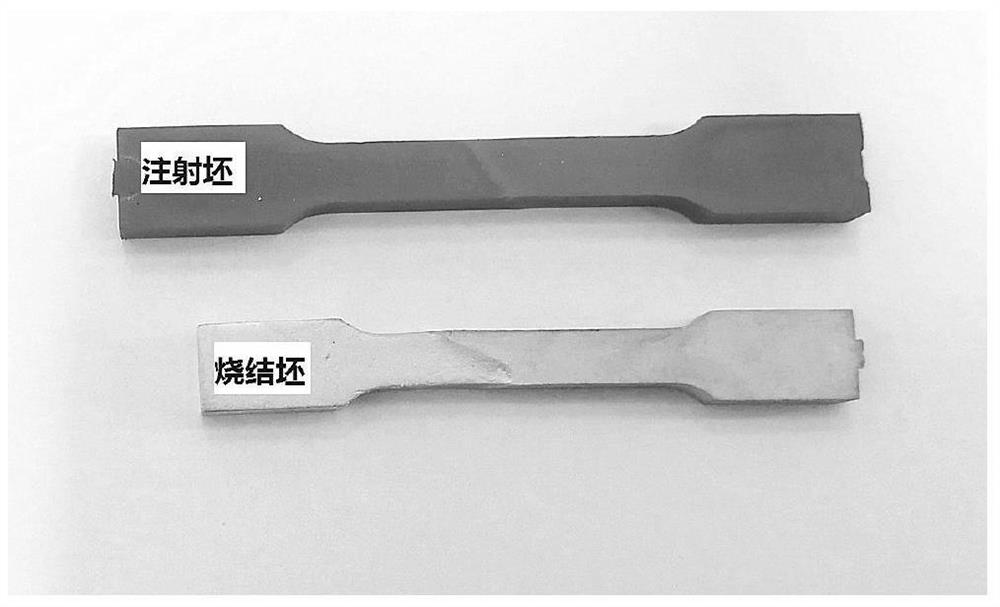

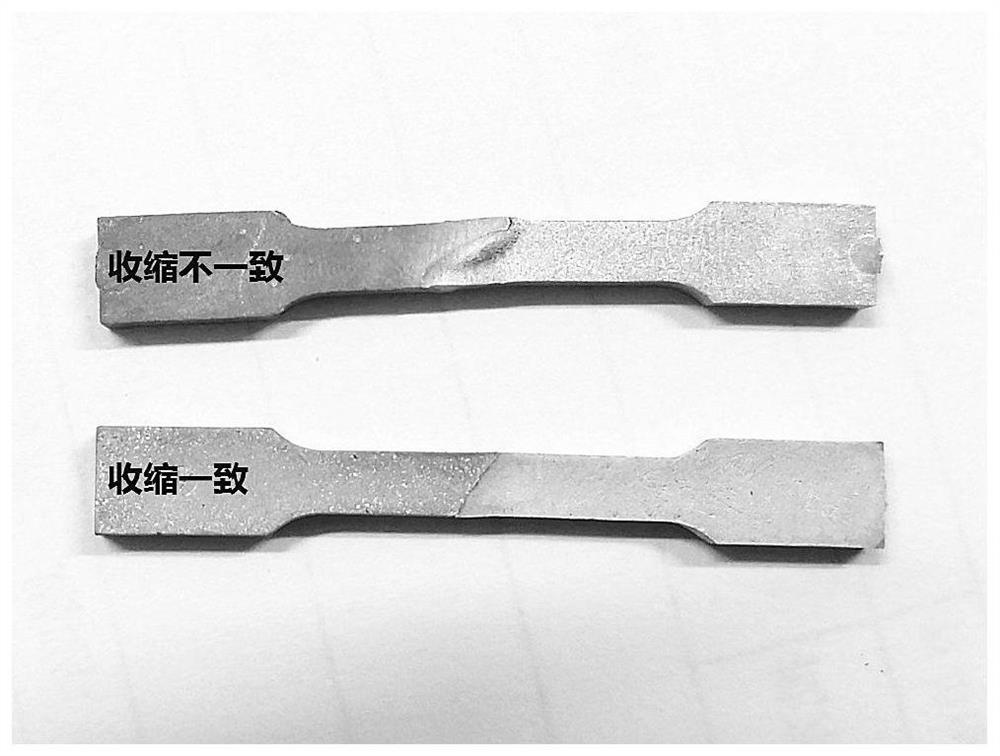

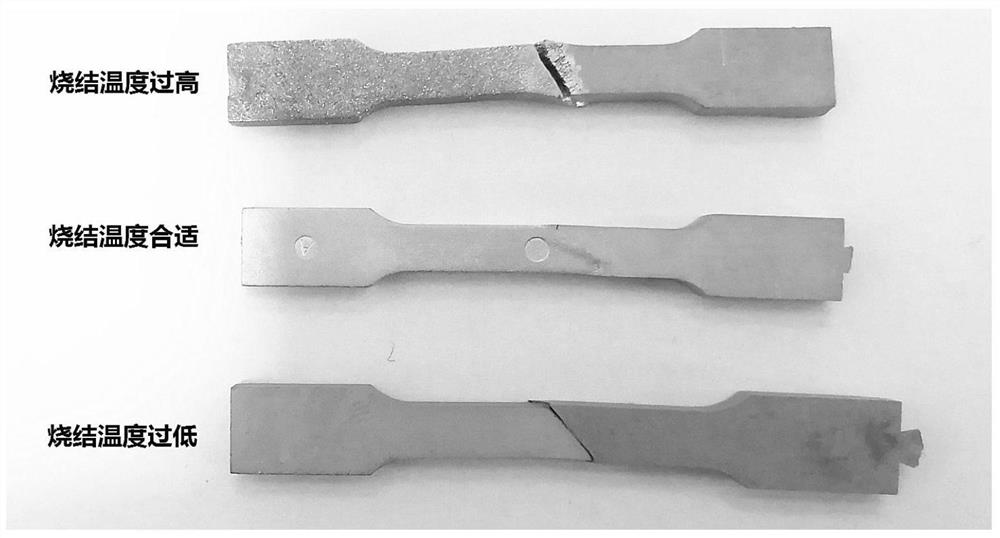

Powder metallurgy preparation method for step-by-step formed cemented carbide hard alloy/steel double-layer structure composite material

A technology of sintering carbide and hard alloy, which is applied in the field of composite material technology preparation, can solve the problems of low strength, easy deformation of steel, and easy cracking of carbide hard alloy, and achieve high precision and avoid deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] A. Select steel material powder, carbide carbide material powder and binder:

[0048]The steel material powder is nickel-based alloy steel Inconel713 powder, with an average particle size of 17.6 μm. The mass percentages of its main chemical elements are: C: 0.04%, Cr: 12.4%, Mo: 4.5%, Si: 0.8%, Al: 5.6%, Ti: 0.8%, Nb: 1.8%, Ni: the balance.

[0049] Carbide cemented carbide material powder is made of WC+TiC as the main material, where the mass fraction of TiC is 5%, and the average particle size of the main material is 7.2 μm; Ni60 alloy powder is used as the auxiliary material, with an average particle size of 19.4 μm. The mass percentage of the main chemical elements is: C : 0.8%, Cr: 16.4%, B: 3.5%, Si: 3.0%, Fe: 14%, Ni: balance. According to the mass percentage, the main material: auxiliary material = 13:7 is put into the tank and an appropriate amount of absolute ethanol is added to mix evenly and then dry.

[0050] Preparation binder: by mass percentage, polyo...

example 2

[0057] A. Select steel material powder, carbide carbide material powder and binder:

[0058] The steel material powder is martensitic stainless steel 0Cr17Ni4Cu4Nb powder with an average particle size of 12.6 μm. The mass percentages of its main chemical elements are: C: 0.07%, Cr: 16.8%, Mn: 0.8%, Si: 0.8%, Ni: 4.5%, Cu: 3.8%, Nb: 0.25%, Fe: balance.

[0059] The carbide cemented carbide material powder is made of WC, with an average particle size of 6.8 μm; Co-Cr alloy powder is used as an auxiliary material, with an average particle size of 10.6 μm. The mass percentages of the main chemical elements are: C: 1.2%, Cr: 29.5%, W: 3.8%, Si: 1.3%, Fe: 3.2%, Mo: 1.1%, Ni: 2.8%, Co: balance. According to the mass percentage, the main material: auxiliary material = 6:4, put it into a tank, add an appropriate amount of absolute ethanol, mix it evenly, and then dry it.

[0060] Preparation binder: by mass percentage, polyoxymethylene (POM): 85%; Polyethylene (PP): 10%; Polyolefin e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com