Preparation method of oxide film

An oxide film and oxide powder technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of limited metal oxide film, and achieve the effect of expanding the preparation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

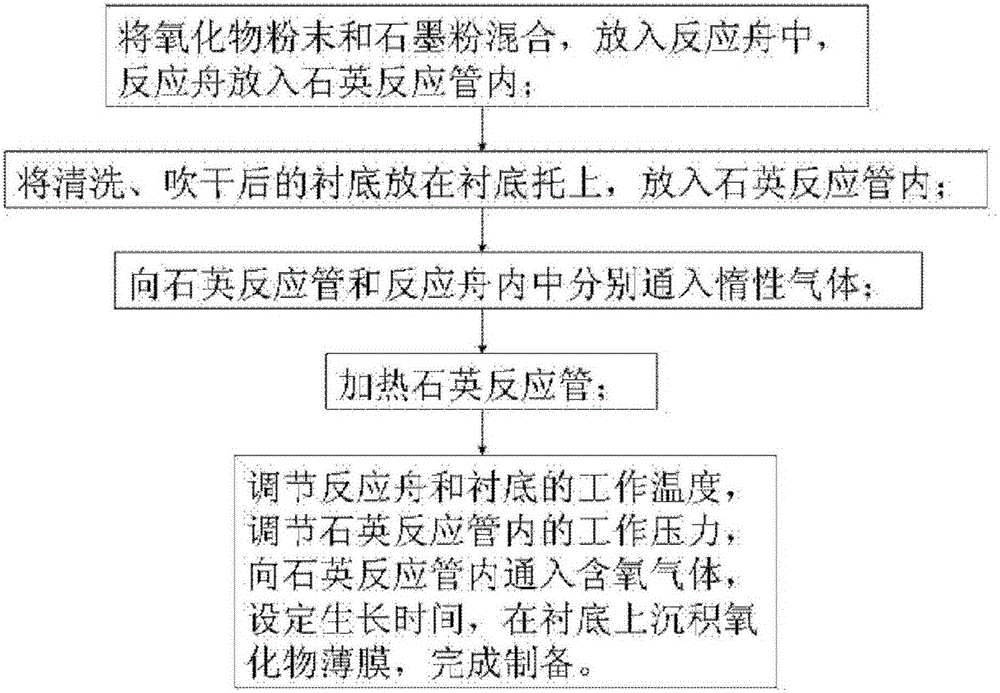

[0019] see figure 1 As shown, the present invention provides a method for preparing an oxide film grown in a chemical growth reaction device, comprising the steps of:

[0020] Step S1: Mix oxide powder and graphite powder and put them into a quartz reaction boat. The mixing ratio refers to the stoichiometric ratio or the amount of graphite powder is lower than the stoichiometric ratio, but not less than a quarter of the molar amount of the stoichiometric ratio . The oxide powder is an oxide powder of a metal element or an oxide powder of a non-metal element; the elements therein have multiple oxidation valence states, at least one of which is gaseous; the oxide powder and the oxide film The oxidation states are the same or different;

[0021] Step S2: Put the cleaned and dried substrate on the substrate holder and put it into the quartz reaction tube;

[0022] Step S3: feeding inert gas into the quartz reaction tube and the reaction boat respectively; the inert gas includes...

Embodiment 1

[0029] This specific embodiment provides a method for preparing an oxide film, specifically a non-metal oxide film, specifically silicon oxide.

[0030] Silica is thermodynamically stable at normal temperature and pressure, which is solid, and the silicon ions in it are positive tetravalent (Si 4+ ), written as SiO 2 (s). The intermediate valence state has positive divalence (Si 2+ ), unstable, gaseous, written as SiO(g).

[0031] The whole reaction principle is as follows:

[0032] SiO 2 (s)+C(s)--->SiO(g)+CO(g)

[0033] SiO(g)+[O](g)--->SiO 2 (s)

[0034] C(s)--->C(g)

[0035] C(g)+[O](g)--->CO(g)

[0036] C(g)+[O](g)--->CO 2 (g)

[0037] Note: [O] means oxygen-containing gas, which is oxygen, water vapor, nitrous oxide (N 2 O), nitric oxide (NO), nitrogen dioxide (NO 2 ), one or a mixture of several of them.

[0038] Specifically include the following steps:

[0039] S1) Mix silica powder and graphite powder (C), and put them into a reaction boat.

[0040] S...

Embodiment 2

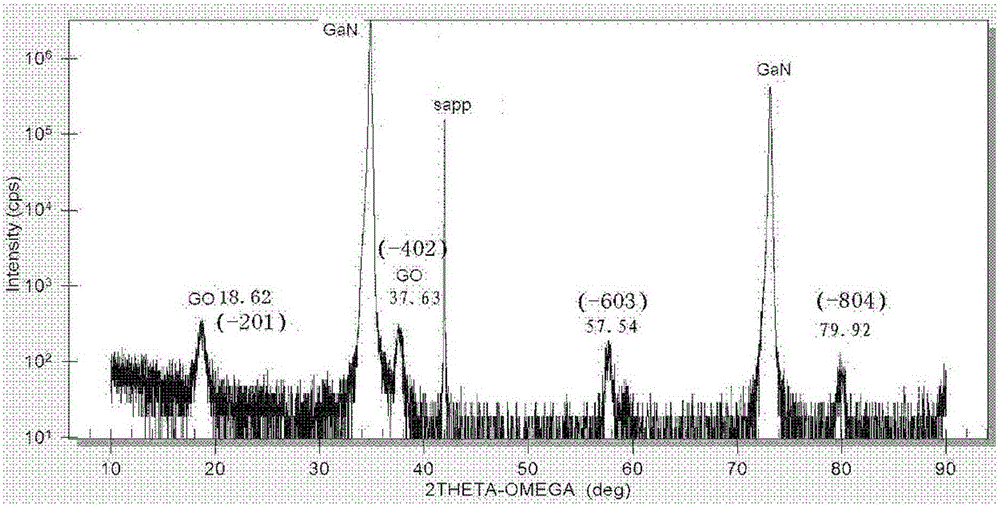

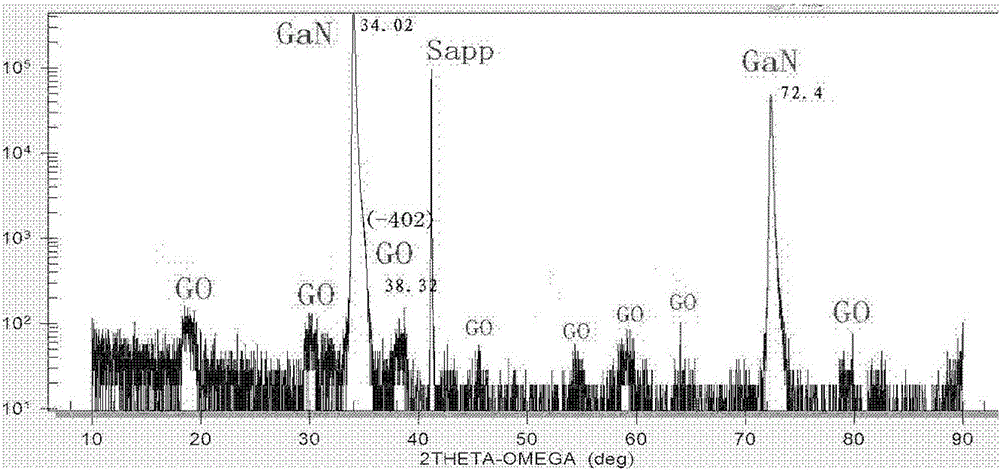

[0047] This example is used to illustrate the preparation of the metal oxide gallium oxide thin film.

[0048] The gaseous intermediate valence oxide is gallium oxide (Ga 2 O) and gallium monoxide (GaO). The preparation principle is as follows:

[0049] Ga 2 o 3 (s)+2C(s)--->Ga 2 O(g)+2CO(g)

[0050] Ga 2 o 3 (s)+C(s)--->2GaO(g)+CO(g)

[0051] Ga 2 O(g)+2[O](g)--->Ga 2 o 3 (s)

[0052] 2GaO(g)+[O](g)--->Ga 2 o 3 (s)

[0053] Among them, the vapor pressure of gallium oxide is greater than that of gallium monoxide, and the selection of the mixing ratio refers to the chemical reaction formula of gallium oxide.

[0054] The difference between this embodiment and embodiment 1 is: in step S1), gallium oxide powder and graphite powder (C) are mixed, put into reaction boat 4; Wherein the purity of gallium oxide powder and graphite powder is all greater than 99.999%, The mixing ratio is 1:2-2:1. In step S3), the inert gas is helium; in step S5), the oxygen-containing gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com