Micro-lens forming method by means of wet method side guide

A technology of microlens and guide, applied in the direction of lens, microlithography exposure equipment, optics, etc., can solve the problems of affecting the optical quality of components, increasing the cost of components, complicated polishing process, etc., and achieve the improvement and reduction of relief depth and numerical aperture Production cost and the effect of expanding the scope of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

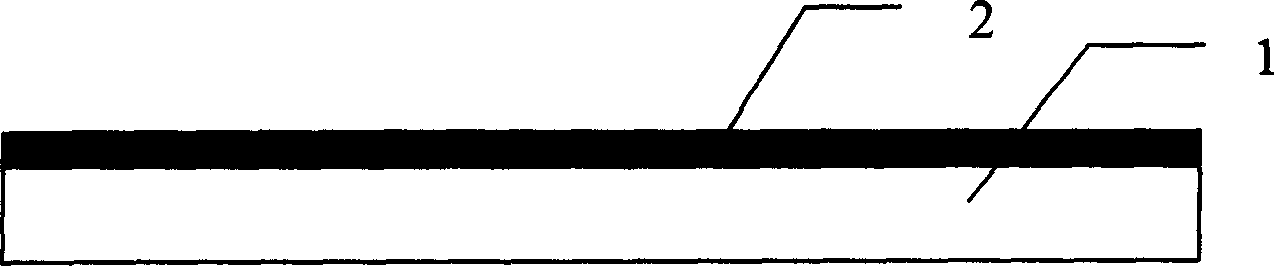

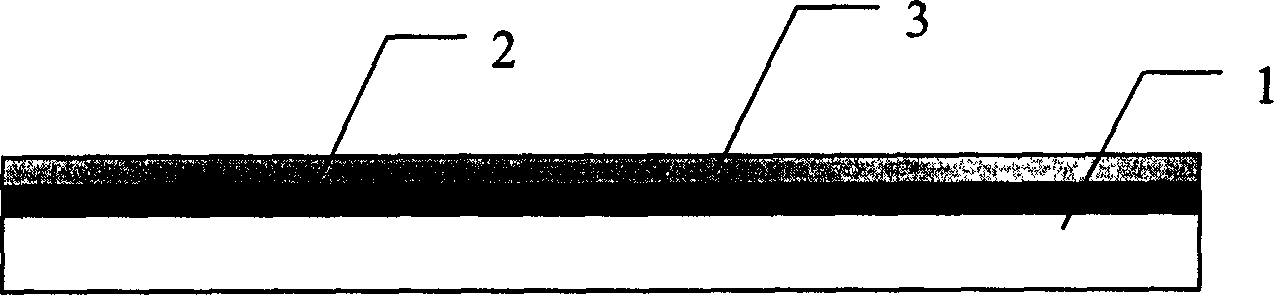

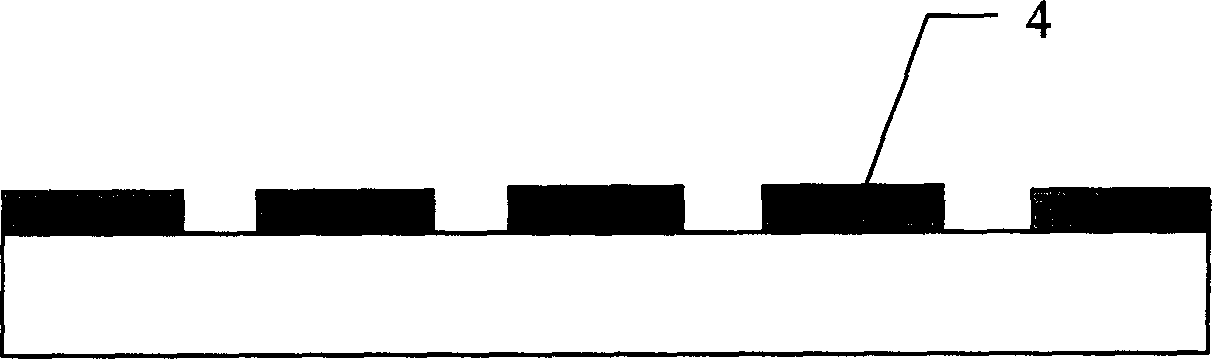

[0029] Embodiment 1, make aperture φ=500 μm, interval 200 μm (total 5), the quartz material continuous embossment microcylindrical lens array of etching depth h=3 μm, its manufacturing process is as follows:

[0030] ① First determine the base material and the main etchant, as well as the material of the sacrificial layer and the auxiliary etchant. The material of the target component is metal: steel, so choose hydrochloric acid as the main etchant, sio 2 The membrane can be corroded with HF acid, usually with a concentration of 49%, while hydrochloric acid can coexist with HF, with a concentration of 49%. At the same time, hydrochloric acid does not corrode quartz, so sio 2 Membrane and HF acid meet the conditions of sacrificial layer and auxiliary etching solution, choose sio 2 As the sacrificial layer material, HF acid is selected as the auxiliary etching solution;

[0031] ② Evaporate a certain thickness on the surface of the base material, usually a 200nm sacrificial la...

Embodiment 2

[0037] Embodiment 2, make aperture φ=30 μ m, interval 700 μ m (total 5), the quartz material micro grating array of etching depth h=70 μ m, its manufacturing process is as follows:

[0038] ① First determine the base material and the main etchant, as well as the material of the sacrificial layer and the auxiliary etchant. The material of the target element is fused silica, so HF solution is selected as the main etchant. Silver Ag film can be treated with HNO 3Corrosion, while nitric acid can coexist with HF solution, at the same time, nitric acid HNO 3 Does not corrode quartz, so silver Ag and HNO 3 Meet the conditions of the sacrificial layer and auxiliary etching solution, choose silver as the material of the sacrificial layer, choose HNO3 3 as an auxiliary etchant;

[0039] ② Evaporate a certain thickness on the surface of the base material, usually 200nm sacrificial layer material silver Ag;

[0040] ③ Coating a layer of photoresist on the surface of the sacrificial l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com