Method for preparing self-supporting multilayer micro nano structure

A technology of micro-nano structure and nano-structure, applied in the direction of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of limited preparation methods of multi-layer nanowires, achieve high practical application value, and good controllability , the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

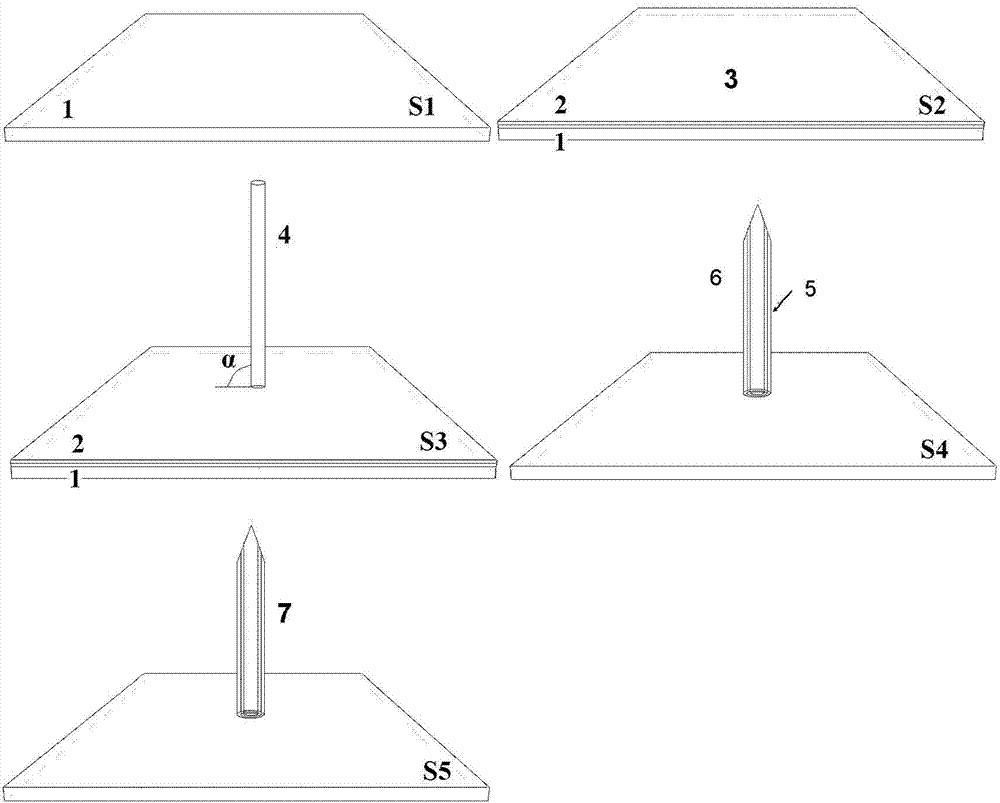

[0025] The preparation method of the self-supporting multilayer micro-nano structure comprises the following steps:

[0026] Step S1: Select a flat substrate 1 and clean it;

[0027] Step S2: preparing a multilayer film structure 2 on a flat substrate 1 to obtain a multilayer film substrate 3;

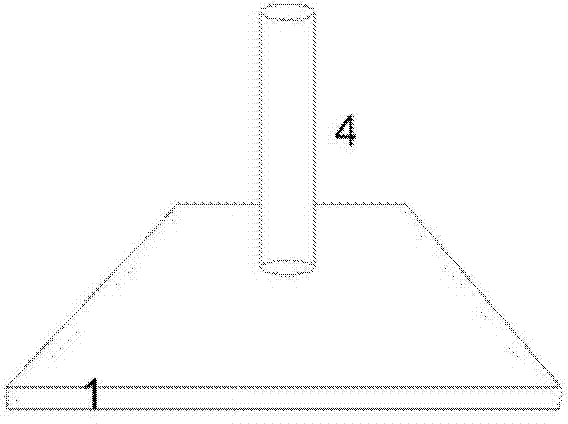

[0028] Step S3: preparing a self-supporting matrix nanostructure 4 on the surface of the multilayer film substrate 3 to obtain a multilayer film substrate self-supporting matrix nanostructure system;

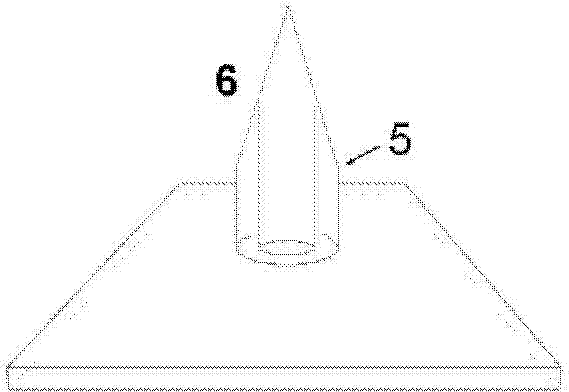

[0029] Step S4: Put the multilayer film substrate self-supporting matrix nanostructure system into the sample chamber of the ion etching system, and perform ion beam dry etching on the multilayer film substrate self-supporting matrix nanostructure system; during the etching process, Except for the part covered by the self-supporting matrix nanostructure 4, the substances on the surface of the multilayer film substrate 3 will be sputtered from top to bottom under the bombardment of the i...

Embodiment 1

[0051] Fabrication of polycrystalline / single-crystalline bilayer concentric Si cone arrays on Si substrates. Include the following steps:

[0052] (1) cleaning of the silicon substrate 1;

[0053] Sonicate the silicon substrate sequentially with acetone, alcohol, and deionized water for a period of time (5min-10min), blow dry the surface of the silicon substrate with a nitrogen gun and bake it on a hot plate at 120-200 degrees Celsius for 10-20 minutes.

[0054] (2) Preparation of monocrystalline silicon self-supporting parent nanowires 4 perpendicular to Si substrate 1;

[0055] Spin-coat one deck electron beam photoresist polymethylmethacrylate PMMA (495,5%) on the silicon substrate 1 after (1) processing, 4000 rev / mins, then use the method for electron beam exposure on Expose the circular hole array on the PMMA photoresist, the electron beam acceleration voltage used is 10 kilovolts, and the exposure dose is 100 microamperes / square centimeter; 3 in the developer solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com