Method for measuring 3D profile surface by trigger measuring head on measuring machine

A profile surface, measuring machine technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low measurement accuracy, narrow application range, small measurement range, etc., to achieve high measurement efficiency and accuracy, improve efficiency, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The 3D profile measurement program can be widely used in the manufacturing industry, such as measurement reverse engineering, reverse design and metrological verification. In tobacco machinery, it can carry out precise measurement for various smoke deflectors, bongs, etc.

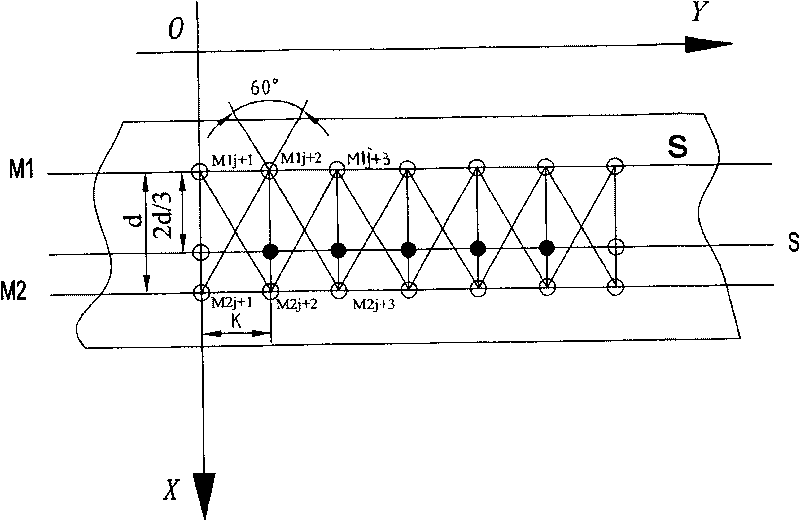

[0052] image 3 It is a tobacco board for GD packaging machine, workpiece number: 2CVBTE36, there are two pairs of workpieces like this, which are AutoCAD two-dimensional drawings, which contain 3D contour surfaces.

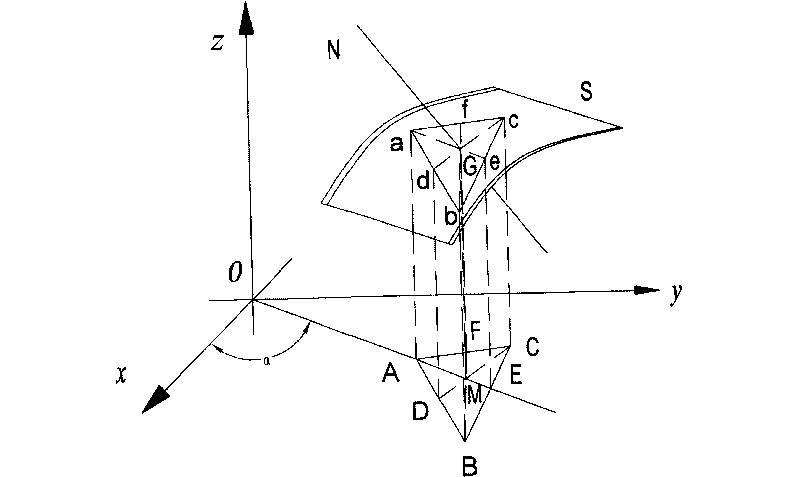

[0053] This embodiment only takes the projection of the miniature triangle Δabc on the XOY plane as an example, and it is also applicable to projection on other projection planes.

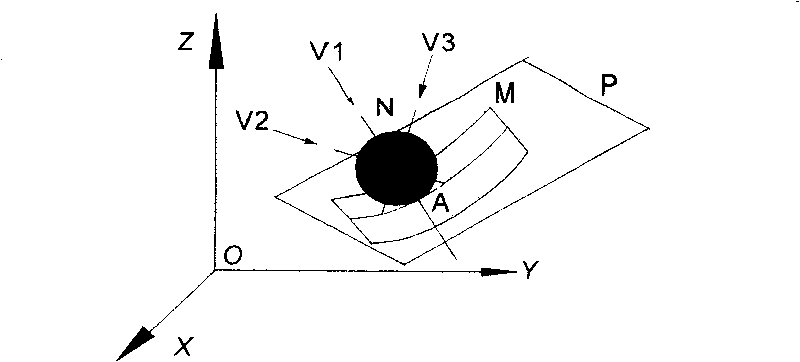

[0054] First, establish a measurement coordinate system on the measurement workpiece (that is, the 3D contour surface), and determine the range covering the 3D contour surface M, such as Figure 2 to Figure 5 .

[0055] 2. Turn off the radius compensation of the stylus so that the stylus measures along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com