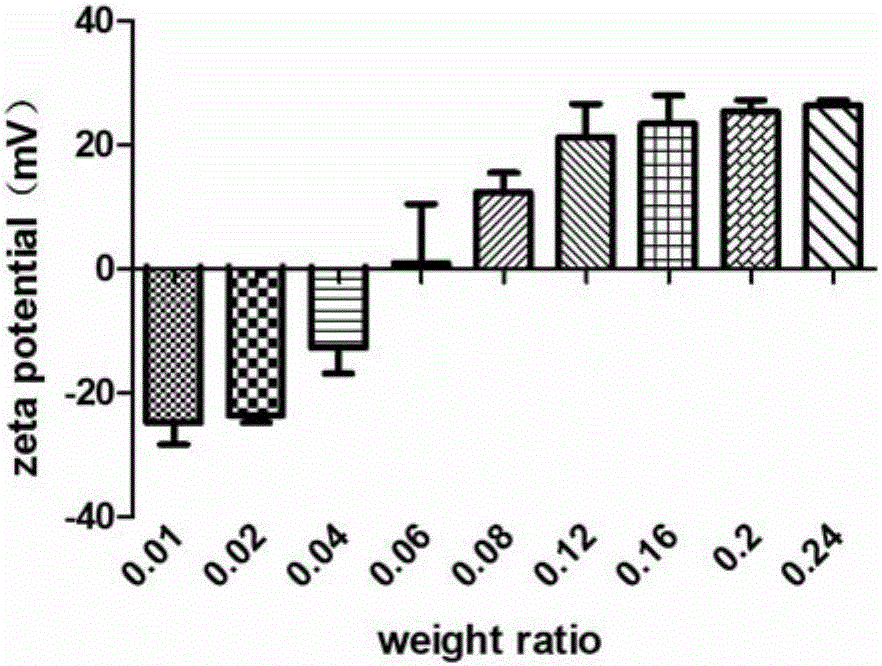

InactiveCN106038514ASmall particle sizeExpand the scope of manufacturingChemical/physical/physico-chemical microreactorsLaboratory glasswaresMicroreactorNanocarriers

The invention belongs to the field of researches of microfluid and microreactor technologies in pharmaceutical preparations and particularly relates to a microfluid preparation method for tumor therapeutic vaccine nanocarriers. According to the microfluid preparation method, Tesla structural chips are adopted for preparation of electronegative protein carrying nanoparticles for the first time. The microfluid preparation method is simple in process, prepared composite particles are small in particle size, uniform in dispersion and high in repeatability, a mass ratio range of nanoparticles formed by combination of polyethyleneimine and derivatives thereof and antigen proteins can be widened, and accordingly application prospect of the nanoparticles to tumor vaccines is broadened.

Owner:SHANGHAI JIAO TONG UNIV +1

Micro-lens forming method by means of wet method side guide

InactiveCN1790063ANo pollutionAdjust depthPhotomechanical exposure apparatusPhotosensitive material processingSemiconductor materialsMicrometer scale

The invention discloses a forming method of wet lateral guiding lenticular, which is characterized by the following: depositing the sacrificial layer on the base material surface; coating the photoresist on the sacrificial layer surface; affirming the base plate surface position of lenticular; adapting photoetching process to remove the photoresist except lenticular caliber scale if the lenticular displays compact distribution; regarding several transverse micrometer scales of the lowest lenticular as opening; removing the corrosion-proof agent in the opening scale; adapting the auxiliary photoresist to remove the exposed sacrificial layer; blending the main etching liquid and auxiliary etching liquid in proportion; placing the removed structure to be corroded in the mixing liquid; cleaning the element; drying the element.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

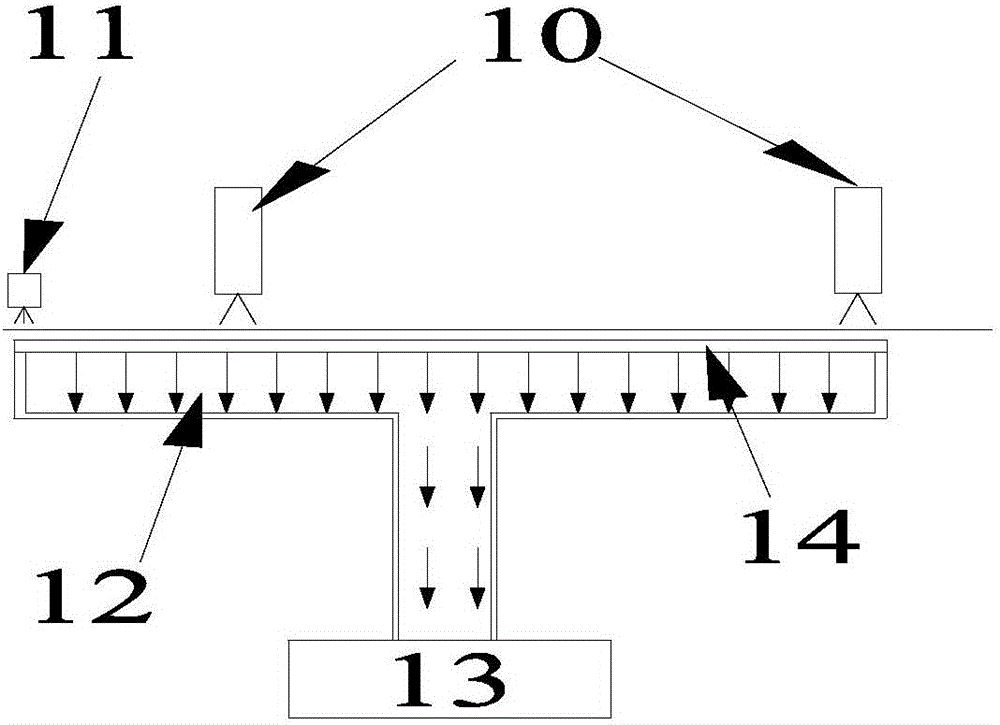

Multi-position laser die pressing process and die cutting hot stamping machine

InactiveCN106079873AReduce the number of paper passesControl scrap rateBronze printingRotary pressesHot stampingEngineering

Disclosed is a multi-position laser die pressing process. The multi-position laser die pressing process comprises the steps that (1) a sheet obtained after indentation or hot stamping through a first die pressing unit enters a laser unit after passing an aluminum foil control unit; (2) the laser unit conducts die cutting on a product so as to reduce the platemaking cost and save time of halt plate replacement; and (3) the die-cut product enters a second die pressing unit for a indentation or hot stamping process. A die cutting hot stamping machine comprises the first die pressing unit, the aluminum foil control unit and the second die pressing unit, is characterized in that the laser unit is installed behind the aluminum foil control unit, and has the advantages that die cutting of the laser unit is cutting through a laser, a die cutting tool does not need to be made, and thus the platemaking cost is reduced effectively. During laser die cutting, automatic transformation of the cutting shape, position and size can be achieved in the nonstop state according to the needs of the machined sheet, and thus the production efficiency can be improved effectively.

Owner:MASTERWORK GROUP CO LTD

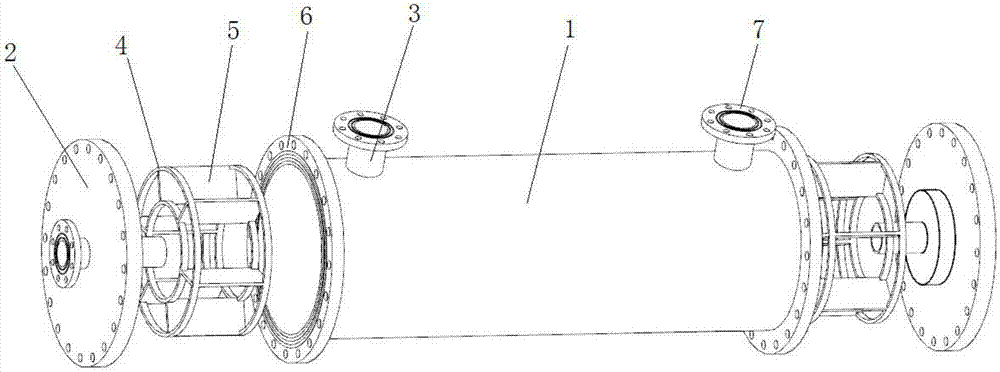

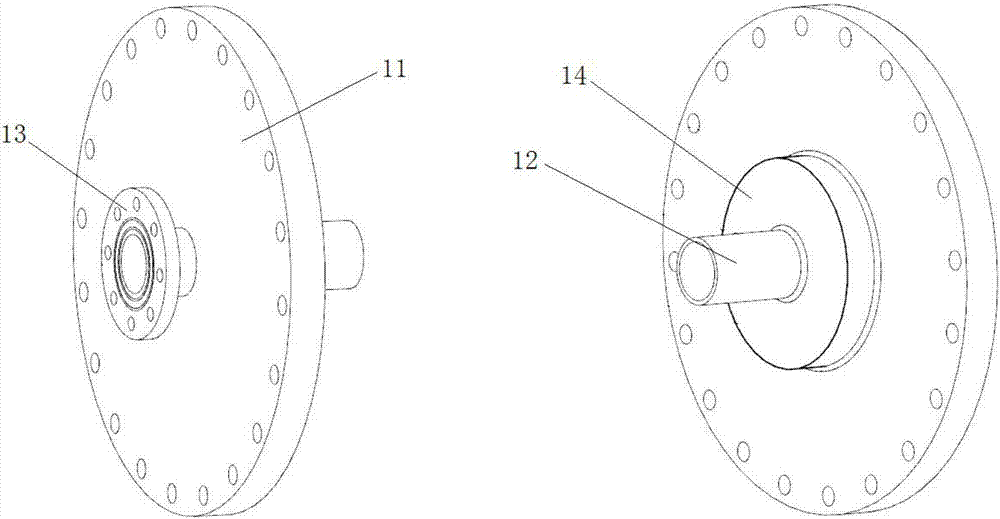

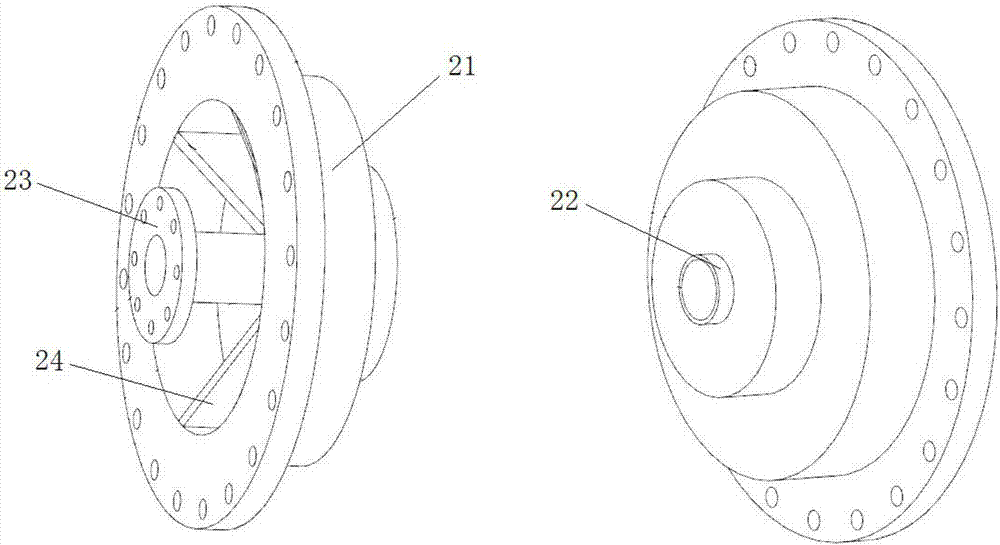

Novel high pressure resistant, anti-corrosion and high temperature resistant membrane shell and preparation method thereof

PendingCN107986398AExpand the scope of manufacturingWide range of useSeawater treatmentReverse osmosisCorrosion resistantUnit volume

The invention provides a novel high pressure resistant, anti-corrosion and high temperature resistant membrane shell, which comprises a shell, wherein two ends of the shell are connected with end covers; two axial ends of the outer side surface of the shell are respectively provided with a branch pipe; a membrane element bracket is arranged on a position corresponding to each branch pipe in the shell; each membrane element bracket comprises two circular ring groups which are fixedly connected through a rib plate; each circular ring group comprises at least two concentric circular rings. The invention simultaneously provides a preparation method for the novel high pressure resistant, anti-corrosion and high temperature resistant membrane shell and the preparation method thereof have the advantages of simple structure, easiness in processing, low manufacture cost, large manufacture size range and high compatibility. When the diameter is greater than 8 inches (203.2mm), the aspects including the pressure resistance degree, the flow condition, the mass transfer efficiency and the cost of the novel high pressure resistant, anti-corrosion and high temperature resistant membrane shell areall superior to that of the mainstream 8-inch membrane shell in the traditional market, a space use ratio is improved, and a larger membrane area can be provided in unit volume so as to obtain higherwater yield in the unit volume.

Owner:XIAMEN JIANGTIAN MEMBRANE BIOTECH LTD

Method for making integral product by using wood and bamboo as raw material

InactiveCN104772809AExpand the scope of manufacturingIncrease widthWood working apparatusEngineeringUltimate tensile strength

The invention provides a method for making integral products by using wood and bamboo as raw materials. The method comprises the steps of 1) forming meshes in wood and bamboo materials; 2) enabling all surfaces of the wood and bamboo materials with the meshes in each direction to be mutually supported and stressed to form an integral framework through a perforation method, an all-round intersection method or a weaving method; 3) uniformly wrapping the framework through the meshes by using resin, plastic or cement as inner and outer layer raw materials to form an integral body. The method for making integral products by using wood and bamboo as raw materials has the advantages that the width and thickness size accuracy of the made products is high, the overall strength is high and heavy loads can be born.

Owner:杨世豪

Hollow microspheres based on methacryloxy cage silsesquioxane and its preparation method and application

ActiveCN104226275BReduce usageReduce manufacturing costOther chemical processesAlkali metal oxides/hydroxidesMicrospherePolystyrene

The invention belongs to the technical field of organic-inorganic nano-hybrid materials, and discloses a hollow microsphere based on methacryloxy cage silsesquioxane, a preparation method and application thereof. The method comprises the following steps: preparing an emulsion with a Pickering effect stabilized by methacryloxy cage silsesquioxane, and drying; using a mixed solution of acetone and cyclohexane as an etchant, and performing the above-mentioned emulsion after drying Soaking is performed to remove the polystyrene core to obtain the product. The product has good adsorption performance and can be used in the field of sewage treatment. The operation process of the invention is relatively simple, the experimental conditions are mild, the selected raw materials and reagents are relatively easy to obtain, and the reaction yield is high.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Manufacturing method of Sn contained non-oriented electrical steel and plate coil

ActiveCN101956127BExpand the scope of manufacturingHigh magnetic inductionMetal rolling arrangementsTunnel kilnCooling curve

The invention discloses a method for preparing a Sn-containing non-oriented electrical steel, including a continuous casting process, a heating process, a rolling process and a cooling process. In the continuous casting process, the molten steel overheating is controlled in a liquidus line +15-30 DEG C. A crystallizer adopts a sine vibration curve with a vibration frequency of 260-300time / s and an amplitude of 6-7mm. A casting speed of the continuous casting is 3.0-4.5m / min. The cooling water distribution form after two cooling curve crystallizers is a sine curve. The cooling water volume is 5000L-7000L / min. Protective slag of the crystallizer is superlow carbon protective slag. The heating system adopts a tunnel kiln and heats at 1150+ / -20DEG C. The continuous rolling process comprises: a beginning rolling temperature of 1070+ / -30 DEG C, a final rolling temperature of 800-900 DEG C, and a reeling temperature of 650-750 DEG C. A depressing system includes that: a relative depressing rate of former two racks is 40-65%, the relative depressing rate of the third to the fifth racks is 30-45%, the relative depressing rate of the sixth rack is 15-35%, and the relative depressing rate of the seventh rack is less than or equal to 20%. The cooling process adopts cooling between the racks and secondary descaling of F1-F2 and the F2-F3, and laminar flow cooling for the back segment cooling.

Owner:MAANSHAN IRON & STEEL CO LTD

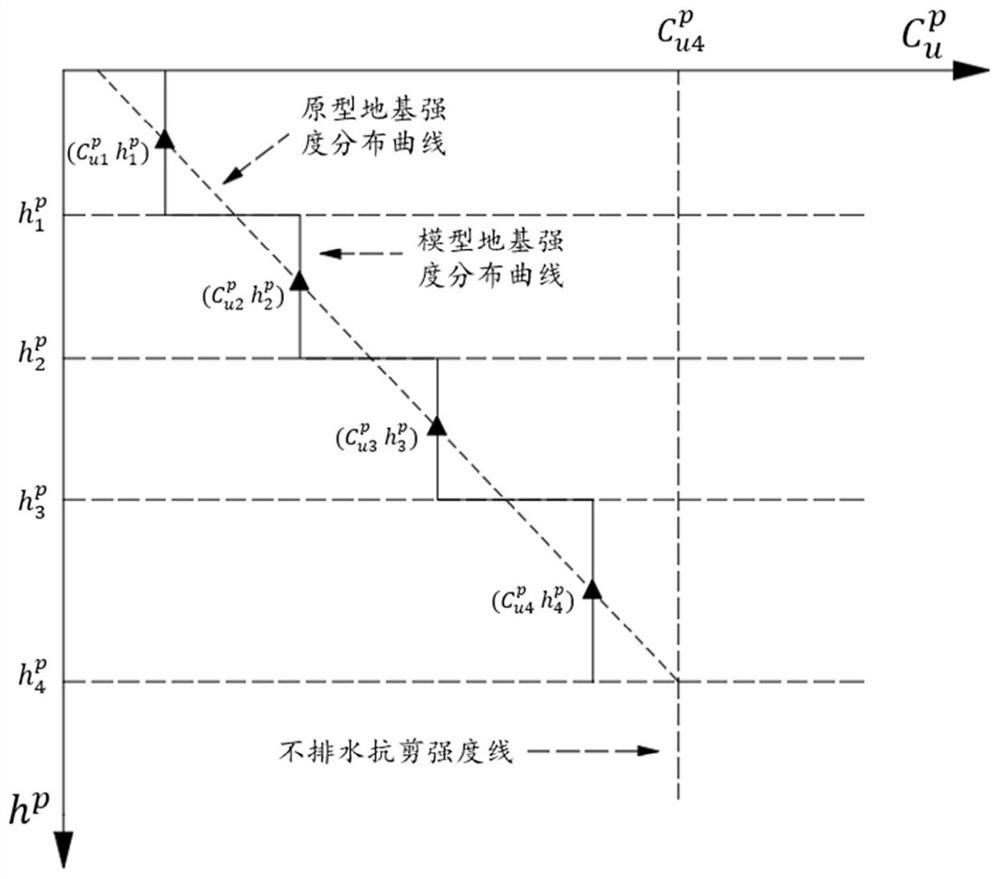

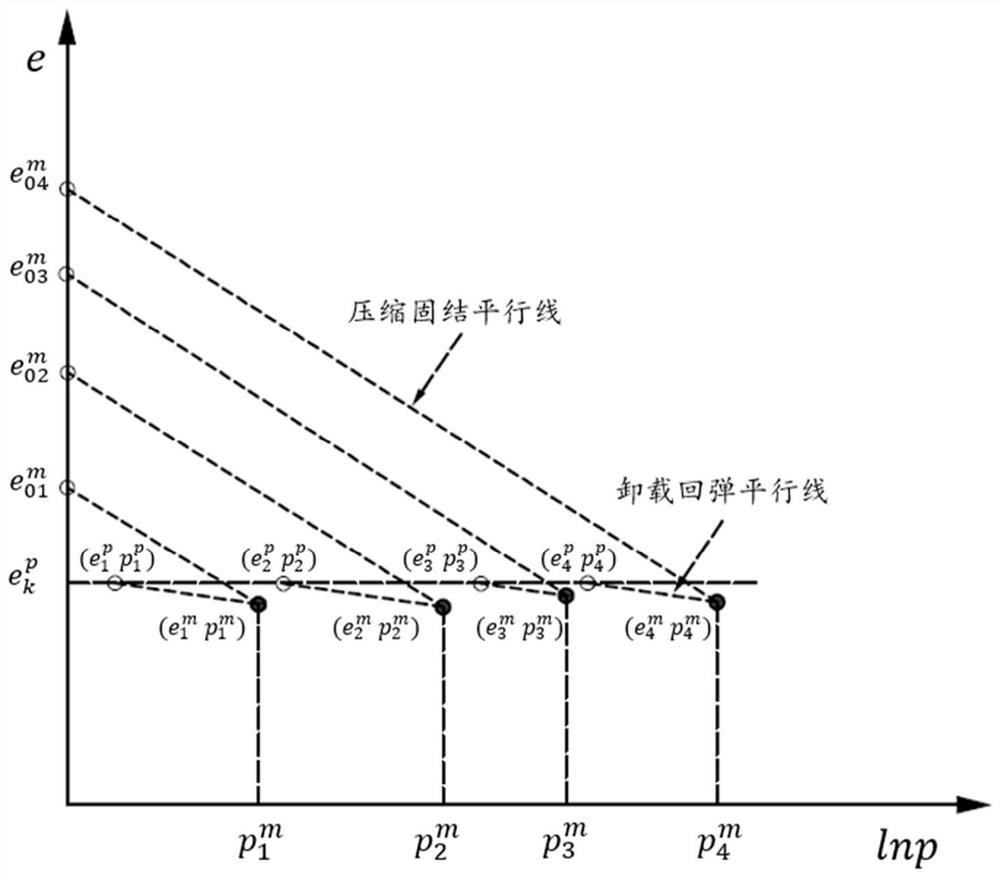

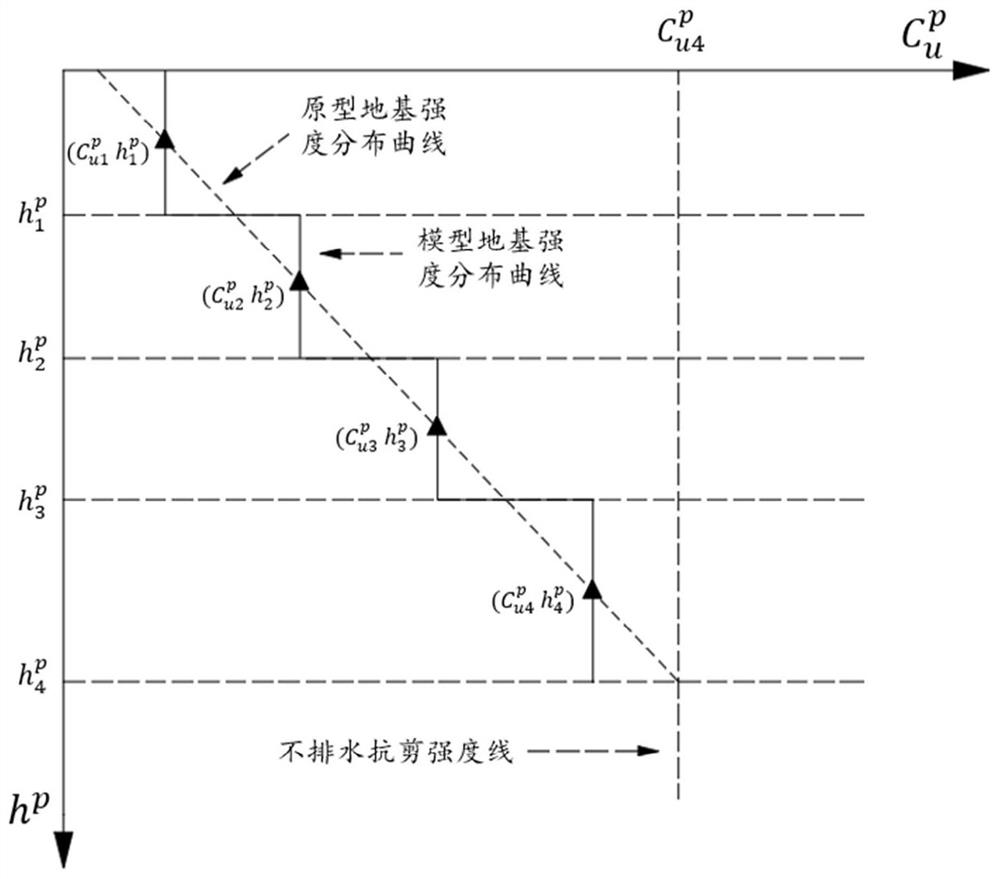

A preparation method of clay model foundation for restoring prototype state and strength

ActiveCN112964533BReduce energy consumptionReduce complexityPreparing sample for investigationMaterial strength using steady shearing forcesVoid ratioArchitectural engineering

The invention discloses a method for preparing a clay model foundation for restoring prototype state and strength. Including determining the total thickness and layering of the prototype foundation and the model foundation; obtaining the undrained shear strength of each layer of the prototype foundation; calculating and obtaining the state parameters of the middle part of each layer of the prototype foundation and the average effective value of each layer of the model foundation Consolidation compressive stress; determine the indoor compression consolidation line of the prototype foundation soil and the slope of the unloading springback line, and obtain the initial void ratio of each layer of the model foundation soil through inversion; and prepare the model foundation layers. On the premise of restoring the state and strength of the prototype foundation, the present invention improves the economy and ease of operation of model foundation preparation, expands the range of model foundation preparation, overcomes the problem of sensor misalignment that may occur in the centrifugal model preparation process, and improves the model performance. The economy of preparation and the flexibility of sensor arrangement ensure the accuracy of centrifugal model tests.

Owner:ZHEJIANG UNIV

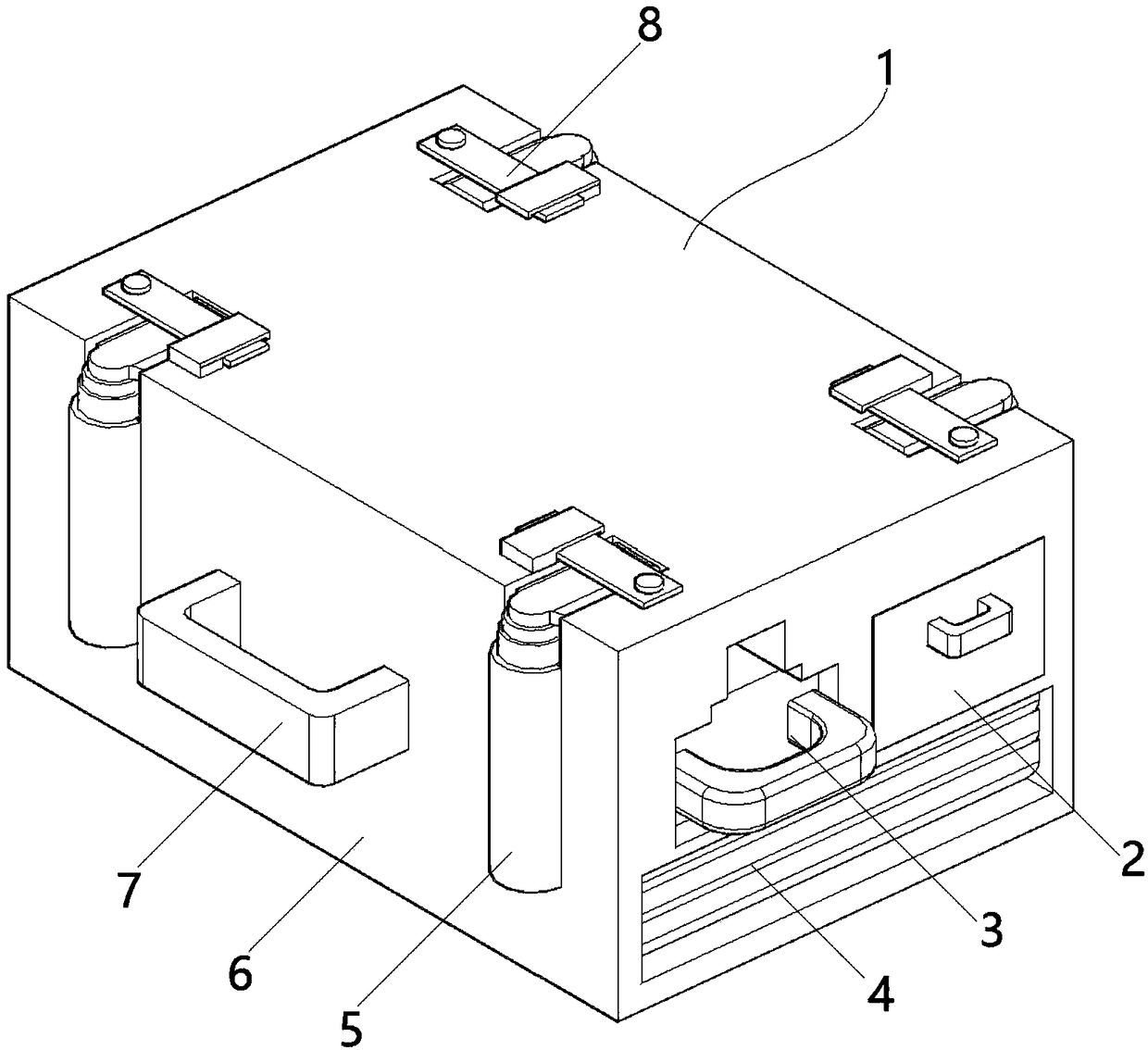

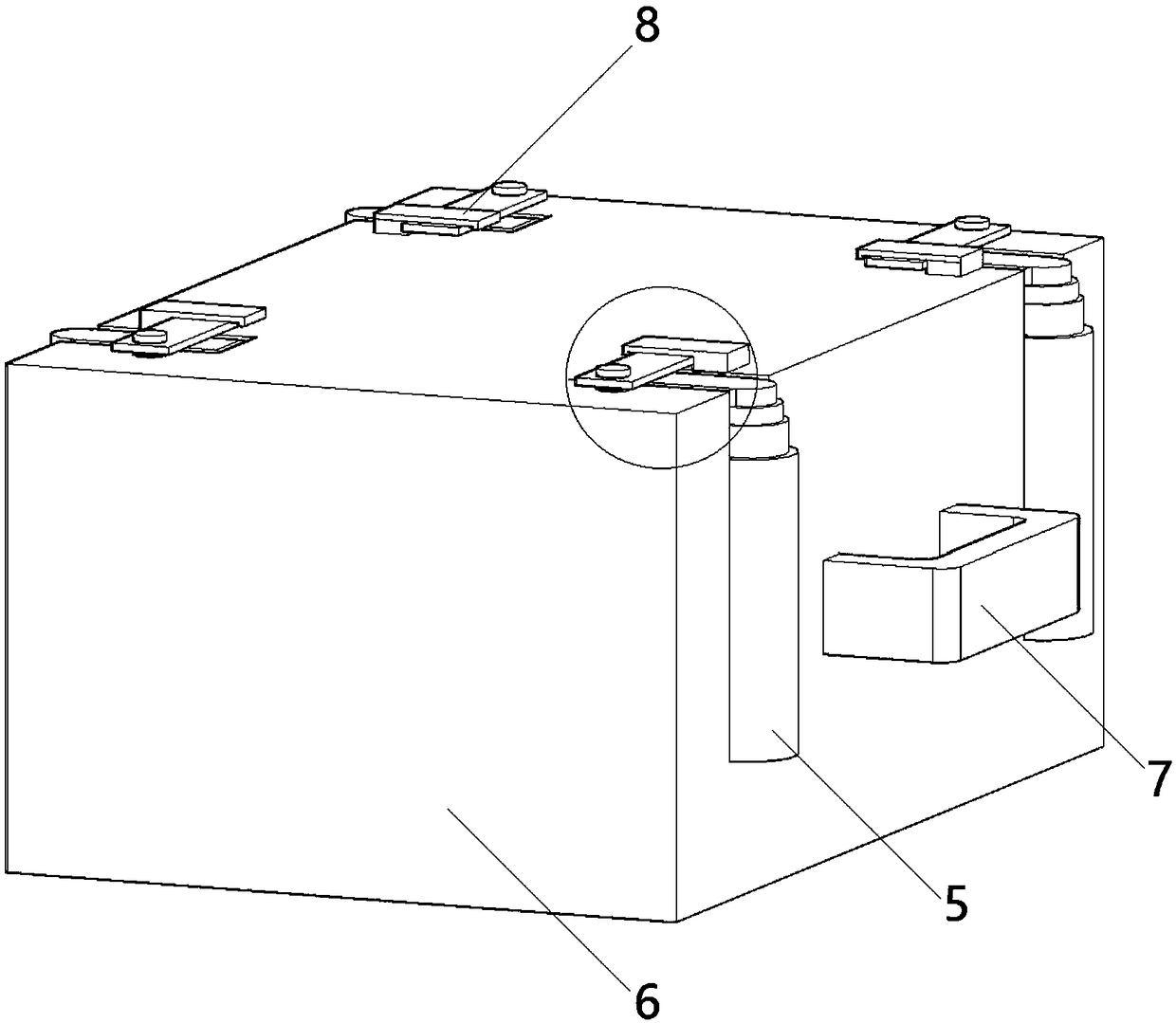

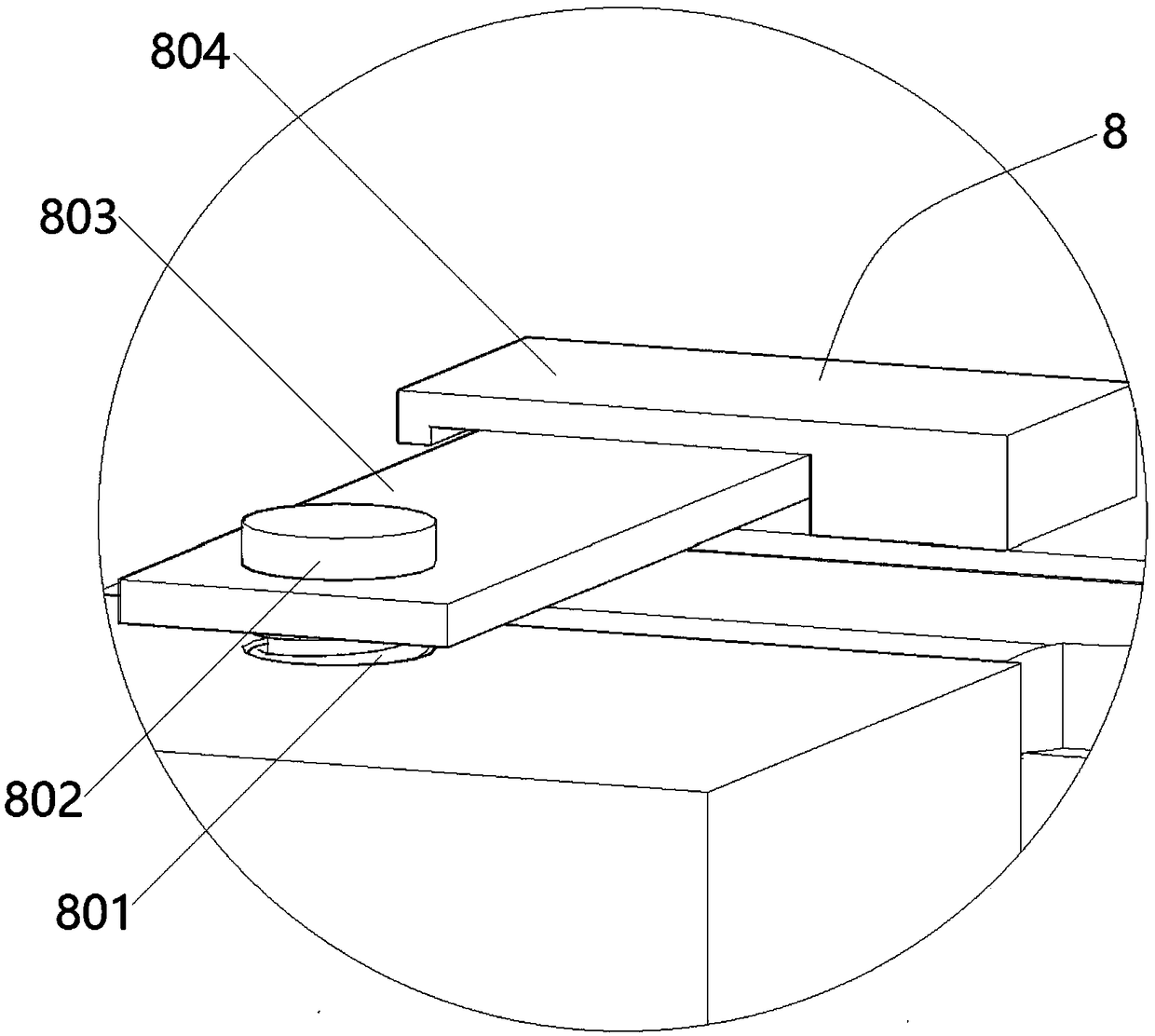

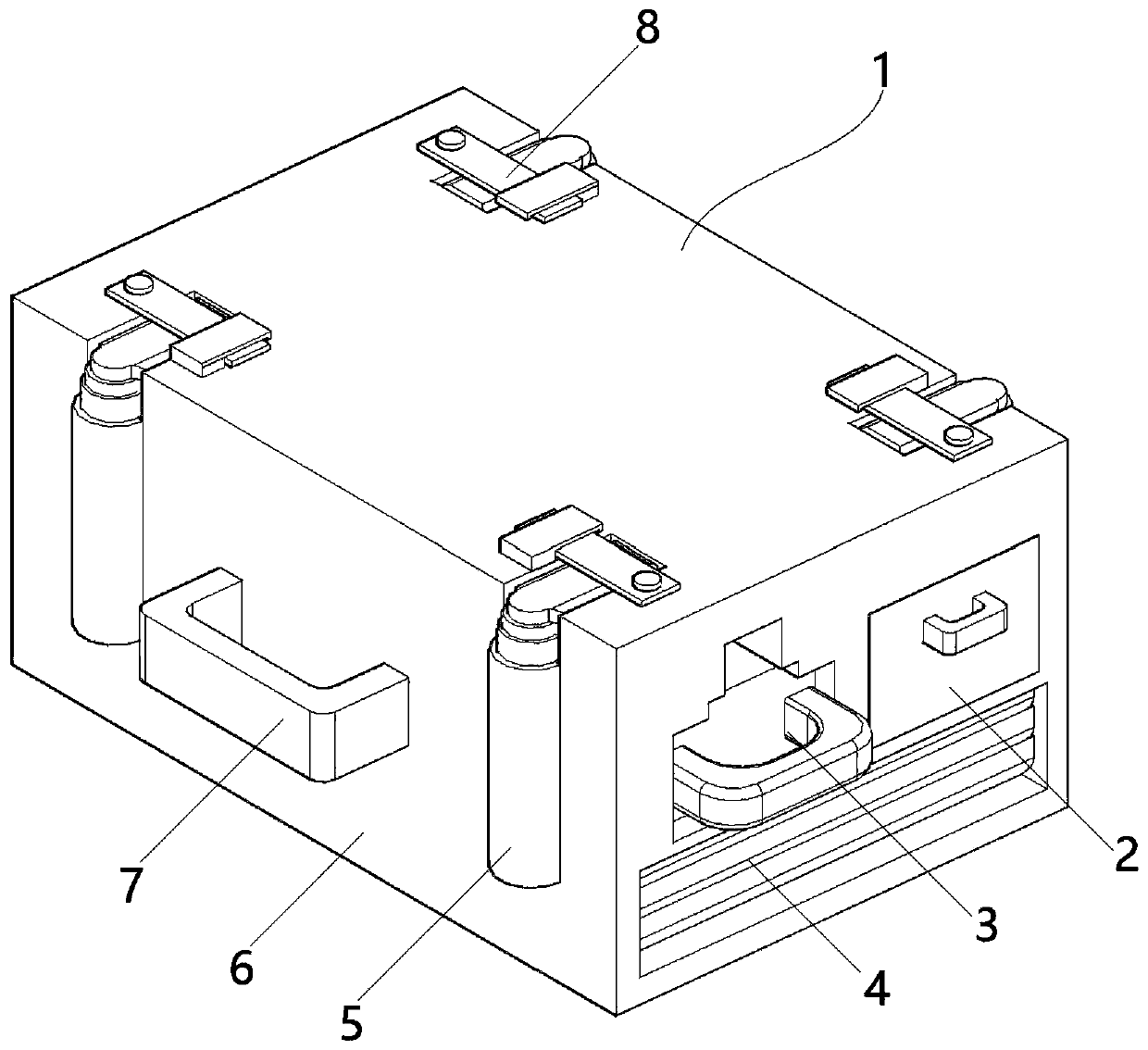

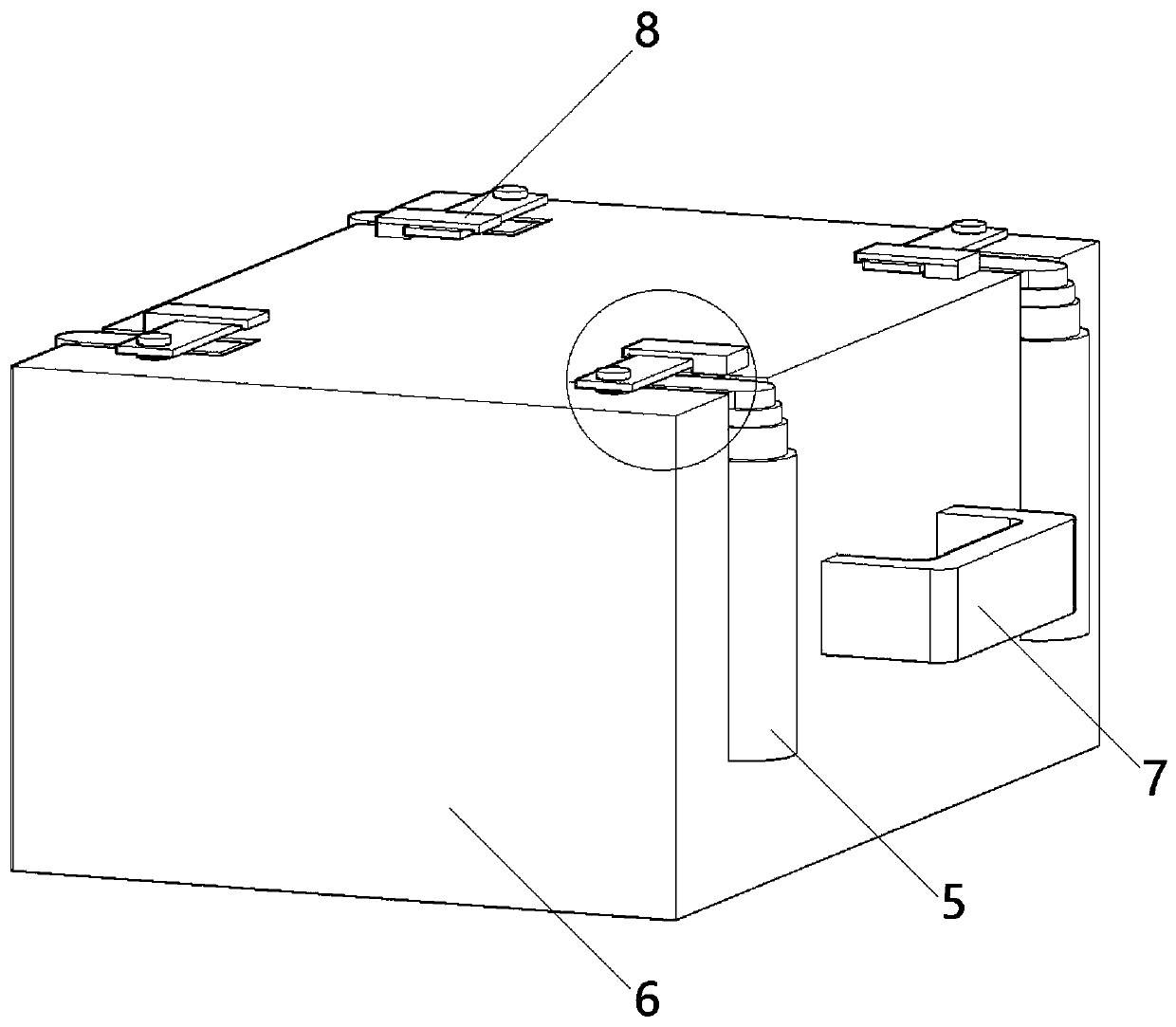

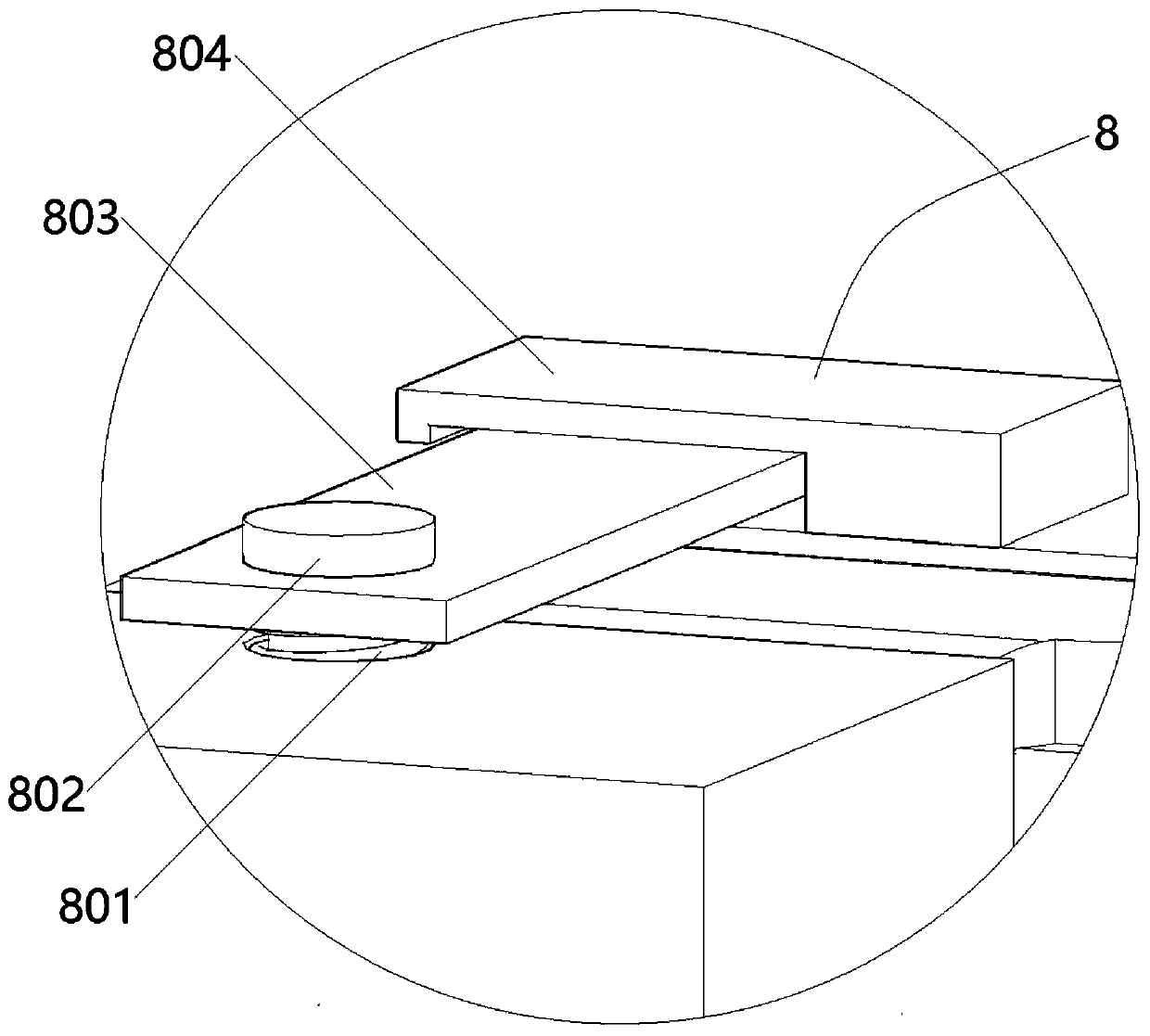

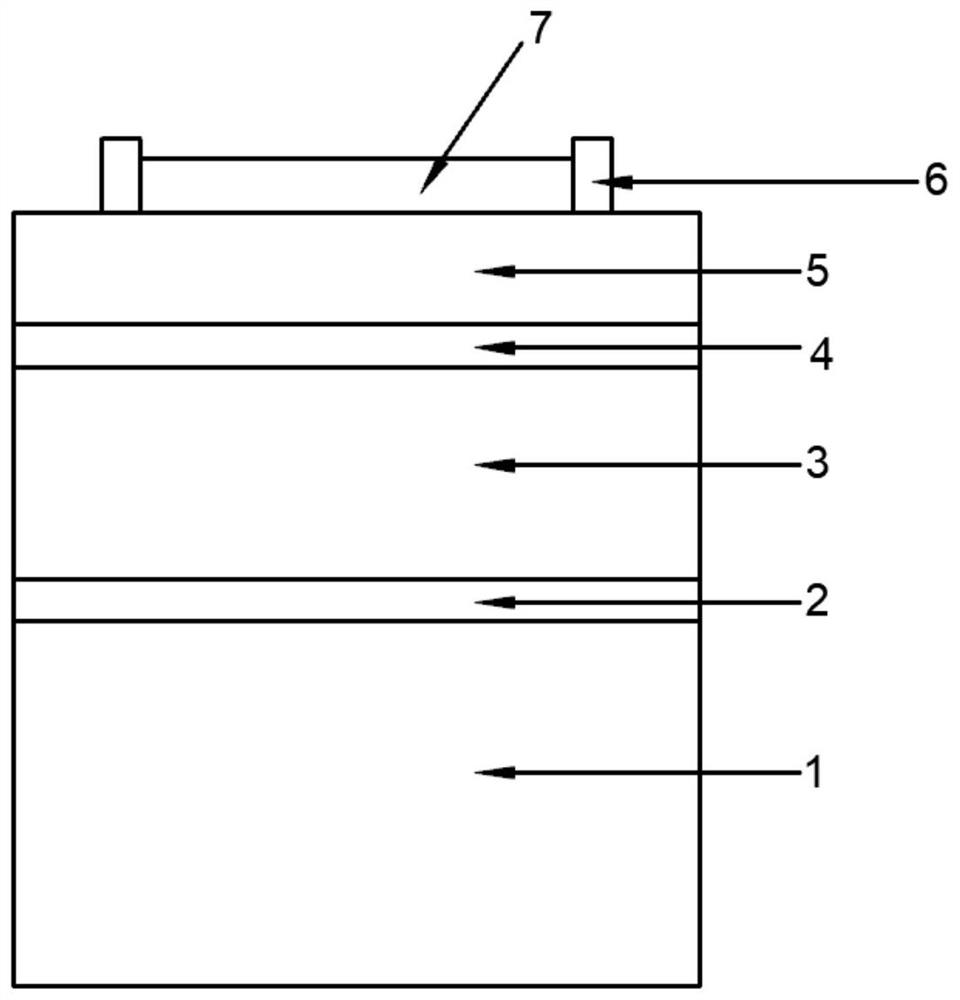

A biscuit printing mold that is easy to carry and store

ActiveCN108142473BPrevent poppingEasy to operateDough embossing machinesStructural engineeringMechanical engineering

Owner:安徽品滋味食品股份有限公司

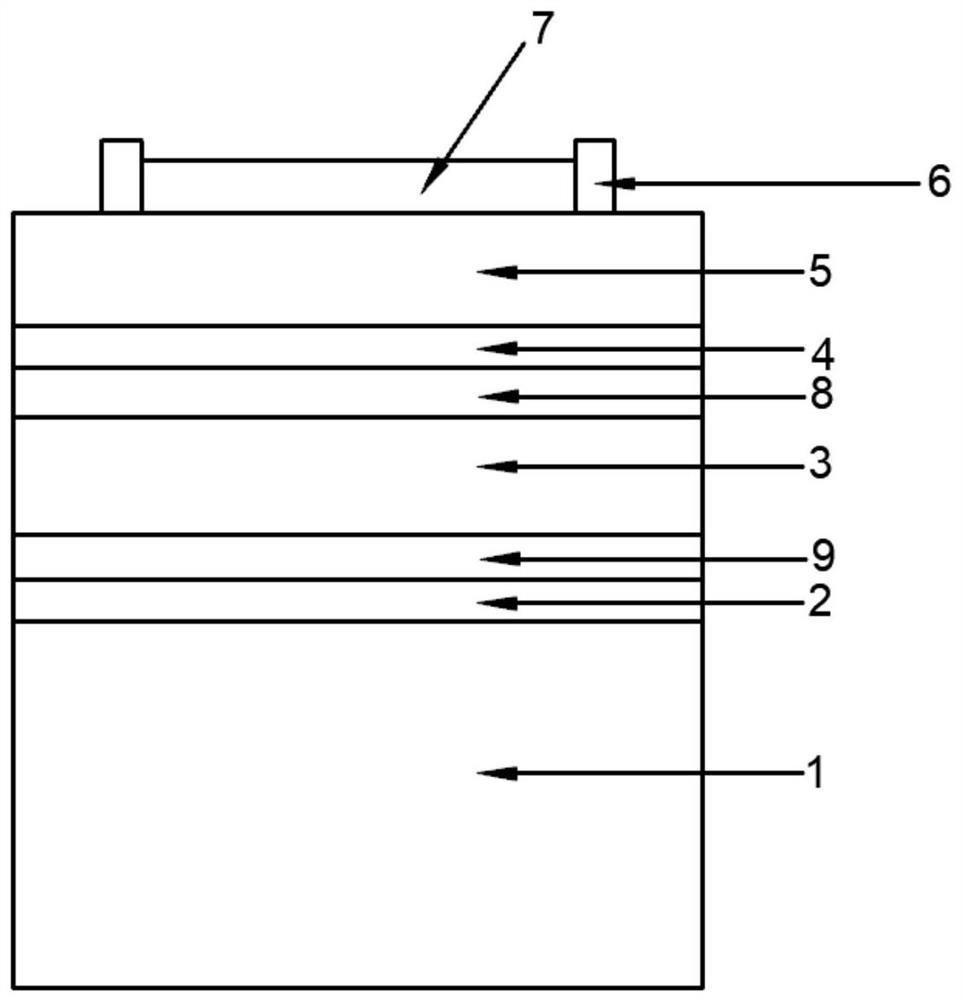

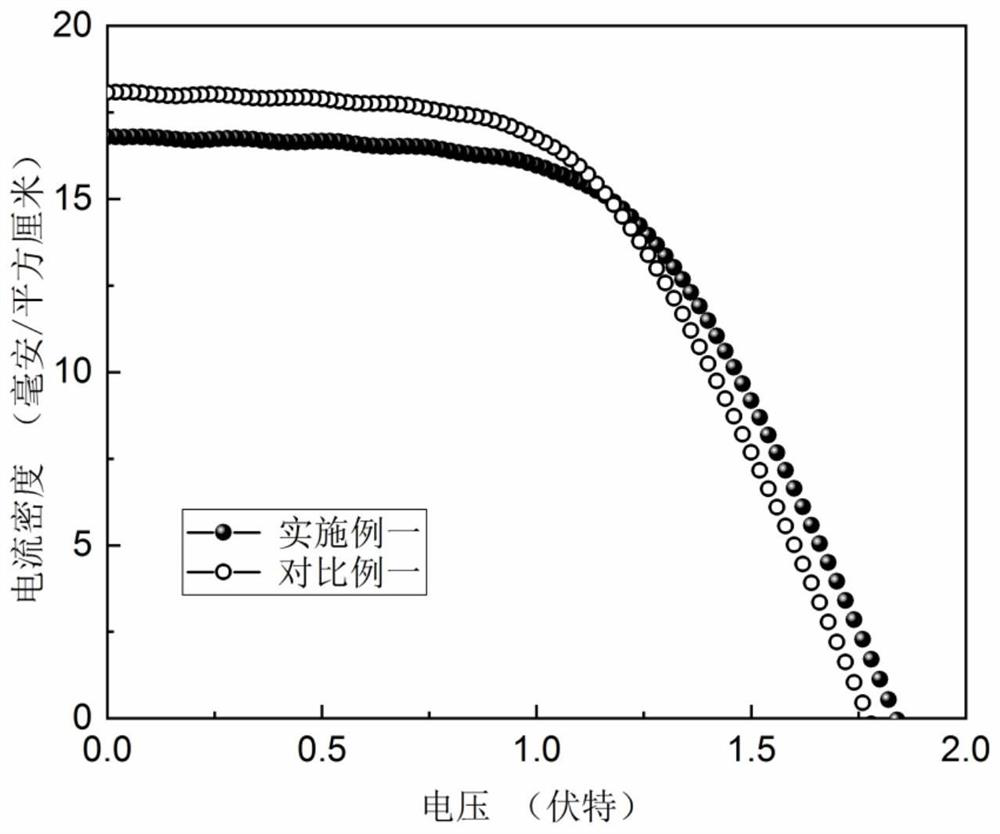

Laminated solar cell and preparation method thereof

PendingCN112952002ASimple structureReduce manufacturing costFinal product manufactureSolid-state devicesElectron transporting layerHole transport layer

The invention provides a laminated solar cell and a preparation method thereof. The laminated solar cell comprises a crystalline silicon substrate, a perovskite layer, a buffer layer, a conductive layer, a metal electrode layer and an anti-reflection layer which are sequentially laminated and tightly attached to one another; and the surface of the metal electrode layer is provided with a metal electrode. According to the laminated solar cell provided by the invention, an electron transport layer and a hole transport layer are omitted, the structure of the cell is simplified; and the preparation process of partial functional layers is omitted, so that the overall manufacturing cost of the cell is further reduced.

Owner:TRINA SOLAR CO LTD

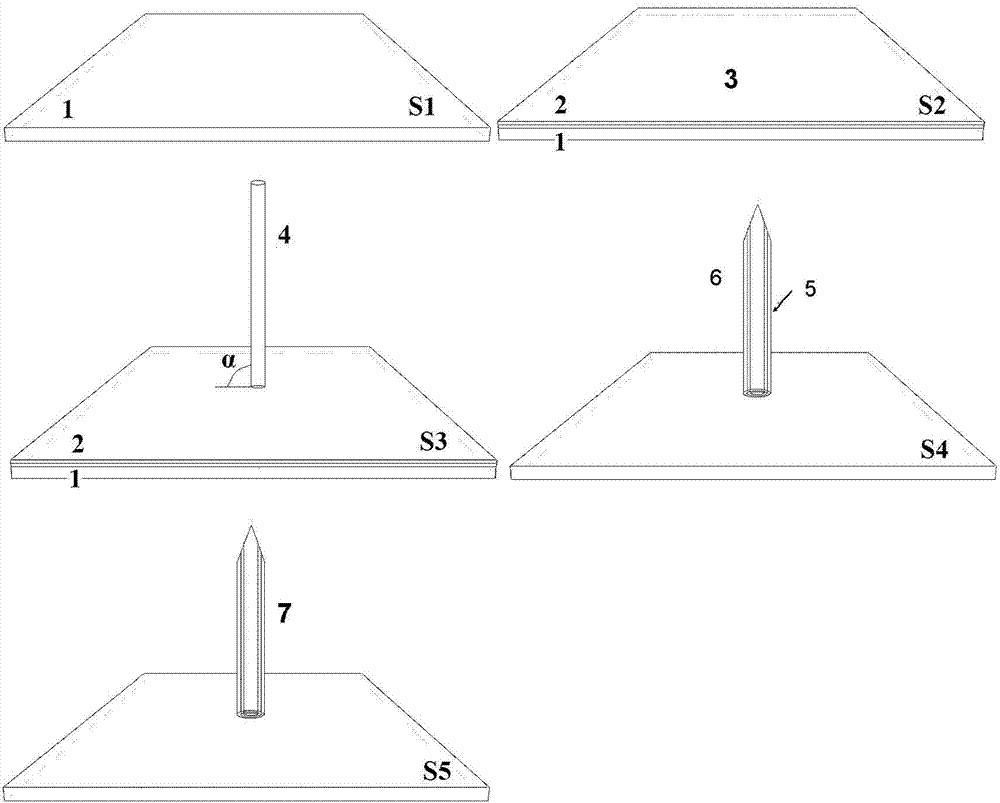

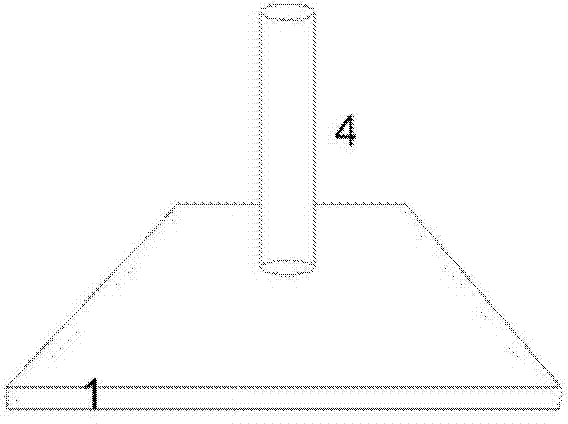

Method for preparing self-supporting multilayer micro nano structure

ActiveCN102976264BImprove performanceComplex graphicsMaterial nanotechnologyDecorative surface effectsMicro nanoNanostructure

The invention discloses a method for preparing a self-supporting multilayer micro nano structure. The method comprises the following steps of: selecting and cleaning a flat substrate; growing a multilayer film structure on the flat substrate to form a multilayer film substrate; preparing a self-supporting mother body nano structure on the multilayer film substrate to form a self-supporting mother body nano structure system with the multilayer film substrate; performing ionic beam dry-method etching on the self-supporting mother body nano structure system with the multilayer film substrate to obtain the self-supporting multilayer micro nano structure; and performing annealing treatment on the self-supporting multilayer micro nano structure to obtain a self-supporting multilayer micro nano structure finished product. According to the preparation method, based on a re-deposition phenomenon of the multilayer film substrate material in the dry-method etching process, the self-supporting nano structure on the multilayer film substrate is wrapped with a layer of substrate material, so that the self-supporting multilayer micro nano structure which is not positioned in the plane of the multilayer film substrate; and the method has the characteristics that the process is simple and is easy to implement; the cost is low; the flexibility is high; the construability is high; large-area processing is realized; and structure materials used for preparation are readily available.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

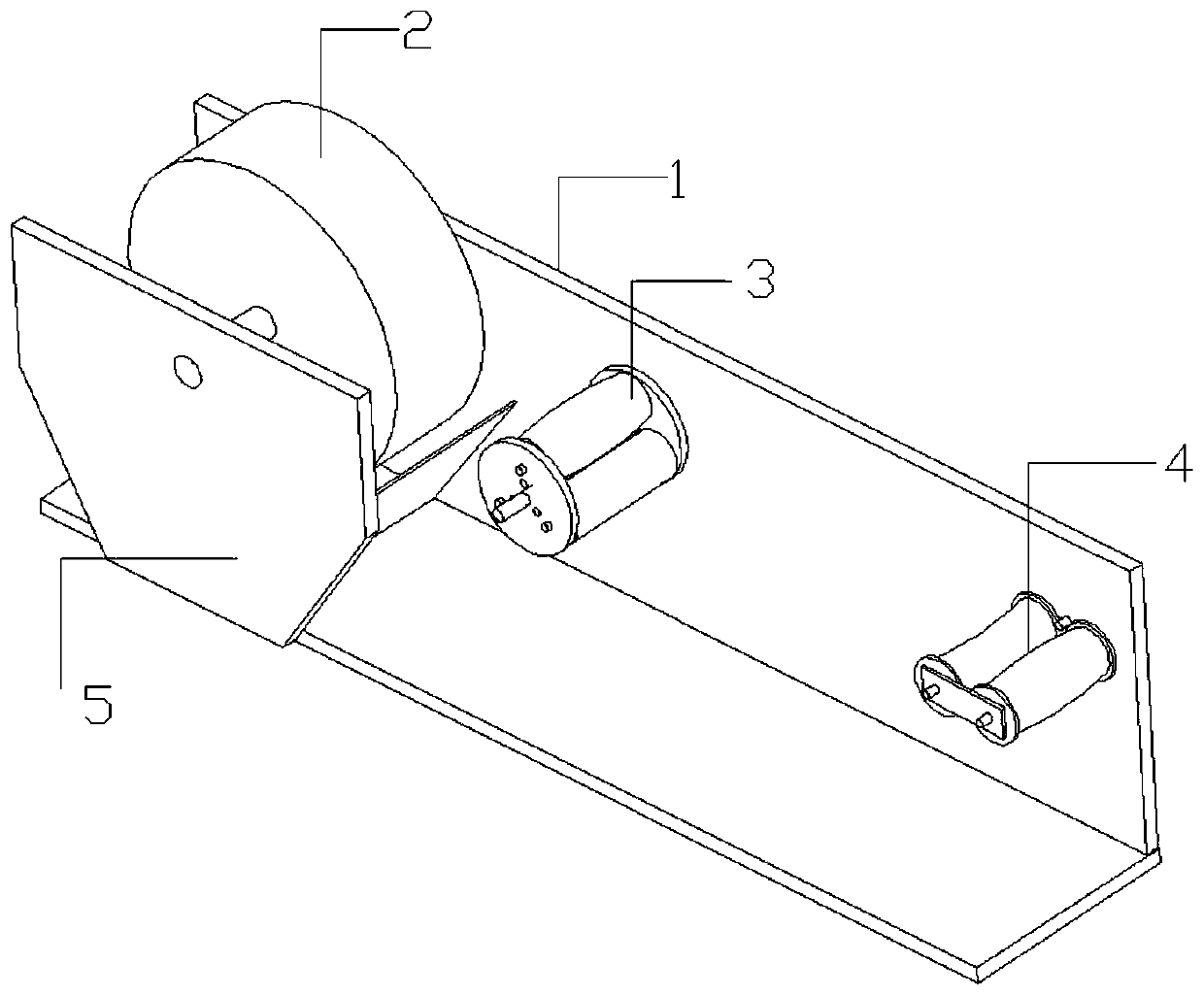

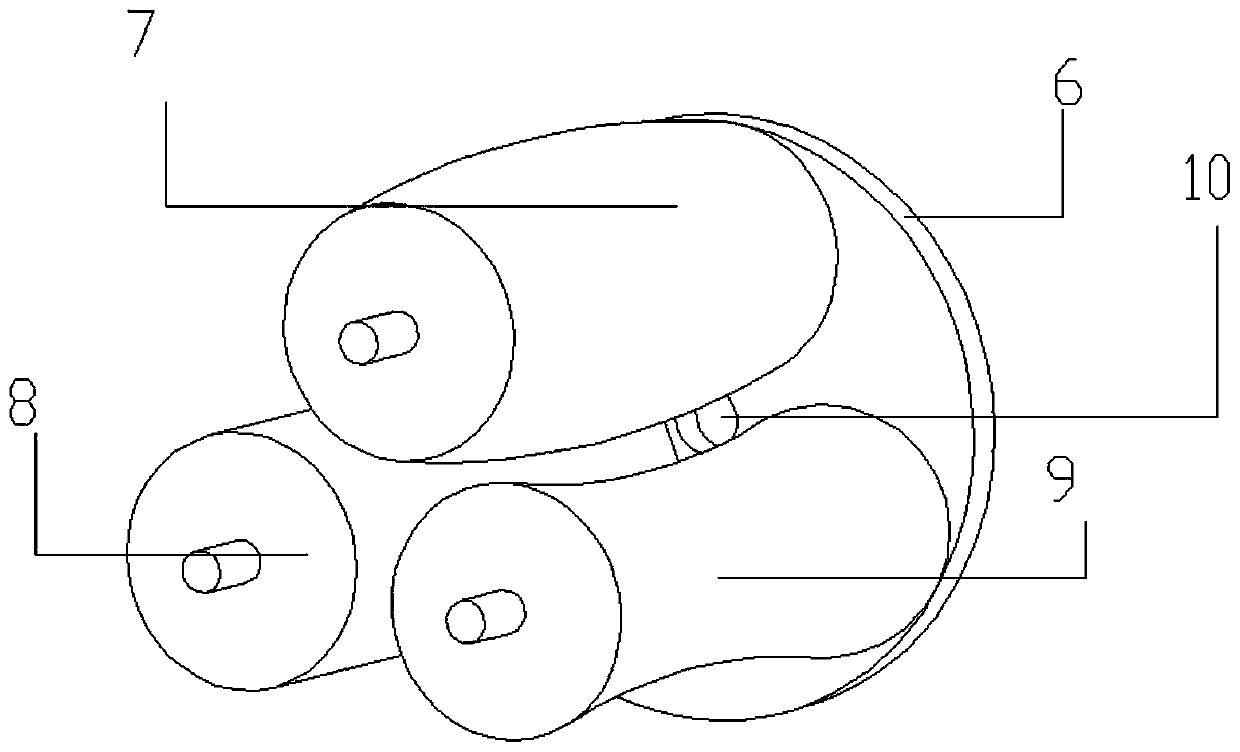

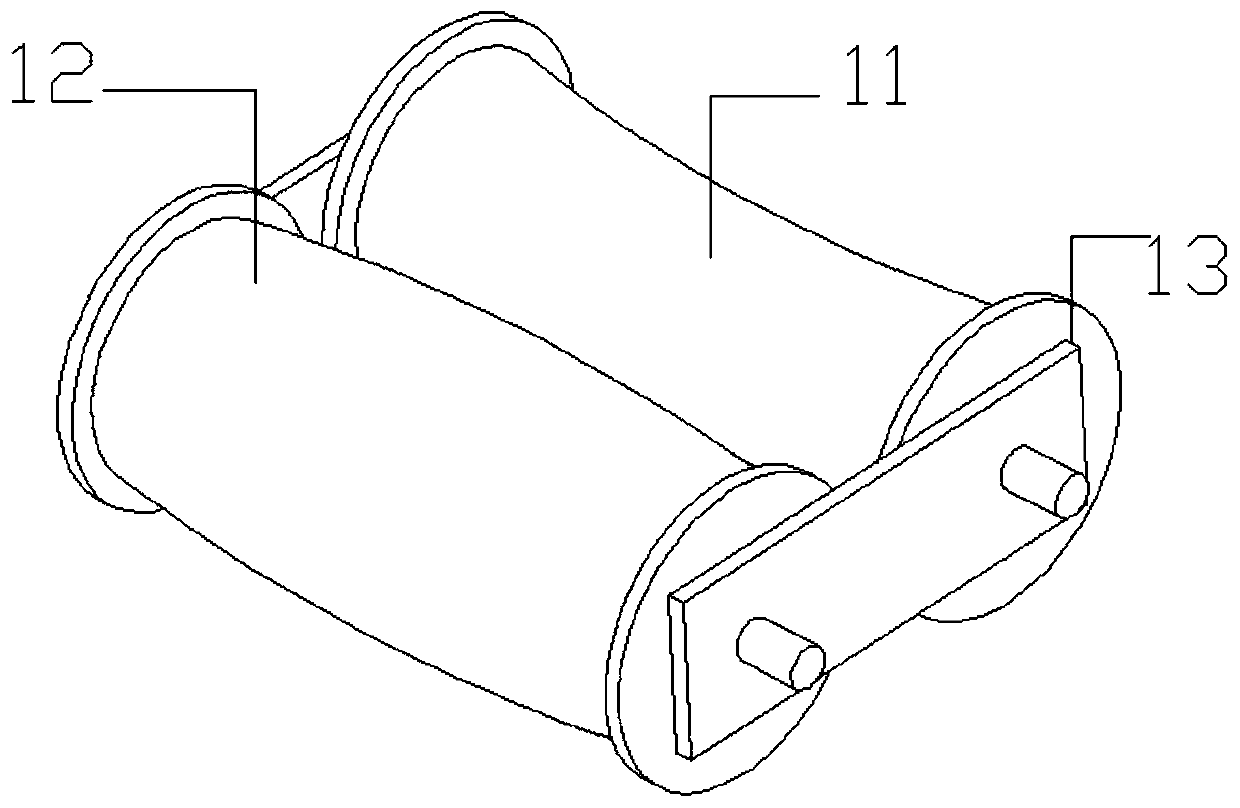

Wire nozzle structure and method of use for wet forming prepreg

The invention provides a spinning nozzle structure for a wet molding process of prepreg and a using method thereof. The spinning nozzle structure comprises a support module, an impregnation module, a yarn pre-spreading module and a yarn spreading module. The support module comprises a side plate and a base plate. The impregnation module, the yarn pre-spreading module and the yarn spreading module are sequentially arranged on the side plate in the horizontal direction of the side plate. According to the spinning nozzle structure, due to the design of yarn spreading rollers and pre-spreading rollers, the widths of yarn sheets can be controlled, yarn spreading of the widths of different yarn sheets is achieved under the condition of cross sectional shapes of the different yarn spreading rollers and yarn pre-spreading rollers, and the carbon fiber reinforced resin matrix composite prepreg of different thicknesses is prepared so as to meet the requirement for the thicknesses of the prepreg in the composite product design process. The spinning nozzle structure can be applied to yarn spreading phenomena of different fiber types and fiber bundle sizes, the spinning nozzle structure can adjust the widths of the yarn sheets by adjusting the cross sectional shapes of the yarn spreading rollers so as to achieve the purpose of preparing the carbon fiber prepreg of different thicknesses.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

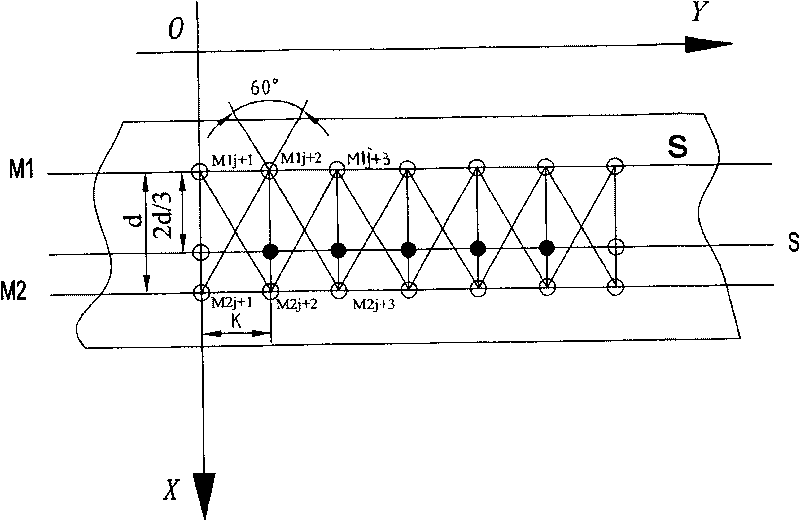

Method for measuring spatial rotating surface by taking coordinate of ball center of steel pin as target point

ActiveCN101738175BExpand the scope of manufacturingFast reverse analysisMeasurement devicesData fileMeasurement precision

The invention discloses a method for measuring spatial rotating surface by taking the coordinate of a ball center of a steel pin as a target point. The method comprises the following steps: building a coordinate system according to a spatial rotating surface; determining the measuring range of the spatial rotating surface, and selecting a plurality of polar radii Rs in the range; aiming at each polar radius R, building a plurality of exiguous triangles by adopting an identical graduation method, calculating the normal vector of the plane determined by the exiguous triangles; generating data files conforming to reading format of professional software; and analyzing the numeric area of the height d of the regular triangle through master ball experiment. By adopting the method in the invention, the spatial rotating surface can be measured and the method has high measuring precision.

Owner:HONGTA TOBACCO GRP

A kind of production method of electrical steel plate

The invention relates to a production method of electrical steel plates, comprising the following steps: (1) molten steel smelting in a converter; (2) RH refining; (3) continuous casting and rolling of thin slabs; (4) normalized pickling; (5) stand-alone (6) continuous annealing. Further, the following steps are also included: (7) coating; (8) finishing. The cold-rolled non-oriented steel strip produced by the method has excellent magnetic properties and low production cost, and can meet the needs of downstream motor users. And for the first time in China, a thin slab continuous casting and rolling production process for producing non-oriented electrical steel sheets without phase change chemical composition is fully utilized to produce non-oriented electrical steel sheets with lower iron loss and high magnetic permeability by thin slab continuous casting and rolling The advantages of steel provide technical support for the production of high-grade strip products in the thin slab continuous casting and rolling line, and further expand the manufacturing range of thin slab continuous casting and rolling process products.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

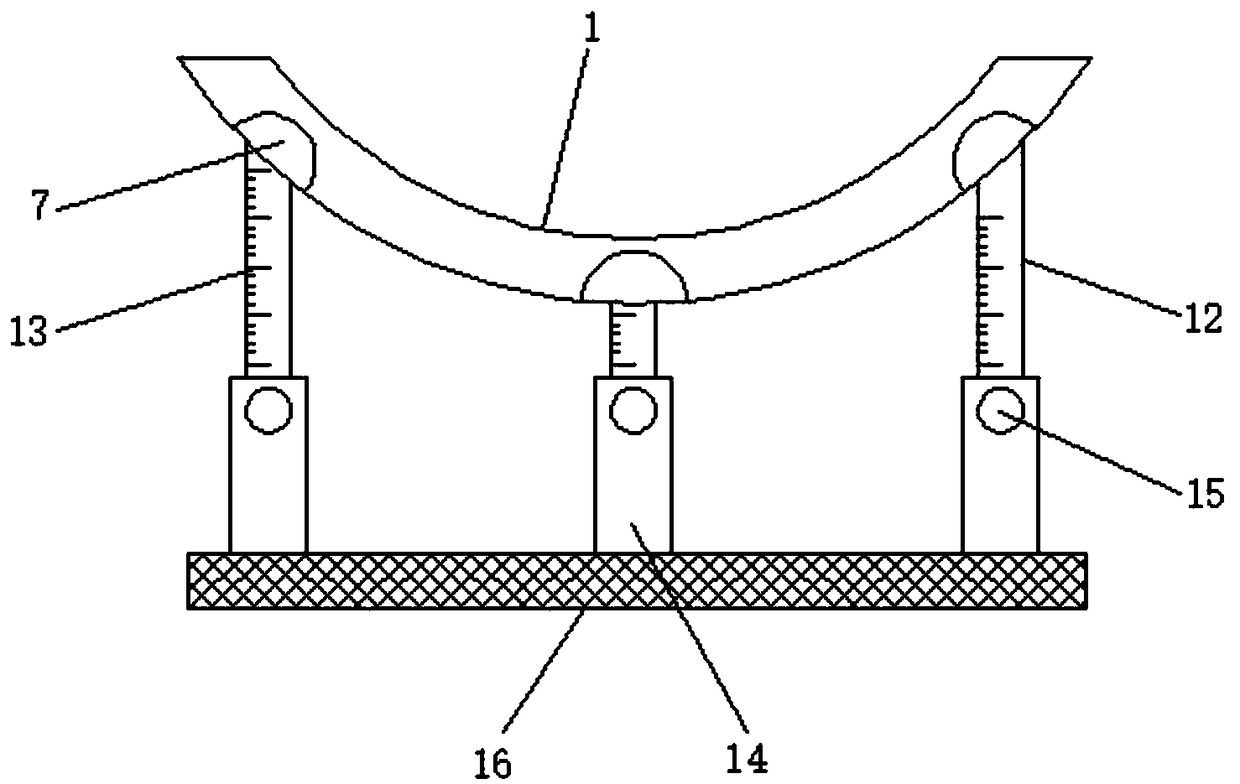

Process for manufacturing pre-components of curved cement products for buildings

InactiveCN109203189AExpand the scope of manufacturingReduce the number of template replacementsMouldsMould auxillary partsCementCivil engineering

The invention discloses a process for manufacturing pre-components of curved cement products for buildings. The process structurally comprises an elastic model plate, wherein the elastic model plate is provided with a cement product groove, embedding grooves, a curved cover plate, connecting plates and embedding plates. The cement product groove is located in the inner surface of the elastic modelplate, the embedding grooves are located inside the upper edge of the elastic mold plate, the curved cover plate is movably connected inside the cement product groove, the connecting plates are fixedly connected to the left and right sides of the curved cover plate, the embedding plates are fixedly connected to the lower surfaces of the connecting plates, and the bottom of the elastic model plateis provided with a fixing hole. The process increases the manufacturing range of the pre-components, reduces the number of times of replacing a mold plate when the pre-components of the different curved cement products are manufactured, improves the convenience in the procedure of manufacturing the pre-components of the curved cement products, enhances the smoothness of the molded pre-componentsof the curved cement products, and avoids the unevenness of the pre-components of the curved cement products.

Owner:浙江南洋水泥制品有限公司

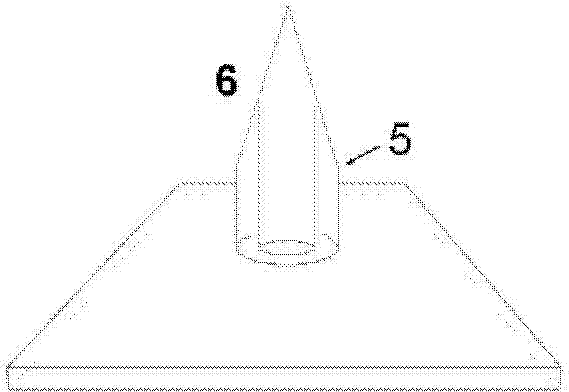

Processing method of micro-nano tubular structure

InactiveCN105836700AIncrease the areaEfficient preparationSpecific nanostructure formationGraphicsMicro nano

The invention provides a processing method of a micro-nano tubular structure, and belongs to the technical field of three-dimensional micro-nano structures and devices. The processing method comprises the following steps: preparing a transition layer on a base; preparing a nano film on the transition layer; separating the nano film from the base to obtain a separated nano film; transferring the separated nano film to a support substrate; performing processing of a micro-nano structure in a plane on the nano film to obtain a micro-nano graphic structure; and performing ion beam irradiation deformation on the micro-nano graphic structure to obtain a finished product of a micro-nano tubular structure. The processing method of the micro-nano tubular structure, provided by the invention, can be used for high-controllability, high-precision, large-area and high-efficiency preparation of a material with a micro-nano tubular structure

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

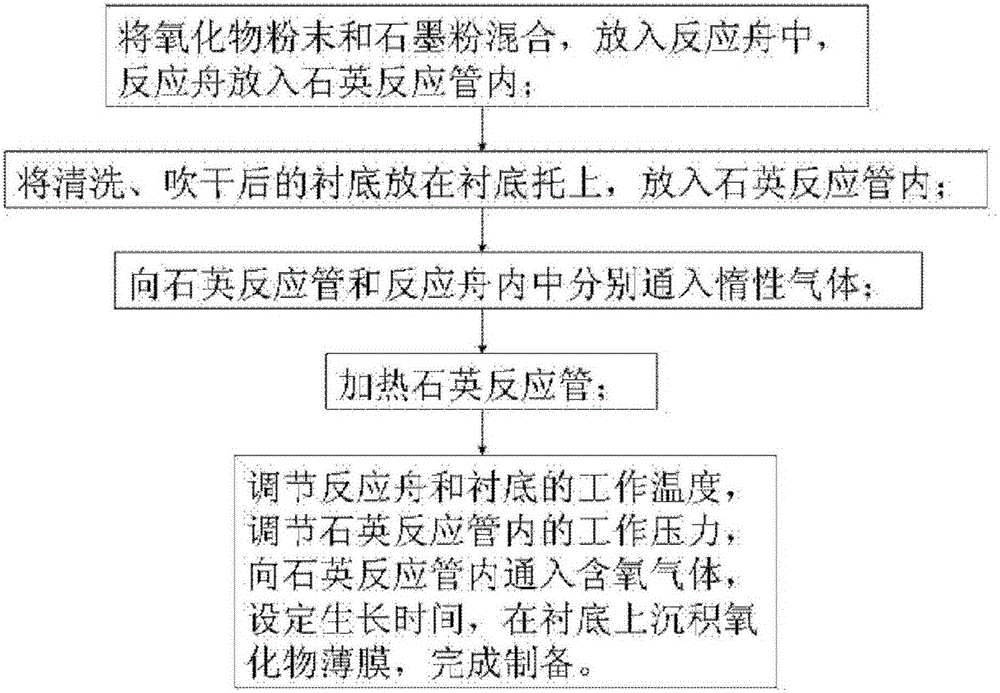

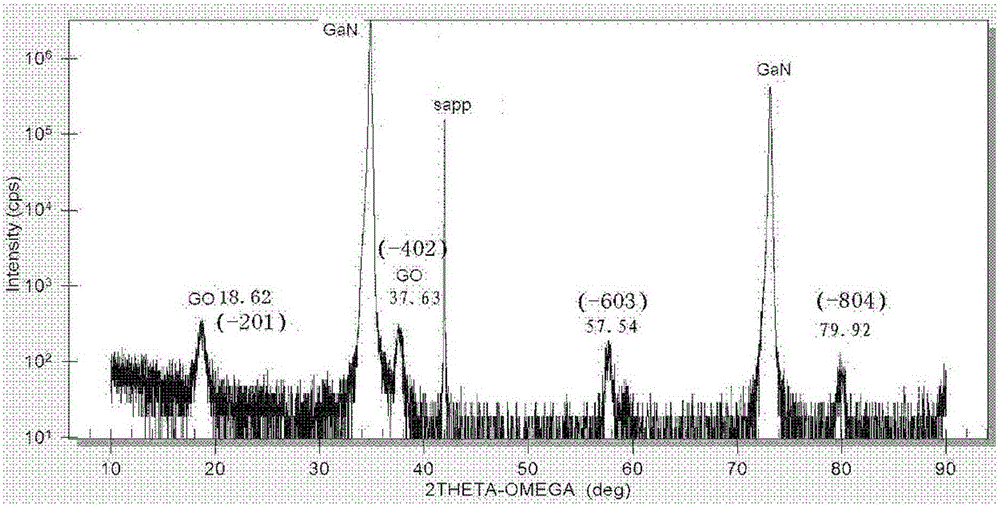

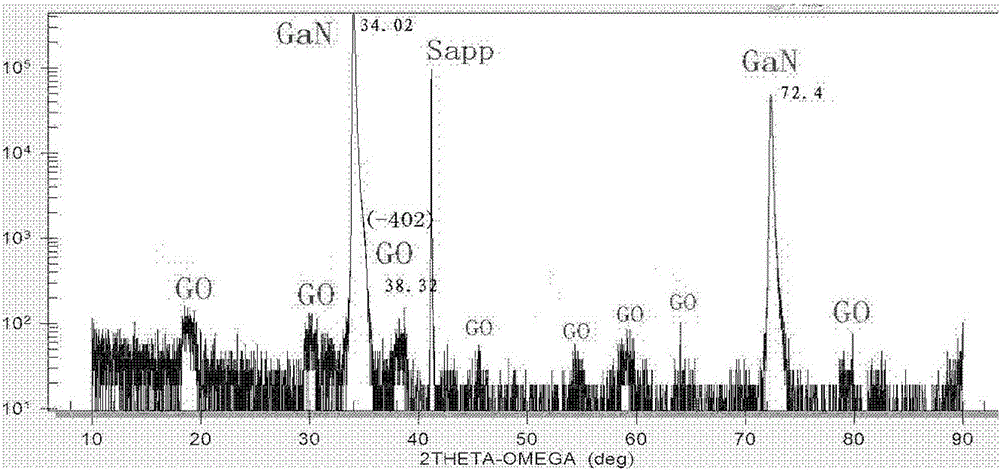

Preparation method of oxide film

The invention provides an oxide film preparation method. The oxide film preparation method comprises the following steps: step 1, mixing oxide powder and graphite powder, putting the mixture in a reaction boat, and putting the reaction boat in a quartz reaction tube; step 2, putting a cleaned and blow-dried substrate on a substrate support and putting the substrate support in the quartz reaction tube; step3, respectively feeding inert gas into the quartz reaction tube and the reaction kettle boat; step 4. heating the quartz reaction tube; step 5, adjusting the operating temperatures of the reaction boat and the substrate, and adjusting the operating pressure in the quartz reaction tube, feeding oxygen-containing gas into the quartz reaction tube, setting growth time, and depositing an oxide film on the substrate, thus completing oxide film preparation. The oxide film preparation method expands the preparation range of the oxide films and can be used for preparing metallic oxide films and non-metallic oxide films, particularly for certain oxide films difficult to prepare by using other methods at present.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

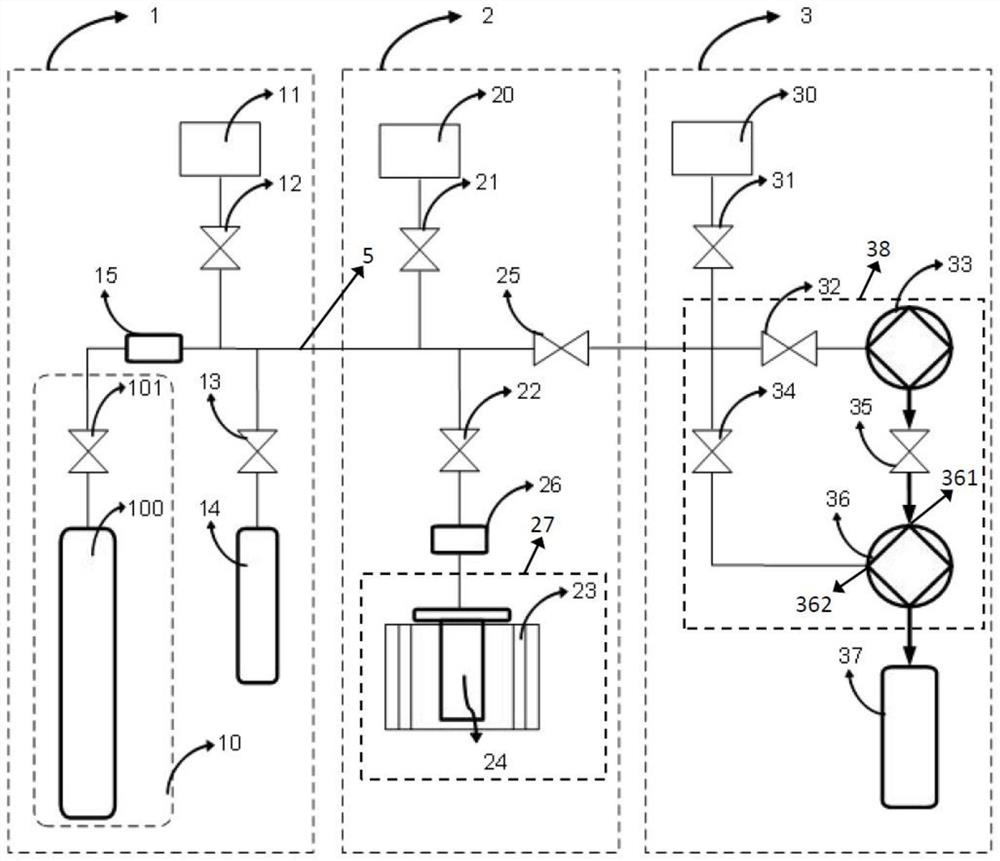

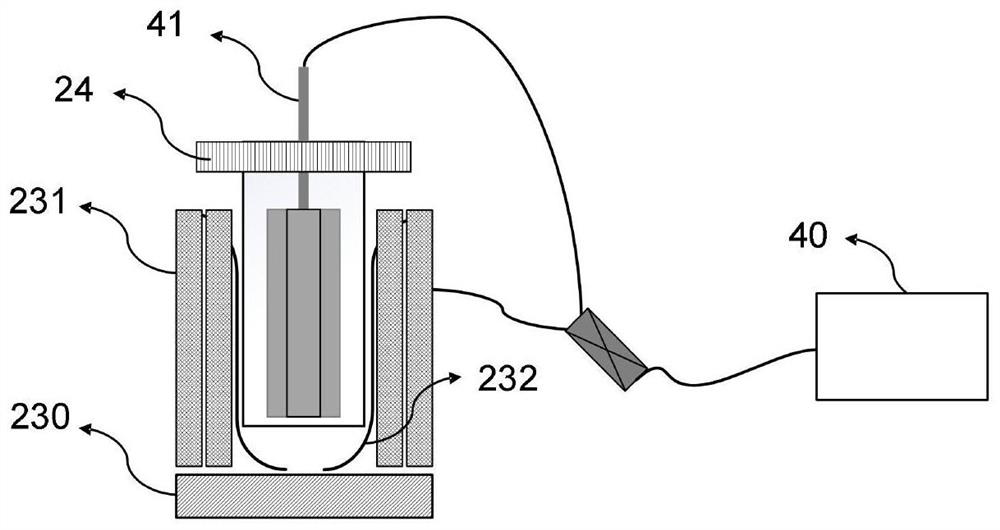

Preparation device for body material hydrogen-containing isotope sample

PendingCN114813271AExpand the scope of manufacturingPreparing sample for investigationExhaust fumesProcess engineering

The invention discloses a device for preparing a hydrogen-containing isotope sample of a body material. The device comprises a gas preparation area, a reaction area, a vacuum control area and a main pipe, the gas preparation area comprises a gas source capable of being controlled to be opened and closed and a purifier; the gas source is communicated with a gas inlet of the purifier; the reaction area comprises a filter and a body material reaction unit, and an air outlet of the filter is communicated with an air inlet of the body material reaction unit; the vacuum control area comprises a draw-off pump set capable of being controlled to be opened and closed and a waste gas treater, and an exhaust port of the draw-off pump set is communicated with an air inlet of the waste gas treater; a gas outlet of the purifier, a gas inlet of the filter and a gas inlet of the draw-off pump set are connected in parallel to the main pipe; barometers are mounted in the gas preparation area and the reaction area; the vacuum control area is provided with a vacuum gauge; the purity of the hydrogen isotope is improved by the purifier, so that the quality of a prepared body sample is improved; the installation of the filter also prevents the powder generated by the sample in the hydrogen filling process from damaging the draw-off pump set.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com