Preparation method of three-dimensional self-supporting micro-nano functional structure based on thin film material

A technology of functional structure and support structure, which is applied in the field of preparation of three-dimensional self-supporting micro-nano functional structures based on thin film materials, can solve the problem that high aspect ratio pattern metallization or functionalization cannot be realized, pattern resolution depends on exposure spot, Inability to prepare metal materials, etc., to achieve high flexibility and operability, unique functions, and the effect of expanding the scope of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

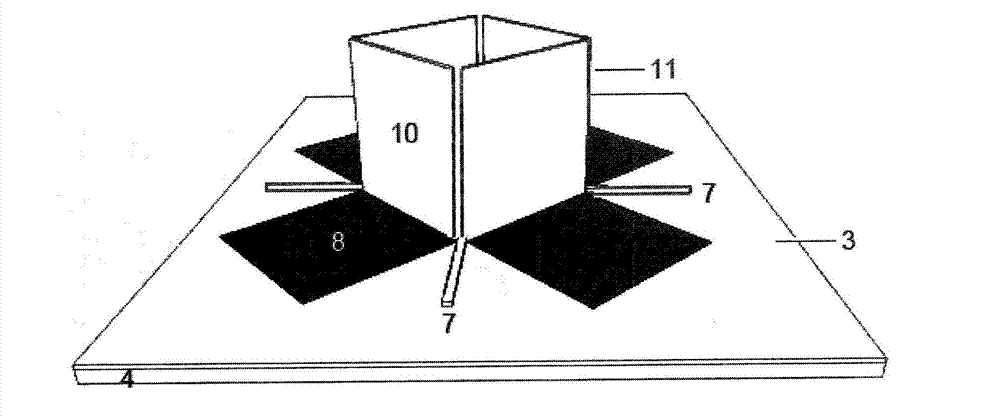

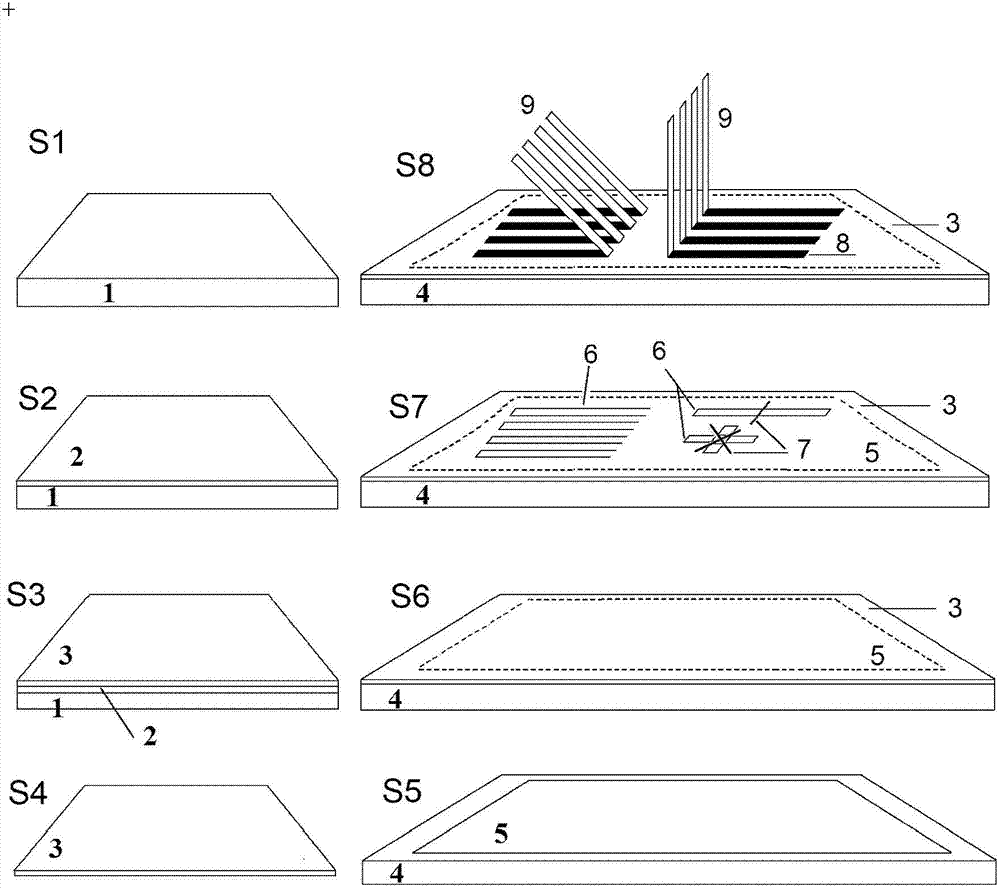

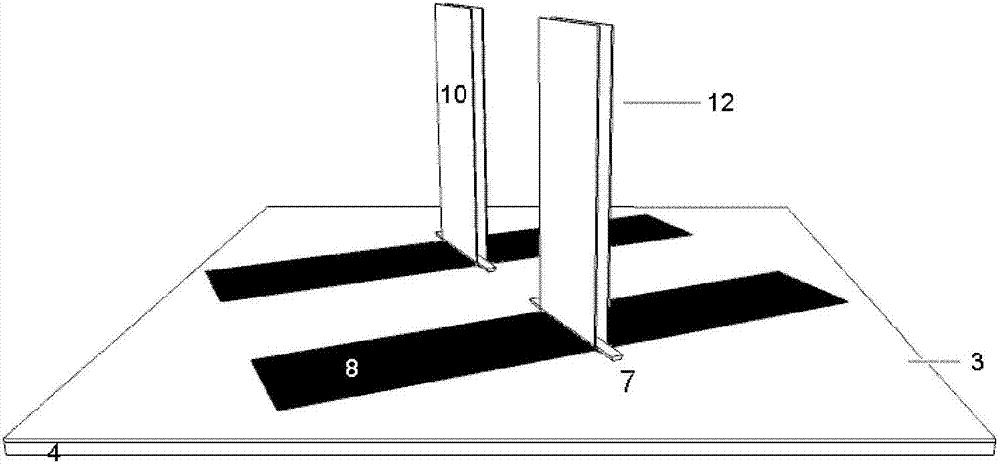

[0045] Using "a method for preparing a three-dimensional self-supporting micro-nano functional structure array" to prepare a three-dimensional metal metamaterial structure array (taking a single-layer gold film as an example), includes the following steps:

[0046] (1) Silicon substrate cleaning

[0047] The silicon substrate was cleaned with acetone, ethanol and deionized water in sequence, then blown dry with nitrogen, baked on a hot plate at 180 degrees Celsius for 10 minutes, and allowed to cool naturally.

[0048] (2) Application of transition layer 2

[0049] Coat one deck electron beam photoresist PMMA (495,5%) on the clean and smooth Si substrate that step (1) has processed (1300 rev / mins, 180 degrees centigrade baking 1 minute after spin-coating, can repeat spin-coating ).

[0050] (3) Preparation of metallic gold nanofilm 3

[0051] On the substrate 1 coated with electron beam photoresist PMMA, a gold thin film layer 3 with a thickness of 100 nanometers is deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com