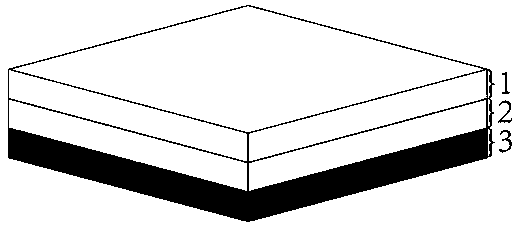

Rubber flexographic engraving plate and manufacturing method thereof

A rubber and flexo printing technology, applied in printing plate, printing, printing foil and other directions, can solve the problems of affecting printing accuracy, easy expansion, and time-consuming resin plate plate-making method, so as to improve enterprise economic benefits, improve printing durability, The effect of reducing the cost of plate making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

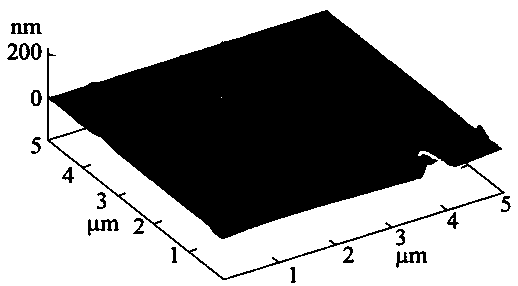

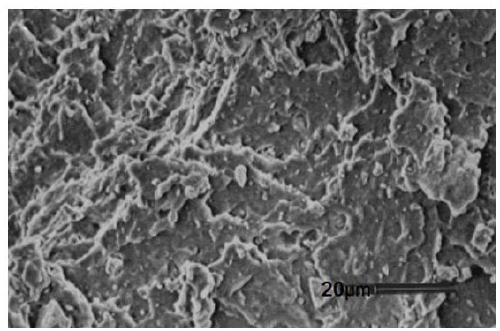

Method used

Image

Examples

Embodiment 1

[0061] Suspend 100 g of bentonite powder (purchased from Tianjin Yandong Mining Company) in 400 deionized water, perform ultrasonic dispersion treatment at a frequency of 18.5 kHz, an effective power of 90 W / L, and an ultrasonic vibration amplitude of 3 µm for 30 minutes, and then add ten Dioxanedioic acid, lauric acid and mercaptobenzothiazole, wherein the dosages of dodecanedioic acid, lauric acid and mercaptobenzothiazole are respectively 2wt.%, 2wt.% and 1.5wt.% of the bentonite powder, and proceed with ultrasonic dispersion Treat for 20 minutes, filter, and dry to obtain modified nano-bentonite particles; then mix natural rubber (purchased from Hainan Haijiao Company) with the modified nano-bentonite particles, SiO 2 Nanoparticles, sulfur, the vulcanization accelerator shown in the aforementioned formula (I) are mixed, natural rubber is 100 parts by weight, nano-bentonite particles are 9 parts by weight, SiO 2 5 parts by weight of nanoparticles, 2 parts by weight of sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com