Radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing

An AC/DC hybrid and magnetic bearing technology, which is applied in shafts, bearings, bearings, mechanical equipment, etc., can solve problems such as poor heat dissipation performance, reduced bearing capacity of magnetic bearings, limited space between axial control coils and radial control coils, etc. Achieve the effects of good heat dissipation performance, increased critical speed, and simplified drive control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

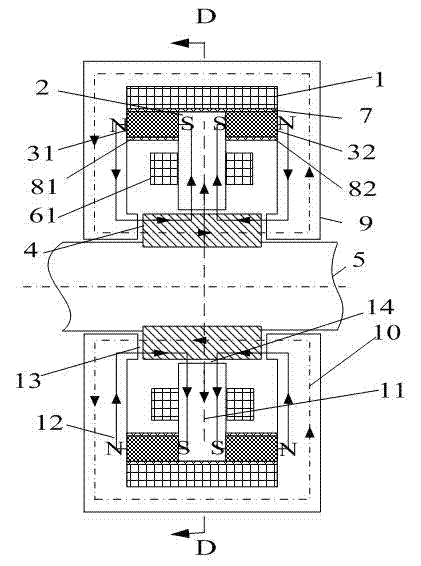

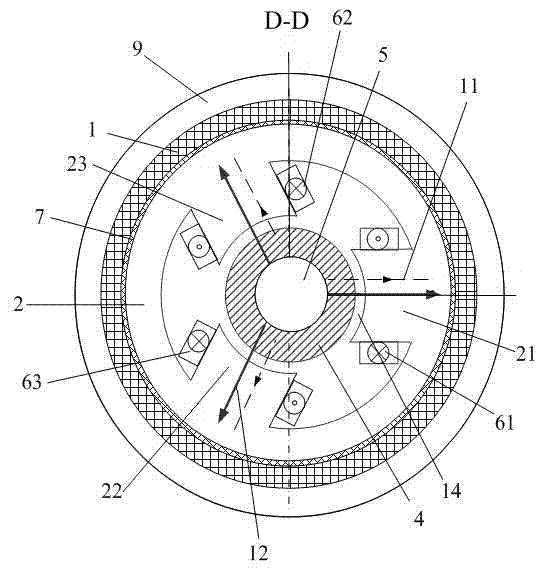

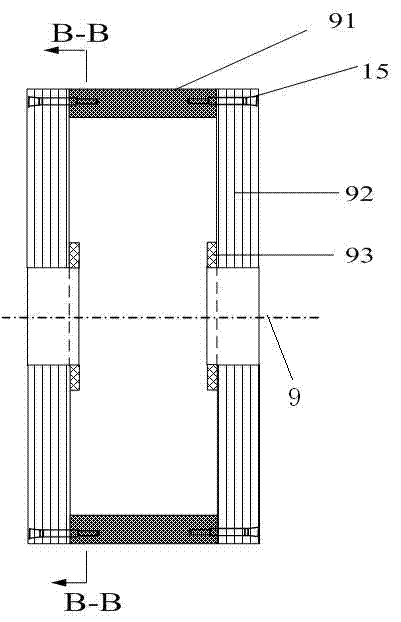

[0019] Such as figure 1 with figure 2 As shown, the present invention is an inner rotor magnetic bearing structure, which includes a rotating shaft 5, a rotor 4, a radial stator core 2 and an axial stator core 9 coaxially installed. The axial stator core 9 is the outer shell of the magnetic bearing and is located at the outermost periphery of the magnetic bearing. The cross section of the axial stator core 9 is a hollow cylindrical shape. The axial stator core 9 is sleeved on the shaft 5 and the axial stator core 9 is sleeved. In the radial stator core 2, an axial control coil 1 is provided in a cavity between the radial stator core 2 and the axial stator core 9. The radial stator core 2 is sleeved with a rotor 4, the rotor 4 is formed by laminating round silicon steel sheets, the cross section of the rotor 4 is a hollow cylindrical shape, and the rotor 4 is fixedly sleeved on the rotating shaft 5.

[0020] Both the rotor 4 and the radial stator core 2 are made of laminated sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com