High-speed motor with solid rotor

A high-speed motor, solid rotor technology, applied in asynchronous induction motors, electric components, electrical components, etc., can solve the problem of difficulty in manufacturing high-speed motors, and achieve the effect of increasing the critical speed, expanding the manufacturing range, and improving the critical speed and deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

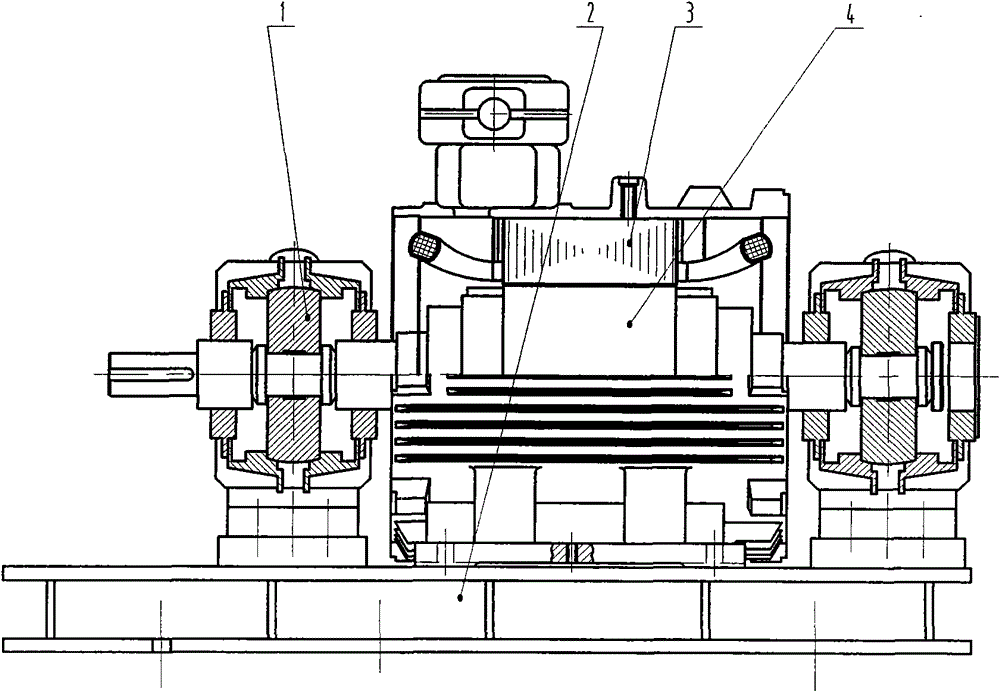

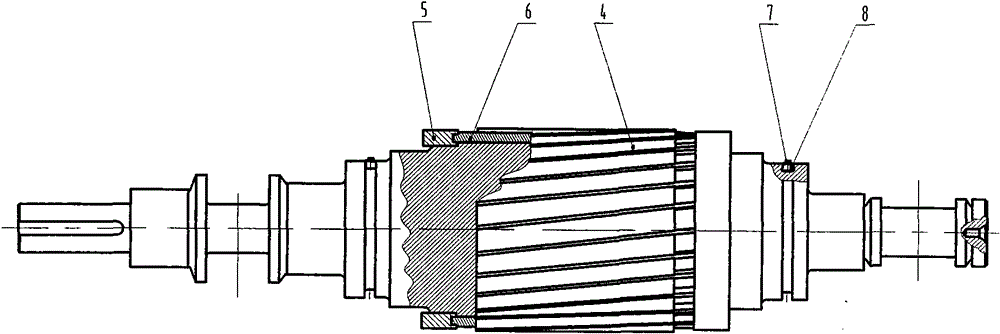

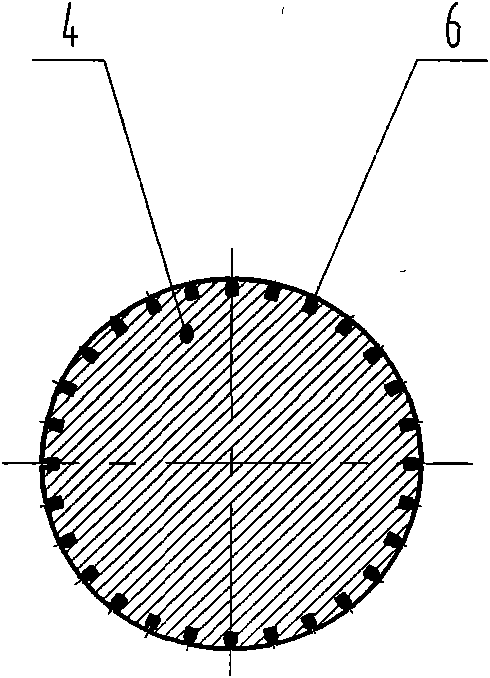

[0010] exist figure 1 Among them, the tilting pad high-speed sliding bearing (1) and the motor stator (3) are installed on the chassis (2), and the rotor core (4) is supported by the tilting pad high-speed sliding bearing (1) to maintain contact with the motor stator (3). Concentricity. In order to improve the torque of the motor, slots are made on the surface of the rotor iron core (4), and the rotor guide bar (6) is inlaid, and the two ends of the rotor guide bar (6) are welded together with the rotor end ring (5). Form a mouse cage. Slots are installed at both ends of the rotor iron core (4) to install balance weights (8) and balance screws (7). Improve the accuracy of dynamic balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com